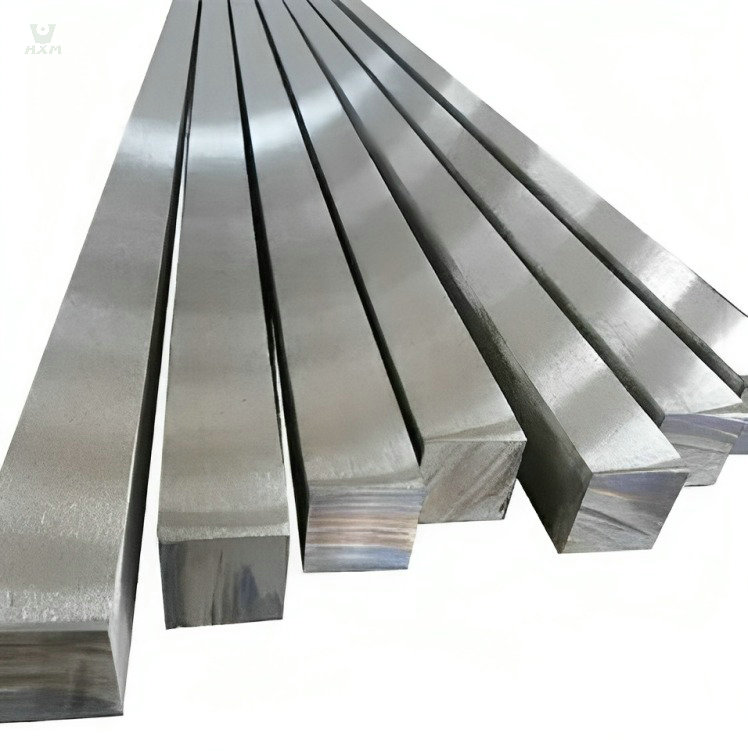

302 stainless steel wire supplier in China

Size: Diameter 0.2mm-5.5mm, 5.5mm-12mm

Standard:GB1220, ASTM A 484/484M, ASTM A276, EN 10060/ DIN 1013, EN 10278

Finish: Black, NO.1, mill finish, cold draw

product description of 302 stainless steel wire

302 stainless steel wire is an austenitic chromium-nickel stainless steel with a higher nickel content, which gives it superior performance in certain specific corrosive environments. 302 stainless steel wire exhibits excellent corrosion resistance, good formability, and high strength. Its corrosion resistance allows it to maintain structural stability and integrity in humid, high-temperature, and chemically corrosive environments. Additionally, its high strength and good ductility enable it to withstand high pressure and tension, making it suitable for manufacturing various components with high-strength requirements. Moreover, 302 stainless steel wire also has good electrical conductivity and thermal conductivity, suitable for applications in the electronics and electrical fields.

specification of 302 stainless steel wire

chemical composition of 302 stainless steel wire

| Element | Carbon (C) | Silicon (Si) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Chromium (Cr) | Nickel (Ni) | Nitrogen (N) |

|---|---|---|---|---|---|---|---|---|

| Content (%) | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 17.00-19.00 | 8.00-10.00 | ≤0.10 |

physical property of 302 stainless steel wire

| Physical Property | Value |

|---|---|

| Density | 7.93 kg/dm³ (20°C) |

| Melting Point | 1398-1420°C |

| Specific Heat Capacity | 0.5 kg/(kg·K) (0-100°C) |

| Thermal Conductivity | 16.3 W/(m·K) (100°C) |

| Thermal Conductivity | 21.5 W/(m·K) (500°C) |

| Linear Expansion Coefficient | 17.3 × 10⁻⁶ /K (0-100°C) |

| Linear Expansion Coefficient | 18.7 × 10⁻⁶ /K (0-504°C) |

| Electrical Resistivity | 0.73 Ω·mm²/m (20°C) |

| Young’s Modulus (Longitudinal) | 193 GPa (20°C) |

| Magnetism | Non-magnetic |

mechanical property of 302 stainless steel wire

| Mechanical Property | Value |

|---|---|

| Ultimate Tensile Strength | 1115 MPa (125000 psi) |

| Yield Strength | – |

| Tensile Modulus | 193 GPa (28000 ksi) |

| Shear Modulus | 77.2 GPa (11200 ksi) |

| Poisson’s Ratio | 0.25 |

| Fatigue Strength | 485 – 550 MPa (70300 – 79800 psi) |

features of 302 stainless steel wire

- Excellent Corrosion Resistance: 302 stainless steel wire contains a high content of chromium, which effectively resists corrosion from most corrosive media, especially suitable for acidic and alkaline environments. This makes it widely used in chemical, marine facilities, and food processing industries.

- Outstanding High Temperature Performance: 302 stainless steel rope maintains good toughness and oxidation resistance even under high temperature conditions, capable of withstanding stress and deformation in high-temperature environments. Therefore, it is suitable for applications requiring heat resistance, such as photography, food industry, etc.

- High Strength: 302 stainless steel wire has high yield strength and tensile strength, capable of withstanding large loads. This characteristic makes it excel in aerospace, automotive manufacturing, and other fields, especially under high stress and load conditions.

- Good Machinability: 302 stainless steel wire has good ductility and machinability, allowing it to form various shapes without cracking or fracturing. Moreover, it has high dimensional accuracy, excellent surface quality, and brightness, suitable for various machining processes such as cold working and welding.

- Excellent Conductivity: 302 stainless steel cable has excellent conductivity, making it widely used in the electronics industry, especially in the manufacture of batteries, contacts, etc.

- Good Biocompatibility: Due to its good biocompatibility and corrosion resistance, 302 stainless steel wire is also widely used in the manufacture of medical devices.

application of 302 stainless steel wire

- Spring and Wire Manufacturing: 302 stainless steel cable is commonly used in the manufacturing of springs and wires due to its high tensile strength and ability to withstand repeated deformation. It performs exceptionally well in these applications, meeting the requirements for various complex shapes and sizes.

- Electronics and Electrical Equipment: With its excellent conductivity, 302 stainless steel wire finds wide applications in the electronics industry for manufacturing batteries, contacts, and other electrical equipment. Additionally, it plays a significant role in the production of casings for electronic devices such as mobile phones, tablets, and laptops.

- Medical Instruments and Implants: The biocompatibility and corrosion resistance of 302 stainless steel cable make it a popular choice for surgical instruments and implants. It plays a crucial role in the manufacture of medical instruments such as surgical knives, needles, dental implants, and more.

Thank you very much for taking the time to read through our product page for 302 stainless steel wire. We hope it has provided you with valuable insights for your work or daily life. If you are in need of stainless steel products in the near future, we sincerely invite you to contact Huaxiao Metal.

Huaxiao Metal is a company with over 15 years of experience in exporting stainless steel products, headquartered in Shanghai, China. We are committed to providing our customers with a one-stop stainless steel solution, covering every aspect from production to packaging and transportation. With customers around the globe, we have earned their trust and praise through our professional product knowledge and excellent after-sales service.

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China