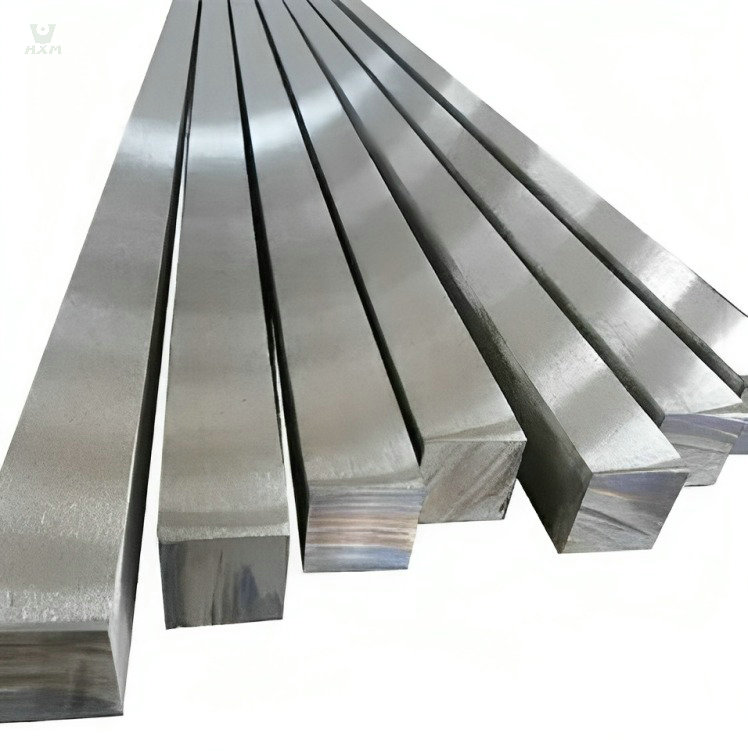

440C Stainless Steel Bar Supplier In China

Diameter: 3mm-480mm, 1/8″ to 2 1/4″

Standard: GB1220, ASTM A484/484M, EN 10060/ DIN 1013 ASTM A276, EN 10278, DIN 671

Shape: round, flat, square, angle, hexagonal

Finish: Black, NO.1, mill finish, cold draw, H9, H11

Product Description Of 440C Stainless Steel Bar

Renowned as the go-to alloy for crafting cutting tools, the 440C stainless steel bar stands out as a high-carbon chromium alloy favored for its remarkable hardness and strength achieved through heat treatment. Its chemical composition includes nickel, molybdenum, and copper among other elements, offering a balanced blend conducive to its superior properties. This steel variant exhibits exceptional wear resistance, making it a preferred choice for applications such as bearings, valve seats, top-tier blades, surgical instruments, and chisels. Following heat treatment, it maintains an impressive hardness of Rc 60 and exceptional wear resistance. This stainless steel bar undergoes conventional heat treatment methods, attaining the highest hardness among stainless steels while showcasing superior mechanical prowess. However, its machining ease diminishes after hardening, presenting challenges in the machining process. Widely regarded for its varied applications and unmatched attributes, the 440C stainless steel bar continues to serve industries demanding durable and high-performance stainless steel products.

specification Of 440C Stainless Steel Bar

chemical composition of 440C stainless steel bar

| Element | Composition (%) |

|---|---|

| Nickel (Ni) | 0.75 |

| Molybdenum (Mo) | 0.75 |

| Copper (Cu) | 0.5 |

| Manganese (Mn) | Up to 1 |

| Iron (Fe) | Balance |

| Carbon (C) | 0.95 – 1.2 |

| Chromium (Cr) | 16 – 18 |

| Phosphorus (P) | Up to 0.04 |

| Sulfur (S) | Up to 0.03 |

| Silicon (Si) | Up to 1 |

physical property of 440C stainless steel bar

| Property | Value |

|---|---|

| Density | 7.75 g/cm³ |

| Melting Point | 1480 – 1530°C |

| Specific Heat Capacity | 460 J/kg·K |

| Thermal Conductivity | 24 W/m·K |

| Electrical Resistivity | 600 nΩ·m |

| Modulus of Elasticity (Young’s Modulus) | 200 GPa |

| Poisson’s Ratio | 0.27 |

| Hardness (Rockwell C) | 58-62 HRC |

mechanical property of 440C stainless steel bar

| Property | Value |

|---|---|

| Tensile Strength | 760 – 1000 MPa |

| Yield Strength | 450 MPa |

| Elongation at Break | 15% |

| Modulus of Elasticity | 200 GPa |

| Hardness (Rockwell C) | 58-62 HRC |

| Impact Strength (Charpy) | 7 – 10 J |

features Of 440C Stainless Steel Bar

440C stainless steel bar is distinguished by its elevated carbon and chromium content, contributing significantly to its distinct properties. The high carbon content, typically between 0.95% to 1.2%, promotes exceptional hardness and wear resistance upon heat treatment. Chromium, present in quantities of 16% to 18%, fortifies the alloy’s corrosion resistance, essential for applications requiring resilience in harsh environments. This amalgamation of carbon and chromium in precise proportions reinforces the alloy’s hardness, wear resistance, and corrosion resistance, defining its suitability for demanding industrial applications such as cutting tools and bearings.

The exceptional hardness of 440C stainless steel bar stems from its unique composition and heat treatment characteristics. Post heat treatment, typically reaching 58-62 HRC (Rockwell C scale), this alloy achieves outstanding hardness due to its high carbon content (0.95% – 1.2%) and chromium content (16% – 18%). The controlled heat treatment processes, such as quenching and tempering, refine the microstructure, forming carbide precipitates, enhancing the alloy’s hardness, and enabling it to sustain its robustness, making it ideal for applications requiring superior wear resistance and durability in harsh conditions.

440C stainless steel bar exhibits excellent wear resistance owing to its specific alloy composition and heat treatment. The alloy’s high carbon content, typically ranging from 0.95% to 1.2%, contributes significantly to its wear-resistant properties. Additionally, the heat treatment process, including quenching and tempering, refines the microstructure, forming a uniform distribution of fine carbides. These carbides enhance the alloy’s ability to withstand abrasion, friction, and wear over prolonged use, making it an ideal choice for applications where durability and resistance to wear are crucial, such as in cutting tools, bearings, and other high-wear environments.

440C stainless steel bar showcases corrosion resistance primarily in its hardened state, attributed to its composition and structural transformation during heat treatment. The alloy’s chromium content, typically within 16% to 18%, forms a chromium oxide layer on the surface when properly heat-treated, augmenting its corrosion resistance. This hardened state, achieved through suitable heat treatment processes like quenching and tempering, enhances the alloy’s ability to withstand certain corrosive environments, albeit its primary strength lies in wear resistance. It’s vital to note that while 440C stainless steel exhibits improved corrosion resistance post-hardening, it may not match the corrosion resistance levels of some austenitic stainless steels in all environments due to its martensitic structure.

440C stainless steel bar possesses exceptional heat treatability owing to its alloy composition and microstructural transformation during heat treatment. The alloy’s high carbon content, typically ranging from 0.95% to 1.2%, and adequate chromium levels of 16% to 18%, enable precise hardening procedures. Through heat treatment methods like quenching and tempering, the alloy undergoes a phase change, transforming from austenite to martensite, enhancing its hardness and wear resistance. This treatability allows manufacturers precise control over the alloy’s mechanical properties, enabling customization to meet specific application requirements in diverse industries such as cutlery, bearings, and surgical tools. Successful heat treatment plays a critical role in achieving the desired balance between hardness, toughness, and corrosion resistance in 440C stainless steel.

application Of 440C Stainless Steel Bar

Cutting Tools

440C stainless steel bar finds widespread use in crafting premium cutting tools like kitchen knives, surgical blades, and razors due to its exceptional hardness and enduring wear resistance. Its high hardness sustains sharpness while its wear resistance ensures prolonged durability, ideal for extended use.

Bearings and Bearings Components

Employed in crafting rolling element bearings, valve seats, and bearing races, 440C stainless steel bar showcases durability and anti-corrosive properties in specific environments. Its resilience in high-pressure, high-temperature, and corrosive settings is particularly advantageous.

Chisels and Specialty Tools

Utilized in chisel and specialty tool fabrication, requiring superior wear resistance and durability for heavy-duty tasks. 440C stainless steel bar's resilience under extreme conditions provides robust material for crafting various professional tools.

FAQ

In 440C stainless steel, the “C” denotes carbon as an essential alloying element. Carbon content significantly impacts the steel’s properties. In this specific grade, the elevated carbon content, ranging from 0.95% to 1.20%, enhances the steel’s hardness, wear resistance, and edge retention. The increased carbon enables superior performance in applications requiring high hardness and wear resistance, such as manufacturing cutting tools, bearings, and surgical instruments. Stainless steel bar supplier often highlight the carbon content as a crucial factor for customers seeking materials with enhanced hardness and wear resistance.

440C stainless steel bar, known for its exceptional hardness and wear resistance, is recognized for its ability to retain sharp edges. However, due to its high hardness, it can be relatively challenging to sharpen compared to softer stainless steels. Its hardness enhances edge retention but requires appropriate sharpening techniques, often involving specialized sharpening tools and methods. Stainless steel bar supplier may advise on specific sharpening methods tailored for 440C steel, emphasizing the need for precision and proper tools to maintain and restore its sharpness effectively.

440C and 440B stainless steel bars are high-carbon martensitic stainless steels, but they differ primarily in their carbon content and subsequent properties. 440C stainless steel bar contains higher carbon content (0.95-1.20%) compared to 440B (0.75-0.95%), enhancing its hardness, wear resistance, and edge retention. The increased carbon in 440C stainless steel bar enhances its attainable hardness through heat treatment, making it superior for high-performance cutting tools and bearings. Conversely, 440B stainless steel bar, with slightly lower carbon, exhibits less hardness but offers improved corrosion resistance and toughness. Stainless steel bar supplier often offer these grades, tailoring choices based on the specific application’s demands and balancing hardness against corrosion resistance and toughness.

Chemical Composition:

440C Stainless Steel: It belongs to the martensitic stainless steel group, characterized by high carbon content (0.95-1.20%) and chromium (16-18%) along with small amounts of other elements like manganese, silicon, and molybdenum. Its composition emphasizes high hardness and wear resistance, making it suitable for cutting tools, bearings, and surgical instruments.

430 Stainless Steel: Classified as a ferritic stainless steel, 430 consists of chromium (16-18%) with lower carbon content (0.12%) compared to 440C. It also contains small amounts of nickel and manganese. Its composition primarily focuses on corrosion resistance and affordability, often used in appliances and architectural applications.

Properties:

440C Stainless Steel: Recognized for outstanding hardness, wear resistance, and edge retention. Ideal for applications requiring exceptional cutting performance, such as high-quality knives, bearings, and surgical instruments. However, it may have reduced corrosion resistance compared to other stainless grades.

430 Stainless Steel: Offers good corrosion resistance in non-corrosive environments but lacks the hardness and wear resistance of 440C. It is more susceptible to corrosion than austenitic stainless steels but remains popular due to its cost-effectiveness and suitable performance in mildly corrosive environments.

Applications:

440C Stainless Steel: Primarily used in manufacturing cutting tools, high-performance knives, bearings, and surgical instruments where superior hardness and wear resistance are essential.

430 Stainless Steel: Frequently employed in kitchen appliances, architectural features, and automotive trim due to its corrosion resistance and affordability, albeit in applications where extreme corrosion resistance is not critical.

Use in Manufacturing:

440C Stainless Steel: Preferred for producing high-quality cutting tools, surgical instruments, bearings, and premium knives due to its hardness and wear resistance.

430 Stainless Steel: Commonly utilized in fabricating kitchen appliances, architectural trim, and automotive components where corrosion resistance and cost-effectiveness are required, but not in highly corrosive environments.

Stainless steel bar supplier differentiate between these grades, guiding customers based on their specific application needs, emphasizing the importance of hardness, corrosion resistance, and affordability for various industries and applications.

440C and 304 stainless steels differ significantly in their composition, properties, and applications.

Chemical Composition:

440C Stainless Steel: Known as a high-carbon martensitic stainless steel, 440C is composed of higher carbon content (0.95-1.20%) and chromium (16-18%) with small amounts of elements like manganese, silicon, and molybdenum. This composition significantly contributes to its high hardness and wear resistance, making it suitable for high-performance applications.

304 Stainless Steel: Classified as austenitic stainless steel, 304 comprises lower carbon content (max 0.08%) and higher chromium (18-20%). Additionally, it contains nickel and small amounts of manganese and silicon. Its composition emphasizes corrosion resistance and excellent formability, making it versatile across various industries.

Properties:

440C Stainless Steel: Renowned for exceptional hardness, wear resistance, and edge retention. Ideal for applications demanding superior cutting performance, such as high-end knives, bearings, and surgical instruments. However, it may have lower corrosion resistance compared to austenitic grades.

304 Stainless Steel: Known for its excellent corrosion resistance, weldability, and formability. It is widely used in applications requiring resistance to corrosion from various environmental factors, making it prevalent in the food industry, architecture, and kitchen equipment.

Applications:

440C Stainless Steel: Due to its superior hardness and wear resistance, it’s primarily used in manufacturing cutting tools, high-performance knives, bearings, and surgical instruments where edge retention and durability are critical.

304 Stainless Steel: Utilized in various industries such as food processing, architecture, and automotive due to its outstanding corrosion resistance, making it suitable for applications involving exposure to moisture, acidic environments, and chlorides.

Use in Manufacturing:

440C Stainless Steel: Often used in producing high-quality cutting tools, surgical instruments, bearings, and high-end knives, thanks to its hardness and wear resistance.

304 Stainless Steel: Commonly employed in fabricating kitchen equipment, architectural features, food processing equipment, and automotive components, primarily due to its corrosion resistance and formability.

Stainless steel bar supplier highlight these distinctions to guide customers in selecting the most suitable stainless steel grade based on the specific demands of their applications, emphasizing the importance of hardness and corrosion resistance for diverse industries.

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China