When engaging in metalworking or renovation projects, it’s common to need to cut various types of metal sheets, with stainless steel sheets being a popular choice due to their corrosion resistance, strength, and aesthetic appeal. However, for many, effectively cutting stainless steel sheets can pose a challenge. The hardness and toughness of stainless steel make traditional cutting methods potentially unsuitable, thus mastering the correct cutting techniques and selecting appropriate tools becomes crucial. In this article, we will explore how to cut stainless steel sheets, including the necessary tools, steps, and safety precautions, to assist readers in completing metal-cutting tasks more effectively.

Choose The Right Method to cut stainless steel sheet

There are several methods to cut stainless steel sheets, including plasma cutting, waterjet cutting, laser cutting, and saw cutting. Each method has its advantages and disadvantages, and the choice depends on the material thickness, desired cut quality, and budget.

Plasma Cutting

Plasma cutting is a widely used method to cut stainless steel sheets. It involves using a high-temperature plasma arc to melt the metal and create a clean, precise cut. Plasma cutting is suitable to cut stainless steel plates up to 6 inches thick and is faster than many other cutting methods.

One of the benefits of plasma cutting is its speed, which can help reduce production times and increase efficiency. However, plasma cutting produces a rougher edge than some other cutting methods and may require additional finishing processes.

-Huaxiao Stainless Steel Supplier

Waterjet Cutting

Saw cutting is a traditional method to cut stainless steel sheets. It involves using a saw blade to cut through the metal, producing a straight, clean cut. Saw cutting is suitable for thicker materials and can be cost-effective for large-volume production.

One of the benefits of saw cutting is its ability to produce precise, clean cuts without creating any rough edges. However, saw cutting can be slower than other methods, and it may not be suitable for cutting complex shapes or patterns.

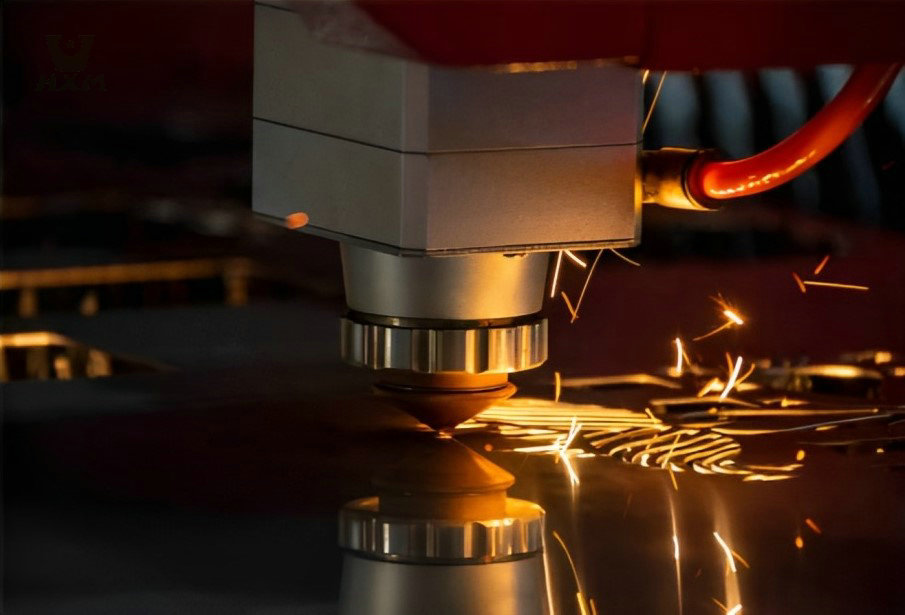

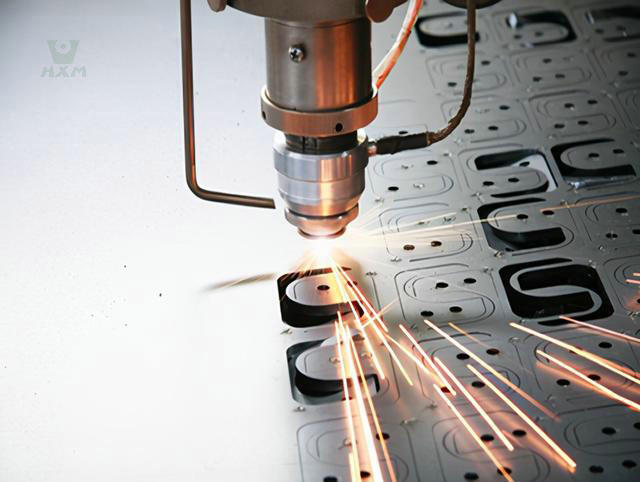

Laser Cutting

Laser cutting is another popular method to cut stainless steel sheets. It uses a laser beam directed onto the stainless steel, which melts the metal and creates a clean, precise cut. Laser cutting is ideal for thin sheets of stainless steel plates and produces minimal distortion and waste.

Laser cutting is particularly useful for cutting complex shapes and patterns, making it a popular choice for decorative stainless steel pieces. However, laser cutting can be expensive and may not be suitable for thicker materials.

-Huaxiao Stainless Steel Supplier

Saw Cutting

Saw cutting is a traditional method to cut stainless steel sheets. It involves using a saw blade to cut through the metal, producing a straight, clean cut. Saw cutting is suitable for thicker materials and can be cost-effective for large-volume production.

One of the benefits of saw cutting is its ability to produce precise, clean cuts without creating any rough edges. However, saw cutting can be slower than other methods, and it may not be suitable for cutting complex shapes or patterns.

Select The Appropriate Tool to cut stainless steel sheet

To cut stainless steel sheets of different thicknesses or materials may require different cutting tools to achieve the desired results. Here are some guidelines for selecting the right cutting tool:

Thick Sheets (Above 25mm):

- Plasma Cutting: Plasma cutting is often the preferred method for cutting thick stainless steel plates. It provides fast and efficient cutting, even for thick materials.

- Waterjet Cutting: Waterjet cutting can also be used for thick sheets, providing precise and clean cuts without generating excessive heat.

- Laser Cutting: Laser cutting can handle thicker stainless steel sheets, but it may require higher-powered lasers and longer cutting times compared to plasma or waterjet cutting.

Thin Sheets (Up to 3mm):

- Shearing: For thin stainless steel plates, shearing is a common and cost-effective method. It involves using sharp blades to cut through the sheet.

- Electric Snips: Electric snips or aviation snips can also be suitable for thin sheets, providing a clean and precise cut.

- Laser Cutting: Laser cutting is another option for thin sheets, offering high precision and the ability to cut complex shapes.

Medium Thickness Sheets

(3mm to 25mm):

- Plasma Cutting: Plasma cutting is commonly used for medium-thickness stainless steel plates. It utilizes ionized gas and a high-velocity jet to cut through the material effectively.

- Waterjet Cutting: Waterjet cutting can provide precise cuts for medium-thickness sheets. It uses a high-pressure stream of water mixed with an abrasive substance to cut through the stainless steel.

- Laser Cutting: Laser cutting is versatile and can be used for a range of thicknesses, including medium-thickness sheets. It offers high accuracy and a clean cut.

ensure the safety and operation specification

- Wearing Protective Gear: When cutting stainless steel sheets, it is essential to wear appropriate protective gear such as safety goggles, gloves, and flame-resistant work clothing. These equipment effectively protects your eyes, hands, and body from splashes, sparks, and high temperatures.

- Maintaining a Clean Work Area: The work area should be kept clean, avoiding flammable materials and debris. Sparks generated during the cutting process may cause fires, so ensuring that the work area is free from flammable materials is crucial.

- Inspecting Cutting Tools and Equipment: Before using cutting tools and equipment, it is imperative to inspect them to ensure they are in good working condition. Check critical components such as power cords, cutting blades, or laser heads for damage or wear, and identify any potential safety hazards.

- Following Operating Procedures: Strictly adhere to operating procedures for cutting operations to avoid improper operation. This includes following the correct cutting sequence, appropriate cutting speed, and depth. Following operating procedures ensures stability and safety during the cutting process.

- Being Aware of Surrounding Environment: When performing cutting operations, be mindful of changes in the surrounding environment, especially noise, smoke, and dust generated during cutting. Maintain good ventilation and avoid prolonged exposure to hazardous environments to prevent adverse effects on health.

- Promptly Addressing Abnormalities: If any abnormalities are noticed during the cutting process, such as overheating of cutting tools or uneven cutting surfaces, stop the operation immediately and address the issue promptly. Do not attempt to continue cutting forcefully to avoid larger safety hazards.

Conclusion

After delving into how to cut stainless steel sheets and the related safety precautions, we have gained a deeper understanding of the professionalism and complexity of this process. Cutting stainless steel sheets not only requires suitable tools and techniques but also demands operators to possess a high level of safety awareness and meticulous work attitude. Only by ensuring safety can we better accomplish cutting tasks, improve work efficiency, and safeguard the physical health of operators.

As a professional stainless steel export trading company, Huaxiao Metal is committed to providing customers with high-quality products and services. Located in Shanghai, China, we have over 15 years of industry experience, which has enabled us to accumulate rich expertise and practical experience. Our factory is equipped with multiple advanced production lines, enabling us to flexibly meet various demands for stainless steel products, including sheets, coils, pipes, bars, strips, wires, and more. Wherever you are and whatever type of stainless steel products you need, Huaxiao Metal can provide you with satisfactory solutions.