Analysis Of Stainless Steel Application In New Energy Industry In The Next 30 Years

Analysis of stainless steel application: With the proposed goal of carbon peak and carbon neutrality, the direction of China’s future energy transition development has been determined. New energy sources will gradually replace coal, thereby reducing carbon dioxide emissions and realizing China’s transition from high carbon to low carbon.

Stainless steel is our strategic emerging industry and equipment manufacturing industry upgrading high-end material, is the implementation of the national dual carbon strategy, energy structure transformation key material, is getting more and more attention.

To obtain stainless steel information or buy stainless steel please Contact Us

(1) The Application Of Stainless Steel In Energy Generation

1. Hydroelectric Power Generation

The impeller of the hydraulic turbine is made of stainless steel and is applied in the form of casting in the early stage.

Due to the development of the turbine to large capacity and high drop direction, in order to improve the performance of the impeller, forged products have been adopted, and the steel type has been transferred from the early Cr13 type to 00Cr13Ni5Mo steel with good weldability.

In addition, 0Cr18Ni9N(304N) and 2205 duplex stainless steel composite plates have been successfully used for some corrosion-resistant and wear-resistant components in hydropower stations.

2. Thermal Power Generation

The important problem of thermal power generation is to improve thermal efficiency.

In order to improve the thermal efficiency of thermal power plant boilers, large-scale equipment and high temperature and high-pressure steam conditions are the inevitable development direction.

At present, subcritical and super intermediate boilers have been industrialized. With the increase in pressure and temperature, the original material of the superheater steel tube can no longer meet the requirements, and austenitic stainless steel with good high-temperature strength, such as 321 and 316 stainless steel, is used instead.

(1) Type Cr12, 304, 310 stainless heat-resistant steel series for ultra-supercritical thermal power units.

(2) Turbine blades with Cr13 type, lCr12Ni3Mo2Nb, 17-4PH; Stem, slide valve, sleeve with N 1Cr13 infiltration; Spring with 3Cr13, 4Cr13; CF8C and so on; Rotor X12Cr MoWVNb N10.1.1.

(3) Generator constant pressure spring with 17-7PH.

(4) The surface self-nano improves the oxidation resistance of 1Cr17 stainless steel.

3. Nuclear Power Generation

Nuclear power plant involves a wide range of materials, mainly including nuclear fuel, neutron moderator, nuclear reaction control and reflection materials, reactor coolant, and reactor structure materials. Among them, stainless steel is mainly used as a reactor structure material.

Nuclear fuel cladding material of nuclear power plants, pressure shell of nuclear reactors, reactor internals, steam generator heat transfer tube, and so on are all key structural materials.

Steel and nickel alloys have become the target of structural materials selection for nuclear power plants due to mature production technology and wide sources.

According to the introduction, the consumption of power generation capacity of 1 million kilowatts of nuclear power plants more than 50000 tons of steel, the reactor body pressure vessel, pile component, control rod drive mechanism, equipment, components, parts of the circuit system key parts such as steel and nickel alloy, its number as many as thousands of tons, in terms of pressurized water reactor and boiling water reactor, equipment and components in contact with the primary circuit of coolant, More than 90% are made of steel and nickel alloy, and stainless steel accounts for 80-90% of the steel and nickel alloy

4. Tidal Power Generation

Many devices are being developed to harness wave and tidal power. Some of the prototypes use stainless steel, which has a long track record in seawater environments in the oil and gas industry. Transferring knowledge to this new energy will become even more important.

Biphasic and super biphasic alloys combine strength with corrosion resistance and are likely to play an important role in this harsh service environment.

(1) Seawater corrosion-resistant stainless steel, high strength stainless steel for wave energy generation.

(2) 06 Cr17Ni7Ti0.8Al2 and 00Cr13Ni8Mo2Al high strength stainless steel for control roller and track of tidal power generation sea dam.

(3) Resistance to abrasive sea water cavitation stainless steel series.

5. Solar Power Generation

Stainless steel is a natural material for solar energy applications, including solar water heaters, substrates for thin-film photovoltaic (PV) pool panels, support panels and connectors for crystal light panels, and large-area mirrors for sun harvesting systems.

(1) Stainless steel for solar light power generation collection plate, storage tank, amorphous honeycomb bottom plate, a pleated plate of the heat exchanger, and so on.

(2) solar thermal power generation with a heat exchange medium corrosion resistance, low hydrogen permeability coefficient with economic stainless steel.

(3) direct absorption of solar energy of amorphous stainless steel.

(4) high heat absorption rate, less reflected heat energy, black surface treatment of stainless steel.

(5) The solar water heater uses AISI304, 444, Cr17Mo2Ti and B445J1M stainless steels.

(6) AISI304 stainless steel for solar electrode flexible film and battery flexible substrate.

6. Magnetic Fluid Power Generation Equipment

(1) 00Cr26 Mol, 0Cr27 for the anode of coal-fired magnetic threesomes power generation channel, 02Cr27.5Al6.5RE stainless heat resistant steel for China.

(2) Stainless steel and Fe-Cr-Al steel for MHD power generation cold wall materials.

(3) Superconducting magnetic sulfur frame, magnetic fluid generator rotor, transmission equipment for ultra-low temperature non-magnetic stainless steel.

7. Geothermal Energy

(1) Sulfide resistance, chloride ion acid high-temperature geothermal water heat exchanger with Mo economic stainless steel.

(2) Corrosion resistance is weak, high-temperature geothermal water heat exchanger with 0Cr13, lCr13 stainless steel.

(3) 0 Cr13 Ni5 Mo martensitic stainless steel for the rotor of the geothermal power station turbine.

8. Waste Power Generation

(1) Stainless steel and abrasion-resistant stainless steel series for waste incineration power generation.

(2) Stainless steel heat-resistant steel for plant mass power generation.

(3) High-efficiency waste power generation boiler overheating pipe 0Cr25 Ni20, 0Cr25 Ni20Nb0.4N, 0Cr22Ni25 Mo1.5Nb0.15N, 0Cr 25Ni13Mo1W, etc.

9. Fuel Cells

(1) Cr22Al 10 stainless heat-resistant steel for fused carbonate fuel cells.

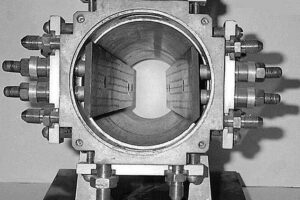

(2) Super stainless steel for polymer electrolyte fuel cell separators.

(3) Stainless steel treated by film technology for solid fuel cells.

(4) XlNi Cr MoCu25.20.5, XlNi Cr Ni MoCu25.20.7, X2 Cr Ni Mn MoN 25.18.6.5 super stainless steel for proton exchange membrane fuel cell bipolar plates.

(5) 500~700℃ fuel cell support plate AISI 430.

(6) Different types of stainless steel for cryogenic fuel cells with polymers as electrolytes.

(7) Stainless steel RMG, 232J3 for solid oxide fuel cells.

(8) Third-generation ferritic stainless steel for fuel cell interconnecting rod.

(9) Stainless steel for amorphous silicon solar cell substrate.

(10) 0.3mm composite plate material of oxygen-free copper/stainless steel/vacuum tube grade Ni for micro button battery.

(2) The Application Of Stainless Steel In Hydrogen Energy Development

The use of hydrogen needs to start from hydrogen production because hydrogen rarely exists in nature as a simple substance, it needs to be produced by industrial processes, and all hydrogen production equipment requires stainless steel.

According to relevant information, Europe will invest more than 750 billion euros in carbon dioxide in 2025. Between now and 2040, green hydrogen energy (which relies mostly on emission-free energy, namely wind, solar (00591), and hydro electrolysis) will increase from 8.5 million tonnes to 30 million tonnes.

Large quantities of stainless steel and nickel alloys are used in the production, transportation, storage, and use of hydrogen. Electrolyzers that produce green hydrogen require a lot of stainless steel and some nickel alloys, such as bipolar plates.

Long-distance high-capacity transport and storage of hydrogen, such as port terminal systems, trailers, and refueling stations, contain some stainless steel and even nickel-alloy components.

And from hydrogen production equipment to hydrogen energy utilization need stainless steel.

After liquefaction, hydrogen needs to be stored and transported by truck, ship, trailer, and pipeline. Hydrogen stations use stainless steel and may need hydrogen for energy in the future.

Hydrogen will also be used as a power source for boiler power plants, thermal power plants, cars, buses, trucks, trains, ships, forklifts, and other vehicles. Most components of electrolytic generators and fuel cells are made of stainless steel to transport and store hydrogen over long distances and in large volumes, such as port terminal systems, trailers, and refueling stations.

These facilities and tools include some stainless steel and even nickel alloy parts. In the process of using hydrogen, there are fixed power components, cogeneration units, and more stainless steel and nickel alloys. In the future, fuel cells will be used more in buses, trucks, trains, ships, and forklifts, and will use more bipolar plates, stainless steel, and nickel alloy assemblies.

Conclusion

In the medium to long term (the next 30 years, to 2050), the energy transition is the trend of The Times.

It is clear that the future of society depends on new and renewable energy sources. It is also clear that stainless steel will be an indispensable part of these production technologies.