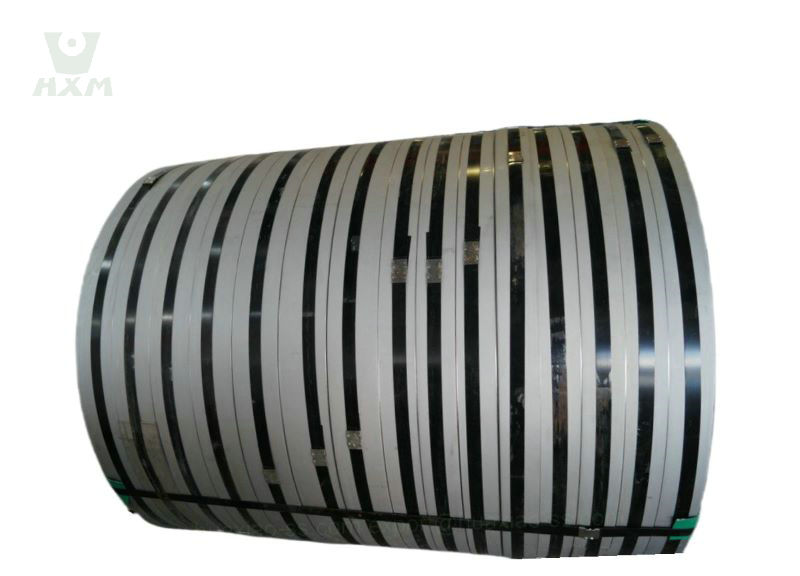

Hot Rolled Stainless Steel Strips Supplier

- Thickness: 1.2mm – 10mm

- Width: 30mm – 600mm, the wider products pls check in coil products

- Finish: NO.1, 1D, #1, Hot rolled

- Coil diameter /ID: 200mm, 400mm, 508mm, 610mm.

- Main Grade ASTM-A240: 304 304L 304H 304DQ 316 316L 201 202 301 310s 430 410s 409 409L 444 441 2205 2507 etc.

- MOQ: 2MT

Product Description of Hot Rolled Stainless Steel Strips

Hot rolled stainless steel strips are a stainless steel product with excellent mechanical properties and corrosion resistance. The hot-rolling process makes it has high hardness and strength for various high-strength and corrosion-resistant applications. Hot rolled stainless steel strips can be divided into different models such as conventional hot rolled stainless steel strips, high strength hot rolled stainless steel strips, ultra-low temperature hot rolled stainless steel strips,s, and high temperature resistant hot rolled stainless steel strips.

The surface of hot-rolled stainless steel strips is usually gray with high gloss and smoothness. Depending on customers’ requirements, they can be customized into different sizes, shapes, and surface treatments such as cold rolled, annealed, polished, etc. Hot rolled stainless steel strips are widely used in aerospace, automotive, chemical, construction, electric power, and other fields, such as manufacturing aircraft, automotive parts, chemical containers, construction materials, power generation equipment, etc.

Production Range of Hot Rolled Stainless Steel Strips

- Thickness: 1.2mm – 10mm

- Width: 30mm – 600mm, the wider products pls check in coil products

- Finish: NO.1, 1D, #1, Hot rolled

- Inner Diameter /ID: 508mm, 610mm

- Main Grade ASTM-A240: 304 304L 304H 304DQ 316 316L 201 202 301 310s 430 410s 409 409L 444 4412205 2507 etc.

Types of Hot Rolled Stainless Steel Strips

Conventional hot rolled stainless steel strips are the stainless steel strip made by continuous hot rolling process under high temperature. Usually the production process of AOD and VOD furnace melting is used, and the commonly used materials include 201, 202, 304, 316L, etc.

This kind of strip has a smooth surface, with a certain mechanical strength and toughness, and is widely used in construction, manufacturing, chemical industry and other fields. The composition of conventional hot rolled stainless steel strip is mostly an alloy of chromium, nickel, manganese and other elements, with chromium content above 10.5% to improve its corrosion resistance. Conventional hot rolled stainless steel strips are available in a variety of specifications and can be custom manufactured according to customer needs.

High strength hot rolled stainless steel strips are a class of stainless steel strip products made of high strength stainless steel material with higher tensile strength than conventional hot rolled stainless steel strip. Mainly used in aerospace, marine, military and other fields. Advanced vacuum melting process and material design are usually used to improve the strength and hardness of the material. Commonly used materials include GH4169, GH4145, GH2132, etc. High strength hot rolled stainless steel strip has the advantages of high strength, high hardness, high wear resistance and better corrosion resistance. The cost of high-strength hot-rolled stainless steel strip is relatively high, and it is generally widely used in high-end fields such as automotive, marine, aerospace, construction and electronics.

Ultra-low temperature hot rolled stainless steel strips refer to stainless steel strip that is hot-rolled under low temperature conditions, usually at around -196°C. This stainless steel strip has extremely high corrosion resistance, low temperature toughness and fatigue resistance, usually using a vacuum melting process, commonly used materials include 0Cr18Ni9, 00Cr19Ni10, 0Cr17Ni12Mo2, etc. Ultra-low temperature hot-rolled stainless steel strip manufacturing process is relatively complex, more difficult to produce, and therefore the price is relatively high. It is usually applied to some special applications, such as aviation, aerospace and other high-end fields.

High temperature resistant hot rolled stainless steel strips generally refers to the use of special high temperature resistant stainless steel materials made of stainless steel strip that can maintain better performance in high temperature environments. This stainless steel strip is usually produced using high-temperature alloying technology to give it better corrosion resistance, oxidation resistance, heat resistance, wear resistance and other properties at high temperatures. The vacuum melting process is usually used, and the commonly used materials include 310S, 253MA, HR3C, etc.

High temperature resistant hot rolled stainless steel strip is difficult to produce and relatively expensive, so it is widely used in aerospace, nuclear energy, petrochemical and other fields, such as the manufacture of gas turbine blades, gas turbine blades, high temperature heat exchangers, etc.

Main Grade Mechanical Property in Different Standards

| 201 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

| ASTM | 260 | 655 | 40 | 207 | 95 | — | 218 |

| JIS | 275 | 520 | 40 | 241 | 100 | — | 253 |

| GB | 205 | 515 | 30 | 183 | 99 | — | 218 |

| 202 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

| ASTM | 260 | 620 | 40 | 183 | 88 | 210 | 290 |

| JIS | 245 | 590 | 40 | 183 | 95 | 207 | 218 |

| GB | 245 | 590 | 40 | 183 | 95 | 207 | 218 |

| 301 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

| ASTM | 205 | 515 | 40 | 207 | 95 | 217 | 218 |

| JIS | 205 | 520 | 40 | 207 | 95 | — | 218 |

| GB | 205 | 515 | 40 | 207 | 95 | — | 218 |

| 304 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

| ASTM | 205 | 515 | 40 | 201 | 92 | 201 | – |

| JIS | 205 | 520 | 40 | 187 | 90 | 200 | 210 |

| GB | 205 | 515 | 40 | 187 | 90 | — | — |

| 310S | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

| ASTM | 205 | 515 | 40 | 217 | 95 | 217 | 207 |

| JIS | 205 | 520 | 40 | 187 | 90 | – | 200 |

| GB | 205 | 515 | 40 | 187 | 95 | 217 | 220 |

| 316L | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

| ASTM | 170 | 485 | 40 | 217 | 95 | 217 | 217 |

| JIS | 175 | 480 | 40 | 187 | 90 | 200 | 200 |

| GB | 170 | 485 | 40 | 187 | 95 | 217 | 220 |

| 409 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

| ASTM | 175 | 360 | 20 | 88 | 68 | 183 | 200 |

| JIS | 175 | 360 | 22 | 162 | 80 | 183 | 175 |

| GB | 175 | 360 | 25 | 88 | 68 | 183 | 200 |

| 409L | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

| ASTM | 170 | 380 | 20 | 179 | 88 | 179 | – |

| JIS | 175 | 360 | 25 | 162 | 80 | – | 175 |

| GB | 170 | 380 | 20 | 179 | 88 | 179 | 200 |

| 410S | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

| ASTM | 205 | 415 | 22 | 183 | 89 | 183 | 200 |

| JIS | 205 | 410 | 20 | 183 | 88 | 183 | 200 |

| GB | 205 | 415 | 20 | 183 | 89 | 183 | 200 |

| 430 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

| ASTM | 205 | 450 | 22 | 183 | 89 | 183 | 200 |

| JIS | 205 | 450 | 22 | 183 | 88 | – | 200 |

| GB | 205 | 450 | 22 | 183 | 89 | 183 | 200 |

| 2205 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRC ≤ | HBW ≤ | HV ≤ |

| ASTM | 450 | 655 | 25 | 293 | 31 | 293 | 293 |

| JIS | 450 | 620 | 25 | – | – | – | – |

| GB | 450 | 620 | 25 | – | 31 | 293 | – |

| 2507 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRC ≤ | HBW ≤ | HV ≤ |

| ASTM | 550 | 795 | 15 | 290 | 32 | 310 | – |

| JIS | 450 | 620 | 25 | 270 | 25 | 290 | – |

| GB | 550 | 795 | 15 | – | 32 | 310 | – |

Standards may vary slightly between stainless steel suppliers, and the data in the table above is for reference only.

Features of Hot Rolled Stainless Steel Strips

Hot rolled stainless steel strips have higher strength, which can meet the needs of some projects that require high strength materials.

Compared with cold rolled stainless steel strips, hot rolled stainless steel strips have better plasticity and ductility, which can be easily processed by stamping, stretching, bending and other processing operations.

Hot rolled stainless steel strips have good corrosion resistance and can maintain stable chemical properties in various media such as acids, alkalis and salts.

Hot rolled stainless steel strips can maintain stable physical and chemical properties in high temperature environment, which can meet the needs of some projects that need to be used in high temperature.

Compared with cold rolled stainless steel strips, the production cost of hot rolled stainless steel strips are relatively low, and the price is also relatively low.

Application of Hot Rolled Stainless Steel Strips

Construction Industry

Hot rolled stainless steel strips can be used for curtain walls, skylights, roofs, decorative wall panels, and other building exterior decoration, and also for indoor flooring, ceiling, wall panels, furniture, etc. Hot rolled stainless steel strips are also an ideal material for structural parts of buildings, such as beams, columns, suspension parts, etc.

Automotive Manufacturing Industry

Hot rolled stainless steel strips can be used in the manufacture of automotive body shells, such as door panels, roofs, doors, cabin side panels, etc. Hot rolled stainless steel strips can be used for the manufacture of the automobile exhaust systems, such as exhaust pipes, mufflers, etc. Hot rolled stainless steel strips can even be used for the manufacture of automotive fuel systems, such as fuel tanks, fuel pumps, fuel lines, etc. The hot rolled stainless steel strips are also an ideal material for automotive parts, such as brake systems, suspension systems, transmission system, etc.

Chemical Industry

Hot rolled stainless steel strips are suitable for chemical equipment manufacturing, such as chemical reactors, heat exchangers, distillation towers, etc. Hot rolled stainless steel strips are also widely used in petrochemical pipelines, coal chemical pipelines, and other fields. Hot rolled stainless steel strip has an excellent performance in electrolytic cell manufacturing and is also a rational material for heat exchangers, such as automobile radiators, air conditioners, condensers, etc.

Electronic and Electrical Industry

In electronic manufacturing, some precision components and equipment require the use of hot rolled stainless steel strips as raw material for electronic parts, precision instruments, equipment, etc. In electrical manufacturing, hot rolled stainless steel strips can be used to manufacture high-quality electrical components and parts. For example, hot rolled stainless steel strips can be made into electrical connectors, sockets, cable protection tubes, and other electrical equipment.

Aerospace Industry

Hot rolled stainless steel strips can be used to manufacture aircraft engine parts, such as turbine blades, blade discs, air inlets, etc. Hot rolled stainless steel strips can be used to manufacture parts such as aircraft interior and exterior finishes, screws and fasteners, key components such as spacecraft shells, combustion chambers, valve seat rings, and connections and joints in corrosive environments.

FAQ

Hot rolled stainless steel strips and cold-rolled stainless steel strips are both commonly used stainless steel products, and they have different characteristics, advantages, and disadvantages in terms of the manufacturing process, performance, and application.

Advantages of hot rolled stainless steel strips:

- Thicker stainless steel strips can be manufactured, usually above 3mm in thickness.

- Large internal grain size, loose structure, good plasticity, and good workability.

- The surface finish is not high, but good corrosion resistance.

- Suitable for the manufacture of large stainless steel plates, coils, and other products, high yield, and low cost.

Disadvantages of hot rolled stainless steel strips:

- The surface quality is not smooth enough and requires secondary processing to get a smooth surface.

- Poorer shape stability than cold-rolled stainless steel strip, easy to deform.

- The product size error is large.

Advantages of cold rolled stainless steel strip:

- Smooth surface quality, good gloss, beautiful appearance.

- Good shape stability of the product, a small error, suitable for the manufacture of products requiring high precision.

- Excellent mechanical properties, high tensile strength, and good fatigue resistance.

Disadvantages of cold rolled stainless steel strip:

- Thickness and width are limited, usually only thin-thickness stainless steel strips can be manufactured.

- Small internal grain size, dense structure, poor processability, easy fatigue.

- High production costs.

Compared to cold rolled stainless steel strips, the processing difficulty of hot rolled stainless steel strips is slightly higher. Because hot rolled stainless steel strip undergoes a variety of complex processes such as high temperature and high pressure during the production process, there will be greater stress and deformation during processing, coupled with the high hardness and high toughness of stainless steel itself, so a certain amount of pretreatment and control is required during processing. At the same time, the surface of hot rolled stainless steel strips is relatively rough and needs to be surface treated before processing to ensure processing accuracy and surface quality.

To ensure the quality of your products, we recommend you choose an experienced and professional supplier of hot rolled stainless steel strips.

The good corrosion resistance of hot rolled stainless steel strips is mainly due to the presence of at least 10.5% chromium in stainless steel, which makes it corrosion-resistant. In addition, stainless steel also contains other alloying elements, such as nickel, molybdenum, vanadium, and titanium, which can further improve the corrosion resistance of stainless steel.

In the atmosphere, the surface of the stainless steel strips forms a dense chromium oxide layer, which prevents the erosion of oxygen, moisture, and other corrosive media. In acid, alkali, and other strong corrosive media, stainless steel also has good corrosion resistance. In addition, the surface of stainless steel can be subjected to special surface treatment, such as plating, spraying, etc., to further improve its anti-corrosion properties.

Good quality hot rolled stainless steel strips have better anti-corrosion performance, we recommend you carefully select the hot rolled stainless steel strip supplier to ensure the service life of the product.

Hot rolled stainless steel strips can usually be classified according to its composition, application and surface condition. The following are common ways of classification:

Composition Classification: According to different chemical compositions, hot rolled stainless steel strips can be classified into austenitic stainless steel strips, ferritic stainless steel strips, duplex stainless steel strips, martensitic stainless steel strips, etc.

Application Classification: According to different applications, the hot rolled stainless steel strips can be divided into stainless steel strips for architectural decoration, stainless steel strips for automobile manufacturing, stainless steel strips for electronic appliances, stainless steel strips for mechanical equipment, etc.

Surface State Classification: According to the different surface state, the hot rolled stainless steel strips can be divided into 2B state stainless steel strips, 2D state stainless steel strips, BA state stainless steel strips, NO.1 state stainless steel strips, etc.. Among them, 2B state and BA state are the more common surface state. 2B state stainless steel strips surface is relatively smooth, suitable for less demanding occasions, BA state stainless steel strips surface is more bright and flat, suitable for high-grade decorative field.

The service life of hot rolled stainless steel strips depends on several factors, such as the chemical composition of the material, physical properties, processing process, and the environment in which it is used. Generally speaking, hot rolled stainless steel strip can be used in harsh environments and has a long service life due to their high corrosion resistance and high-temperature resistance.

In addition, the service life of hot rolled stainless steel strips is also related to the use conditions. For example, if the hot rolled stainless steel strips are exposed to high temperature, humidity, or corrosive media such as acid and alkali for a long time, their service life may be affected. Therefore, when using hot rolled stainless steel strips, it is necessary to select and design the material according to the actual situation and take appropriate maintenance measures to extend its service life.

The service life of hot rolled stainless steel strips is closely related to its quality. If you need a professional and reliable supplier of hot rolled stainless steel strips, Huaxiao is undoubtedly your best choice.

The following are some common methods that can help extend the service life of hot rolled stainless steel strips:

Reasonable selection of stainless steel materials and specifications. According to the use environment and requirements, choose the appropriate stainless steel material and specifications to ensure that its properties such as corrosion resistance and mechanical strength meet the needs.

Correct installation and maintenance. The installation and maintenance of hot rolled stainless steel strips should be carried out in strict accordance with relevant regulations and standards. For example, in the installation process, to ensure that the connections are tight, to avoid adverse factors such as stress concentration or vibration; in the maintenance process, to regularly check the use of stainless steel strips, timely detection and treatment of abnormalities.

Avoid prolonged exposure to harsh environments. Hot rolled stainless steel strips should avoid prolonged exposure to acid rain, humidity, high salinity, high chloride ions and other harsh environments to avoid corrosion and damage.

Use protective measures. For example, in certain highly corrosive environments, hot rolled stainless steel strips can be protected by electrochemical or electroplating methods to enhance its corrosion resistance.

Pay attention to keep the surface clean. Stainless steel strips surface contamination and corrosion will affect its performance and life, so pay attention to keep its surface clean, and the use of appropriate cleaning methods.

In short, the correct selection of materials, reasonable installation and maintenance, avoid harsh environments, the use of protective measures and keep the surface clean, etc., can effectively extend the service life of hot rolled stainless steel strips.

Yes, hot rolled steel can be bent. However, the degree to which it can be bent depends on a number of factors, including the thickness of the steel, the radius of the bend, and the type of steel being used. In general, thinner steel and larger bend radii are easier to work with and can be bent more easily without cracking or breaking. It’s also important to note that the specific properties of the steel, such as its strength and ductility, can affect how easily it can be bent without damage.

Stainless steel strips and coils are used in a wide range of industries and the duty drawback rate for exporting these products from China is an important factor for suppliers of hot rolled stainless steel strips to consider. The rebate rate for stainless steel strip exported in coil form with a width of 600 mm or less is 13 percent. However, if the product is exported after processing, there are two ways to do this. The HS-CODE for strips and coils is different and the diameter point is set at 600 mm. If the product is exported as coils with a diameter over 600 mm, the rebate rate is 9%.

To ensure the best rebate rate, suppliers must carefully consider the size and shape of their stainless steel products. If suppliers want to export as strips, they need to ensure that the width is under 600mm, and if suppliers want to export as coils, they should keep the diameter under 600mm. This will help the suppliers to get the higher rebate rate of 13%. If the coil diameter is more than 600 mm, suppliers can still export the product, but they will receive a lower rebate rate of 9%.

It is worth noting that suppliers can also choose to use the coil-to-strip method to receive a 13% rebate on strip exports. This involves processing the coil and slitting it to the required width prior to export. With proper attention to these details, suppliers can maximize their rebates and ensure that their products remain competitive in the global marketplace.

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China