Duplex Steel 2205 Coils: Understanding the Applications and Uses

Duplex Steel 2205 Coils: Understanding the Applications and Uses Duplex Steel 2205 Coils Duplex Steel 2205 coils are widely used duplex stainless steel alloy known

Corrugated metal and galvanized steel are two terms often used interchangeably, but they are not exactly the same. As an expert in the metal materials industry, following discuss the differences between these two terms and clarify any misconceptions.

What is Corrugated Metal?

Corrugated metal refers to a type of sheet metal that features a series of parallel ridges and grooves, giving it a distinct wavy pattern. This design provides added strength and rigidity to the metal sheet, making it suitable for various construction and roofing applications.

Applications of Corrugated Metal

They are widely used in roofing, siding, fencing, and agricultural applications due to its durability, weather resistance, and ease of installation. It is commonly seen on barns, sheds, warehouses, and industrial buildings.

What is Galvanized Steel?

Galvanized steel refers to steel that has been coated with a layer of zinc through a process called galvanization. This coating serves as a protective barrier against corrosion, extending the lifespan of the underlying steel substrate.

Benefits of Galvanized Steel

Galvanized steel offers excellent corrosion resistance, even in harsh environments exposed to moisture, chemicals, and saltwater. It is commonly used in outdoor structures, automotive parts, fencing, and HVAC systems.

Corrugated Metal: Composition

Corrugated metal sheets can be made from a variety of materials, including galvanized steel, aluminum, copper, and stainless steel. While galvanized steel is a common choice due to its corrosion resistance and affordability, corrugated metals can also be manufactured from other materials depending on the specific application and desired properties.

Galvanized Steel: Coating

Galvanized steel can be used in various forms, including flat sheets, coils, and corrugated panels. When referring to corrugated metal, it often implies that the steel sheets have been galvanized to enhance their durability and resistance to rust and corrosion. However, not all corrugated metal is made from galvanized steel.

If you’re considering corrugated metal for your project, you’ll find it offers numerous benefits that make it a popular choice in various applications. The advantages of corrugated metal include:

Durability

Versatility

Ease of Installation

Aesthetic Appeal

Weather Resistance

Recyclable

Galvanized steel is an excellent choice if you’re seeking a high-quality metal that provides robust corrosion protection. The benefits of galvanized steel include:

Low Maintenance

Economical

Enhanced Strength

Long-Lasting

Superior Protection

Wide Range of Applications

Both corrugated metal and galvanized steel offer unique advantages that cater to different needs and applications. Consulting with experienced metal suppliers can help you determine the best material for your specific project, ensuring you benefit from the right properties and performance characteristics.

In conclusion, while corrugated metals and galvanized steel are closely associated, they are not synonymous. Corrugated metal refers to the wavy pattern of the metal sheet, while galvanized steel refers to the coating applied to protect the steel from corrosion. While corrugated metal panels are often made from galvanized steel due to its favorable properties, corrugated metal can also be made from other materials. Understanding these distinctions is crucial when selecting the appropriate material for construction and industrial projects.

Consulting reputable metal suppliers can provide further insights into choosing the right material for specific applications, ensuring optimal performance and longevity.

Duplex Steel 2205 Coils: Understanding the Applications and Uses Duplex Steel 2205 Coils Duplex Steel 2205 coils are widely used duplex stainless steel alloy known

What are steel coils used for? stainless steel coils supplier in China Steel has been at the core of industrial development for centuries, and steel coils play

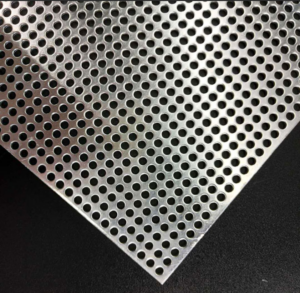

Top 10 Applications of Perforated Metal in Architectural Projects perforated metal (stainless steel sheet) Perforated metal has long been a staple in industrial design, but

Guide to Stainless Steel Pipe Rolling: Process, Benefits, and Applications stainless steel pipe What is Stainless steel pipe rolling? Stainless steel pipe rolling is a

How Are Stainless Steel Welded Tubes Made? stainless steel welded tubes Stainless steel welded tubes are a vital component in various industries, including construction, automotive,

Comparing Stainless Steel Sheets: 409 vs. 410 vs. 410S vs. 420 vs. 430 vs. 440 vs. 446 Each stainless steel sheet has its own unique

15 years professional stainless steel supplier

24 hours quick reply!