Do you have any questions about our products or are you looking for a professional 410/410S stainless steel sheets supplier?

410 410S Stainless Steel Sheet and Plate Supplier

Specifications: UNS S41000 (410) / UNS S41008 (410S), 1.4006 (410) / 1.4000 (410S), ASTM A240, Swedish SS 2302, JIS SUS 410, AISI 416, X12Cr13 (1.4006), 410 stainless steel, Alloy 410, Grade 410, FeMi35Cr20Cu4Mo2, DIN 2.4660, AWS E410, ER410

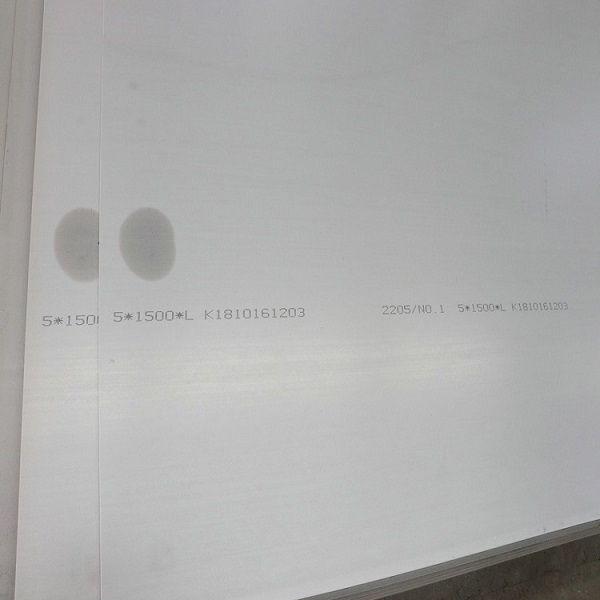

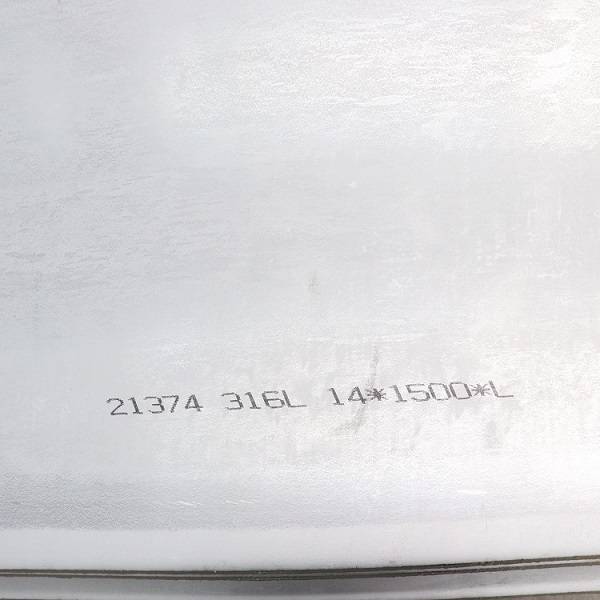

Thickness: 0.2mm – 8.0mm, Customer’s Requirement.

Width: 1000mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, etc. (Customer’s Requirement)

Length: 500mm – 6000mm

Standards: ASTM, DIN/EN, JIS, GB, Other

Finish: 2B, 2D

Certification: ISO9001:2015

MOQ: 2MT

Payment method: T/T, LC

Price: Inquiry Grade 410 Stainless Steel Sheets Lastest Price Now!

410&410s Grade Description in Different Standard

| Grade | ISO Name | ASTM | DIN / EN | JIS | GB | Other |

|---|---|---|---|---|---|---|

| 410 | X12Cr13 | S41000, 410 | 1.4006 | SUS410 | 12Cr13, 1Cr13 | 06Cr13, 0Cr13 |

| 410S | X6Cr13 | S41008 / 410S | 1.4000 | SUS410S | S11306 | – |

Specification of 410&410s Stainless Steel Sheets

| Grade | Standard | C % | Si % | Mn % | P % | S % | Cr % | Ni % | Mo % |

|---|---|---|---|---|---|---|---|---|---|

| 410 | ASTM | 0.15-0.60 | ≤ 1.00 | ≤ 1.00 | ≤ 0.04 | ≤ 0.030 | 11.5-13.5 | ≤ 0.75 | ≤ 0.75 |

| 410 | EN | 0.08-0.15 | ≤ 1.00 | ≤ 1.00 | ≤ 0.04 | ≤ 0.03 | 11.5-13.5 | ≤ 0.75 | ≤ 0.75 |

| 410 | JIS | ≤ 0.15 | ≤ 1.00 | ≤ 1.00 | ≤ 0.04 | ≤ 0.03 | 11.5-14.5 | ≤ 0.6 | – |

| 410 | GB | ≤ 0.15 | ≤ 1.00 | ≤ 1.00 | ≤ 0.04 | ≤ 0.03 | 11.5-13 | ≤ 0.6 | – |

| 410S | ASTM | ≤ 0.08 | ≤ 1.00 | ≤ 1.00 | ≤ 0.04 | ≤ 0.030 | 11.5-14.5 | ≤ 0.06 | ≤ 0.06 |

| 410S | EN | ≤ 0.08 | ≤ 1.00 | ≤ 1.00 | ≤ 0.04 | ≤ 0.030 | 11.5-14.5 | ≤ 0.06 | ≤ 0.06 |

| 410S | JIS | ≤ 0.08 | ≤ 1.00 | ≤ 1.00 | ≤ 0.04 | ≤ 0.030 | 11.5-14.5 | ≤ 0.06 | ≤ 0.06 |

| 410S | GB | ≤ 0.08 | ≤ 1.00 | ≤ 1.00 | ≤ 0.04 | ≤ 0.030 | 11.5-14.5 | ≤ 0.06 | ≤ 0.06 |

Physical Properties of 410&410s Stainless Steel Sheets

| Physical Properties | 410 Stainless Steel | 410S Stainless Steel |

|---|---|---|

| Density (g/cm³) | 7.7 | 7.7 |

| Melting Point (°C) | 1480-1530 | 1480-1530 |

| Coefficient of Thermal Expansion (10⁻⁶/K) | 10.4 at 68-212°F (20-100°C) | 10.4 at 68-212°F (20-100°C) |

| Thermal Conductivity (W/m-K) | 24.9 at 212°F (100°C) | 24.9 at 212°F (100°C) |

| Resistivity (nΩ-m) | 500 at 68°F (20°C) | 500 at 68°F (20°C) |

Mechanical Properties of 410&410s Stainless Steel Sheets

| Mechanical Properties | 410 Stainless Steel | 410S Stainless Steel |

|---|---|---|

| T.S. (MPa) | ≥450 | ≥440 |

| Y.S. (MPa) | ≥205 | ≥205 |

| L. (%) | ≥20 | ≥20 |

| HB (Hardness, Brinell) | ≤217 | ≤183 |

| HRB (Hardness, Rockwell B) | ≤96 | ≤88 |

| HBW (Brinell Hardness) | ≤223 | ≤192 |

The Advantages of 410s 410 Stainless Steel

- High thermal conductivity, smaller growth coefficient, excellent oxidation resistance, outstanding resistance to stress corrosion, etc. Using external optimizing engineering (AOD or VOD) may significantly reduce the gap parts like nitrogen and carbon.

- Stainless steel is comparable to China’s 1Cr13 stainless steel S41000 (American Corrosion Resistance, valves, and machinability purpose generators. AISI, ASTM). 0.01% carbon, 0.13% chromium 0.1 410 stainless steel: good 410

- Heating therapy of 410 stainless steel: solution treatment (°C) 800-9000 slow cooling or 750 speedy heating system.

Application of 410s 410 Stainless Steel

Pharmaceutical Industry

In the field of oil refining, chemical industry, and natural gas, 410 and 410S stainless steel sheets are often used in the manufacture of pipelines, valves, storage tanks, heat exchangers, reactors, steam generators, and other equipment.

Petrochemical Industry

410 and 410S stainless steel sheets are widely used in pharmaceutical equipment, such as pharmaceutical stirrers, emulsifiers, drying equipment, storage tanks, etc.

Paper Industry

410 and 410S stainless steel sheets are widely used in paper making equipment, such as pulping equipment, drums, heaters, etc.

Food Processing Industry

410 and 410S stainless steel sheets are widely used in the manufacture of food processing equipment, such as food processing machinery, storage tanks, food packaging materials, etc., because of their corrosion resistance and easy cleaning properties.

Ship Manufacturing Industry

410 and 410S stainless steel sheets are widely used in ship manufacturing, such as ship bearings, propellers, bathroom, and kitchen equipment, etc.

Tool Manufacturing Industry

Due to their high hardness and high strength, 410 and 410S stainless steel sheets are also used in the manufacture of some high-performance tools, such as blades, cutting tools, etc.

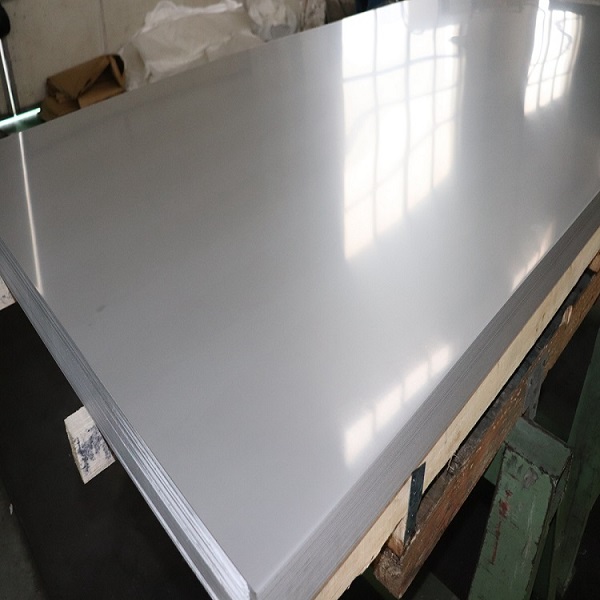

Stainless Steel Sheets Supplier --- HUAXIAO

As a Chinese supplier with over 15 years of experience in the export of stainless steel products, Huaxiao Stainless Steel has always prioritized professionalism, quality, and innovation. We not only provide stainless steel plates in standard sizes but also offer custom-sized plates to meet the diverse needs of different industries and projects, tailored to the specific requirements of our customers.

Our competitive Stainless Steel Sheets

We will answer your email in 24 hours!

FAQ

- Carbon Content and Hardness: 410 stainless steel has a relatively higher carbon content, which helps to enhance its hardness. In contrast, 410S stainless steel is a non-hardening variant of the 410 type with lower carbon content, which may result in slightly lower hardness compared to 410 stainless steel.

- Corrosion Resistance: Although both types exhibit similar corrosion resistance, 410S stainless steel has slightly better corrosion resistance than 410 stainless steel, making it more resistant to chemical erosion.

- Heat Treatment Characteristics: 410S stainless steel exhibits unique characteristics after heat treatment. Its low carbon content and the addition of a small amount of alloy reduce the formation of austenite at high temperatures, limiting the alloy’s hardening ability. This means that even when rapidly cooled from temperatures above the critical point, 410S remains soft and ductile. This non-hardening feature helps prevent cracking of the alloy when exposed to high temperatures or during welding.

- Application Range: Due to its higher hardness and better corrosion resistance, 410S stainless steel is more suitable for use in high-temperature and corrosive environments. On the other hand, 410 stainless steel, with its higher hardness, is more suitable for general applications such as blades, mechanical components, and so on.

Similarities:

- Chemical Composition: 410 and 410S stainless steels have similar chemical compositions and are both ferritic stainless steels, containing high chromium and low carbon.

- Magnetism: Due to their ferrite organization, 410 and 410S stainless steels have strong magnetic properties.

- Weldability: Both 410 and 410S stainless steels have good weldability.

- Strength and Toughness: 410 and 410S stainless steels have high strength and good toughness, with certain heat resistance properties.

Differences:

- Carbon Content: 410 stainless steel has a higher carbon content of 0.15%, while 410S stainless steel has a lower carbon content of 0.08%.

- Chromium Content: The chromium content of 410 stainless steel is 13-18%, while the chromium content of 410S stainless steel is 11.5-14.5%.

- Corrosion Resistance: Since 410S stainless steel contains small amounts of nickel and molybdenum elements, it has better corrosion resistance in certain corrosive media.

- Heat Treatability: Because of its lower carbon content, 410S stainless steel has better heat treatability, allowing it to further improve strength and toughness through machining, welding and quenching.

These differences are mainly caused by the differences in their chemical compositions, and also lead to some differences in their properties.

The corrosion resistance of 410 and 410S stainless steels is relatively poor, mainly due to their chemical composition containing less nickel and molybdenum elements, which are very important to improve the corrosion resistance of stainless steels. Therefore, 410 and 410S stainless steels have poor corrosion resistance in corrosive media such as strong acids, strong alkalis and chlorides, and are prone to corrosion and rusting.

However, 410S stainless steel has better corrosion resistance in certain corrosive media, for example, in environments such as chlorides and sulfates, compared to 410 stainless steel. In addition, the corrosion resistance of 410 and 410S stainless steels can also be improved by taking measures such as suitable surface treatment and anti-corrosion coating.

As for the service life, it depends on a variety of factors, such as the use environment, operating conditions, maintenance and so on. Under good use environment and proper use and maintenance, 410 and 410S stainless steel can have a relatively long service life.

The machining of 410 and 410S stainless steels is relatively difficult, mainly due to their high hardness and easy chip formation, as well as their strong plastic deformation capability, so suitable tools and techniques need to be used for machining.

During machining processes such as drilling and milling, high hardness and high speed cutting tools need to be used, while attention should be paid to controlling the feed rate and cutting speed to reduce chip formation and cutting forces. In the welding process, due to the low coefficient of thermal expansion of 410 and 410S stainless steel, it is easy to produce deformation and stress concentration, so it is necessary to use appropriate methods such as preheating and post heat treatment to control the temperature and stress during the welding process.

In conclusion, 410 and 410S stainless steels require attention to control factors such as cutting speed, feed rate and tool wear during machining to ensure machining quality and tool life. Also, the machining properties of these two materials need to be taken into account when designing products to better apply them during machining and fabrication.

The surface treatment methods of 410 and 410S stainless steel can be divided into two types: mechanical treatment and chemical treatment.

Mechanical treatments include polishing, grinding and sandblasting methods. Polishing is done by grinding the surface of the material using abrasive materials with different grains to obtain a high gloss and smooth surface. Sanding is the grinding of a surface by using sandpaper or grinding wheels to remove impurities such as burrs, oxidation and stains from the surface. Sandblasting, on the other hand, uses high-pressure gas to blast abrasives onto the surface to remove oxidation, stains and uneven roughness from the surface.

Chemical treatments include electrolytic polishing, pickling and electrochemical grinding methods. Electrolytic polishing is done by adding certain chemical reagents to the electrolytic solution and electrolyzing the stainless steel sheet to remove impurities such as oxidation skin, stains and burrs on the surface. Acid washing is done by soaking and rinsing the stainless steel plate in an acidic solution to remove oxidation and impurities from the surface. Electrochemical grinding, on the other hand, is done by applying a voltage in an electrolytic solution to remove burrs and roughness from the surface.

Overall, the choice of surface treatment method should be based on the specific application scenario and requirements. It should be noted that during the surface treatment process, care should be taken to control the treatment time and temperature in order to avoid any impact on the properties and dimensions of the material.

The price of 410 and 410S stainless steel is relatively low compared to other stainless steels. This is mainly due to the relatively low chromium content in 410 and 410S stainless steels, which is one of the more expensive elements in stainless steel. In addition, the production cost of 410 and 410S stainless steels is lower than other high-end stainless steels because 410 and 410S stainless steels do not require the addition of valuable alloying elements such as molybdenum and nickel.

Therefore, in applications where stainless steel is required, 410 and 410S stainless steel can be an economical and practical choice if the requirements for corrosion resistance and high temperature resistance of the material are not very high.

If you have a need for any stainless steel products, please feel free to contact us.

Maintenance is very important to extend the life of 410 and 410S stainless steels. The following are some recommendations for maintenance:

Clean regularly: Clean the stainless steel surface regularly of dirt and dust by wiping with a soft cloth or sponge moistened with soapy water or detergent.

Avoid using scratchy tools: Using scratchy tools such as wire balls and brushes can damage the stainless steel surface and cause problems such as rusting.

Prevent erosion by chemicals: Avoid erosion of 410 and 410S stainless steel by strong acids, strong alkalis and other chemicals, which can lead to surface rusting, discoloration and other problems.

Regular maintenance: For 410 and 410S stainless steel products, maintenance should be carried out regularly to identify and solve problems in a timely manner in order to avoid long-term accumulation leading to bigger problems.

Avoid prolonged contact with water: Although stainless steel has excellent resistance to rust and corrosion, prolonged immersion in water can lead to scale and oxidation on the surface of stainless steel, affecting its aesthetics and service life.

Overall, for the maintenance of 410 and 410S stainless steel, the key is to keep its surface clean and dry, and avoid mechanical damage and chemical erosion. This will ensure that the stainless steel maintains its excellent performance and aesthetics for a long time.