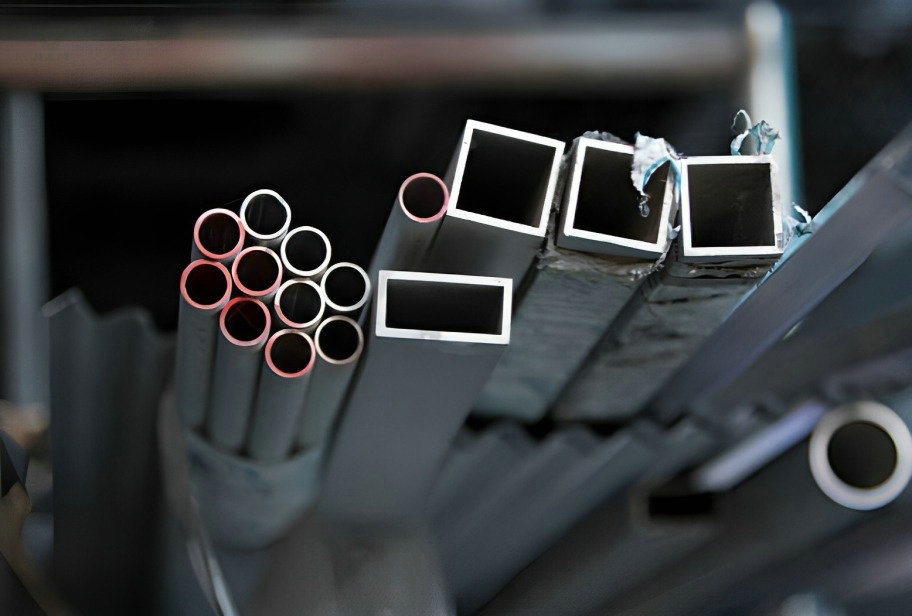

Stainless Steel Boiler Tubes Supplier

Our products are used in most types of boilers such as:

- Advanced Ultra-Supercritical (AUSC) Boiler

- Biomass boiler

- Black liquor recovery boiler

- Coal-fired power boiler

- Concentrated Solar Energy (CSP) Boilers

- Reheater

- Superheater

- Syngas cooler

- Waste heat boiler

Product Description Of Stainless Steel Pipe for boiler

Boiler steel pipes are used in all fields, mainly power generation boilers. They are manufactured to maintain both high quality and high performance. There has also emerged a need for various steel tubes and pipes such as economic steel tubes and specially-shaped steel tubes.

Boiler steel pipes include medium pressure boiler pipe and high pressure boiler pipe, it is often manufactured in seamless procedures, welded steel pipe is not applicable. It has been widely used at heat exchanger pipe and tubing services, tube exchanger bundle, high pressure boiler, economizer, super heater, petrochemical industry pipes, etc.

Specification Of Stainless Steel Pipe for boiler

Production Standard

ASME Sa213 Seamless Ferrite and Austenitic Alloy Steel Tube for Boiler, Superheater, and Heat Exchanger

Production Range

Normal Pipe Size | Outside Diameter | Normal Wall Thickness (mm) | |||||

NPS | in | BN | mm | SCH5s | SCH10s | SCH40s | SCH80s |

1/8 | 0.405 | 6 | 10.3 | — | 1.24 | 1.73 | 2.41 |

1/4 | 0.540 | 8 | 13.7 | — | 1.65 | 2.24 | 3.02 |

3/8 | 0.675 | 10 | 17.1 | — | 1.65 | 2.31 | 3.2 |

1/2 | 0.840 | 15 | 21.3 | 1.65 | 2.11 | 2.77 | 3.73 |

3/4 | 1.050 | 20 | 26.7 | 1.65 | 2.11 | 2.87 | 3.91 |

1 | 1.315 | 25 | 33.4 | 1.65 | 2.77 | 3.38 | 4.55 |

1 1/4 | 1.660 | 32 | 42.2 | 1.65 | 2.77 | 3.56 | 4.85 |

1 1/2 | 1.900 | 40 | 48.3 | 1.65 | 2.77 | 3.68 | 5.08 |

2 | 2.375 | 50 | 60.3 | 1.65 | 2.77 | 3.91 | 5.54 |

2 1/2 | 2.875 | 65 | 73.0 | 2.11 | 3.05 | 5.16 | 7.01 |

3 | 3.500 | 80 | 88.9 | 2.11 | 3.05 | 5.49 | 7.62 |

3 1/2 | 4.000 | 90 | 101.6 | 2.11 | 3.05 | 5.74 | 8.08 |

4 | 4.500 | 100 | 114.3 | 2.11 | 3.05 | 6.02 | 8.56 |

5 | 5.563 | 125 | 141.3 | 2.77 | 3.4 | 6.55 | 9.53 |

6 | 6.625 | 150 | 168.3 | 2.77 | 3.4 | 7.11 | 10.97 |

8 | 8.625 | 200 | 219.1 | 2.77 | 3.76 | 8.18 | 12.7 |

10 | 10.750 | 250 | 273.1 | 3.4 | 4.19 | 9.27 | 12.7 |

12 | 12.750 | 300 | 323.9 | 3.96 | 4.57 | 9.53 | 12.7 |

14 | 14.000 | 350 | 355.6 | 3.96 | 4.78 | 9.53 | — |

16 | 16.000 | 400 | 406.4 | 4.19 | 4.78 | 9.53 | — |

18 | 18.000 | 450 | 457.2 | 4.19 | 4.78 | 9.53 | — |

20 | 20.000 | 500 | 508.0 | 4.78 | 5.54 | 9.53 | — |

22 | 22.000 | 550 | 558.8 | 4.78 | 5.54 | — | — |

24 | 24.000 | 600 | 609.6 | 5.54 | 6.35 | 9.53 | — |

26 | 26.000 | 650 | 660.4 | — | — | — | — |

28 | 28.000 | 700 | 711.2 | — | — | — | — |

30 | 30.000 | 750 | 762.0 | 6.35 | 7.92 | — | — |

32 | 32.000 | 800 | 812.8 | — | 7.92 | — | — |

34 | 34.000 | 850 | 863.6 | — | 7.92 | — | — |

36 | 36.000 | 900 | 914.4 | — | 7.92 | — | — |

38 | 38.000 | 950 | 965.2 | — | — | — | — |

40 | 40.000 | 1000 | 1016.0 | — | 9.53 | — | — |

If you need more sizes, please consult with us | |||||||

Main grade description in different standard

ASTM | DIN / EN | JIS | GB | ISO Name | Other |

S20100 201 | 1.4372 | SUS201 | S35350 | X12CrMnNiN17–7-5 | J1 L1 LH 201J1 |

S20200 202 | 1.4373 | SUS202 | S35450 | X12CrMnNiN18–9-5 | 202 L4, 202 J4, 202 J3 |

S30400 304 | 1.4301 | SUS304 | S30408 | X5CrNi18-10 | 06Cr19Ni10 0Cr18Ni9 |

S31603 316L | 1.4404 | SUS316L | S31603 | X2CrNiMo17-12-2 | 022Cr17Ni12Mo2 00Cr17Ni14Mo2 |

S40900 409 | – | SUH409 | S11168 | X5CrTi12 | 0Cr11Ti |

S40910 409L | 1.4512 | SUH409L | S11163 | X2CrTi12 | 00Cr11Ti 022Cr11Ti |

S41008 410S | 1.4000 | SUS410S | S11306 | X6Cr13 | – |

S43000 430 | 1.4016 | SUS430 | 10Cr17 | X6Cr17 | 1Cr17 |

Main grade chemical components in different standard

201 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | 260 | 515 | 40 | – | 95 | 217 | – |

JIS | 275 | 520 | 40 | 241 | 100 | – | 253 |

GB | 205 | 515 | 30 | - | 99 | – | - |

202 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | 260 | 620 | 40 | – | – | 241 | – |

JIS | 275 | 520 | 40 | – | 95 | 207 | 218 |

GB | – | – | – | – | – | – | – |

304 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | 205 | 515 | 40 | – | 92 | 201 | – |

JIS | 205 | 520 | 40 | 187 | 90 | – | 200 |

GB | 205 | 515 | 40 | – | 92 | 201 | 210 |

316L | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | 170 | 485 | 40 | – | 95 | 217 | – |

JIS | 175 | 480 | 40 | 187 | 90 | 200 | |

GB | 170 | 485 | 40 | – | 95 | 217 | 220 |

409 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | – | – | – | – | – | – | – |

JIS | 175 | 360 | 22 | 162 | 80 | – | 175 |

GB | – | – | – | – | – | – | – |

409L | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | 170 | 380 | 20 | – | 88 | 179 | – |

JIS | 175 | 360 | 25 | 162 | 80 | – | 175 |

GB | 170 | 380 | 20 | – | 88 | 179 | 200 |

410S | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | 205 | 415 | 22 | – | 89 | 183 | – |

JIS | 205 | 410 | 20 | – | 88 | 183 | 200 |

GB | 205 | 415 | 20 | – | 89 | 183 | 200 |

features Of Stainless Steel Pipe for boiler

Our stainless steel pipes for boilers are engineered to provide exceptional performance in demanding boiler applications. With a focus on reliability and durability, these pipes exhibit a remarkable level of corrosion resistance when exposed to oxidizing media. This essential feature ensures prolonged service life and consistent functionality, making them a reliable choice for critical boiler systems. Count on our stainless steel pipes to effectively withstand the challenges posed by corrosive environments, contributing to the efficiency and longevity of your boiler operations.

Our stainless steel pipes for boilers are designed to offer exceptional formability and weldability, making them versatile and easy to work with in various applications. The material’s malleability allows for shaping and customization to meet specific requirements, while its excellent weldability ensures seamless and reliable connections. These attributes enhance the adaptability and efficiency of your boiler projects, ensuring smooth installation and long-lasting performance. Choose our stainless steel pipes to streamline your fabrication processes and achieve optimal results in boiler systems.

Our stainless steel pipes for boilers are engineered to deliver exceptional strength and toughness, making them ideal for demanding boiler applications. With a focus on durability and reliability, these pipes provide robust structural integrity even in challenging environments. Their high strength-to-weight ratio ensures reliable performance under varying pressures and temperatures, while their toughness guarantees resistance to mechanical stresses. Count on our stainless steel pipes to contribute to the long-term efficiency and safety of your boiler systems.

Our stainless steel pipes for boilers are readily available, ensuring prompt access to the essential components you need for your boiler projects. With a well-maintained inventory and efficient distribution network, you can rely on us to provide the stainless steel pipes you require, when you need them. This accessibility streamlines your procurement process, enabling seamless planning and execution of your boiler installations and maintenance. Trust our readily available stainless steel pipes to support your operational needs effectively and efficiently.

Application Of Stainless Steel Pipe for boiler

High-Pressure Water-Tube Boiler Heating Surfaces

- Seamless steel pipes for boilers are specifically designed to create heating surfaces in high-pressure and ultra-high-pressure water-tube boilers.

- These pipes are used to form the inner components of the boiler where heat is transferred to the water to generate steam for various industrial processes.

Medium Pressure and High Pressure Boiler Pipes

- Boiler steel pipes cater to both medium and high-pressure boiler systems.

- Medium-pressure boiler pipes are used in boilers operating at intermediate pressure levels, while high-pressure boiler pipes are designed for boilers with elevated pressure requirements.

Seamless Manufacturing Process

- Seamless steel pipes are favored for boiler applications due to their seamless manufacturing process.

- The absence of welds eliminates potential weak points and ensures consistent material properties, critical for reliable and efficient boiler operation.

Heat Exchanger Pipe and Tubing Services

- Seamless steel pipes serve as essential components in heat exchanger systems.

- They facilitate efficient heat transfer between different fluids, enhancing overall system performance and energy efficiency.

Tube Exchanger Bundle

- Seamless pipes are integral to creating tube exchanger bundles, which are assemblies of interconnected tubes used for heat transfer in various industrial processes.

- These bundles find applications in a wide range of industries, including power generation and chemical processing.

Economizers

- Economizers are heat exchangers that recover heat from the flue gas and transfer it to the incoming feedwater.

- Seamless steel pipes are used in economizers to facilitate this heat exchange process, increasing boiler efficiency and reducing fuel consumption.

Superheaters

- Superheaters raise the temperature of steam beyond its saturation point, enhancing its energy content for specific applications.

- Seamless pipes play a vital role in superheater assemblies, contributing to the generation of high-quality, superheated steam.

Economizers

- Economizers are heat exchangers that recover heat from the flue gas and transfer it to the incoming feedwater.

- Seamless steel pipes are used in economizers to facilitate this heat exchange process, increasing boiler efficiency and reducing fuel consumption.

In summary, seamless steel pipes for boilers play a multifaceted role in various industrial applications. Their usage spans from forming integral components of high-pressure boilers to facilitating efficient heat exchange in heat exchangers and tube exchanger bundles. Whether in economizers, superheaters, or serving the petrochemical sector, these pipes ensure reliable heat transfer, enhanced energy efficiency, and optimal performance in critical industrial processes.

FAQ

According to different operating temperatures, medium pressure boiler tubes and high pressure boiler tubes shall be used. They are usually categorized as follows:

a. General boiler tubes are operated at temperatures below 450°C. Medium pressure boiler tubes are mainly used in hot rolling or cold drawing process.

b. High-pressure boiler tubes are commonly used under high temperature and high pressure conditions. Under the action of high-temperature flue gas and steam, the pipes are subject to oxidation and corrosion. High-pressure boiler tubes are required to have high endurance strength, high oxidation corrosion resistance and good organizational stability.

Seamless steel pipes for boilers are made from a solid round steel ‘billet’ which is heated and pushed or pulled over a form until the steel is shaped into a hollow pipe. The hollow pipe is then extruded through a die and mandrel combination to reduce the outside diameter and to expand the inside diameter. These pipes are manufactured from steel billets which are heated and drilled to generate the tubular section.

Seamless steel pipes are ideal for boiler applications due to their inherent strengths and attributes, making them a preferred choice for reliable and efficient boiler systems. Sourced from reputable stainless steel pipe suppliers, these pipes offer distinct advantages:

- Uniform Strength: Seamless steel pipes lack welded seams, ensuring uniform strength throughout the pipe’s length. This property is crucial for withstanding the high pressures and temperatures typical of boiler environments.

- Enhanced Safety: The absence of welds reduces the risk of potential weak points, minimizing the likelihood of leaks or failures, which is essential for maintaining a safe boiler operation.

- Durability: Seamless steel pipes are manufactured from high-quality materials, such as carbon steel, alloy steel, or stainless heat-resistant steel, ensuring long-term durability and resistance to corrosion and stress.

- Efficient Heat Transfer: The seamless construction facilitates efficient heat transfer within the boiler, promoting rapid and consistent heating of water or fluids. This translates to improved energy efficiency and faster steam generation.

- Reliable Performance: Seamless steel pipes offer consistent mechanical properties and dimensional accuracy, contributing to reliable and predictable performance in various boiler systems.

- Versatility: These pipes can be customized to suit specific boiler designs and requirements, ensuring seamless integration and optimal functionality within diverse boiler setups.

- Reduced Maintenance: Seamless steel pipes, with their robust construction and corrosion resistance, require minimal maintenance, resulting in reduced downtime and maintenance costs.

Industry Standards: Sourced from reputable stainless steel pipe suppliers, these pipes often adhere to industry standards and certifications, ensuring high-quality materials and manufacturing processes.

Yes, seamless steel pipes are highly suitable for both industrial and residential boiler systems. Sourced from reputable stainless steel pipe suppliers, these pipes offer versatile and reliable performance across a wide range of boiler applications.

In industrial settings, seamless steel pipes excel in high-pressure and high-temperature environments, making them a trusted choice for power plants, manufacturing facilities, and other industrial complexes. Their robust construction and resistance to stress and corrosion ensure the seamless operation of critical boiler systems in these demanding environments.

Similarly, in residential boiler systems, seamless steel pipes provide efficient heat transfer and reliable performance. Whether in heating systems for homes, apartments, or other residential structures, these pipes contribute to effective energy transfer, ensuring comfortable living spaces during colder months.

Regardless of the scale or complexity of the boiler system, seamless steel pipes, sourced from reputable stainless steel pipe suppliers, offer a dependable solution for ensuring optimal heat exchange, energy efficiency, and safe operation in both industrial and residential contexts.

Seamless steel pipes, sourced from reputable stainless steel pipe suppliers, play a vital role in enhancing boiler efficiency through several key mechanisms:

- Efficient Heat Transfer: The seamless design of these pipes allows for smooth fluid flow, reducing friction and enhancing heat transfer efficiency. This results in quicker and more effective heating of water or fluids within the boiler.

- Consistent Performance: Seamless steel pipes offer uniform mechanical properties and dimensional accuracy. This consistency ensures predictable fluid flow patterns and optimal heat exchange, contributing to stable and reliable boiler performance.

- Reduced Energy Loss: The seamless construction minimizes the potential for leaks or weak points along the pipe’s length. This, in turn, prevents energy loss due to escaping steam or water, enhancing overall energy efficiency.

- Fast Steam Generation: Seamless steel pipes facilitate rapid and efficient steam generation. Their smooth interior surfaces and consistent material properties enable the transfer of heat from the combustion process to the water, resulting in faster steam production.

- Minimized Downtime: Seamless steel pipes, with their durability and resistance to corrosion, require less maintenance and replacement. This reduces downtime associated with maintenance activities, ensuring continuous and efficient boiler operation.

- Optimal Combustion: Seamless pipes contribute to maintaining optimal combustion conditions within the boiler. By efficiently transferring heat, they support consistent temperature levels, ensuring efficient fuel utilization and minimizing energy wastage.

- Long-Term Reliability: The superior strength and stress resistance of seamless steel pipes ensure their longevity in demanding boiler environments. Their resistance to corrosion and wear further prolongs the life of the boiler system, leading to sustained efficiency over time.

In summary, seamless steel pipes sourced from reputable stainless steel pipe suppliers optimize heat transfer, minimize energy loss, and promote consistent performance within boiler systems. These pipes are integral components that contribute to improved boiler efficiency, reduced energy consumption, and enhanced overall operational effectiveness.

Yes, seamless stainless steel pipes sourced from reputable stainless steel pipe suppliers are engineered to withstand the extreme temperatures and high pressures prevalent in boiler environments. Their robust construction and high-quality materials, such as carbon steel, alloy steel, and stainless heat-resistant steel, make them exceptionally suited for these demanding conditions.

Seamless steel pipes possess inherent strength and stress resistance, allowing them to maintain their structural integrity even under elevated temperatures and pressures. Their seamless design eliminates the weak points associated with welded seams, further enhancing their ability to handle intense boiler operating conditions.

Yes, there are specific maintenance considerations for seamless steel pipes in boilers, and reputable stainless steel pipe suppliers can offer guidance on best practices:

- Regular Inspections: Schedule routine inspections to check for signs of corrosion, wear, or damage on the seamless steel pipes. Early detection helps prevent potential issues and ensures continued boiler performance.

- Cleaning: Periodically clean the pipes to remove scale, debris, or buildup that could hinder heat transfer and efficiency. Proper cleaning methods recommended by stainless steel pipe suppliers should be followed.

- Water Treatment: Implement effective water treatment practices to minimize the risk of corrosion or scaling within the pipes. Proper water chemistry helps maintain the integrity of the pipes and prolongs their service life.

- Corrosion Protection: Depending on the operating environment, consider applying corrosion inhibitors or protective coatings to the pipes. These measures can enhance the pipes’ resistance to corrosive agents.

- Temperature Monitoring: Regularly monitor the operating temperatures of the boiler to ensure they remain within the safe range for the seamless steel pipes. Excessive temperatures can accelerate wear and decrease the pipes’ longevity.

- Pressure Checks: Maintain proper pressure levels within the boiler system to prevent overloading the seamless steel pipes. Periodic pressure checks contribute to the pipes’ long-term performance.

- Documentation: Keep accurate records of maintenance activities, inspections, and any repairs performed on the seamless steel pipes. This documentation helps track the pipes’ condition and informs future maintenance decisions.

By adhering to these maintenance practices and seeking guidance from reputable stainless steel pipe suppliers, you can ensure the optimal performance, durability, and longevity of seamless steel pipes in boiler systems.

Seamless stainless steel pipes, sourced from reputable stainless steel pipe suppliers, offer distinct advantages over welded pipes in boiler applications:

- Strength and Integrity: Seamless steel pipes have uniform strength along their length due to the absence of welded seams. This enhances their structural integrity, critical for withstanding high pressures and temperature differentials in boilers.

- Corrosion Resistance: Seamless pipes exhibit superior resistance to corrosion, thanks to their continuous and smooth interior surfaces. This property minimizes the risk of corrosion-related failures, which can be more prevalent in welded pipes.

- Efficient Heat Transfer: The seamless construction of pipes facilitates efficient heat transfer, vital for effective boiler performance. In contrast, welded seams in pipes can disrupt fluid flow and heat exchange, potentially reducing efficiency.

- Reduced Weak Points: Welded pipes have welded seams that can be susceptible to corrosion and stress concentration points. Seamless pipes eliminate these weak points, enhancing reliability and minimizing the potential for failures.

- Higher Pressure Applications: Seamless pipes are better suited for high-pressure boiler systems, as they can handle the elevated stress levels without compromising their integrity.

- Aesthetics and Cleanliness: Seamless pipes provide a smoother and more aesthetically pleasing appearance, which is advantageous in visible sections of the boiler system. Additionally, the lack of seams reduces the accumulation of debris and bacteria.

- Uniform Composition: Seamless pipes maintain consistent material composition throughout, ensuring predictable mechanical properties. Welded pipes might have variations in composition due to the welding process.

- Reduced Maintenance: The durability and corrosion resistance of seamless pipes contribute to reduced maintenance requirements, minimizing downtime and associated costs.

While both types of pipes have their place, seamless steel pipes, backed by reputable stainless steel pipe suppliers, are often preferred in critical boiler applications due to their reliability, efficiency, and longevity.

Absolutely, seamless stainless steel pipes sourced from reputable stainless steel pipe suppliers can indeed be customized to meet specific boiler design requirements. This adaptability is a key advantage in ensuring seamless integration and optimal performance within various boiler systems.

Huaxiao stainless steel pipe suppliers with expertise in customization can tailor seamless pipes to specific dimensions, materials, and performance characteristics. This includes adjusting pipe diameter, thickness, and length to align with the unique specifications of different boiler designs.

Customization also extends to the choice of materials. Depending on the boiler’s operating conditions, stainless steel pipe suppliers can recommend the most suitable material, whether it’s carbon steel, alloy steel, or stainless heat-resistant steel, ensuring compatibility with the boiler’s requirements.

Furthermore, custom features such as fittings, flanges, and connections can be incorporated into the seamless steel pipes to facilitate seamless installation and integration into the boiler system.

The quality of seamless stainless steel pipes for boilers is assured through adherence to recognized certifications and standards, often overseen by reputable stainless steel pipe suppliers. Some of these important certifications and standards include:

ASTM (American Society for Testing and Materials): ASTM standards provide guidelines for materials, manufacturing, and testing processes to ensure consistent quality and performance of seamless steel pipes.

ASME (American Society of Mechanical Engineers): ASME codes establish criteria for the design, construction, and operation of boilers and pressure vessels. Compliance ensures the pipes meet safety and quality requirements.

API (American Petroleum Institute): API standards are relevant for seamless steel pipes used in the petrochemical industry, ensuring their suitability for critical applications.

EN (European Standards): EN standards provide specifications for seamless steel pipes used in various industrial applications, including boilers. Compliance signifies adherence to quality and performance benchmarks.

ISO (International Organization for Standardization): ISO certifications validate that the manufacturing and quality management processes of stainless steel pipe suppliers meet international standards for consistency and reliability.

PED (Pressure Equipment Directive): For boilers used within the European Union, PED certification ensures compliance with safety and quality requirements for pressure equipment.

DIN (Deutsches Institut für Normung): DIN standards provide specifications for materials and manufacturing processes, ensuring seamless steel pipes meet stringent quality criteria.

IBR (Indian Boiler Regulations): Relevant for boilers in India, IBR certification ensures that materials, manufacturing, and design meet safety and quality standards.

Certifications from Reputable Organizations: Certifications from classification societies like ABS (American Bureau of Shipping), BV (Bureau Veritas), DNV (Det Norske Veritas), or other reputable organizations validate the pipes’ quality and suitability for maritime and industrial applications.

Adhering to these certifications and standards provides assurance that seamless steel pipes for boilers meet strict quality, safety, and performance benchmarks. Reputable stainless steel pipe suppliers prioritize compliance with these certifications to deliver reliable and high-quality products for boiler applications.

FAQ

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China