Chromium Metal vs. Stainless Steel: What’s the Difference?

Chromium Metal vs. Stainless Steel: What’s the Difference? When it comes to choosing materials for industrial and commercial applications, understanding the differences between chromium metal and stainless steel is essential. Both materials have unique properties and benefits, but they are used for distinct purposes.

uses of chromium metal

Chromium metal is a versatile material used in various industrial and commercial applications due to its unique properties. Here are some primary uses:

- Electroplating

Chromium is widely used in electroplating to provide a decorative and protective coating on various metal products. The resulting chrome plating is highly reflective, resistant to tarnish, and provides a durable surface that withstands wear and corrosion.

- Alloy Production

Chromium is a crucial component in the production of stainless steel and other alloys. When added to steel, chromium enhances its hardness, tensile strength, and resistance to corrosion and oxidation. Stainless steel typically contains about 10.5% chromium, which forms a protective oxide layer on the surface, preventing rust and corrosion.

- Refractory Applications

Due to its high melting point and stability at elevated temperatures, chromium is used in the manufacturing of refractory materials. These materials are essential in high-temperature industrial processes such as the production of glass, cement, and metals.

- Pigments and Dyes

Chromium compounds, such as chromium oxide, are used as pigments in paints, inks, and dyes. These pigments provide vibrant and durable colors, commonly used in ceramics, plastics, and construction materials.

- Catalysts

Chromium is used as a catalyst in various chemical reactions, including the production of synthetic rubbers and plastics. Its catalytic properties enhance reaction efficiency and product yield.

Chemical Composition and Properties: Chromium Metal vs. Stainless Steel

Chromium Metal

Is chromium a transition metal? Chromium metal is a transition metal with the symbol Cr and atomic number 24. It is known for its high melting point, hardness, and resistance to corrosion. Pure chromium is steel-gray, lustrous, hard, and brittle. precision, ensuring your projects meet the highest standards of quality and craftsmanship. So, let’s embark on this journey into the realm of stainless steel cutting, where precision meets craftsmanship.

Key Properties:

- Density: 7.19 g/cm³

- Melting Point: 1907°C (3465°F)

- Boiling Point: 2671°C (4840°F)

- Hardness: 8.5 on the Mohs scale

Stainless Steel

Stainless steel is an alloy primarily made of iron, with a minimum of 10.5% chromium content by mass. Other elements such as nickel, molybdenum, and carbon are often added to enhance its properties. The chromium in stainless steel forms a passive layer of chromium oxide, which prevents surface corrosion and blocks corrosion from spreading into the metal’s internal structure.

Key Properties:

- Density: 7.8 g/cm³

- Melting Point: 1400-1450°C (2552-2642°F)

- Boiling Point: Not well-defined due to alloy composition

- Hardness: Varies with composition, typically around 5-6 on the Mohs scale

Industrial Applications: Chromium Metal vs. Stainless Steel

Chromium Metal

Chromium metal is widely used in electroplating, where it is deposited onto other metals to form a decorative and protective layer. It is also used in the production of stainless steel and other alloys, enhancing their hardness and resistance to corrosion.

Applications:

- Electroplating: Used to provide a shiny, corrosion-resistant coating on various products.

- Alloy Production: Added to steel and other alloys to improve hardness and corrosion resistance.

- Refractory Applications: Used in high-temperature industrial applications due to its high melting point.

Stainless Steel

Stainless steel’s versatility makes it an essential material in numerous industries, including construction, automotive, aerospace, and medical. Its resistance to rust and staining, combined with low maintenance, makes it an ideal material for many applications.

Applications:

- Construction: Used for structural components, cladding, and roofing.

- Automotive: Utilized in exhaust systems, trim, and structural components.

- Medical: Commonly used in surgical instruments, implants, and hospital equipment.

- Food Processing: Preferred for its hygiene and ease of cleaning in food handling and processing equipment.

Corrosion Resistance: Chromium Metal vs. Stainless Steel

Chromium Metal

Chromium’s excellent corrosion resistance is due to the formation of a thin oxide layer on its surface. This oxide layer acts as a protective barrier, preventing further oxidation and corrosion.

Resistance:

- Excellent: In most environments, especially in the presence of air or oxygen.

Stainless Steel

The corrosion resistance of stainless steel is primarily due to its chromium content. The chromium in stainless steel reacts with oxygen to form a stable layer of chromium oxide, which protects the underlying metal from corrosion.

Resistance:

- Excellent: In a wide range of environments, including acidic, alkaline, and marine conditions.

Mechanical Properties: Chromium Metal vs. Stainless Steel

Chromium Metal

Chromium is known for its high hardness and brittleness. It can be challenging to work with due to its tendency to fracture under stress.

Mechanical Strength:

- High: Very hard but brittle, making it less suitable for structural applications where flexibility is required.

Stainless Steel

Stainless steel offers a balance of strength, flexibility, and workability. It can be easily welded, machined, and formed into various shapes.

Mechanical Strength:

- Variable: Depending on the alloy composition, stainless steel can range from highly ductile to very strong, suitable for a wide range of applications.

Cost Considerations

Chromium Metal

Chromium is generally more expensive due to its limited availability and the complexity of its extraction and refining processes.

Cost:

- Higher: Due to the extraction and refining process.

Stainless Steel

The cost of stainless steel varies depending on the specific alloy and market conditions. However, it is generally more cost-effective than pure chromium due to its wide availability and ease of production.

Cost:

- Variable: Generally lower than pure chromium, but can increase with higher alloy content.

Environmental Impact: chromium metal vs. Stainless Steel

Chromium Metal

The mining and refining of chromium have significant environmental impacts, including habitat destruction, pollution, and energy consumption. Chromium compounds can also be hazardous to health if not handled properly.

Impact:

- High: Due to mining, refining, and potential health hazards.

Stainless Steel

Stainless steel is highly recyclable, which helps to reduce its environmental footprint. The production process can still be energy-intensive, but the ability to recycle stainless steel mitigates some of the environmental impacts.

Impact:

- Moderate: Highly recyclable, reducing its overall environmental impact.

In conclusion, both chromium metal and stainless steel have distinct properties and applications. Chromium metal is prized for its hardness and corrosion resistance but is brittle and expensive. Stainless steel, on the other hand, offers versatility, strength, and corrosion resistance, making it suitable for a wide range of applications.

Recommended Articles

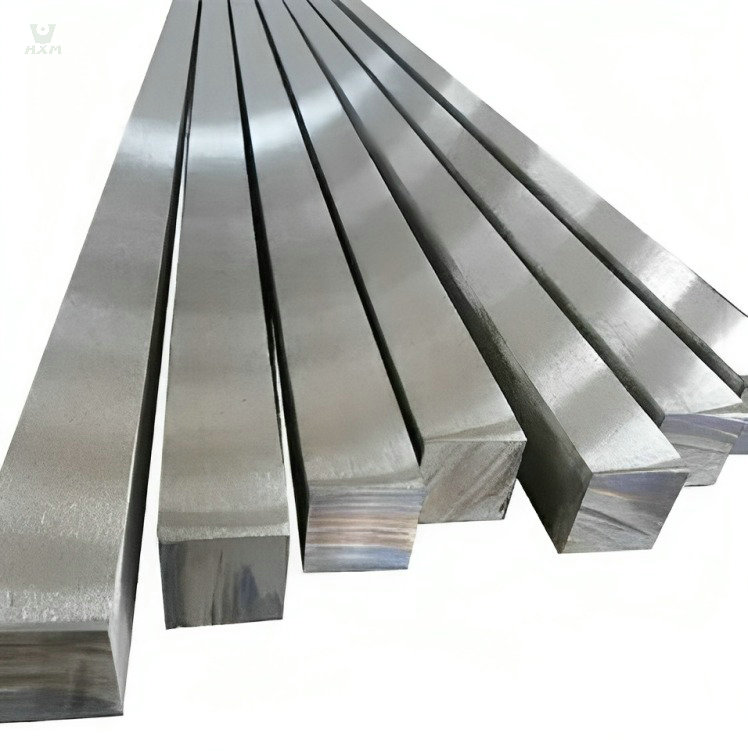

Our Stainless Steel Bar Products