How to cut stainless steel bar?

Cut stainless steel bars requires not only suitable tools but also certain skills and experience. Choosing the right cutting method, mastering the correct operating procedures, and understanding potential issues during the cutting process are all keys to ensuring cutting quality and efficiency. In this blog post, I will provide you with detailed introductions to different cutting methods, including mechanical cutting, flame cutting, and laser cutting, while also sharing some practical tips and precautions.

Basic Knowledge to Cut Stainless Steel Bars

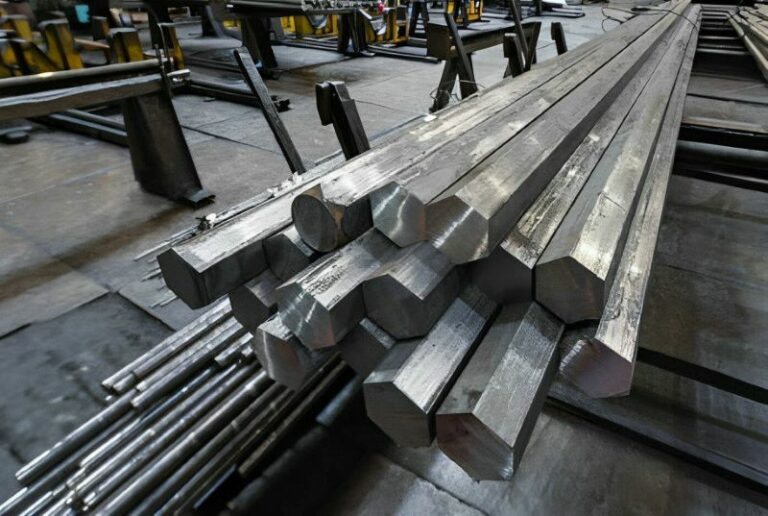

Stainless steel bars, as a widely used raw material in various industrial fields, stand out among many metal materials due to their unique physical and chemical properties. Before embarking on cut stainless steel bars, it is essential to understand their basic characteristics and factors to consider during cutting.

Basic Characteristics of Stainless Steel Bars

- Hardness: Stainless steel bars typically have high hardness, allowing them to maintain structural stability in various harsh environments. However, this hardness also poses certain challenges to the cutting process.

- Corrosion Resistance: The reason stainless steel bars are "stainless" is because they can resist oxidation and corrosion in most environments. This characteristic enables stainless steel bars to maintain their physical properties in humid, acidic, and alkaline environments.

- Thermal Conductivity: Stainless steel bars have relatively low thermal conductivity, meaning that heat generated during the cutting process is not easily dissipated, which may affect cutting quality and efficiency.

Factors to Consider When Cut Stainless Steel Bars

- Material Thickness

- Cutting Precision

- Cutting Speed

- Selection of Cutting Tools

Understanding this basic knowledge and considerations will help us better carry out the cutting of stainless steel bars, ensuring that the resulting products meet the requirements of various application scenarios.

Cutting Methods for Stainless Steel Bars

Due to their high strength and corrosion resistance, stainless steel bars are widely used in industrial manufacturing. To meet various production needs, we have multiple cutting methods to choose from, including mechanical cutting, flame cutting, and laser cutting. Below, we will delve into the principles, required tools or equipment, advantages and disadvantages, as well as applicable scenarios of these cutting methods.

Mechanical Cutting

Principle and Common Tools: Mechanical cutting mainly involves the physical cutting of stainless steel bars using machinery such as saw blades, grinding wheels, or cutting machines. Common tools include band saws, abrasive cut-off machines, and hacksaws.

Advantages and Disadvantages Analysis:

- Advantages: Fast speed, suitable for mass production. Relatively flat cutting surface, suitable for applications with certain cutting precision requirements. Lower cutting cost, suitable for economical cutting needs.

- Disadvantages: For thicker or harder stainless steel bars, cutting difficulty may be higher, requiring more advanced equipment. The cutting process may generate considerable heat, affecting cutting quality.

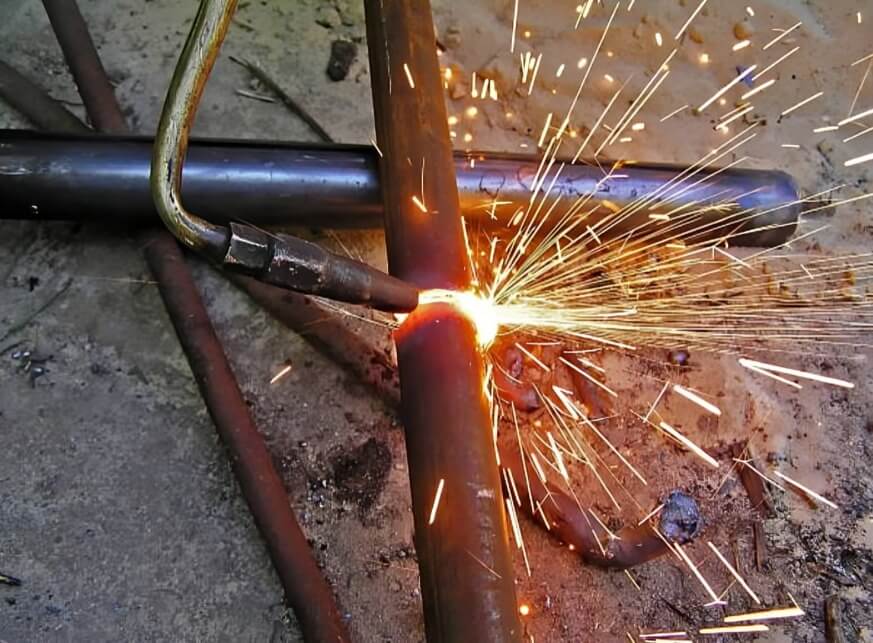

Flame Cutting

Working Principle and Required Equipment:

Flame cutting utilizes a flame generated by mixing fuel gas and oxygen to heat the stainless steel bar to a molten state. Then, a high-speed oxygen stream is used to blow away the molten part, thereby achieving cutting. Required equipment includes flame cutting machines, gas and oxygen supply systems, etc.

Applicable Scenarios and Potential Issues:

Applicable Scenarios:

- Suitable for thicker or harder stainless steel bars.

- Suitable for outdoor or environments without power supply.

Potential Issues: - The cutting surface may not be sufficiently flat and may require post-processing.

- The heat generated during flame cutting may cause material deformation.

- Specific equipment and fuel are required, resulting in relatively high costs.

Laser Cutting

Principle and Advantages:

Laser cutting utilizes a high-energy laser beam to irradiate the surface of the stainless steel bar, causing rapid melting or vaporization. At the same time, a high-speed airflow blows away the melted or vaporized part, achieving cutting. Laser cutting has the advantages of high precision, high speed, and high efficiency.

Comparison with Other Cutting Methods:

- Compared with mechanical cutting, laser cutting has higher precision and speed, suitable for applications with higher cutting quality requirements.

- Compared with flame cutting, laser cutting has a smaller heat-affected zone, less material deformation, and a smoother cutting surface.

- However, laser cutting equipment costs are higher, and maintenance costs are also relatively high, so it may not be suitable for economical cutting needs.

process of cut stainless steel bar

- Marking Cutting Lines: Mark the required cutting lines on the stainless steel bar using a scribe or ruler to ensure cutting accuracy.

- Adjusting Cutting Parameters: Adjust cutting speed, cutting depth, gas flow rate, and other parameters according to the characteristics of the stainless steel bar and the required cutting requirements.

- Starting Cutting: Place the stainless steel bar in the fixture of the cutting equipment, ensuring it is securely fixed. Start the cutting equipment and proceed with cutting according to the pre-set parameters.

- Monitoring the Cutting Process: During the cutting process, closely monitor the cutting quality and equipment status to ensure smooth cutting progress.

- Completing the Cutting: After the cutting is completed, turn off the cutting equipment and carefully remove the cut stainless steel bar from the fixture.

Operating Tips and Precautions

- Choose the appropriate cutting speed: Cutting too quickly may result in uneven cutting surfaces, while cutting too slowly may affect cutting efficiency. It is recommended to select the appropriate cutting speed based on the material and thickness of the stainless steel bar.

Keep the equipment clean: Regularly clean the cutting equipment to remove dust and debris, ensuring the normal operation of the equipment and cutting quality.

Perform regular equipment checks: Perform maintenance and inspections on the cutting equipment regularly to ensure that the equipment is in good working condition, and replace worn parts promptly.

Practice safe operation: Maintain focus during the cutting process and avoid distractions. Ensure the safety of the work area and follow the safety regulations in the equipment operation manual.

Handle cutting waste: Dispose of the waste generated during the cutting process promptly to maintain the cleanliness and safety of the work area.

conclusion

Thank you for reading, and I’m glad to share with you the knowledge about how to cut stainless steel bars. Through the detailed analysis in this article, I believe you now have a deeper understanding of the cutting methods for stainless steel bars. Cut stainless steel bars not only involves choosing the right cutting tools and methods but also requires mastering a series of operating techniques and precautions. I hope you can apply these key points and techniques in practical operations to ensure smooth cutting processes and obtain high-quality cutting results.

Stainless steel, as an important industrial material, is widely used in various fields. As a professional stainless steel supplier, Huaxiao Metal is committed to providing customers with high-quality stainless steel products to meet the needs of various applications. We have multiple production lines and can provide a variety of products including stainless steel bars, pipes, coils, strips, plates, wires, etc., with customizable sizes. If you have any purchasing needs or questions, please feel free to send us an email for inquiries. We will serve you wholeheartedly and provide you with professional solutions.