Seamless 330 Stainless Steel Pipe Supplier

- Size Range: From 4mm4mm to 800mm800mm

- Wall Thickness Range: From 1mm to 150mm (SCH10-XXS)

- Length Options: 4000mm, 5800mm, 6000mm, 12000mm, or as required.

- Finish: 2B, BA,4K,8K, NO.1,2D,3#, HL

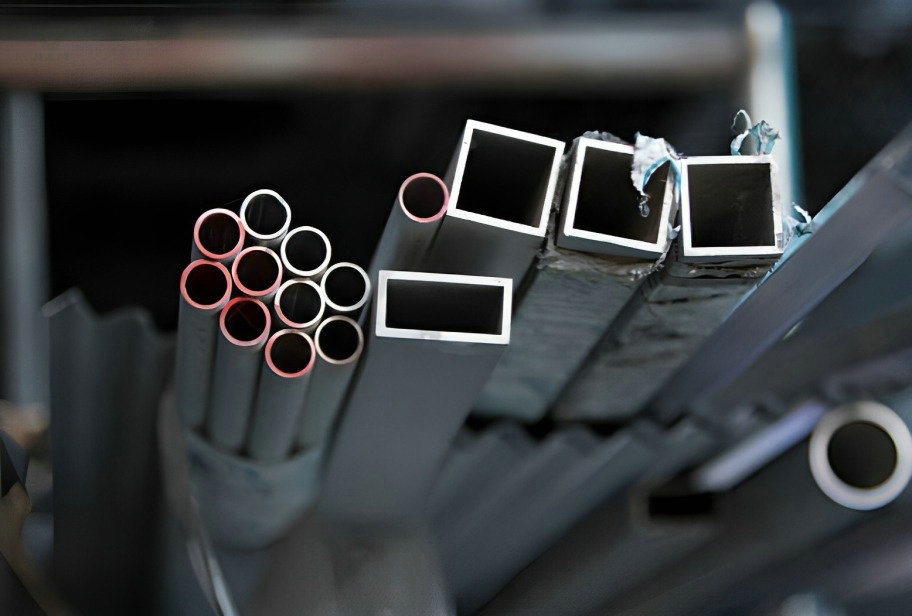

- Type: Round, square, rectangular, hexagonal, flat, angle

- Technique: Cold rolled, hot rolled

Product Description Of Seamless 330 Stainless Steel Pipe

Seamless 330 stainless steel pipe, an austenitic alloy, is characterized by remarkable corrosion and oxidation resistance, withstanding high temperatures up to 2200°F. Its elevated nickel content provides excellent stress-corrosion cracking resistance, while offering ductility and high-strength performance. The production process involves heating, perforation, annealing, acid pickling, oil coating (copper plating), multiple cold drawing passes, heat treatment, straightening, hydrostatic testing, marking, and warehousing. These exceptional qualities position Seamless 330 Stainless Steel Pipe as a favored choice across various industrial applications.

specification Of Seamless 330 Stainless Steel Pipe

Chemical Components Of Seamless 330 Stainless Steel Pipe

| Element | Content |

|---|---|

| Carbon | ≤0.08 |

| Manganese | ≤2.00 |

| Silicon | 0.75~1.5 |

| Chromium | 17.0~20.0 |

| Nickel | 34.0~37.0 |

| Phosphorus | ≤0.04 |

| Sulfur | ≤0.03 |

physical property Of Seamless 330 Stainless Steel Pipe

| Property | Value |

|---|---|

| Density | 0.285 lb/in³ |

| Melting Point | 2,525°F |

| Specific Heat | 0.11 BTU/lb-°F |

| Thermal Conductivity | 88.5 BTU-in./ft²-hr-°F |

| Electrical Resistivity | 28.4 Microhm-in |

mechanical property Of Seamless 330 Stainless Steel Pipe

| Property | Value |

|---|---|

| Yield Strength | 30 ksi |

| Tensile Strength | 75 ksi |

| Elongation | 40% |

| Reduction in Area | 50% |

characteristics Of Seamless 330 Stainless Steel Pipe

The Corrosion Resistance of Seamless 330 Stainless Steel Pipe is a standout feature. It exhibits exceptional resistance to corrosion in various challenging environments. This resistance is primarily attributed to its high chromium and nickel content, along with the reinforcing effect of silicon. The result is a stainless steel pipe that can effectively withstand corrosive agents, including acids, alkalis, and chloride-containing substances, making it ideal for applications where corrosion resistance is a critical requirement, such as in chemical processing, petrochemical industries, and high-temperature environments.

Seamless 330 Stainless Steel Pipe also boasts remarkable Oxidation Resistance. Thanks to its elevated nickel and chromium content, as well as the reinforcing influence of silicon, this stainless steel pipe demonstrates outstanding resistance to oxidation. This means it can endure high-temperature conditions, even up to 2200°F, without succumbing to oxidation or degradation. This quality is invaluable in applications where exposure to extreme heat is commonplace, such as in industrial furnaces, combustion chambers, and high-temperature processing equipment.

Seamless 330 Stainless Steel Pipe exhibits exceptional Heat Resistance. With the presence of substantial nickel, chromium, and the strengthening effect of silicon, this stainless steel pipe can withstand high temperatures, even up to 2200°F (1204°C). Its ability to maintain its structural integrity and performance under extreme heat conditions makes it a preferred choice for applications in industries like aerospace, power generation, and industrial heating, where exposure to elevated temperatures is common. This attribute ensures the longevity and reliability of the pipe in demanding, high-temperature environments.

Seamless 330 Stainless Steel Pipe boasts outstanding Stress Corrosion Cracking (SCC) Resistance, thanks to its exceptionally high nickel content ranging from 34% to 37%. This attribute makes it highly resilient in chloride-rich environments, where many other materials might succumb to SCC. The elevated nickel levels provide a robust defense against the corrosive effects of chlorides, ensuring the pipe’s structural integrity and reliability in critical applications. This resistance to stress corrosion cracking is particularly advantageous in industries such as chemical processing, where exposure to corrosive substances is prevalent.

Ductility refers to the exceptional ability of Seamless 330 Stainless Steel Pipe to deform or stretch without breaking under tensile stress. This property is a key feature, demonstrating the material’s capacity to undergo plastic deformation and maintain its integrity even when subjected to significant mechanical loads. The high ductility of this stainless steel alloy ensures that it can withstand bending, forming, and shaping processes during manufacturing without experiencing brittleness or failure. It is a valuable characteristic in various industrial applications where the material needs to be molded into specific shapes and configurations while maintaining its structural integrity.

Strength is a significant characteristic of Seamless 330 Stainless Steel Pipe, demonstrating its ability to withstand mechanical forces and loads without deformation or failure. This stainless steel alloy boasts high tensile strength, with a yield strength of 30 ksi and a tensile strength of 75 ksi. These values indicate the maximum amount of stress the material can endure before permanent deformation or fracture occurs. The exceptional strength of Seamless 330 Stainless Steel Pipe makes it suitable for applications where structural integrity and resistance to mechanical forces are essential, such as in aerospace, automotive, and industrial equipment manufacturing.

application Of Seamless 330 Stainless Steel Pipe

Chemical and Petrochemical Processing

Seamless 330 Stainless Steel Pipe is instrumental in chemical and petrochemical processing due to its outstanding corrosion resistance and high-temperature tolerance. It plays a crucial role in various applications within these industries, such as the construction of reaction vessels, heat exchangers, and piping systems that transport corrosive chemicals and hot fluids. This stainless steel alloy effectively resists the corrosive effects of acids, alkalis, and aggressive chemicals, ensuring the integrity and longevity of critical equipment in chemical and petrochemical plants. Its exceptional performance in these environments contributes to the safe and efficient processing of chemicals and fuels.

Heat Treatment

Heat treatment is a crucial process in metallurgy, aimed at modifying the properties of materials, including stainless steel. For seamless 330 stainless steel pipes, heat treatment enhances their mechanical strength, ductility, and resistance to stress corrosion cracking. This involves heating the pipes to specific temperatures and then cooling them slowly to relieve internal stresses, improve toughness, and optimize their microstructure. It's a vital step that ensures these pipes can withstand high-temperature and high-stress applications in industries like chemical processing, petrochemicals, and power generation, making them dependable components in demanding environments.

Ore Processing

Ore processing is a critical application for seamless 330 stainless steel pipes due to their exceptional resistance to high temperatures and corrosion. These pipes play a pivotal role in the extraction and refinement of various ores, including iron, copper, and nickel. Their robustness and heat resistance make them ideal for conveying hot, aggressive liquids and gases involved in the ore processing steps. Whether in smelting, refining, or transporting ore-related materials, seamless 330 stainless steel pipes ensure durability and integrity, contributing to the efficiency and longevity of ore processing operations in industries such as mining and metallurgy.

Power Generation

In the realm of power generation, seamless 330 stainless steel pipes are indispensable components. These pipes exhibit exceptional heat resistance, making them vital in power plants, particularly in applications involving high-temperature environments like boilers and heat exchangers. They excel in conveying superheated steam, hot gases, and various corrosive fluids critical to power generation processes. Their resistance to corrosion and stress cracking ensures the longevity and safety of power generation systems, contributing significantly to the efficient production of electricity across a range of energy sources, from fossil fuels to renewables. In this sector, seamless 330 stainless steel pipes are instrumental in keeping the world powered.

FAQ

Seamless 330 stainless steel pipes are manufactured through a precise and controlled process to ensure their exceptional quality. The production process involves several key steps:

Raw Material Selection: The process begins with the careful selection of high-quality raw materials, including iron ore, chromium, silicon, nickel, and other alloying elements.

Melting: The selected raw materials are melted in an electric arc furnace to create a homogeneous molten metal.

Continuous Casting: The molten metal is then cast into cylindrical shapes using a continuous casting process. This results in the formation of billets or round bars.

Heating: The billets or round bars are heated to a suitable temperature to make them more malleable and ready for further processing.

Piercing: The heated billets are pierced to create a hollow shell, which will become the pipe’s outer shell.

Rotary Piercing and Extrusion: The hollow shell is further processed through rotary piercing and extrusion. This process elongates and reduces the wall thickness of the shell to the desired dimensions.

Heat Treatment: Heat treatment is performed to optimize the pipe’s mechanical properties. This involves heating the pipe to specific temperatures and then gradually cooling it. Heat treatment enhances the pipe’s strength and durability.

Cold Working: The pipe undergoes cold working processes such as cold drawing or cold rolling to achieve the final dimensions, including the outer diameter and wall thickness.

Finishing: The seamless 330 stainless steel pipe is finished through processes like pickling and passivation to remove any surface impurities and enhance corrosion resistance.

Quality Control: Stringent quality control measures are implemented throughout the manufacturing process to ensure the pipe meets industry standards and specifications.

Testing: The pipes are subjected to various tests, including dimensional checks, mechanical property tests, non-destructive testing (e.g., ultrasonic testing), and corrosion resistance tests.

Cutting and Inspection: The pipes are cut into specified lengths and thoroughly inspected for defects or irregularities.

Packaging and Shipping: Once the pipes pass all quality checks, they are carefully packaged and prepared for shipping to customers.

Seamless 330 stainless steel pipes are known for their reliability and consistent quality due to the precision involved in their manufacturing process. Stainless steel pipe suppliers play a crucial role in ensuring these high standards are met at every stage of production.

Yes, seamless 330 stainless steel pipes can be welded. However, it’s essential to use appropriate welding techniques and filler materials to maintain the pipe’s corrosion resistance and mechanical properties. Welding should be performed by skilled professionals who are experienced in working with stainless steel alloys. Stainless steel pipe suppliers can provide guidance on suitable welding methods and filler materials to ensure the integrity of the welded joints and maintain the pipe’s performance in various applications.

Seamless pipes offer several advantages over welded ones:

Corrosion Resistance: Seamless pipes have no welded seams, reducing the risk of corrosion and leaks in critical applications.

Strength: Seamless pipes are generally stronger and can withstand higher pressure, making them suitable for high-stress environments.

Uniformity: Seamless pipes have consistent wall thickness, ensuring uniform mechanical properties throughout the length.

Cleaner Interior: There are no weld seams inside seamless pipes, making them ideal for applications with strict cleanliness requirements, such as food or pharmaceutical industries.

Smooth Flow: Seamless pipes provide smoother fluid or gas flow due to their uninterrupted interior surface.

Reduced Maintenance: Fewer joints and welds mean lower maintenance and inspection requirements.

Stainless steel pipe suppliers can provide seamless pipes tailored to specific applications, ensuring optimal performance and reliability.

Ensuring the quality of seamless 330 stainless steel pipes involves several key steps:

Material Selection: High-quality raw materials with precise chemical compositions are essential.

Manufacturing Process: Employing advanced manufacturing techniques and stringent quality control during the pipe’s production process is crucial.

Testing and Inspection: Pipes undergo various tests, including visual inspection, dimensional checks, and non-destructive testing (NDT) methods like ultrasonic or radiographic testing.

Certifications: Reputable stainless steel pipe suppliers ensure their products meet industry standards and provide certifications to verify quality and compliance.

Traceability: Maintaining traceability of materials and processes throughout production helps identify any potential issues and ensures accountability.

Packaging and Delivery: Proper packaging prevents damage during transportation, ensuring the pipes arrive in pristine condition.

Customer Support: Reliable suppliers offer excellent customer support, addressing any concerns or issues promptly.

By adhering to these practices, stainless steel pipe suppliers can consistently deliver high-quality seamless pipes to meet their customers’ requirements.

Using seamless 330 stainless steel pipe offers several environmental benefits:

Recyclability: Stainless steel is highly recyclable, and using it in pipes means that the material can be reused, reducing the demand for new resources and minimizing waste.

Longevity: Stainless steel pipes have a long lifespan and require less frequent replacements, reducing the overall environmental impact associated with manufacturing and disposal.

Corrosion Resistance: Stainless steel’s corrosion resistance means it requires minimal maintenance and fewer chemicals for protection, leading to a reduced environmental footprint.

Energy Efficiency: Seamless pipes are manufactured with energy-efficient processes, and their properties, such as low thermal conductivity, can contribute to improved energy efficiency in various applications.

Reduced Emissions: Stainless steel’s durability and resistance to high temperatures can lead to reduced emissions in industries where it’s used, contributing to cleaner air and reduced environmental harm.

Water Conservation: In applications like water transport, stainless steel pipes minimize water leakage and loss, supporting water conservation efforts.

By choosing seamless 330 stainless steel pipes, industries can not only benefit from their exceptional properties but also contribute to a more sustainable and eco-friendly approach to infrastructure and construction.

You can source reliable seamless 330 stainless steel pipes from reputable stainless steel pipe suppliers. These suppliers typically specialize in providing high-quality stainless steel pipes and related products. It’s essential to conduct thorough research and choose a supplier with a proven track record for delivering top-notch stainless steel products, adhering to quality standards, and offering excellent customer service. You may find such suppliers through industry referrals, online directories, or by directly contacting stainless steel manufacturers and distributors. Additionally, ensure that the supplier meets your specific requirements in terms of product specifications, quantities, and delivery times.

other products

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China