How to Get Scratches off Stainless Steel?

Are you tired of seeing scratches on your beautiful stainless steel appliances or fixtures? Whether it’s from daily wear and tear or accidental mishaps, scratches can be unsightly and detract from the overall aesthetic of your space. But don’t worry, there are ways to get those pesky scratches out and restore your stainless steel to its former glory.

With the right tools and techniques, getting rid of those pesky scratches is easier than you think.

how to get scratches off stainless steel?

To get scratches off stainless steel, you can use a non-abrasive cleaner, like baking soda or vinegar, and a soft cloth to gently rub the scratches in a circular motion. For deeper scratches, you can use a stainless steel scratch removal kit or sandpaper to buff out the scratch. Always remember to follow the grain of the stainless steel and test any method on a small, inconspicuous area first.

In this article, we’ll look at different ways to address scratches of stainless steel surfaces, from minor scuffs to deeper chisels, from simple home remedies to professional-grade solutions. Whether you’re dealing with scratches on kitchen appliances, stainless steel furniture, or industrial equipment, we can help you. Next, let’s dive into how to get scratches off stainless steel and restore your products to their former glory.

Table of Contents

We will answer your email in 24 hours!

What causes scratches on stainless steel?

Stainless steel is a popular material for various applications, thanks to its durability, resistance to corrosion, and appealing aesthetic qualities. However, even this tough material is susceptible to scratches under certain conditions.

Scratches on stainless steel can be caused by a variety of factors, including mechanical damage from abrasive surfaces, exposure to corrosive substances, and improper cleaning techniques. When stainless steel is exposed to abrasive surfaces, such as metal scrubbers or rough cleaning tools, it can lead to scratches on the surface of the material. Similarly, exposure to corrosive substances, such as chemicals or salts, can also lead to scratches on the material.

Improper cleaning techniques can also be a factor in causing scratches on stainless steel. Using harsh chemicals or cleaning tools can damage the surface of the material, leading to scratches. To avoid scratches, it is recommended to use gentle cleaning agents and soft cloths or sponges to clean stainless steel.

In addition to external factors, the structure and composition of stainless steel itself can also contribute to the likelihood of scratches. For example, stainless steel with a high carbon content is more susceptible to scratches than stainless steel with a lower carbon content. Additionally, the surface finish of the stainless steel, such as a mirror or satin finish, can also affect its susceptibility to scratches.

Best way to get scratches off stainless steel

Home remedies

Stainless steel is a popular material used in many industries due to its durability and resistance to corrosion. However, scratches on stainless steel can diminish its aesthetic appeal and affect its functionality. As one of the leading stainless steel suppliers, we have some tips to help you restore your stainless steel to its original shine.

One of the easiest methods is to use a non-abrasive cleaner, such as a mixture of water and vinegar or baking soda. Apply the solution to a soft cloth and gently rub the scratched area in a circular motion until the scratch is no longer visible. For deeper scratches, you may need to use a commercial stainless steel cleaner that contains abrasive particles. Be sure to follow the instructions carefully and test the cleaner on an inconspicuous area first. Here are some simple and effective ways to get scratches off stainless steel:

The use of toothpaste to get scratches off stainless steel is a common home remedy. The particles of toothpaste fill the scratches, while the toothpaste contains abrasives and bleaching agents in its composition that act as a polish, thus reducing or removing scratches from the surface of stainless steel. In addition, toothpaste also has deodorizing, antiseptic, and cleaning properties to keep the surface of stainless steel clean and tidy.

It is important to note that toothpaste is only suitable for minor scratches and not for deep dents or chisels. In addition, when using toothpaste to remove scratches from stainless steel surfaces, care needs to be taken to use a gentle cloth and the right amount of force to avoid causing more scratches.

If home remedies do not solve the problem, it is recommended to seek professional help. Stainless steel suppliers can provide more specialized solutions such as professional polishes and machines. These solutions can effectively remove deeper scratches and restore luster and smoothness to the stainless steel surface.

The use of baking soda and water can get scratches off stainless steel surfaces. This is because baking soda is an alkaline substance that neutralizes acids, such as oxidized layers on the surface of stainless steel, thereby reducing the visibility of scratches. At the same time, the micro-particles of baking soda can act as a slight abrasive on the surface, helping to remove scratches. It should be noted that when using baking soda and water to remove scratches, choose a soft cotton cloth or sponge to gently wipe to avoid leaving more scratches on the stainless steel surface.

In addition, for deeper scratches, the effect of baking soda and water may be limited and other more specialized methods or tools will be needed to repair them. If you have stainless steel material purchasing needs, you can contact Huaxiao stainless steel suppliers for more information.

White vinegar is an acidic substance that has the effect of dissolving metals and can therefore be used to get scratches off the surface of stainless steel. The surface of stainless steel is usually composed of a chromium oxide layer and ferrite, and the chromium oxide layer has the property of corrosion resistance, which can protect the surface of stainless steel from oxidation corrosion. And scratches will destroy the chromium oxide layer, making the stainless steel surface more susceptible to oxidation corrosion.

The acetic acid in white vinegar can react with the oxide layer and dissolve away some of the oxide layers, thus leaving the ferrite at the scratch exposed and forming a more uniform surface. Of course, it should be noted that white vinegar may also cause damage to stainless steel if used improperly, so it needs to be tested before use. In addition, when using white vinegar to remove stainless steel scratches, it is best to choose a high-quality stainless steel material that can be obtained from reliable stainless steel suppliers.

In conclusion, Whether you choose a simple household remedy or a professional-grade solution, always follow the instructions carefully and test the method on an inconspicuous area first. And if all else fails, don’t hesitate to reach out to stainless steel suppliers or professional repair companies for expert assistance.

Techniques for Removing Scratches from Stainless Steel

Using Non-Abrasive Cleaners: For minor scratches, use products like Comet or Revere Stainless Steel and Copper Cleaner. These non-abrasive cleaners are available as dry powders that you mix with water or as cream-based formulas that gently buff the surface. Many appliance manufacturers also offer their own specially formulated cleaners available at home improvement stores.

Sanding for Deeper Scratches: For more significant scratches, wet sandpaper is recommended. Sandpaper comes in various grits, so it’s best to consult your appliance manufacturer to determine the most suitable type for your stainless steel.

How do you remove gouges from stainless steel?

Removing gouges from stainless steel requires care to avoid damaging the surface further. Here’s a step-by-step guide on how to address and potentially remove gouges from stainless steel surfaces:

Materials Needed:

- Fine-grit sandpaper (start with 400-grit and move up to 800 or 1000-grit)

- Stainless steel cleaner or degreaser

- Non-abrasive sponge or soft cloth

- Steel wool (optional, for deeper gouges)

- Polishing compound or stainless steel polish

- Microfiber cloth

Step-by-Step Process:

Clean the Surface:

- Before starting, clean the area around the gouge with a stainless steel cleaner or degreaser to remove any dirt, grease, or debris. This will help you see the gouge clearly and prevent further scratching during the repair process.

Assess the Depth of the Gouge:

- Determine how deep the gouge is. If it’s a light scratch, you may be able to remove it with just a fine-grit sandpaper or a polishing compound. For deeper gouges, more intensive sanding may be required.

Start with Fine-Grit Sandpaper:

- Begin with 400-grit sandpaper if the gouge is relatively deep. If it’s shallow, start with a finer grit like 600 or 800. Wrap the sandpaper around a sanding block or use it with a soft, flat surface for even pressure.

- Sand the gouge gently, always in the direction of the grain of the stainless steel. Avoid sanding in circles or across the grain, as this can create noticeable scratches.

Move to Finer Grits:

- Gradually move to finer grits (e.g., 800 to 1000-grit) to smooth the area and blend it with the surrounding surface. Continue sanding in the direction of the grain until the gouge is less visible or has been removed.

Use Steel Wool for Deeper Gouges (Optional):

- For deeper gouges, you might need to use fine-grade steel wool (0000 grade). Rub gently along the grain of the stainless steel to remove the gouge. Follow up with finer sandpaper to smooth the surface.

Polish the Area:

- Once the gouge is removed or minimized, apply a polishing compound or stainless steel polish to the area. Use a microfiber cloth to buff the surface, restoring the shine and blending the repaired area with the rest of the surface.

Final Cleaning:

- Clean the entire area again with a stainless steel cleaner to remove any residue from sanding and polishing.

Additional Tips:

- Test in an Inconspicuous Area: Before sanding or using any abrasive material on the stainless steel, it’s a good idea to test in a less visible area to ensure you don’t accidentally damage the surface.

- Avoid Coarse Sandpaper: Using sandpaper that is too coarse can create scratches that are more difficult to remove, so always start with the finest grit possible.

- Work Gradually: Don’t rush the process. Gradually sanding and polishing will give you the best results with minimal damage to the surrounding area.

professional-grade solutions

Mechanical polishing is a common method to get scratches off stainless steel surfaces and is usually provided by professional stainless steel suppliers. In the mechanical polishing process, specialized equipment and tools are used to remove thin layers of the surface to eliminate scratches and other imperfections.

This process involves the use of a rotating grinding head that is placed under a certain amount of pressure on the stainless steel surface and then the head is moved along the steel surface until the desired finish is achieved. The use of different grinding heads allows you to control the roughness of the polish and the final surface finish.

Mechanical polishing is a relatively expensive method, but usually results in a very high surface quality and is suitable for the production of high-end stainless steel products. Stainless steel suppliers often offer this service to meet the high-quality surface finish needs of their customers.

Chemical polishing is a technique that uses a chemical reaction to get scratches off stainless steel. Its basic principle is to convert the metal oxides on the surface of the material into water-soluble compounds through chemical reactions, and subsequently wash these compounds away by rinsing with water to achieve a polishing effect. General chemical polishing using chemical reagents are mainly acid or alkaline solutions, commonly used acidic solutions such as nitric acid, sulfuric acid, hydrochloric acid, etc., and alkaline solutions such as potassium hydroxide, sodium hydroxide, etc.. These reagents can react with the oxides on the metal surface, converting the oxides into soluble compounds. Since the chemical polishing process requires the use of chemical reagents, it is important to pay attention to safe operation in order to avoid causing harm to the environment and personnel.

Grinding is a common method to get scratches off stainless steel by abrading the surface to remove the scratches and make the surface smoother.

First, you need to choose the right abrasive and abrasive tools. The abrasive is usually some abrasive powder, such as aluminum oxide, silica gel, silicon carbide, etc. They have different particle sizes, and you can choose the right particle size according to your needs. The abrasive tool can be sandpaper, abrasive cloth, abrasive wheel, etc.

Next, the abrasive needs to be evenly applied to the stainless steel surface, and then use the abrasive tool to rub. During the grinding process, it is necessary to maintain an even strength and direction in order to avoid further scratching the stainless steel surface. Attention also needs to be paid to the particle size of the abrasive and the abrasive strength to avoid excessive damage to the surface.

The grinding process may need to be carried out several times until the desired result is achieved. Finally, the abrasive residue on the stainless steel surface needs to be thoroughly cleaned with a cleaning cloth to avoid corrosion or damage to the surface.

Effect of scratches on stainless steel

Stainless steel is a corrosion-resistant and easy-to-clean material commonly used in kitchen appliances, medical equipment, architectural structures and other areas. However, if scratches exist on the surface of stainless steel, they can negatively affect the performance and use of stainless steel.

Scratches can damage the protective layer on the surface of stainless steel, allowing potentially corrosive media (such as water, acid, salt, etc.) to enter the tiny cracks in the surface of stainless steel, leading to rust and corrosion.

Scratches may also affect the cleanliness and hygiene of the stainless steel surface. Bacteria and dirt in scratches are more likely to hide and difficult to clean, which may pose a potential health risk.

Scratches may affect the appearance of stainless steel. For those applications that require a high level of appearance (e.g. architectural structures, furniture, etc.), scratches may reduce their aesthetics and value.

In summary, scratches can have an impact on the performance and appearance of stainless steel. Therefore, when the surface of stainless steel has been scratched, please use the measures mentioned before to get scratches off stainless steel products in a timely manner, shallow scratches can be removed from stainless steel at home by yourself, for deep scratches please seek professional and experienced stainless steel suppliers to solve. With these methods, you can maintain the beauty and performance of your stainless steel surface and extend its life.

How to prevent scratches on stainless steel?

When buying stainless steel products, you can consult with stainless steel suppliers and choose stainless steel materials with high scratch resistance, such as 316L and other high hardness, high corrosion resistance stainless steel materials to reduce the generation of surface scratches.

When cleaning and maintaining stainless steel surfaces, avoid using cleaners that are scratchy, abrasive or contain abrasives. You can use a soft cloth or sponge with a special stainless steel cleaner.

Stainless steel surfaces are susceptible to impact and friction from external objects, so avoid scraping or hitting objects on the surface. When moving or handling stainless steel products, care should be taken to hold and place them gently to avoid impact and scraping.

For long-term use of stainless steel products, regular maintenance and care is required to extend their service life and maintain the appearance of beautiful. Regular cleaning and waxing can reduce the generation of surface scratches.

conclusion

In conclusion, understanding how to remove scratches from stainless steel is essential for maintaining both its aesthetics and functionality. It’s crucial to consider factors like the depth and type of scratches when choosing the appropriate method. Regular maintenance and preventive measures are equally vital for preserving stainless steel’s appearance and prolonging its lifespan.

We encourage readers to learn and apply these techniques, ensuring that stainless steel remains in top condition. If you encounter challenges in maintaining stainless steel, don’t hesitate to consult stainless steel suppliers. They can offer valuable advice and solutions to help you keep stainless steel looking its best.

Duplex Steel 2205 Coils: Understanding the Applications and Uses

Duplex Steel 2205 Coils: Understanding the Applications and Uses Duplex Steel 2205 Coils Duplex Steel 2205 coils are widely used duplex stainless steel alloy known

What Are Steel Coils Used For ?

What are steel coils used for? stainless steel coils supplier in China Steel has been at the core of industrial development for centuries, and steel coils play

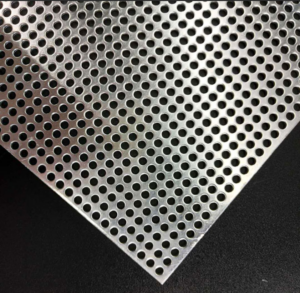

Top 10 Applications of Perforated Metal in Architectural Projects

Top 10 Applications of Perforated Metal in Architectural Projects perforated metal (stainless steel sheet) Perforated metal has long been a staple in industrial design, but

Guide to Stainless Steel Pipe Rolling: Process, Benefits, and Applications

Guide to Stainless Steel Pipe Rolling: Process, Benefits, and Applications stainless steel pipe What is Stainless steel pipe rolling? Stainless steel pipe rolling is a

How Are Stainless Steel Welded Tubes Made?

How Are Stainless Steel Welded Tubes Made? stainless steel welded tubes Stainless steel welded tubes are a vital component in various industries, including construction, automotive,

Comparing Stainless Steel Sheets: 409 vs. 410 vs. 410S vs. 420 vs. 430 vs. 440 vs. 446

Comparing Stainless Steel Sheets: 409 vs. 410 vs. 410S vs. 420 vs. 430 vs. 440 vs. 446 Each stainless steel sheet has its own unique