Stainless steel, as an indispensable material in modern industry, comes in various types, each with its own characteristics. Among the many types of stainless steel, 304 and 316 have attracted much attention due to their wide range of applications and unique performance characteristics. Today, let’s delve into a comparison between 304 VS 316 stainless steel, exploring their similarities, differences, and respective advantages.

304 VS 316

What Makes Them So Popular?

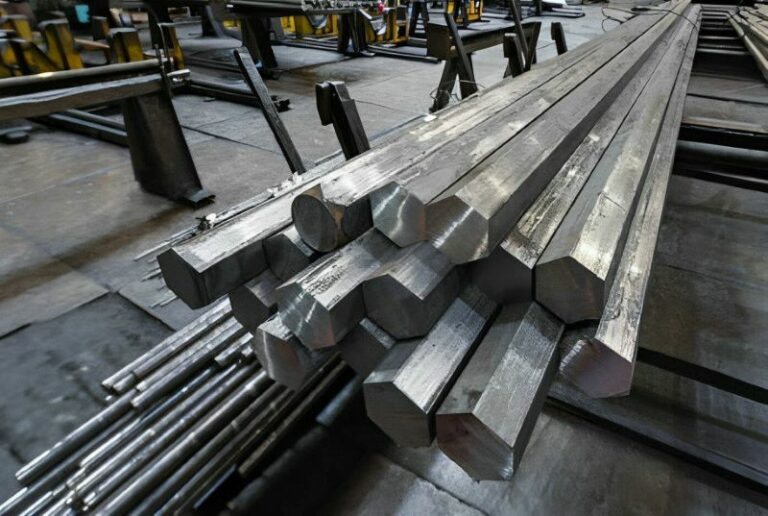

304 and 316 are two of the most widely used stainless steel grades, each known for their unique properties and versatility. 304 stainless steel is popular for its excellent corrosion resistance, affordability, and widespread use in kitchen equipment, appliances, and general industrial applications. On the other hand, 316 stainless steel stands out for its added molybdenum content, which provides superior resistance to corrosion, especially in harsh environments like marine, chemical, and saltwater applications. Their strength, durability, and resistance to rust make both 304 and 316 essential choices for industries requiring long-lasting, reliable materials.

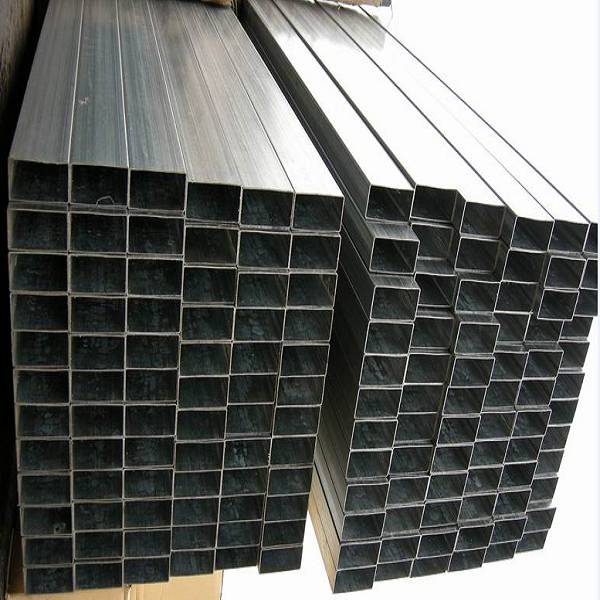

Both 304 and 316 stainless steel are widely used across various industries. 304, often referred to as “18/8” stainless steel, is the most commonly used grade due to its durability and ease of fabrication into forms like stainless steel sheets and stainless steel plates. In contrast, 316 stainless steel is particularly valued for its superior resistance to chemicals and marine environments, making it a top choice for manufacturers needing enhanced corrosion protection.

304 VS 316

304 VS 316 in Chemical Composition

| Chemical Element | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Carbon (C) | 0.03-0.08% | Below 0.08% |

| Silicon (Si) | ≤1% | ≤1% |

| Manganese (Mn) | ≤2% | ≤2% |

| Phosphorus (P) | ≤0.05% | ≤0.045% |

| Sulfur (S) | ≤0.03% | ≤0.03% |

| Chromium (Cr) | 18-20% | 16-18% |

| Nickel (Ni) | 8-11% | 10-14% |

| Molybdenum (Mo) | None | 2-3% |

- Chromium (Cr) content: The chromium content in 304 stainless steel typically ranges from 18-20%, while in 316 stainless steel, it is slightly lower, generally between 16-18%. Chromium is a key element for the corrosion resistance of stainless steel. Although both contain sufficient chromium to form a protective oxide film, 316 stainless steel maintains good corrosion resistance while reducing chromium content through adjustments in other elements.

- Nickel (Ni) content: The nickel content in 304 stainless steel is generally between 8-11%, while in 316 stainless steel, it is slightly higher, ranging from 10-14%. The addition of nickel helps improve the crystal structure of stainless steel, enhancing its ductility and toughness, especially at low temperatures.

- Molybdenum (Mo) element: 316 stainless steel contains 2-3% molybdenum, while 304 stainless steel does not contain molybdenum. The addition of molybdenum gives 316 stainless steel stronger corrosion resistance in chloride environments, making it particularly suitable for corrosive environments such as marine and chemical industries.

304 VS 316

304 VS 316 in Physical Properties

| Physical Properties | 304 Stainless Steel | 316 Stainless Steel |

| Density (g/cm³) | 8.03 | 8.00 |

| Melting point (℃) | 1400-1450 | 1370-1400 |

| Coefficient of thermal expansion (10^-6/K) | 17.2 | 16.5 |

| Thermal conductivity (W/m-K) | 16.2 | 16.3 |

| Electrical resistivity(nΩ•m) | 72.1 | 74 |

※ Please note that the properties of stainless steel may vary depending on the stainless steel suppliers and specifications

- Firstly, although the densities of both stainless steels are close to 8g/cm³, the density of 316 stainless steel is slightly higher.

- Secondly, the melting point range of 316 stainless steel is relatively wide, and its lowest melting point is slightly lower than that of 304 stainless steel.

- However, their tensile strength and yield strength are the same, indicating that they are comparable in terms of mechanical properties.

304 VS 316

304 VS 316 in Mechanical Properties

| Mechanical Properties | 304 Stainless Steel | 316 Stainless Steel |

| Yield Strength(MPa) | 205 | 205 |

| Tensile Strength(MPa) | 515 | 515 |

| Elongation(%) | 40 | 40 |

| Hardness(HB) | 201 | 217 |

| Cross-Sectional Shrinkage(%) | 50 | 60 |

| Impact Toughness(J) | >100 | >100 |

※ Please note that the properties of stainless steel may vary depending on the stainless steel suppliers and specifications

Strength:

- 304 stainless steel has good strength and hardness, suitable for general structural components and decorative materials. Its yield strength is moderate, meeting the requirements of most conventional applications.

- In contrast, 316 stainless steel has higher strength. Its yield strength and tensile strength are typically higher than those of 304 stainless steel, making it perform better in applications requiring higher loads and stricter mechanical performance requirements.

Wear resistance:

- 304 stainless steel exhibits good wear resistance under normal operating conditions, but its wear resistance may decrease under high friction or heavy load conditions.

- 316 stainless steel has excellent wear resistance, maintaining stable surface hardness and wear resistance even under high-speed motion and heavy load conditions. This gives it an advantage in applications requiring long-term maintenance of good mechanical performance.

Toughness:

- 304 stainless steel retains some toughness at low temperatures, but its toughness may be affected under extremely low temperature conditions.

- 316 stainless steel maintains good toughness at low temperatures, able to withstand low-temperature impacts and vibrations, making it suitable for use in extreme environments.

304 VS 316

Conclusion

If you are looking for a versatile, moderately priced stainless steel suitable for most conventional applications, then 304 stainless steel would be an ideal choice. Its strength and wear resistance are sufficient for most common applications, while it also excels in aesthetics.

However, if you need stainless steel to perform excellently in corrosive environments, especially in chloride environments, or in situations requiring higher strength and wear resistance, then 316 stainless steel would be the better choice. The addition of molybdenum significantly enhances the corrosion resistance and mechanical properties of 316 stainless steel.

Huaxiao Metal is a company located in Shanghai, China, specializing in the stainless steel export industry for over 15 years. We have a professional sales team that responds quickly and possesses extensive knowledge to provide you with quick quotations and recommend the most suitable stainless steel products for you. Whether you need 304, 316, or other grades of stainless steel, Huaxiao Metal can provide them. Their production lines are well-equipped to meet all your needs.

If you have stainless steel procurement needs, don’t hesitate to inquire from Huaxiao Metal!

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WeChat:

+86 13381673250

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China