Is Stainless Steel Recyclable?

Is stainless steel really recyclable? This is a question that many people may have when they consider using stainless steel products. Stainless steel is known for its durability, strength, and resistance to corrosion, making it a popular choice for a wide range of applications. However, as concerns about environmental sustainability and resource conservation continue to grow, recycle stainless steel has become an increasingly important issue.

is stainless steel recyclable?

Stainless steel is indeed recyclable, and it is a highly valuable material in the recycling industry. The recyclability of stainless steel is a testament to its sustainability and environmental benefits.

Stainless steel recycling involves collecting used stainless steel products, such as appliances, cookware, construction materials, and industrial equipment. These items are then processed at recycling centers, where they are cleaned, sorted, and melted down to extract the raw stainless steel material. This material can be used to manufacture new stainless steel products.

The process of recycling stainless steel has several advantages. It conserves natural resources by reducing the need for mining and refining new raw materials. It also saves energy, as recycling stainless steel consumes less energy compared to producing it from scratch. Moreover, recycling stainless steel helps reduce landfill waste and minimizes the environmental footprint associated with its production.

While stainless steel is generally considered to be a highly recyclable material, there are some factors that can impact its recyclability, such as the presence of certain alloys and contaminants. In this article, we will explore the recyclability of stainless steel, the challenges and opportunities that exist in the recycling process, and the steps that stainless steel suppliers and consumers can take to ensure that this valuable material is used and reused in the most sustainable way possible.

table of contents

Feasibility

of recycling stainless steel

Opportunities

and challenges of recycle stainless steel

How

to recycle stainless steel?

Can

all types of stainless steel be recycled?

What

happens to stainless steel when it is not recycled?

How

can we promote the recycling of stainless steel products?

Feasibility of recycle stainless steel

Stainless steel is a highly recyclable material due to its unique chemical and physical properties. Stainless steel suppliers and manufacturers recognize the importance of sustainability and have made great strides in developing closed-loop recycling systems. These systems involve collecting scrap stainless steel from various sources, including industrial waste, consumer products, and end-of-life items, and melting them down to produce new stainless steel products.

The recycling process for stainless steel is energy-efficient and requires fewer resources than producing new stainless steel from raw materials. This is because stainless steel is a metal alloy composed of iron, chromium, and other elements, including nickel and molybdenum. The high value of these materials makes it economically viable to recycle stainless steel.

Recycle stainless steel also has significant environmental benefits. It reduces the demand for mining and refining raw materials, conserves energy, and reduces greenhouse gas emissions. Stainless steel can be recycled repeatedly without losing its properties, making it a sustainable choice for a wide range of applications.

Stainless steel suppliers and manufacturers play a critical role in promoting the recyclability of stainless steel. By incorporating recycled content into new stainless steel products, they help to reduce the environmental impact of their operations and promote the circular economy. Overall, the recycling of stainless steel is a sustainable and economically viable solution that benefits both the environment and industry.

Opportunities and challenges of recycle stainless steel

Opportunities of recycling stainless steel

reduce the demand for natural resources

Recycling stainless steel can reduce the manufacture of new stainless steel, thus reducing the demand for natural resources and contributing to environmental protection.

reduce costs

Recycling stainless steel is less costly than mining and refining new stainless steel because no additional energy and resources are required in the recycling process.

improve the efficiency of the circular economy

Recycling stainless steel is in line with the concept of circular economy, which can maximize the use of resources and reduce waste.

challenges of recycling stainless steel

distinguishing different types of stainless steel

When recycle stainless steel, different types of stainless steel may be mixed together, which can affect the efficiency and quality of recycling.

Packaging and disposal of unregulated waste

The waste from recycled stainless steel may be packaged and disposed of in an unregulated manner, leading to contamination and environmental problems.

High cost of recycled stainless steel

Although recycled stainless steel is less expensive than manufacturing new stainless steel, the cost of the recycling process is still high and requires technical and financial support.

How to recycle stainless steel?

Recycling stainless steel is a complex process that involves several steps:

collection and sorting

For the process of recycling stainless steel, the first step is collection and sorting. Scrap stainless steel usually originates from the construction, manufacturing and dismantling industries, such as scrap steel, pipes, equipment and household items. Collectors need to sort the scrap stainless steel by type, size and purity for subsequent processing.

When sorting, collectors use different tools and equipment, such as magnets, weighers and gloves, to ensure that scrap stainless steel is properly identified and sorted. Some stainless steel collectors also obtain high quality scrap stainless steel materials for reuse by recycling scrap equipment and parts, etc.

Cutting and crushing

Cutting and crushing is one of the important steps in the stainless steel recycling process. In this step, recyclers use professional machinery and equipment to process the scrap stainless steel material, cutting it into the right size or crushing it into small, uniform pieces. This is done to facilitate subsequent processing and recycling to improve the recovery rate and utilization of stainless steel. In the process of cutting and crushing, attention needs to be paid to safety and environmental protection, and effective measures are taken to prevent pollution and damage to the scrap stainless steel materials to ensure a smooth recycling process.

Magnetic separation and screening

Stainless steel suppliers need to use magnetic separation and screening techniques to separate scrap stainless steel from other materials. Since scrap stainless steel may be mixed with other materials, such as iron, copper, and aluminum, magnetic separation separates out stainless steel containing magnetic impurities such as iron. Sieving, on the other hand, separates scrap stainless steel of different sizes and shapes for the next step of processing.

remelting and refining

In the remelting and refining step, the stainless steel suppliers feed the magnetically sorted and screened stainless steel scrap into a high-temperature furnace for melting. After melting, the stainless steel liquid is removed and other metallic elements are added to control its composition. To ensure the purity of the stainless steel, the recycler also needs to refine it. This usually includes the use of techniques such as gas blowing or vacuum furnaces to remove impurities from the stainless steel and improve its purity. Ultimately, after remelting and refining, the scrap stainless steel can be used again to manufacture a variety of stainless steel products for sustainable recycling.

Processing and manufacturing

After the refining process, the purified recycled stainless steel can be processed and manufactured into various stainless steel products, such as furniture, kitchen utensils, medical equipment, ships, and building materials. The processing and manufacturing of recycled stainless steel products follow similar procedures as those of newly-produced stainless steel products. Recycled stainless steel can be melted and formed into different shapes through casting, rolling, and extrusion. It can also be welded, machined, and polished like newly-produced stainless steel. The use of recycled stainless steel in manufacturing not only reduces the demand for newly-produced stainless steel but also reduces the environmental impact of stainless steel production.

To overcome these challenges, it is essential to establish efficient collection systems, invest in innovative technologies, and promote sustainable production and consumption patterns. Collaboration between stakeholders, including stainless steel suppliers, recyclers, and policymakers, is also crucial in promoting a circular economy for stainless steel.

Can all types of stainless steel be recycled?

When talking about recycle stainless steel, one needs to be aware of the type and composition of the stainless steel. Some stainless steel alloys may contain elements or additives that are difficult to recycle, such as aluminum, titanium, and niobium. The presence of these elements may affect the cost and feasibility of recycling stainless steel.

In general, most stainless steels can be recycled and reused, such as the most common types of 304 and 316 stainless steels. These stainless steels typically contain high purity chromium and nickel, which can be effectively recovered during remelting and refining.

However, some stainless steels of special alloys may contain significant amounts of other metals such as tungsten, molybdenum, and cobalt, which are more costly to recover and may affect the economics of the overall recovery process. Therefore, stainless steels of these special alloys may not be suitable for recycling.

Overall, while there are some limitations to the recyclability of certain types of stainless steel, the vast majority of stainless steel products can be recycled and reused in new applications. With proper management and recycling practices in place, stainless steel suppliers can help to ensure that this valuable material is utilized to its fullest potential and that waste is minimized.

What happens to stainless steel when it is not recycled?

When stainless steel is not recycled, it is typically discarded as waste and may end up in landfills or the natural environment. Stainless steel is a durable material and does not easily degrade, so it can persist in the environment for a long time, potentially causing harm to wildlife and ecosystems. In addition, the resources used to produce stainless steel, such as iron ore, chromium, and nickel, are finite and non-renewable. When stainless steel is not recycled, these valuable resources are wasted, and the production of new stainless steel must rely on extracting new resources from the earth, which can have environmental impacts. Stainless steel suppliers may also face supply chain disruptions and price volatility if the availability of these resources is uncertain. Therefore, recycling stainless steel is not only beneficial for the environment but also for the economy and resource sustainability.

Stainless steel suppliers and consumers can reduce the waste of resources by recycling stainless steel, and the impact on the environment and ecosystem will be reduced.

BENEFITS OF RECYCLING STAINLESS STEEL

Energy Savings: Recycling stainless steel uses significantly less energy compared to producing new steel from raw materials. It reduces the energy needed for extraction, refining, and manufacturing.

Resource Conservation: Stainless steel is made from materials like iron, nickel, and chromium. Recycling conserves these finite natural resources, reducing the need for mining.

Cost Efficiency: Recycled stainless steel is often cheaper to process and purchase than newly mined steel. Manufacturers can save on raw material costs, which makes recycled steel economically attractive.

Environmental Protection: By recycling stainless steel, the industry reduces the need for landfills and minimizes environmental damage caused by mining and refining processes. It helps to lower greenhouse gas emissions and water pollution.

High Recyclability: Stainless steel can be recycled infinitely without losing its quality or strength, making it a highly sustainable material. This durability ensures that recycled steel remains of high utility.

Reduction in CO2 Emissions: The recycling process releases far fewer carbon emissions compared to steel production from virgin materials, contributing to the fight against climate change.

Circular Economy Support: Recycling stainless steel supports a circular economy by ensuring that the material remains in use for longer periods, contributing to a more sustainable and efficient industrial cycle.

How can we promote recycle stainless steel?

The recycling of stainless steel products is essential for sustainable development and protection of the environment. To promote the recycling of stainless steel products, different people and organizations can do the following tips:

Design for recyclability: Manufacturers can design recyclable stainless steel products using removable parts and standardized connections for subsequent recycling and reuse.

Use recycled materials: Manufacturers can use recycled stainless steel materials to manufacture products, which not only saves raw materials, but also reduces production costs and environmental impact.

Provide recycling services: Manufacturers can provide recycling services to collect and recycle discarded stainless steel products, which can then be reprocessed into new products or recycled.

Cooperate with recycling companies: Manufacturers can cooperate with recycling companies to establish stable recycling channels and ensure the quality and stable supply of recycled materials.

Promote recycling awareness: Manufacturers can raise public awareness of recycled stainless steel by promoting recycling awareness and encouraging consumers to recycle stainless steel products.

Provide recycling services: Stainless steel suppliers can consider providing recycling services to collect and recycle stainless steel materials. This will ensure the sustainability of recycled stainless steel materials and provide convenience for customers.

Optimize product design: Stainless steel suppliers can optimize product design to reduce waste and material waste. For example, designing more durable products can extend service life and reduce the amount of stainless steel that is discarded.

Use sustainable materials: Stainless steel suppliers can consider using sustainable materials, such as recycled stainless steel, to reduce the consumption of natural resources.

Promote recycling: Stainless steel suppliers can promote the importance of recycling through various means, such as marking the product packaging with a recycling logo and providing recycling guidelines to increase public awareness of recycled stainless steel.

Separate recycling: Separate used stainless steel from other trash and place it in recycling bins or recycling bags. This will help recyclers find and dispose of scrap stainless steel more easily.

Choose recyclable stainless steel products: When buying stainless steel products, try to choose recyclable products, such as stainless steel products labeled “recyclable” or “green products”.

Extend the life of stainless steel: By properly using and maintaining stainless steel products and extending their life, you can reduce the production of used stainless steel, thus reducing the impact on the environment.

Participate in community recycling programs: Participate in community recycling programs to help recyclers separate scrap stainless steel from other recyclables and ensure that these scrap items are properly disposed of and recycled.

Focus on the sustainability of stainless steel suppliers: Focus on the sustainability of stainless steel suppliers and select those that actively promote recycling and environmental protection, which can indirectly promote the recycling of stainless steel.

Provide convenient recycling facilities: Recycling facilities can provide recycling bins or other recycling facilities in communities, factories, construction sites, etc. to make it easy for people to recycle scrap stainless steel.

Provide recycling information: Recycling facilities can provide information about recycling stainless steel, such as the location of recycling bins, recycling guidelines, recycling processes, etc., to encourage people to actively participate in recycling actions.

Create economic incentives: Recycling facilities can encourage people to recycle stainless steel by providing economic incentives such as rewards, cash rebates, discounts, etc.

Expand recycling channels: Recycling facilities can expand recycling channels and improve recycling efficiency by partnering with local recycling centers, metal recyclers and stainless steel suppliers.

Optimize the recycling process: Recycling facilities can improve the efficiency and quality of recycling by optimizing the recycling process with technologies such as automatic sorting, automatic crushing, and automatic screening.

Establishing relevant laws and regulations: The government can establish laws and regulations that require manufacturers to use recyclable materials, including stainless steel, in the production process and require recycling facilities to be equipped with the necessary equipment and technology to improve the recycling rate.

Provide financial support: The government can provide financial support, including providing financial support and tax breaks, to encourage the construction and upgrading of recycling facilities and improve recycling technology.

Carry out publicity and education: The government can carry out publicity and education activities to increase public awareness and attention to recycling stainless steel and encourage residents to actively participate in recycling activities.

Establish a recycling system: The government can establish a recycling system, including recycling points and recycling centers, etc., to provide consumers with convenient and efficient recycling services, while also providing recyclers with better recycling resources.

Implementation of incentive mechanisms: The government can encourage enterprises and individuals to participate in recycling activities by setting up incentive mechanisms to improve the recycling rate and recycling quality.

Conclusion

Recycling stainless steel is not only good for the environment, it is also financially rewarding. There are challenges and opportunities in recycling stainless steel, but we can all play a part in recycling stainless steel. promoting the recycling of stainless steel products requires collaboration among stainless steel suppliers, manufacturers, consumers, recycling facilities, and government. By working together and prioritizing sustainable practices, we can ensure the long-term viability of stainless steel and protect the environment.

Duplex Steel 2205 Coils: Understanding the Applications and Uses

Duplex Steel 2205 Coils: Understanding the Applications and Uses Duplex Steel 2205 Coils Duplex Steel 2205 coils are widely used duplex stainless steel alloy known

What Are Steel Coils Used For ?

What are steel coils used for? stainless steel coils supplier in China Steel has been at the core of industrial development for centuries, and steel coils play

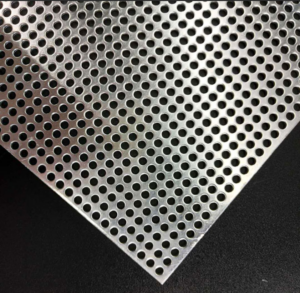

Top 10 Applications of Perforated Metal in Architectural Projects

Top 10 Applications of Perforated Metal in Architectural Projects perforated metal (stainless steel sheet) Perforated metal has long been a staple in industrial design, but

Guide to Stainless Steel Pipe Rolling: Process, Benefits, and Applications

Guide to Stainless Steel Pipe Rolling: Process, Benefits, and Applications stainless steel pipe What is Stainless steel pipe rolling? Stainless steel pipe rolling is a

How Are Stainless Steel Welded Tubes Made?

How Are Stainless Steel Welded Tubes Made? stainless steel welded tubes Stainless steel welded tubes are a vital component in various industries, including construction, automotive,

Comparing Stainless Steel Sheets: 409 vs. 410 vs. 410S vs. 420 vs. 430 vs. 440 vs. 446

Comparing Stainless Steel Sheets: 409 vs. 410 vs. 410S vs. 420 vs. 430 vs. 440 vs. 446 Each stainless steel sheet has its own unique