table of content

what is

stainless steel perforated sheet?

production process

of stainless steel perforated sheets

features

of stainless steel perforated sheet

application

of stainless steel perforated sheet

what is stainless steel perforated sheet?

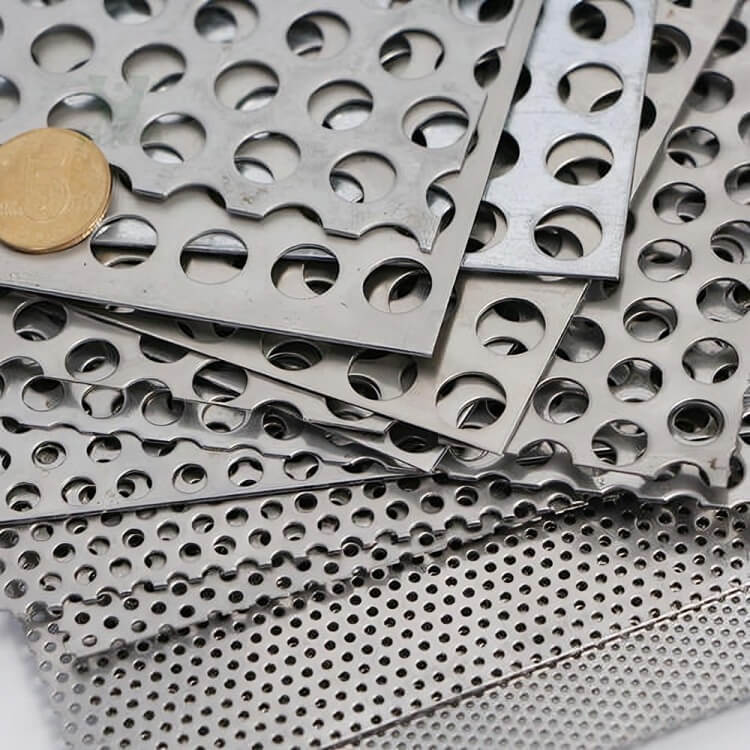

Stainless steel perforated sheets, also known as perforated metal or perforated screens, are specialized sheets made of stainless steel. These sheets are first cut to the appropriate size and then perforated on a CNC punch press to create the desired hole pattern.

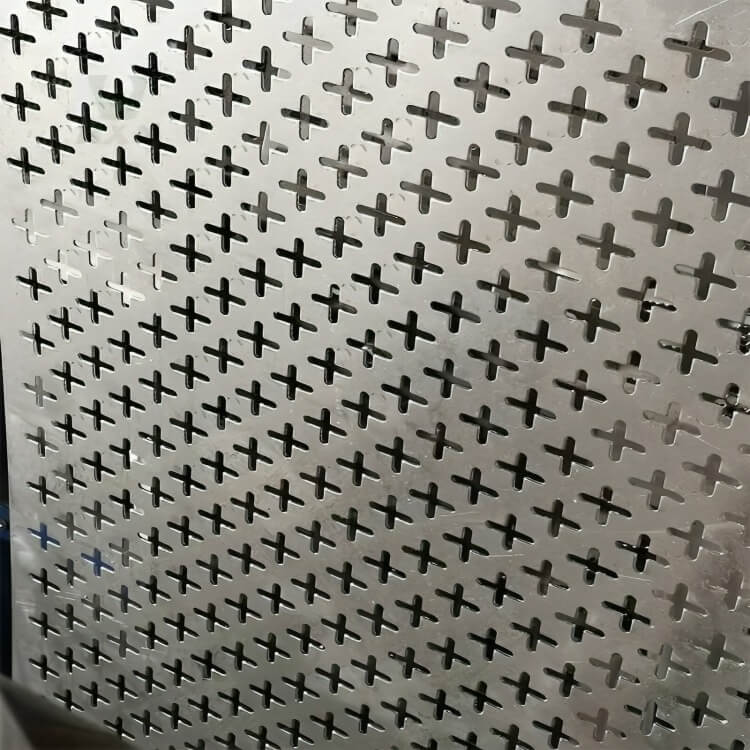

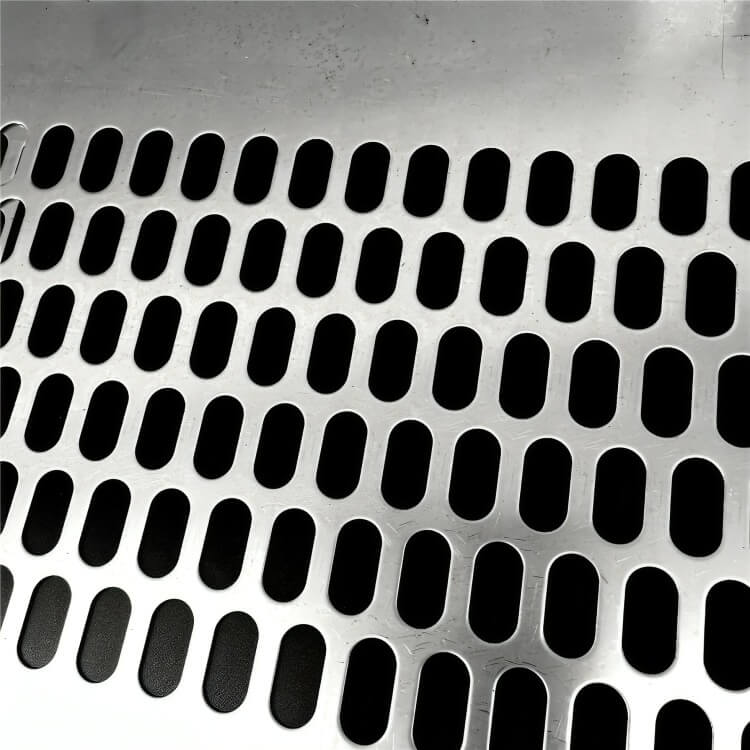

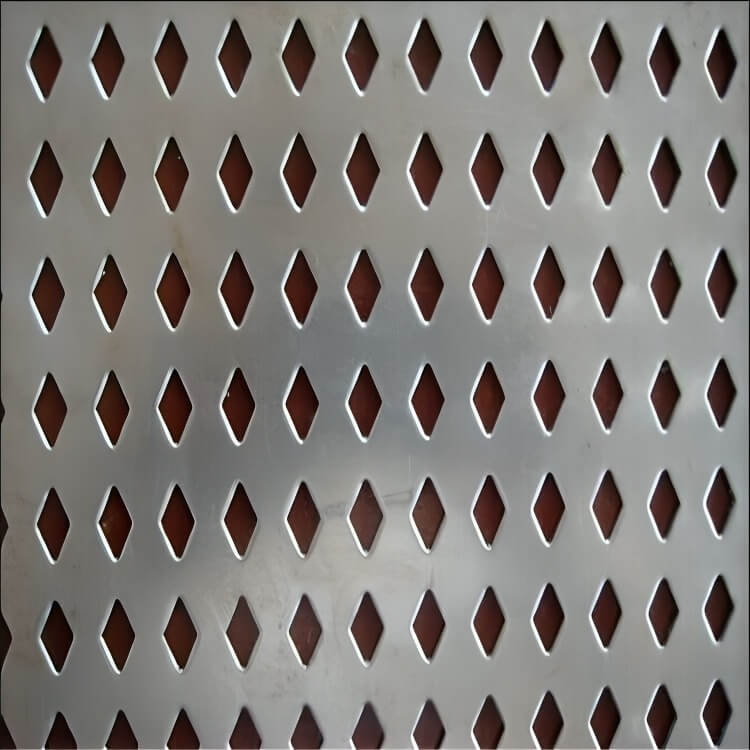

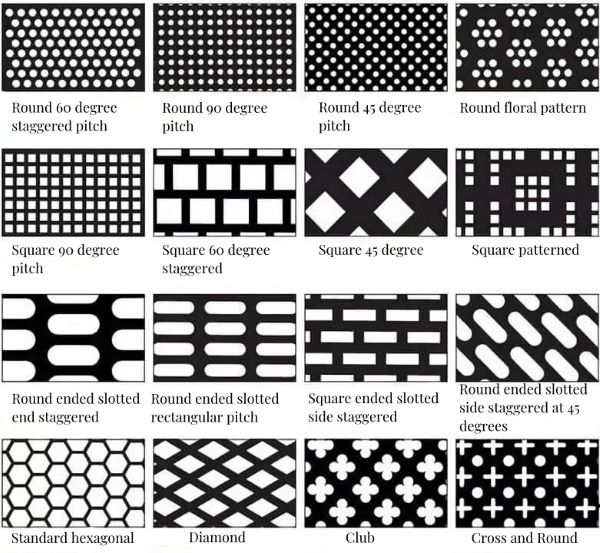

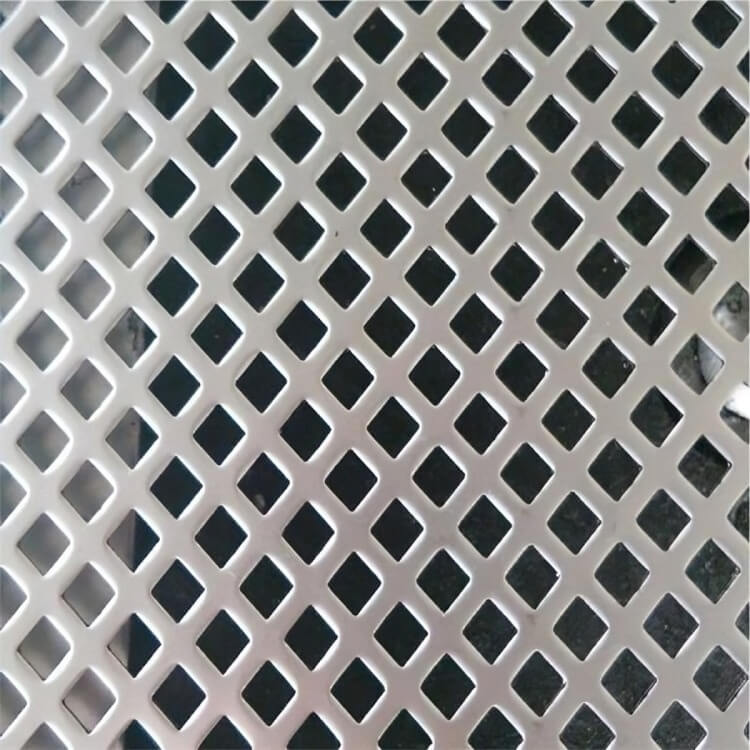

There are various designs for the hole patterns, including round holes, square holes, diamond-shaped holes, triangular holes, star-shaped holes, oblong holes, and more. These hole patterns not only have a visually appealing decorative effect but also serve multiple practical functions. For example, perforated sheets can act as sound-absorbing panels, effectively reducing noise; they can also serve as media for filtration and screening, widely used in food processing, brewing, acoustic diffusers, as well as interior design and architectural features, among other fields.

production process and technology of stainless steel perforated sheets

The production process and technology of stainless steel perforated sheets involve a comprehensive process that combines mechanical, chemical, and physical principles. Here are the main steps and techniques involved:

Material Preparation:

Firstly, high-quality stainless steel sheets are selected as raw materials. These stainless steel sheets should possess excellent corrosion resistance, mechanical properties, and aesthetics. Additionally, depending on the final application and requirements of the product, preprocessing of the stainless steel sheets may be necessary, such as cutting and deburring.

Design and Drafting:

Based on the customer’s requirements and the application scenarios of the product, designers will draw detailed perforation patterns and dimensions. These patterns and dimensions serve as crucial references during the subsequent production process.

Perforation Techniques:

Mechanical Perforation

Utilizing equipment such as punch presses, drilling machines, or milling machines, the stainless steel sheets are perforated using dies or cutting tools. This method is suitable for small-batch production and medium-thickness sheets.

Laser Perforation

High-energy laser beams are used to create holes on the stainless steel sheets. Laser perforation offers advantages such as high precision, efficiency, and contactless operation, making it suitable for high-precision and demanding perforation requirements.

Plasma Perforation

Plasma arcs are used as the heat source to melt the stainless steel sheets and create holes. Plasma perforation offers advantages such as high speed, efficiency, and low cost, making it suitable for large-scale production.

Post-processing: After perforation, stainless steel perforated sheets may require post-processing such as cleaning, deburring, and passivation to improve their appearance quality and performance.

These steps and techniques ensure the production of high-quality stainless steel perforated sheets that meet various application needs and quality standards.

features of stainless steel perforated sheets

corrosion resistance

Stainless steel perforated sheets are renowned for their excellent corrosion resistance, which allows them to maintain their original physical and chemical properties in harsh environmental conditions such as moisture, high temperature, and high salinity. They are less prone to rusting, fading, or deformation.

Ventilation & Light Transmission

Through precise perforation techniques, stainless steel perforated sheets can feature holes of various sizes, shapes, and arrangements on the sheet. These holes not only facilitate air circulation, reducing temperature and humidity differences indoors and outdoors but also allow light to pass through, creating a bright and comfortable indoor environment.

Acoustic performance

Stainless steel perforated sheets offer excellent sound insulation. The design of the holes effectively absorbs and reflects sound waves, reducing sound transmission and diffusion. This versatility makes stainless steel perforated sheets widely used in interior design and noise control applications.

application

architecture

In the field of architecture, stainless steel perforated panels are widely used in facades, sunshades, partitions, and other areas. Their ventilated and transparent design not only enhances the aesthetics of buildings but also improves indoor air quality and lighting effects. Moreover, through proper perforation design, the intensity and direction of indoor light can be adjusted to create different spatial atmospheres.

sound insulation

In places such as conference rooms, recording studios, and theaters where good sound insulation is required, stainless steel perforated panels can be used as decorative materials for walls or ceilings. Their unique perforation design not only beautifies the space but also effectively reduces noise interference, providing a more peaceful and comfortable environment.

With the continuous advancement of technology and the increasing pursuit of a better quality of life, stainless steel perforated panels will play a greater role in the future, bringing more convenience and beauty to our lives and work. Let us look forward to its more innovative applications in the future industrial and architectural fields.

If you are interested in stainless steel perforated sheets or have any questions or needs regarding metal materials, please feel free to contact us. As a professional stainless steel supplier, Huaxiao Metal is committed to providing customers with one-stop metal solutions. We have a rich product line and a professional technical team that can provide customized products and services according to your specific needs. Let’s work together to create a better future!

Inspired by our work?

Ready to discover quality stainless steel solutions tailored to your needs? Send us your inquiry today!