Does Colored Stainless Steel Tarnish or Fade?

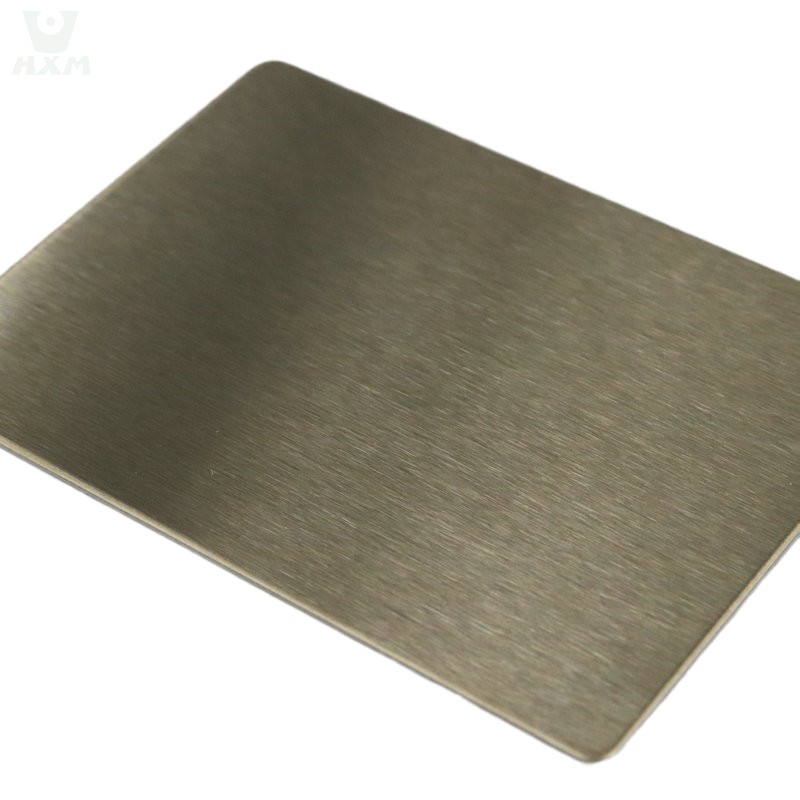

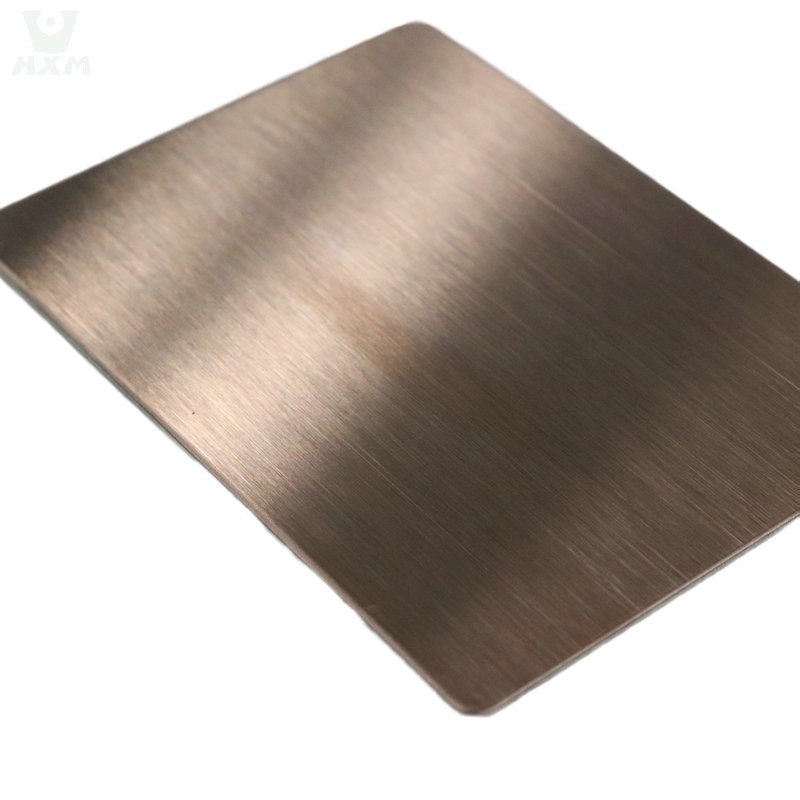

Colored stainless steel sheets, as a building material that combines aesthetics and practicality, have received widespread attention in the field of architectural decoration in recent years. Its unique colors and gloss not only add artistic sense to the space but also provide designers with more creative inspiration. However, many people have a common concern when choosing coloring stainless steel sheets: Will they tarnish over time?

Colored stainless steel sheets, as a building material that combines

Does Colored Stainless Steel Tarnish or Fade?

Typically, any coating on colored stainless steel sheets does not easily tarnish, thanks to its surface coloring treatment technology. This technique colors the surface of the stainless steel substrate, creating a wide range of color effects, making colored stainless steel sheets an excellent decorative material. It’s worth mentioning that this coloring is not a simple paint application but a special transparent film spray, which not only maintains the product’s bright and beautiful appearance but also enhances its durability in various environments.

This transparent coating, sometimes referred to as “clear lacquer,” primarily serves to protect the stainless steel surface while ensuring the color remains vibrant and long-lasting. The color layer on the surface of colored stainless steel sheets can withstand temperatures of up to 200°C, and its resistance to salt spray corrosion exceeds that of ordinary stainless steel. Additionally, these colored stainless steel sheets boast excellent wear and scratch resistance, with performance comparable to foil-coated gold.

four key steps: processing colored stainless steel

Degreasing and Activation:

- Utilize a professional stainless steel degreasing and activation solution to remove surface oil and impurities from the stainless steel sheets.

- Activation treatment helps enhance the reactivity of the stainless steel surface, preparing it for subsequent steps.

- After treatment, thoroughly rinse with clean water to ensure a residue-free surface.

Passivation Treatment:

- Apply stainless steel passivation paste or solution to the cleaned stainless steel sheet surface.

- The passivation process typically lasts from half an hour to over two hours, depending on product requirements and environmental conditions.

- Passivation aims to form a protective film, enhancing the corrosion resistance and stability of the stainless steel sheet.

Alkaline Water Rinsing:

- After passivation, rinse the stainless steel sheet with alkaline water.

- This step aims to remove residual passivation agents and other impurities from the surface, ensuring a clean and smooth surface.

- After rinsing, rinse again with clean water to ensure no alkaline residue on the stainless steel sheet surface.

Spraying Coating:

- After completing the above steps, evenly spray a transparent stainless steel film onto the stainless steel sheet surface.

- This film forms a hard layer, enhancing the stainless steel sheet’s wear resistance, scratch resistance, and preventing fingerprint and other contaminants.

- The choice of coating should be determined based on specific requirements and decorative effects to ensure long-lasting and aesthetically pleasing colors.

reasons for colored stainless steel tarnish

Insufficient Plating Time During Processing:

In pursuit of efficiency or cost reduction, some processing plants may shorten the plating time. However, the plating time is crucial for ensuring the quality and hardness of the coating. In theory, the longer the electroplating time, the more robust the coating, and the better the color durability of the colored stainless steel. If the plating time is insufficient, it may result in gradual fading of the color after 5-10 years of use.

Adverse Environmental Impact:

Colored stainless steel sheets may suffer from the effects of acid-base imbalance in certain specific application environments. For example, in coastal areas or during installation, if the colored stainless steel surface comes into contact with acidic substances and is not promptly or properly treated, it may damage the surface color coating, and even lead to rusting of the stainless steel substrate.

External Physical and Chemical Factors:

During use, colored stainless steel sheets may suffer damage or fading due to improper maintenance or use. For example, long-term physical scratches, contact with corrosive liquids, prolonged exposure to sunlight and rain, etc., may damage the surface of colored stainless steel, leading to color fading or darkening.

conclusion

Colored stainless steel sheets are generally resistant to fading under normal circumstances. However, we cannot overlook certain factors that may contribute to fading. Therefore, to ensure the color durability of colored stainless steel sheets, it is important to choose a professional processing factory, pay attention to the selection of the usage environment, and take proper maintenance measures.

If you have any needs for colored stainless steel sheets, Huaxiao Metal will be your ideal partner. With over 15 years of export experience, we specialize in the production and processing of stainless steel products. Our colored stainless steel sheets are treated with advanced coloring technology to ensure long-lasting vibrant colors. Moreover, we strictly control the processing process to ensure that each colored stainless steel sheet meets the highest quality standards.

Additionally, we provide personalized customization services, allowing us to tailor colored stainless steel sheets to your specific requirements regarding color, specifications, and thickness. Our products are widely used in architectural decoration, home decoration, elevator decoration, and many other fields, earning high praise from customers.

If you are interested in our colored stainless steel sheets or have any other needs, please feel free to contact us.

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China