Huaxiao Metal

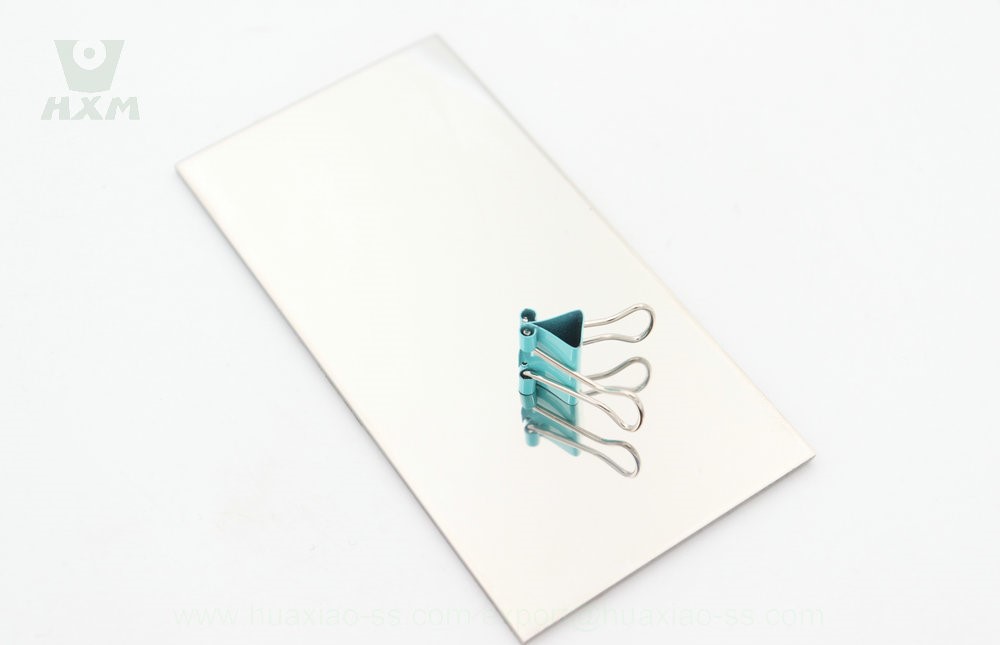

stainless steel BA finish

In the field of science, stainless steel is regarded as an important metallic material due to its excellent corrosion resistance, mechanical properties, and aesthetics. Among the various types of stainless steel, the BA stainless steel finish has gained a prominent position in decoration, construction, home appliances, and other fields because of its unique gloss and texture.

BA finish-stainless steel

Stainless steel BA finish (BA finish, Bright Annealing) refers to the process in which stainless steel cold-rolled sheets undergo bright annealing treatment followed by leveling. This process not only relieves internal stresses in the material but also achieves extremely high flatness and glossiness on the surface.

The stainless steel BA finish, formerly known as 6K, differs from the common 8K finish. The characteristic of the BA finish lies in its clarity and glossiness, comparable to the reflection effect of a copper mirror, providing users with a high-quality smooth, and bright appearance.

The processing technology of the stainless steel BA finish originated from JIS and national standards. Although there is no significant difference in the product standards of BA products compared to 2B in standards such as JIS, ASTM, and national standards, the BA finish exhibits unique glossiness and texture in practical applications.

The stainless steel BA finish sheet is suitable for various scenarios, especially in situations where shallow drawing processes or smooth and bright surface requirements are needed. Whether it’s decorative sheets in the construction industry, appearance parts in the home appliance industry, or other occasions that require a high-quality appearance, the BA finish stainless steel surface is an ideal choice.

technology of stainless steel BA finish

Bright annealing is a thermal metal treatment process primarily used to enhance the physical and mechanical properties of metal materials and achieve a highly polished surface. In the production process of stainless steel BA finish, bright annealing is a crucial step.

Bright annealing is typically carried out in a closed environment, where the heated metal is slowly cooled during the annealing process to at least below 500 degrees Celsius, followed by natural cooling. This method prevents oxidation and decarburization of the metal during heating and cooling, thus maintaining the surface smoothness and glossiness of the metal.

Furthermore, bright annealing is conducted under a protective atmosphere of mixed hydrogen and nitrogen gas. By strictly controlling the purity, residual oxygen, and dew point of the protective atmosphere inside the furnace, oxidation reactions on the metal surface can be further prevented. This treatment not only results in an oxide-free bright surface but also reduces the occurrence of chromium depletion on the metal surface, thereby improving its corrosion resistance.

glossy properties of stainless steel BA Finish

The glossiness of stainless steel BA finish products is one of its prominent features, which mainly manifests in the following three aspects:

1. Resolution:

- Definition: Resolution describes the clarity of imaging of objects on the surface of stainless steel. In simple terms, the higher the resolution, the clearer the reflection of objects on the surface.

- Impact: For applications that require high clarity, such as watch straps, curved mirrors, battery tubes, and car window frames, resolution is a very important indicator.

2. Whitening:

- Definition: Whitening is a whitish state of the stainless steel surface, usually manifested as overall surface roughness and chaotic light reflection, giving a milky white feeling.

- Characteristics: Whitening is mainly required for specific steel grades such as SUS430. For SUS304 steel grades, whitening is usually not specifically required due to its inherent silver-white color.

- Application: In applications that require high resolution, such as panel sheets, household appliance outer panels, beer caps, freezer shelves, draining boards, and bicycle mudguards, the requirement for whitening is correspondingly increased.

3. Coloration:

- Definition: Coloration refers to the state where the stainless steel surface appears brown or blue. This is usually caused by differences in the thickness of the surface oxide film, leading to differences in the wavelength of reflected light.

- Control: In general, coloration issues can be effectively controlled during normal production processes unless special accidents occur.

Material Characteristics of BA finish

Stainless steel BA finish products stand out in numerous applications due to their unique material characteristics. Below is a detailed analysis of its key features:

Lissajous Property: Lissajous is a unique attribute of the 430 steel grade, mainly manifested as surface irregularities after processing. This issue can be effectively addressed during production through specific material treatment methods. In practical applications, for occasions with minor processing requirements such as general utensils, household appliance outer panels, battery casings, dishwashers, etc., the requirements for Lissajous are relatively low; whereas for applications with higher processing requirements such as some precision components, the requirements for Lissajous are higher.

Bg Property (Polishing Quality): Compared to the common 2B surface treatment, BA products have superior polishing quality. When users have higher demands for polishing effects that cannot be met by 2B products, BA products are an ideal choice. It’s worth noting that for the SUS430 steel grade, its Bg property is slightly inferior to SUS304.

Grain Size (GS): The size of the grain size directly affects the physical properties of the material. A smaller grain size implies a softer material with better flexibility and deep drawing properties, but the surface after processing may be rougher with poor polishing performance. Conversely, with a larger grain size, the polishing performance is superior, and the surface after processing is smoother.

Soft Material: This is a material slightly softer than the JIS and national standards, with specific application scenarios and advantages.

Gold Sand Phenomenon: This is a unique phenomenon of the SUS430 steel grade. During the rolling process, if the surface of the strip is rough, it will become smooth after rolling. However, if adhesive tape is used and peeled off in certain situations, it may expose the color of the metal body, creating a gold sand effect. For stainless steel BA finish products, the gold sand phenomenon is usually not a problem. However, if customers have requirements for film covering, please specify it when ordering to increase the corresponding inspection steps.

Anisotropy: This refers to the difference in plastic deformation values (R values) caused by different orientations of the material in the rolling direction. This anisotropy affects the stamping performance of the material and may cause earing phenomena in deep drawing parts. To achieve good anisotropy, the rolling rate during cold rolling can be controlled.

Through a deeper understanding of the production process of BA stainless steel surfaces, we can see the combination of scientific principles and exquisite craftsmanship behind it, ensuring the high quality and outstanding performance of the final products. Whether in construction, home appliances, or other fields, BA stainless steel surfaces endow products with unparalleled beauty and sophistication due to their unique glossiness and texture.

If you are looking for high-quality BA stainless steel surface products, then Huaxiao Metal will be your trusted partner. As a professional Chinese stainless steel supplier specializing in exports, Huaxiao Metal is committed to providing customers with the finest products and services. In addition to stainless steel BA surface products, Huaxiao Metal also offers a wide range of stainless steel decorative panels and other exciting products waiting for your discovery. We have a rich product line and a professional sales team that can provide customized solutions according to your needs.

On the path of pursuing quality and innovation, Huaxiao Metal always walks hand in hand with you, creating a better future together!