Stainless steel brushed sheet, with its unique striped texture effect, has become a leader in stainless steel surface processing techniques, widely favored by various industries. When the matter surface of the stainless steel sheet undergoes fine brushing, the surface presents a delicate and orderly texture, which is visible to the naked eye but smooth to the touch. Compared to ordinary bright surface stainless steel, stainless steel brushed sheet is not only more wear-resistant but also exudes a higher level of sophistication.

After the brushing process is completed, we also apply a layer of protective film on the surface of the stainless steel sheet. The main purpose of this protective film is to prevent the stainless steel brushed sheet from being scratched during subsequent mechanical processing, ensuring the product is flawless. When the product is finally formed and installed, the protective film can be easily removed, revealing the stunning appearance of the brushed stainless steel sheet. These steps not only reflect our rigorous requirements for product quality but also demonstrate our relentless pursuit of beauty.

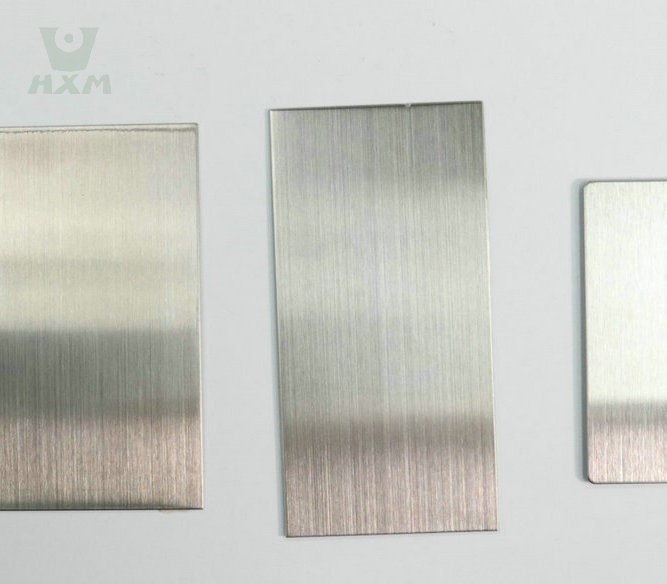

No.4 stainless steel brushed sheet

The NO.4 brushed surface is produced by fine grinding with 150~180 grit abrasives. It exhibits excellent glossiness, giving a sense of elegance and nobility. Its surface presents discontinuous coarse stripes, which are unique and layered, with finer stripes compared to NO.3.

Due to its unique texture and outstanding performance, the NO.4 brushed surface is widely used in various fields such as bathtubs, interior and exterior decoration materials, electrical appliances, kitchen equipment, and food equipment.

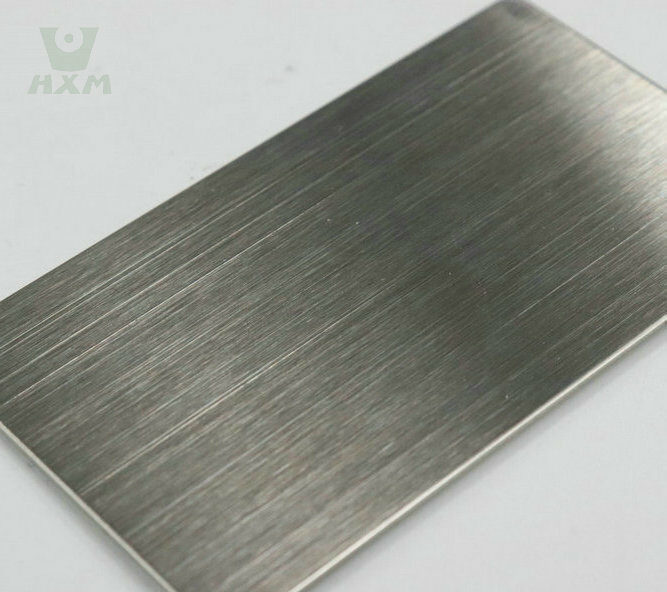

HL stainless steel brushed sheet

Through meticulous grinding, the HL stainless steel brushed sheet is carefully crafted into a continuous filamentous texture, showcasing its unique charm. In daily life, this surface is often affectionately referred to as “brushed” or “long grain” due to its distinctive texture and feel, and it is highly favored. In fact, the HL surface has become one of the most widely used surfaces in the stainless steel field, recognized by users for its beauty, durability, and practicality. Whether in the fields of construction, home furnishing, or industry, the HL stainless steel brushed surface brings convenience and beauty to people’s lives with its outstanding performance and wide range of applications.

dry grinding and oil grinding

The common HL processing equipment in the market is mainly divided into dry grinding and oil grinding. Dry grinding HL utilizes a set of abrasive rollers (usually 2 to 4) to directly grind the stainless steel surface, creating continuous longitudinal patterns. This processing method has relatively low costs and stable quality performance, making it widely used in decoration fields such as household appliances and crafts, meeting the needs of most ordinary users.

On the other hand, oil grinding HL is based on HL grinding and combined with the use of emulsion grinding fluid for processing. The oil grinding HL surface presents a delicate and glossy texture, while also possessing certain stain resistance capabilities. Due to the use of abrasive belt grinding in oil grinding HL, the manufacturing and consumable costs of equipment are relatively high, resulting in higher processing costs compared to dry grinding. However, its outstanding texture and durability make it more suitable for high-end applications, such as elevator panels and household appliance panels.

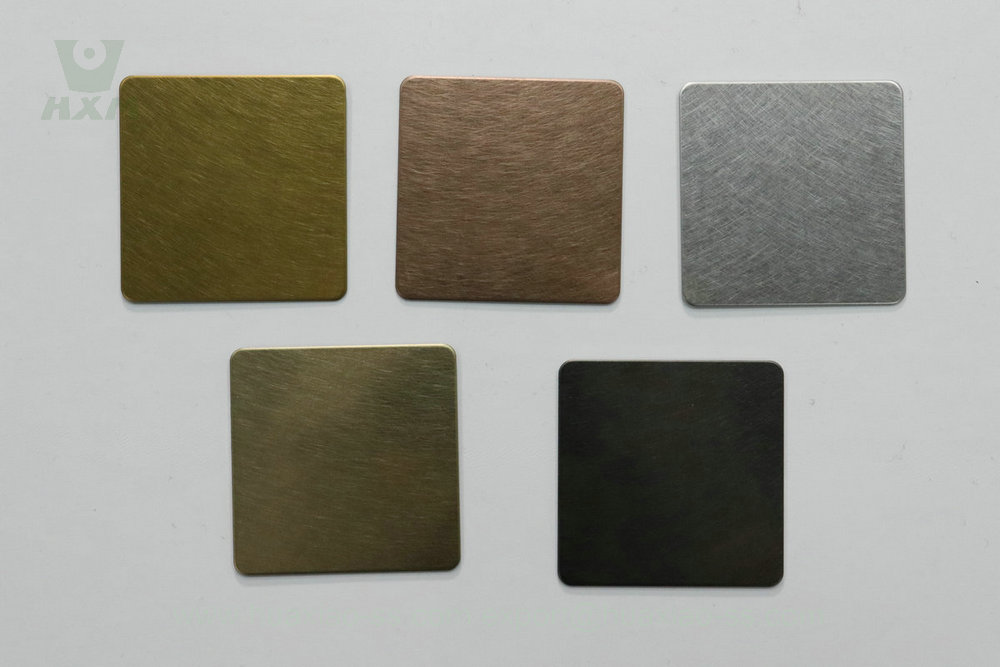

Stainless steel brushed sheet finish classification

The term “brushed sheet” generally refers to the collective term for surface texture processing, formerly known as “sanded plate.” The surface patterns include straight lines, random lines (cross lines), waves, and threads, among others.

brushed sheet with straight pattern

The brushed straight pattern is a surface condition achieved by mechanical friction, creating straight line patterns on the surface of stainless steel. This processing method not only effectively eliminates scratches on the surface of stainless steel plates but also provides a pleasing decorative effect. The patterns on brushed plates are divided into long-line patterns and short-line patterns, achieved by using scouring pads or stainless steel brushes to perform linear or short-line friction processing on the surface of the plates. Additionally, by adjusting the diameter of the steel brush, we can obtain patterns of different thickness, providing a more diverse visual experience for stainless steel plates.

cross-grain brushed sheet

The brushed random pattern, also known as the cross-grain pattern, presents a unique visual effect. From a distance, the surface is composed of intersecting circles of sand patterns, while up close, it reveals irregular, chaotic textures. This distinctive pattern is achieved by the grinding head oscillating irregularly in all directions, followed by electroplating treatment to create a matte surface finish. It’s worth mentioning that producing cross-grain finish requires extremely high standards, demanding exquisite craftsmanship and precise operation to ensure surface texture and aesthetics.

brushed sheet with wave pattern

The brushed wave pattern is created by the axial movement of grinding rollers on a brushing machine or buffing machine, resulting in a unique wavy pattern on the surface of stainless steel after brushing. This manufacturing process ingeniously utilizes mechanical motion to create a surface effect that is dynamic and three-dimensional.

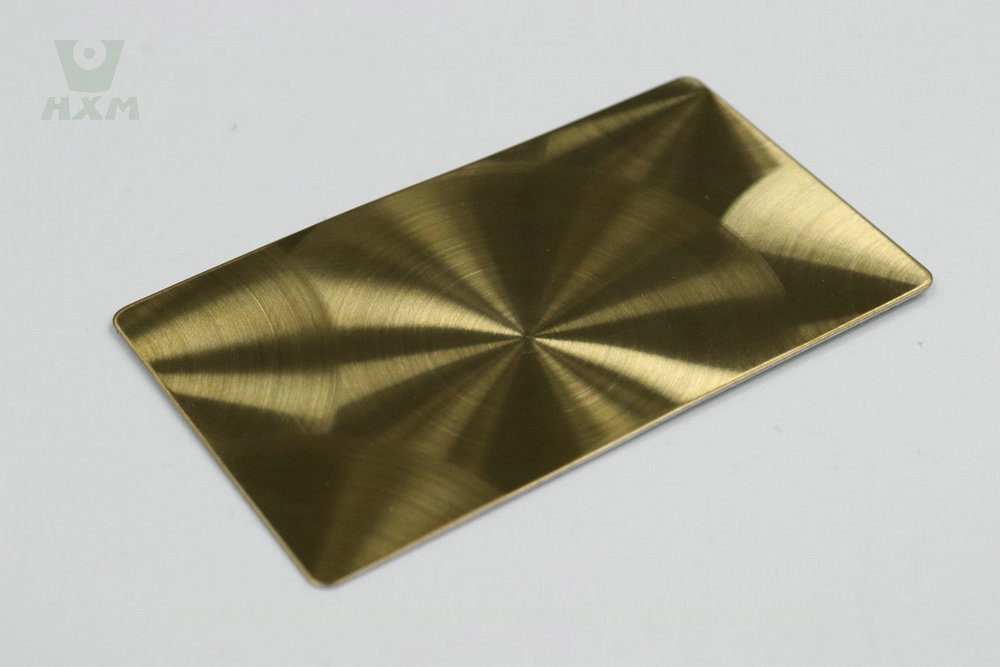

brushed sheet with spiral pattern

The production process of brushed spiral pattern is distinctive and unique. Firstly, a small electric motor with a circular felt pad mounted on its shaft is used, which is securely placed on a table at an angle of approximately 60° to the edge of the table. Next, a drag plate is made to hold the stainless steel sheet in place, and a strip of polyester film is affixed to the drag plate, extending along the edge of the plate to control the speed of the spiral. Subsequently, by rotating the felt pad and linearly moving the drag plate, identical width spiral patterns are precisely created on the surface of the stainless steel sheet, resulting in a unique decorative effect. This process combines rotational and linear movements, showcasing the ingenuity and precision of brushed spiral pattern production.

Thank you all for taking the time to read this article. I believe you now have a preliminary understanding of brushed stainless steel sheets. Brushing, as a technique, is not directly related to the type of stainless steel, meaning that regular steel sheets can also be transformed into brushed sheets. The quality of the brushed effect depends not only on the surface quality of the steel sheet itself but also on the equipment and auxiliary materials used in the brushing process. However, the most crucial factor is the skill of the operator. A skilled and experienced operator, even when faced with equipment of average performance, can create a surface appearance that is truly admirable.

If you are seeking a professional, experienced, and trustworthy supplier of brushed stainless steel sheets, Huaxiao Metal is the perfect choice for you. As a stainless steel supplier headquartered in Shanghai, China, Huaxiao Metal has over 15 years of experience in stainless steel exports. We offer not only brushed stainless steel sheets but also a variety of other types for you to choose from. We look forward to collaborating with you and creating a brilliant future together!