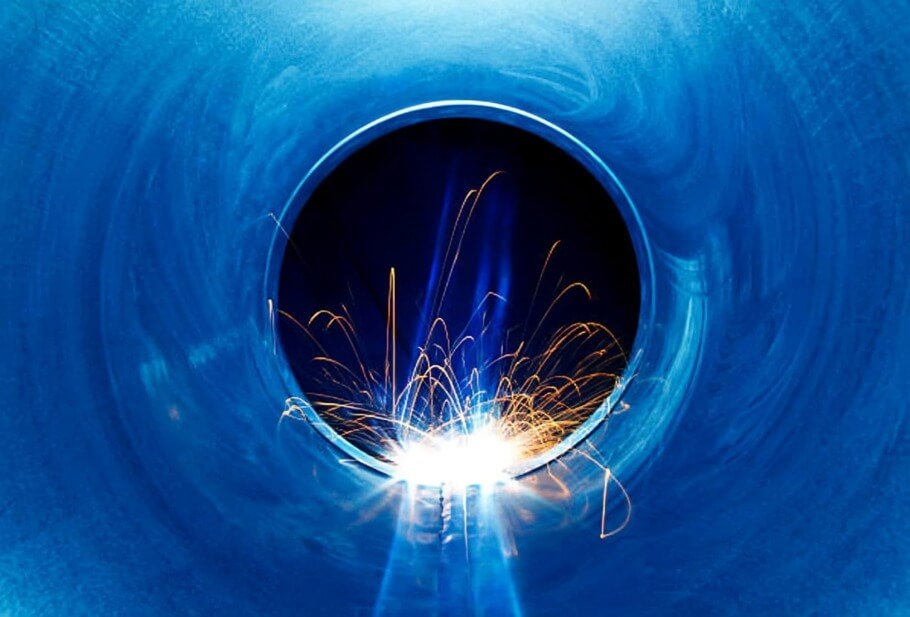

Stainless steel welded tube

A stainless steel welded tube is a type of tubing made by welding stainless steel sheets or strips that have been rolled and formed. It features high smoothness of inner and outer surfaces, good roundness, straightness, and uniform wall thickness, making it a high-precision, high-quality steel tube product. Stainless steel welded tubes not only inherit excellent properties of stainless steel such as corrosion resistance, high strength, and heat resistance, but also boast simple production processes, high production efficiency, and a wide range of specifications.

Therefore, they are widely used in industrial fields such as petroleum, chemical, medicine, food, light industry, machinery, and instrumentation for gas pipelines and mechanical structural components. Additionally, in decoration projects, furniture production, landscape engineering, and other applications, stainless steel welded tubes are also widely used due to their unique metallic texture and excellent corrosion resistance.

classification of stainless steel welded tube

Classification by Welding Technique:

- Automatic Welded Tubes: Utilizing automated welding equipment such as submerged arc welding and plasma welding to achieve efficient and precise welding processes.

- Manual Welded Tubes: Using handheld welding tools operated by workers, such as argon arc welding guns, for flexible and versatile welding operations.

Classification by Weld Seam Form:

- Straight Seam Welded Tubes: The Weld seam presents a straight line along the axis of the tube, featuring simple production processes and high production efficiency.

- Spiral Welded Tubes: Weld seam spirals around the tube, providing higher structural strength and compression resistance.

Classification by Application:

- General Welded Tubes: Suitable for general industrial purposes like gas and water transportation.

- Heat Exchanger Tubes, Condenser Tubes: Used in heat exchange equipment, possessing excellent thermal conductivity and corrosion resistance.

- Galvanized Welded Tubes: Surface coated with zinc to enhance corrosion resistance, suitable for outdoor environments or humid conditions.

- Oxygen Blowing Welded Tubes, Conduit Pipes: Specifically designed for certain industries such as oxygen-blowing operations and wire protection.

- Metric Welded Tubes, Roller Pipes, Deep Well Pump Tubes: Customized according to specific standards or applications to meet special requirements in different industries.

- Automotive Tubes, Transformer Tubes: Specialized for automotive manufacturing and transformer production, among other specific fields.

- Electric Welded Thin-Wall Tubes, Electric Welded Special-Shaped Tubes: Thin-walled or uniquely shaped tubes to meet the demands of special engineering projects.

features of welded tube

- Strong Customization and High Precision

- Flexible Size Customization: Welded stainless steel tubes can be customized according to user requirements to meet different size specifications.

- Precise Tolerance Range: Product precision is strictly controlled, generally within an accuracy of around 0.02 millimeters, meeting the demands of high-precision applications.

- Material Saving and Increased Production Efficiency

- Steel Saving: Customized dimensions can reduce material waste, improving material utilization.

- Reduced Processing Time: No need for additional processing, directly usable for machinery equipment, significantly reducing machining time.

- Excellent Surface Quality

- High Surface Smoothness: Even without polishing, the external surface generally achieves high smoothness.

- Excellent Polishing Effect: Welded stainless steel tubes’ polished surface exhibits higher brightness, enhancing product aesthetics.

- Superior Comprehensive Performance

- Strong Pressure Bearing Capacity: Cold-rolled welded stainless steel tubes have excellent comprehensive performance and can withstand high pressure.

- Good Machinability: Cold bending, expanding, flattening without cracking or wrinkling, suitable for various complex deformations and mechanical processing.

- Wide Range of Applications

- Mechanical Manufacturing: Suitable for manufacturing machinery structures, hydraulic equipment, etc.

- Fluid Transmission: Demonstrates economy and aesthetics in medium to low-pressure fluid applications.

- Economy and Practicality

- High Cost-Effectiveness: When the wall thickness is moderate, the investment-output ratio is the most economical.

- Advantages and Disadvantages Determined by Process: Its characteristics of high precision and uniform wall thickness give it significant advantages in specific applications.

formula

The weight of the welded tube in kg/m = (Od – Wt) * Wt * 0.02466

Note: Where Od is the outer diameter and Wt is the wall thickness.

| Nominal Diameter | Standard Tube | Thickened Tube | ||||

| (mm) | (in) | Outer Diameter(mm) | Wall Thickness (mm) | Theoretical Weight (kg/m) | Wall Thickness (mm) | Theoretical Weight(kg/m) |

| 6 | 1/8″ | 10 | 2 | 0.39 | 2.5 | 0.46 |

| 8 | 1/4″ | 13.5 | 2.25 | 0.62 | 2.75 | 0.73 |

| 10 | 3/8″ | 17 | 2.25 | 0.82 | 2.75 | 0.97 |

| 15 | 1/2″ | 21.25 | 2.75 | 1.26 | 3.25 | 1.45 |

| 20 | 3/4″ | 26.75 | 2.75 | 1.63 | 3.5 | 2.01 |

| 25 | 1″ | 33.5 | 3.25 | 2.42 | 4 | 2.91 |

| 32 | 1 1/4 | 42.25 | 3.25 | 3.13 | 4 | 3.78 |

| 40 | 1 1/2 | 48 | 3.5 | 3.84 | 4.25 | 4.58 |

| 50 | 2″ | 60 | 3.5 | 4.88 | 4.5 | 6.16 |

| 65 | 2 1/2 | 75.5 | 3.75 | 6.64 | 4.5 | 7.88 |

| 80 | 3″ | 88.5 | 4 | 8.34 | 4.75 | 9.81 |

| 100 | 4″ | 114 | 4 | 10.85 | 5 | 13.44 |

| 125 | 5″ | 140 | 4 | 13.42 | 5.5 | 18.24 |

| 150 | 6″ | 165 | 4.5 | 17.81 | 5.5 | 21.63 |

What is stainless steel welded tube? In short, it is a type of pipe made by welding stainless steel plates or strips after they have been curled and shaped. This type of tubing not only inherits the excellent properties of stainless steel, such as corrosion resistance, high strength, and good resistance to high temperatures, but also, through flexible customization and precise process control, it can meet the diverse requirements of different industries for tube size, precision, and performance. From industrial gas pipelines to mechanical structural components, from decorative projects to furniture production, stainless steel welded tubes have become indispensable materials in modern industrial production and architectural decoration due to their outstanding performance and wide range of applications.

As a leading player in the industry, Huaxiao Stainless Steel is committed to providing customers with high-quality and diversified stainless steel welded tube products. We have a rich product line and flexible customization capabilities, offering stainless steel welded tubes in different sizes and grades for your selection. If you have purchasing plans or requirements, feel free to contact us anytime, and we will be dedicated to providing you with professional service and technical support.