brass vs stainless steel

what's the difference?

◦ brass vs stainless steel ◦stainless steel supplier ◦ brass vs stainless steel ◦ stainless steel supplier ◦ brass vs stainless steel

brass vs stainless steel

Have you ever marveled at the sleek and shiny façade of a modern building or wondered about the intricate details of your favorite piece of jewelry? Chances are, you’ve encountered two remarkable materials, brass, and stainless steel, in your everyday life. While they share the allure of a polished finish, these metals are far from identical. In this exploration, we’ll uncover the inherent distinctions between brass and stainless steel, shedding light on their unique characteristics and the scenarios where one outshines the other. So, if you’ve ever pondered the differences between these metals, join us on this journey to decipher the intriguing world of brass and stainless steel.

what's the difference between

brass and stainless steel?

Brass and stainless steel are distinct alloys, each with its unique composition and properties. Brass primarily consists of copper and zinc, offering a reddish-gold hue, while stainless steel is predominantly iron alloyed with chromium and other elements, exhibiting a bright, metallic luster.

Their differences extend to mechanical properties as well. Brass is renowned for its malleability, making it ideal for intricate designs, but it is not as strong as stainless steel. Stainless steel, on the other hand, is renowned for its exceptional strength, corrosion resistance, and durability, making it a preferred choice in applications demanding robust performance.

Furthermore, their corrosion resistance varies significantly. Brass is susceptible to tarnishing over time, requiring periodic maintenance, while stainless steel’s chromium content provides excellent resistance to rust and staining, ensuring longevity in harsh environments.

In summary, the choice between brass vs stainless steel hinges on the specific requirements of a given application. Brass excels in decorative and low-stress scenarios, while stainless steel shines where strength, durability, and corrosion resistance are paramount. Understanding these distinctions allows for informed decisions when selecting the right material for the task at hand.

brass vs stainless steel

Composition and Properties

In this section, we will dive deep into the composition and properties of both brass vs stainless steel, two remarkable alloys used across various industries. We will unravel the specific elements that constitute these materials and the unique characteristics that they bring to the table. By understanding the distinct properties of brass vs stainless steel, we will shed light on how these differences influence their mechanical strength, corrosion resistance, and overall aesthetic appeal. This exploration will provide a solid foundation for grasping the disparities between these alloys and making informed decisions when choosing between brass vs stainless steel for specific applications. Let’s start by examining the composition of brass vs stainless steel and the inherent attributes that set them apart.

chemical composition of brass

Brass is an alloy primarily composed of copper (Cu) and zinc (Zn). The exact proportions of copper and zinc can be adjusted to create various types of brass with distinct properties, making it a versatile material. In addition to copper and zinc, small amounts of other elements like lead, aluminum, and tin can be included to achieve specific characteristics.

The primary elements in brass contribute to its unique properties:

Copper (Cu): It forms the majority of the brass composition and provides the metal’s inherent malleability, thermal conductivity, and excellent electrical conductivity. Copper also gives brass its distinct reddish-gold color.

Zinc (Zn): Zinc enhances the mechanical properties of brass, such as tensile strength and hardness. It also contributes to the corrosion resistance of some brass alloys.

Other Trace Elements: Additional elements like lead, aluminum, and tin are incorporated in trace amounts to modify the alloy’s properties. For example, leaded brass is more easily machinable, while aluminum and tin may improve resistance to corrosion.

The compositional variations allow for a wide range of brass types, each tailored for specific applications. Whether it’s in musical instruments, plumbing fittings, decorative hardware, or more, the composition of brass can be fine-tuned to meet the unique demands of various industries.

characteristics of brass

Brass, an alloy primarily composed of copper and zinc, exhibits a range of unique characteristics that make it valuable in various applications. Here, we’ll delve into the scientific aspects of brass’s characteristics:

Malleability: Brass is highly malleable, which means it can be easily shaped and formed without breaking. This property makes it ideal for crafting intricate designs in jewelry, musical instruments, and decorative hardware.

Ductility: Brass is ductile, allowing it to be drawn into thin wires without losing its strength. This characteristic is essential for producing items like electrical connectors and fine wires.

Corrosion Resistance: Depending on the exact composition, brass can exhibit good resistance to corrosion, especially in marine or humid environments. This is due to the protective layer that forms on its surface, preventing further oxidation.

Excellent Electrical Conductivity: Copper, the primary component of brass, is known for its outstanding electrical conductivity. Brass retains some of this property, making it suitable for electrical connectors and terminals.

Attractive Appearance: Brass has a visually appealing, golden-like color that is widely appreciated for decorative applications. Its color doesn’t tarnish easily, retaining its aesthetic appeal over time.

Antimicrobial Properties: Some brass alloys exhibit antimicrobial properties, meaning they can help inhibit the growth of bacteria on their surfaces. This feature has made brass fittings and doorknobs popular in healthcare settings.

Melting Point: Brass has a lower melting point compared to other metals like steel, which is beneficial for casting and molding processes.

Acoustic Properties: Brass alloys are favored in musical instruments because of their acoustic properties. They produce a bright and resonant sound, making them common in trumpets, trombones, and other brass instruments.

These characteristics, combined with the ability to fine-tune brass compositions for specific needs, result in a versatile material used in a wide array of industries, from construction to healthcare and beyond.

chemical composition of stainless steel

Stainless steel, known for its remarkable properties, is a complex alloy consisting of various elements that provide it with its unique characteristics. Let’s take an in-depth look at the composition of stainless steel, with insights from stainless steel supplier:

Iron (Fe): Stainless steel is primarily composed of iron. The iron content can range from 50% to 70% depending on the specific grade of stainless steel.

Chromium (Cr): Chromium is one of the most critical elements in stainless steel, typically making up at least 10.5% of the alloy. It’s the presence of chromium that gives stainless steel its corrosion-resistant properties. Chromium forms a thin, protective oxide layer on the surface of the steel, preventing rust and staining.

Nickel (Ni): Nickel is another essential element in many stainless steel grades. It enhances the steel’s resistance to corrosion and adds to its durability. The percentage of nickel varies depending on the type of stainless steel.

Carbon (C): The carbon content in stainless steel typically ranges from 0.03% to 0.08%. The carbon level affects the material’s strength and weldability.

Manganese (Mn): Manganese contributes to the steel’s overall strength and is often added in proportions ranging from 1% to 2%.

Silicon (Si): Silicon is present in stainless steel to improve its resistance to oxidation and scaling at high temperatures.

Molybdenum (Mo): Molybdenum is added to certain stainless steel grades to enhance their resistance to specific corrosive environments.

Other Alloying Elements: Various other elements like nitrogen, titanium, and copper may be present in stainless steel to fine-tune its properties for specific applications.

These elements, when combined in precise ratios, result in a wide range of stainless steel grades, each with unique attributes. The diversity in compositions allows stainless steel to serve diverse industries, from construction and healthcare to food processing and aerospace. Stainless steel supplier play a crucial role in providing these tailored alloys to meet the specific needs of their customers.

property of stainless steel

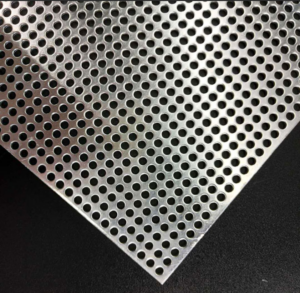

Stainless steel, known for its remarkable properties, is a complex alloy consisting of various elements that provide it with its unique characteristics. Let’s take an in-depth look at the composition of stainless steel, with insights from stainless steel supplier:

Corrosion Resistance: Stainless steel’s primary defining feature is its resistance to corrosion. The high chromium content forms a passive oxide layer on the surface, preventing rust, staining, and corrosion even in aggressive environments.

Strength and Durability: Stainless steel exhibits robust mechanical properties, including high tensile strength and excellent durability. It maintains its integrity in extreme temperatures, making it ideal for applications in challenging conditions.

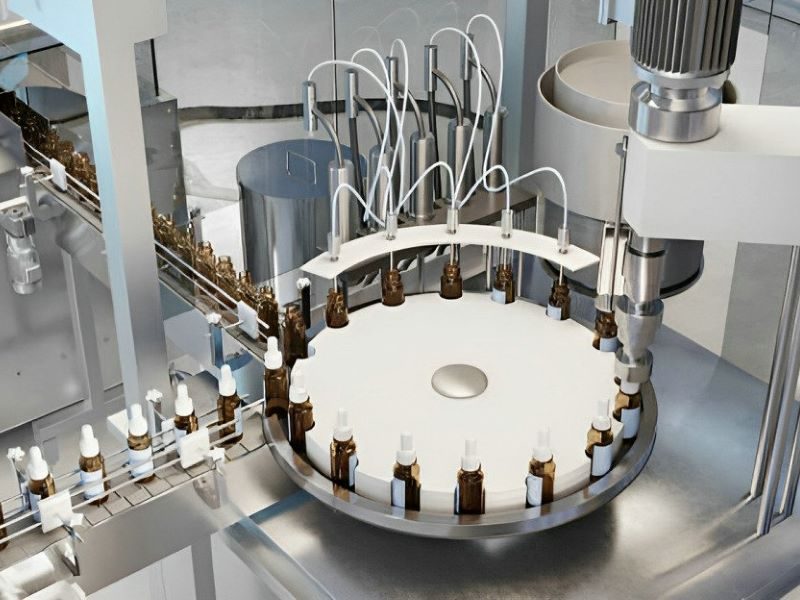

Hygiene and Cleanliness: Stainless steel’s smooth, non-porous surface is easy to clean and maintain. This makes it a top choice for applications in healthcare, food processing, and the pharmaceutical industry, where hygiene is critical.

Aesthetic Appeal: Stainless steel is appreciated for its attractive, lustrous finish. It provides a modern and clean appearance, making it a preferred material for architectural and interior design applications.

Heat Resistance: Stainless steel can withstand high temperatures without deforming or losing its structural integrity. This heat resistance makes it valuable in industries like automotive, aerospace, and manufacturing.

Low Maintenance: Stainless steel requires minimal maintenance and is resistant to discoloration, which contributes to its long lifespan.

Non-Reactivity: Stainless steel does not react with most chemicals, making it suitable for chemical and pharmaceutical processing equipment.

Strength-to-Weight Ratio: Stainless steel offers excellent strength relative to its weight, making it suitable for structural applications in construction and transportation.

Magnetic or Non-Magnetic: Depending on the specific grade, stainless steel can be magnetic (ferritic or martensitic) or non-magnetic (austenitic). This property is important in various industrial applications.

Customization: Stainless steel is available in various grades and finishes, allowing for customization to meet specific requirements in different applications.

The diverse range of properties offered by stainless steel makes it an ideal choice for an array of industries, from construction and architecture to healthcare, aerospace, and beyond. The expertise of stainless steel supplier in providing tailored alloys ensures that these properties can be fine-tuned to meet the precise needs of their customers.

How their differences impact their mechanical and aesthetic attributes?

| Attribute | Brass | Stainless Steel |

|---|---|---|

| Strength | Lower tensile strength, less suitable for heavy loads and structural applications. | Higher tensile strength, ideal for structural integrity and load-bearing. |

| Corrosion Resistance | Prone to tarnishing, requires more maintenance to preserve appearance. | Superior resistance to moisture, chemicals, and environmental factors. |

| Ductility | More ductile and easily molded, suitable for intricate designs and ornamental features. | Less ductile, limiting intricate designs, but offering structural integrity. |

| Magnetic Properties | Typically non-magnetic. | Can be magnetic (ferritic or martensitic) or non-magnetic (austenitic) depending on the grade. |

| Color | Golden or reddish-brown color, offering a warm and classic appearance. | Silver-gray tone, providing a modern and industrial aesthetic. |

| Finish Options | Limited options, typically polished or allowed to patina. | Versatile finishes including mirror-like, satin, brushed, and matte. |

| Luster | Warm, lustrous shine. | Sleek, reflective surface. |

| Aging and Maintenance | Tends to patina and darken over time, some find this appealing. Requires more maintenance. | Maintains appearance with minimal maintenance. Ideal for pristine looks. |

In summary, the differences in mechanical and aesthetic attributes between brass vs stainless steel arise from variations in composition. These distinctions are crucial when choosing between the two materials, as they impact the performance, appearance, and maintenance requirements for different applications. Understanding these differences helps individuals and industries make informed decisions regarding material selection.

brass vs stainless steel

Mechanical Characteristics

| Property | Brass | Stainless Steel |

|---|---|---|

| Tensile Strength | Lower | Higher |

| Ductility | More | Less |

| Corrosion Resistance | Prone to tarnishing | Superior resistance |

| Magnetic Properties | Typically non-magnetic | Can be magnetic (varies) |

-

Tensile Strength:

Brass: Brass exhibits a lower tensile strength compared to stainless steel. This makes it less suitable for applications where heavy loads or structural integrity are crucial.

Stainless Steel: Stainless steel, depending on the grade, offers higher tensile strength, making it ideal for applications requiring structural strength and load-bearing capacity. -

Ductility:

Brass: Brass is more ductile and malleable. It can be easily molded and shaped into intricate designs, making it suitable for applications where ornamental features are desired.

Stainless Steel: Stainless steel is less ductile and not as easily molded. This limits its use in applications with intricate designs but ensures structural integrity. -

Corrosion Resistance:

Brass: Brass is prone to tarnishing over time, requiring regular maintenance to preserve its appearance and resist corrosion.

Stainless Steel: Stainless steel provides superior resistance to moisture, chemicals, and environmental factors, reducing the need for maintenance and ensuring long-term durability. -

Magnetic Properties:

Brass: Brass is typically non-magnetic.

Stainless Steel: Stainless steel can exhibit magnetic properties (ferritic or martensitic grades) or be non-magnetic (austenitic grades), depending on the specific alloy.

These contrasting mechanical properties play a crucial role in determining the suitability of brass vs stainless steel for various applications, from decorative and ornamental uses to structural and load-bearing requirements.

scenarios where brass outperforms stainless steel and vice versa

Acoustic Properties: Brass, with its superior acoustic characteristics, outperforms stainless steel in musical instruments like trumpets and saxophones. Its resonance and malleability are key for achieving rich and warm tones.

Antimicrobial Properties: Brass demonstrates natural antimicrobial properties due to the oligodynamic effect. In applications where limiting bacterial growth is critical, such as doorknobs and handrails, brass is advantageous.

Decorative Elements: Brass offers an attractive, golden appearance, making it preferable for decorative elements like furniture, fixtures, and ornamental architecture due to its aesthetic appeal.

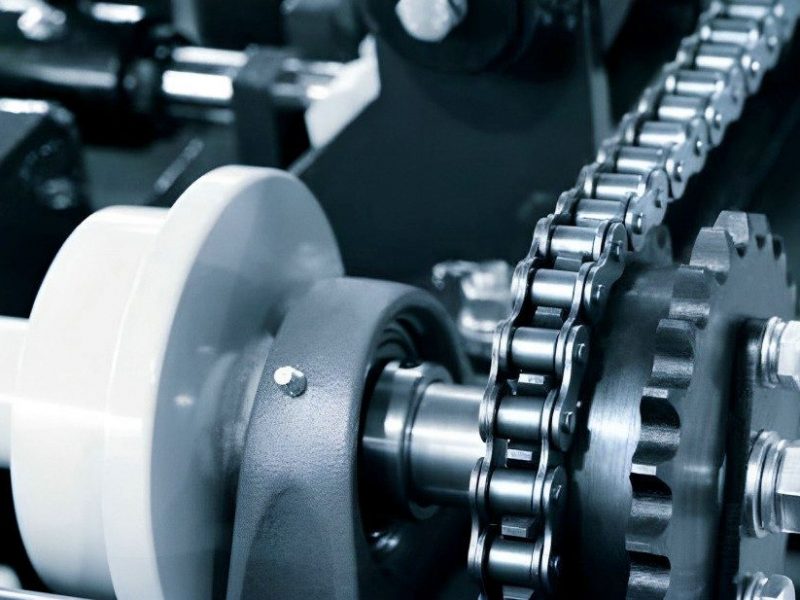

Corrosion Resistance: Stainless steel surpasses brass in applications exposed to harsh environments or corrosive substances, like marine components, industrial machinery, and chemical processing equipment. Its corrosion resistance ensures longevity.

Strength and Durability: Stainless steel excels in applications demanding high strength and structural integrity. This is evident in building construction, bridges, automotive components, and medical instruments where durability is paramount.

Hygiene and Food Processing: In food-related industries, stainless steel is favored for its non-reactive, non-contaminating, and easy-to-clean properties. It is essential for food processing equipment, kitchen appliances, and medical instruments.

brass vs stainless steel

corrosion resistance

Corrosion resistance is a critical factor in material selection, especially in applications where exposure to moisture, chemicals, or harsh environmental conditions is common. Now, let’s analyze how brass vs stainless steel, two widely used materials, perform in terms of corrosion resistance.

Brass:

Brass is an alloy primarily composed of copper and zinc. While it offers reasonable corrosion resistance, especially in indoor or non-corrosive environments, it may tarnish or develop a patina over time due to the presence of copper. This makes it less suitable for applications in highly corrosive settings, like marine environments, where it may not withstand prolonged exposure to saltwater.

Stainless Steel:

Stainless steel, on the other hand, boasts exceptional corrosion resistance due to its unique composition. The addition of chromium forms a passive layer on the surface of stainless steel, protecting it from rust and corrosion. This makes stainless steel ideal for a wide range of applications, including marine, architectural, and food processing, where exposure to corrosive elements is a constant threat.

In conclusion, when it comes to corrosion resistance, stainless steel outperforms brass in a variety of applications, ensuring longevity and reliability even in challenging environments. Stainless steel’s durability is a result of its alloy composition, making it a preferred choice in many industries.

brass vs stainless steel

Cost Considerations

Cost plays a significant role in the selection of materials for various applications. When it comes to brass vs stainless steel, analyzing the cost differences between the two is essential for making informed decisions. Let’s delve into the cost considerations and the factors that should be weighed when choosing between brass and stainless steel.

Analyzing Cost Differences

Brass: Brass is generally more affordable than stainless steel. Its primary components, copper and zinc, are readily available and less expensive than the elements used in stainless steel. This makes brass a cost-effective choice for various applications.

Stainless Steel: Stainless steel is typically pricier than brass due to its more complex composition, which includes elements like chromium and nickel. The cost of stainless steel can vary significantly based on the specific grade and alloy used, and it is often higher than that of brass.

Balancing Material Costs with Benefits

When selecting between brass vs stainless steel, it’s essential to balance material costs with the benefits they offer. Consider the following:

Application Requirements: Evaluate the specific needs of your project. If corrosion resistance is a critical factor and longevity is required, the slightly higher cost of stainless steel may be justified.

Long-Term Maintenance: Stainless steel’s durability often translates into lower maintenance costs, which can offset the initial higher material cost over the long run.

Factors to Consider

Several factors can influence cost considerations:

Material Quantity: The volume of material needed can significantly impact costs. For larger projects, even slight differences in material cost can have a substantial financial impact.

Project Budget: Assess the available budget for your project. While stainless steel may be more expensive, if it fits within the budget, its benefits may outweigh the cost difference.

Environmental Conditions: Consider the environment in which the material will be used. If corrosion or tarnishing is a concern, opting for stainless steel could be more cost-effective over time.

In conclusion, making cost-based decisions between brass vs stainless steel involves assessing the initial material cost, long-term maintenance, project requirements, and budget constraints. While brass is generally more budget-friendly, stainless steel’s unique properties can make it a cost-effective choice in many scenarios. It’s crucial to weigh these factors to determine which material best suits your specific needs and budget constraints.

brass vs stainless steel

conclusion

In the world of materials, brass vs stainless steel stand as unique alloys, each with its own set of attributes and applications. As we’ve explored, their differences encompass composition, mechanical properties, corrosion resistance, and costs. Let’s recap the key takeaways and consider the path forward.

Brass, a copper-zinc alloy, exhibits excellent machinability, making it ideal for various decorative and functional applications. On the other hand, stainless steel, with its diverse grades and compositions, offers exceptional strength, corrosion resistance, and durability, rendering it suitable for more demanding environments. The differences in mechanical properties, corrosion resistance, and cost must be carefully weighed when choosing between the two.

Selecting the right material is crucial in engineering and design. Whether it’s brass or stainless steel, an informed choice can significantly impact the success and longevity of a project. It’s essential to consider specific requirements and the intended use, keeping in mind that no one material is universally superior. Instead, it’s about finding the best fit for the task at hand.

To make an optimal selection between brass and stainless steel, it’s vital to assess the specific needs of your application. Ask questions about the environmental conditions, mechanical demands, aesthetic preferences, and budget constraints. These answers will guide you toward the right choice, ensuring that your project thrives.

In conclusion, understanding the differences between brass and stainless steel is a valuable step toward informed decision-making. By considering the unique properties and costs associated with each material, you can confidently choose the one that aligns with your project’s requirements. Stainless steel, with its renowned strength and corrosion resistance, is a versatile workhorse, while brass, with its elegance and affordability, shines in a variety of applications. The ultimate choice is yours, guided by the specifics of your venture.