Seamless 321H Stainless Steel Pipe Supplier

- Size Range: From 4mm4mm to 800mm800mm

- Wall Thickness Range: From 1mm to 150mm (SCH10-XXS)

- Length Options: 4000mm, 5800mm, 6000mm, 12000mm, or as required.

- Finish: 2B, BA,4K,8K, NO.1,2D,3#, HL

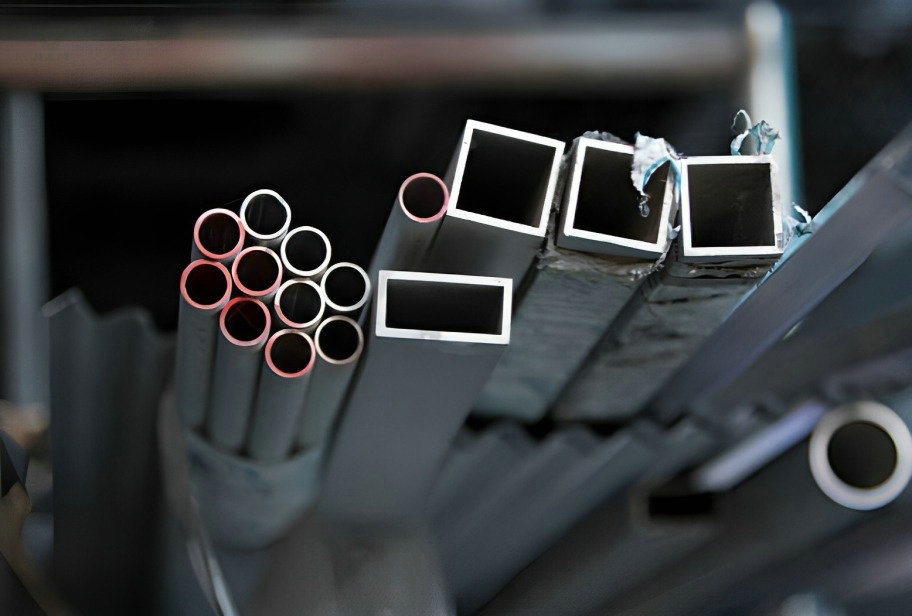

- Type: Round, square, rectangular, hexagonal, flat, angle

- Technique: Cold rolled, hot rolled

Product Description Of Seamless 321H Stainless Steel Pipe

Introducing Seamless 321H Stainless Steel Pipe, a product of excellence from Huaxiao stainless steel pipe suppliers. This exceptional pipe, made from a stabilized austenitic stainless steel alloy enriched with titanium, is your ultimate solution for demanding environments. With superior high-temperature strength, increased carbon content for extreme heat resistance, and outstanding corrosion protection, it stands as the top choice for heavy-duty welding components, dynamic settings, and critical applications. Crafted with precision and intergranular protection, this pipe ensures longevity and reliability, making it ideal for aerospace, petrochemical, industrial, and marine applications. Elevate your performance in extreme conditions with Seamless 321H Stainless Steel Pipe – where quality meets excellence.

specification Of Seamless 321H Stainless Steel Pipe

Chemical Components Of Seamless 321H Stainless Steel Pipe

| Element | 321H |

|---|---|

| Chromium | 17.00 min. – 19.00 max. |

| Nickel | 9.00 min. – 12.00 max. |

| Carbon | 0.04 min. – 0.10 max. |

| Manganese | 2.00 |

| Phosphorus | 0.045 |

| Sulfur | 0.03 |

| Silicon | 0.75 |

| Titanium | ≥ 4x (C + N), ≤ 0.70 |

| Nitrogen | 0.10 |

| Iron | Balance |

physical property Of Seamless 321H Stainless Steel Pipe

| Property | Value |

|---|---|

| Density, g/cm³ | 7.9 |

| Melting Point, °C (°F) | 1400-1425 (2550-2600) |

| Specific Heat Capacity, J/kg·K (Btu/lb ·°F) | 500 (0.12) at 20 °C |

| Electrical Resistivity, μΩ·m | 0.72 at 20 °C |

| Magnetic Permeability | 1.02 (Approximate) |

| Elastic Modulus, GPa (10⁶ psi) | 193 (28) |

| Thermal Conductivity, W/m·K (Btu/ft · h ·°F) | 16.1 (9.3) at 100 °C (212 °F), 22.2 (12.8) at 500 °C (932 °F) |

| Coefficient of Thermal Expansion, 10⁻⁶/K (μin./in. ·°F) | 16.6 (9.2) at 0-100 °C (32-212 °F), 17.2 (9.6) at 0-315 °C (32-600 °F), 18.6 (10.3) at 0-538 °C (32-1000 °F) |

mechanical property Of Seamless 321H Stainless Steel Pipe

| Property | Value |

|---|---|

| Tensile Strength | Above 515 MPa |

| Yield Strength | Above 205 MPa |

| Elongation | 40% (min.) |

| Hardness | 217 Brinell (max.) |

characteristics Of Seamless 321H Stainless Steel Pipe

The Seamless 321H Stainless Steel Pipe is a true “High-Temperature Powerhouse.” This remarkable characteristic stems from its unique composition, which includes a higher carbon content and the addition of niobium. These elements enhance its high-temperature strength, enabling it to excel in extreme heat conditions ranging from 427°C to 816°C (800°F to 1500°F). This stainless steel pipe is a reliable choice for applications demanding exceptional heat resistance.

In addition to its high-temperature prowess, the 321H grade offers impressive corrosion resistance, even in challenging environments like oxidizing and acidic solutions. This resistance extends to pitting and crevice corrosion, making it a dependable option for various industries.

The 321H Stainless Steel Pipe is well-suited for heavy-duty welding components and dynamic settings, showcasing its remarkable strength even in low-temperature environments. It outperforms 321 stainless steel and exhibits superior resistance to creep and fracture compared to 304 stainless steel. However, it’s important to note that while it shares welding and forming characteristics with 321 stainless steel, it cannot be hardened through heat treatment.

In summary, the “High-Temperature Powerhouse” characteristic of Seamless 321H Stainless Steel Pipe makes it a top choice for applications that demand exceptional heat resistance, corrosion protection, and robust mechanical properties, ensuring longevity and performance excellence.

The standout feature of Seamless 321H Stainless Steel Pipe is its “Enhanced Carbon Content.” This unique characteristic sets it apart from its counterpart, 321 stainless steel. The higher carbon content in 321H enhances its high-temperature strength, making it exceptionally well-suited for applications in extreme heat conditions.

This increased carbon content in the alloy enhances several crucial properties:

High-Temperature Strength: The higher carbon content elevates the high-temperature strength of 321H stainless steel, enabling it to perform remarkably well in conditions ranging from 427°C to 816°C (800°F to 1500°F).

Resistance to Carbide Precipitation: The enhanced carbon content helps in resisting carbide precipitation within the material, reducing the risk of corrosion and structural degradation at high temperatures.

Creep and Fracture Resistance: Compared to 321 stainless steel, Seamless 321H Stainless Steel Pipe offers superior resistance to creep and fracture, making it an ideal choice for applications subjected to prolonged high-temperature stress.

Strength and Durability: The increased carbon content contributes to the overall strength and durability of the stainless steel pipe, ensuring its reliability in demanding conditions.

In summary, the “Enhanced Carbon Content” feature of Seamless 321H Stainless Steel Pipe makes it a preferred choice when exceptional high-temperature performance and strength are required, making it a valuable asset in industries that operate in extreme heat environments.

The “Outstanding Corrosion Resistance” of Seamless 321H Stainless Steel Pipe is a remarkable attribute that sets it apart from other materials. This characteristic makes it particularly suitable for applications in challenging environments, even when exposed to corrosive substances and acidic solutions.

Here’s why the corrosion resistance of Seamless 321H Stainless Steel Pipe stands out:

High Alloy Composition: The alloy composition of 321H stainless steel includes elements like titanium, carbon, and nickel. These components significantly contribute to its exceptional corrosion resistance.

Resistance to Carbide Precipitation: The enhanced carbon content in 321H stainless steel helps prevent carbide precipitation along the grain boundaries, reducing the risk of intergranular corrosion.

Acidic and Oxidizing Environments: This stainless steel pipe maintains its integrity and resists corrosion even in the presence of acidic solutions and oxidizing environments.

Pitting and Crevice Corrosion Resistance: Seamless 321H Stainless Steel Pipe exhibits excellent resistance to both pitting and crevice corrosion, which are common forms of localized corrosion in challenging industrial settings.

Wide Application Range: Due to its outstanding corrosion resistance, this stainless steel pipe is widely used in various industries, including chemical processing, petrochemical, and marine applications.

In summary, the “Outstanding Corrosion Resistance” of Seamless 321H Stainless Steel Pipe makes it a reliable choice for applications where resistance to corrosion is paramount. It ensures the durability and longevity of critical components even when exposed to harsh and corrosive environments.

The characteristic of “Stability and Intergranular Protection” in Seamless 321H Stainless Steel Pipe is a key feature that contributes to its excellent performance in corrosive environments. Here’s a detailed explanation:

Stability: Seamless 321H Stainless Steel Pipe is known for its stability, especially at elevated temperatures. This stability is attributed to its alloy composition, which includes elements like titanium and enhanced carbon content. Titanium forms stable carbides with carbon, preventing the formation of harmful chromium carbides at grain boundaries. This stability is crucial in applications where the material is exposed to high temperatures.

Intergranular Protection: One of the primary challenges in stainless steel’s corrosion resistance is intergranular corrosion, where corrosive agents attack the grain boundaries. Seamless 321H Stainless Steel Pipe addresses this issue effectively. Its enhanced carbon content helps to provide intergranular protection by reducing the risk of chromium carbide precipitation along the grain boundaries. This means that the material maintains its corrosion resistance and structural integrity even in harsh environments.

Applications: The stability and intergranular protection offered by Seamless 321H Stainless Steel Pipe make it ideal for applications in industries like chemical processing, petrochemical, and power generation. It can withstand the corrosive effects of chemicals and high-temperature conditions, ensuring the longevity and reliability of critical components.

In summary, the “Stability and Intergranular Protection” feature of Seamless 321H Stainless Steel Pipe is a testament to its ability to resist intergranular corrosion and maintain structural integrity, especially in challenging environments where high temperatures and corrosive substances are present. This makes it a valuable choice for various industrial applications.

application Of Seamless 321H Stainless Steel Pipe

Chemical and Pharmaceutical Equipment

Seamless 321H Stainless Steel Pipe finds extensive use in the chemical and pharmaceutical industries due to its remarkable corrosion resistance and high-temperature endurance. It serves as a primary material for manufacturing reaction vessels, storage tanks, and piping systems, ensuring the integrity of critical processes.

Petrochemical Refineries

In petrochemical refineries, where harsh chemical environments and high temperatures are prevalent, Seamless 321H Stainless Steel Pipe is indispensable. It is employed for constructing various components like heat exchangers, reactors, and pipelines, offering reliability and durability in demanding conditions.

Seawater Equipment

The exceptional corrosion resistance of Seamless 321H Stainless Steel Pipe makes it an ideal choice for marine applications. It is utilized in the fabrication of components such as seawater desalination equipment, offshore platforms, and shipbuilding, where exposure to corrosive seawater is constant, ensuring longevity and performance.

FAQ

Seamless 321H Stainless Steel Pipe distinguishes itself from other stainless steel pipes through its unique alloy composition and enhanced characteristics. A few key distinctions when compared to different stainless steel grades include:

Compared to 304 Stainless Steel: Seamless 321H Stainless Steel Pipe has higher carbon content and is more suitable for high-temperature applications. It offers improved resistance to intergranular corrosion and is preferable for applications above 1000°F (538°C).

Versus 316 Stainless Steel: While 316 stainless steel is highly corrosion-resistant, Seamless 321H Stainless Steel Pipe excels in elevated temperature environments. Its titanium stabilization and higher carbon content enhance its performance in high-temperature applications, making it a preferred choice.

Compared to 310 Stainless Steel: Seamless 321H Stainless Steel Pipe offers better intergranular corrosion resistance and exceptional high-temperature strength compared to 310 stainless steel. The enhanced carbon content in 321H allows for improved performance in specific conditions.

Versus 309 Stainless Steel: When compared to 309 stainless steel, Seamless 321H Stainless Steel Pipe is especially advantageous in applications involving moist or corrosive environments. The titanium alloying element enhances its corrosion resistance.

In summary, Seamless 321H Stainless Steel Pipe stands out due to its ability to withstand high temperatures, corrosion resistance, and specific advantages over other stainless steel grades like 304, 316, 310, and 309. These distinctions make it a preferred choice for industries and applications where these properties are essential. When seeking stainless steel pipes, these factors should guide your selection.

The carbon content in Seamless 321H Stainless Steel Pipe significantly influences its performance. This grade contains a higher carbon content compared to standard 321 stainless steel, which has a lower carbon concentration. The impact of this enhanced carbon content on performance can be summarized as follows:

High-Temperature Strength: The higher carbon content improves the high-temperature strength of Seamless 321H Stainless Steel Pipe. It enables the material to maintain its mechanical properties and structural integrity at elevated temperatures exceeding 1000°F (538°C). This makes it suitable for applications involving extreme heat, such as furnace components and exhaust systems.

Enhanced Creep Resistance: The increased carbon content contributes to enhanced creep resistance. Creep refers to the gradual deformation of a material under constant load at high temperatures. With its higher carbon content, Seamless 321H Stainless Steel Pipe can withstand such conditions better than standard 321 stainless steel.

Intergranular Corrosion Resistance: Despite the higher carbon content, this alloy still maintains good resistance to intergranular corrosion, especially when stabilized with titanium. It forms titanium carbides, which helps prevent chromium depletion along grain boundaries, reducing susceptibility to intergranular corrosion in high-temperature, corrosive environments.

Stainless steel pipe suppliers often recommend Seamless 321H Stainless Steel Pipe for applications where these high-temperature and mechanical properties are crucial, making it a reliable choice for industries like petrochemical, chemical processing, and power generation.

Seamless 321H Stainless Steel Pipe operates effectively within a temperature range typically spanning from 427°C to 816°C (800°F to 1500°F). The specific temperature range may vary slightly based on the application and environmental factors, but these pipes are well-suited for high-temperature conditions, making them ideal for various industrial processes and equipment where elevated temperatures are encountered. Huaxiao stainless steel pipe suppliers can provide more precise information regarding the temperature ranges for specific applications.

Seamless 321H Stainless Steel Pipe offers several advantages over 321 stainless steel:

Higher Temperature Range: Seamless 321H can operate effectively in a broader temperature range, spanning from 427°C to 816°C (800°F to 1500°F). This expanded range makes it suitable for high-temperature applications where 321 stainless steel may not perform optimally.

Enhanced Carbon Content: The increased carbon content in 321H improves its high-temperature strength, making it better suited for applications exposed to extreme heat.

Intergranular Corrosion Resistance: The addition of niobium (or columbium) in 321H provides intergranular corrosion resistance, which is especially valuable in environments prone to this type of corrosion.

Outstanding Corrosion Resistance: Like 321 stainless steel, 321H also exhibits excellent corrosion resistance, making it suitable for use in chemically aggressive environments.

Stability in Dynamic Environments: Its corrosion resistance and high-temperature strength make it an ideal choice for equipment in chemical, petrochemical, pharmaceutical, and other dynamic industries where conditions may vary.

Seamless 321H Stainless Steel Pipe is preferred when higher temperature capabilities and intergranular corrosion resistance are required, offering a performance edge over the standard 321 stainless steel in specific applications. Stainless steel pipe suppliers often recommend 321H for these demanding situations.

Yes, Seamless 321H Stainless Steel Pipe adheres to various industry standards and certifications to ensure its quality and performance. Some of the notable standards and certifications include:

- ASTM Standards: The American Society for Testing and Materials (ASTM) has established standards such as ASTM A312 and ASTM A213 that outline the specifications for seamless and welded austenitic stainless steel pipes, including those made of 321H stainless steel.

- ASME Boiler and Pressure Vessel Code: When the pipe is intended for high-pressure applications, adherence to ASME standards, particularly ASME B31.3 (Process Piping) and ASME B31.1 (Power Piping), is essential for safety and compliance.

- NACE MR0175/ISO 15156: This standard specifies the requirements for materials used in oil and gas production, including the resistance of materials to sulfide stress cracking in sour environments. Seamless 321H Stainless Steel Pipe may need to meet these criteria for applications in the oil and gas industry.

- EN Standards: European standards, such as EN 10216-5, provide specifications for seamless stainless steel tubes, including 321H stainless steel, particularly in European markets.

- PED Certification: The Pressure Equipment Directive (PED) is a European Union directive that ensures the safety of pressure equipment, including pipes. Manufacturers may obtain PED certification to demonstrate compliance with European safety standards.

- ISO Certification: Manufacturers often acquire ISO 9001 certification, signifying adherence to quality management standards. ISO 14001 certification may also demonstrate commitment to environmental management.

When sourcing Seamless 321H Stainless Steel Pipe, it’s essential to verify that the product complies with the relevant standards and certifications required for your specific application, ensuring safety and performance.

When working with Seamless 321H Stainless Steel Pipe, there are several important welding considerations to keep in mind. These considerations are essential for maintaining the integrity and performance of the pipe in various applications. Here are some typical welding considerations:

Preheat and Post-Weld Heat Treatment: Preheating the pipe before welding and applying post-weld heat treatment can help reduce the risk of sensitization and intergranular corrosion in 321H stainless steel. This is especially important in high-temperature applications. Stainless steel pipe suppliers may provide guidance on the specific preheat and heat treatment requirements.

Use of Low Carbon or Stable Grades: Choosing low carbon or stabilized grades of filler materials, such as 347, can help prevent sensitization and carbide precipitation during welding. These filler materials can maintain the corrosion resistance of the pipe.

Welding Techniques: Employing proper welding techniques, such as using a low heat input, controlling the interpass temperature, and ensuring a smooth, even bead, can minimize the risk of distortion and maintain the pipe’s structural integrity.

Avoidance of Contaminants: Preventing contamination of the weld area is crucial. Cleanliness is essential to avoid introducing foreign materials that may compromise the corrosion resistance of the pipe.

Post-Weld Passivation: After welding, it is often necessary to passivate the weld area to restore the pipe’s corrosion resistance. This involves removing any impurities and forming a protective oxide layer on the surface.

Proper Welding Consumables: Selecting the appropriate welding consumables, including electrodes and filler wires, that match the composition of the 321H stainless steel pipe is crucial for achieving strong, corrosion-resistant welds.

Welding Qualification: Ensure that welders performing the work are qualified and experienced in welding stainless steel, especially 321H. Compliance with relevant welding codes and standards is essential.

Quality Control and Inspection: Implement rigorous quality control and inspection procedures to detect any welding defects or issues that may affect the pipe’s performance.

Stainless steel pipe suppliers may offer guidance on the specific welding procedures, filler materials, and post-weld treatments required for Seamless 321H Stainless Steel Pipe, helping to ensure the highest quality and performance in various applications.

No, Seamless 321H Stainless Steel Pipe is typically non-magnetic in its annealed state. This characteristic is due to its austenitic stainless steel structure, which is non-magnetic. However, it’s important to note that if the material undergoes cold working or significant deformation during fabrication, it may become partially magnetic. Nevertheless, in its annealed condition, it should exhibit non-magnetic properties, making it suitable for various applications in industries like chemical, petrochemical, and pharmaceutical, where magnetic materials could interfere with processes or equipment. For specific information regarding the magnetic properties of Seamless 321H Stainless Steel Pipe, you can consult stainless steel pipe suppliers or conduct magnetic testing.

other products

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China