What causes stainless steel to turn green?

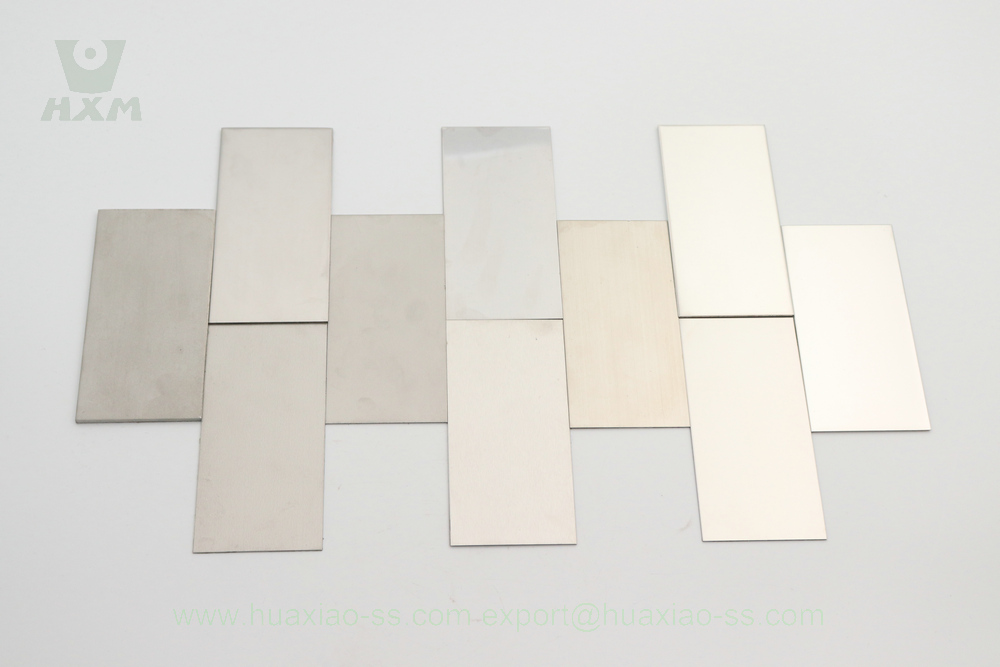

Does stainless steel turn green?

What causes stainless steel to turn green? In the world of metallurgy and materials science, stainless steel stands as a formidable contender against rust and corrosion. However, there are instances where this resilient alloy appears to take on unexpected hues, leaving us to ponder the science behind this phenomenon. Can stainless steel turn green? It’s a query that has intrigued many. Join us as we delve into the intricate world of stainless steel, exploring the factors that may cause it to exhibit shades of green and the conditions under which this intriguing transformation occurs.

Does stainless steel turn green?

Under certain circumstances, such as prolonged exposure to moisture, oxygen, and specific chemicals, stainless steel can indeed exhibit a greenish patina. This phenomenon is commonly known as “tea staining” or “surface rust.” It occurs when the protective chromium oxide layer is compromised, allowing the formation of iron oxide (rust) on the surface.

The greenish tint arises from the interaction of iron oxide with the alloy’s underlying chromium. This process, known as “chromate conversion,” results in the formation of greenish chromium compounds.

It’s important to note that not all stainless steel grades are equally susceptible to this patina. The higher the chromium content, the more resistant the steel is to such discoloration. This is why marine-grade stainless steel, rich in chromium and nickel, is less likely to turn green.

Preventing Green Discoloration on Stainless Steel

To keep your stainless steel items from developing a green tint, consider the following strategies:

Choose High-Quality Stainless Steel: Opt for stainless steel products made from grades like 304 or 316, which offer superior corrosion resistance and are less prone to turning green.

Regular Maintenance: Ensure that your stainless steel items are cleaned and maintained regularly. Use a mild soap and warm water for cleaning, and dry them thoroughly to avoid rust and discoloration.

Avoid Harsh Environments: Minimize exposure to salt water, acidic substances, prolonged moisture, heat, and oxygen, as these can lead to discoloration. If exposure is unavoidable, clean and dry the items immediately afterward.

Separate Different Metals: When storing or using stainless steel items with other metals, ensure they do not come into direct contact to prevent galvanic corrosion.

In summary, although stainless steel is generally resistant to rust and discoloration, lower quality materials can still develop a green hue due to various factors like poor manufacturing, exposure to harsh conditions, and contact with other metals. By investing in high-quality stainless steel and properly maintaining it, you can avoid green discoloration and extend the lifespan of your products.

What causes stainless steel to turn green?

What is stainless steel?

Stainless steel, often referred to as the “miracle metal,” is a remarkable alloy celebrated for its exceptional properties and wide-ranging applications. This alloy is meticulously engineered by stainless steel manufacturers, who combine several key elements, primarily iron, chromium, and sometimes nickel or molybdenum, in precise proportions to create a material that stands unrivaled in the world of metallurgy.

At its core, stainless steel is fundamentally an iron-based alloy, but what sets it apart is the presence of at least 10.5% chromium. This chromium content is pivotal because it forms a thin, invisible, and self-repairing layer of chromium oxide on the surface when exposed to oxygen. This layer is what endows stainless steel with its remarkable resistance to corrosion, stains, and rust.

Main components of stainless steel

The main components of stainless steel include iron, chromium, nickel, and small amounts of carbon, manganese, silicon, phosphorus, and sulfur. Among them, chromium is one of the most important components of stainless steel, usually at a content of 10.5% or more. Chromium can combine with oxygen to form a dense oxide layer called chromium oxide film, which protects the surface of stainless steel from corrosion.

In addition to chromium, nickel is also one of the important components in stainless steel, especially for high-temperature and corrosion-resistant stainless steels with high nickel content. Carbon is one of the main elements in steel, but stainless steel contains only a small amount of carbon, usually no more than 1.2%, to ensure that stainless steel has good weldability and workability. The content of manganese, silicon, phosphorus, and sulfur is also low to ensure the quality of stainless steel and corrosion resistance.

| Ingredients | Content |

| Fe | 50-70% |

| Cr | 10.5-30% |

| Ni | 0-35% |

| C | <1.2% |

| Mn | <2% |

| Si | <1% |

| P | <0.045% |

| S | <0.03% |

What causes stainless steel to turn green?

The Science Behind Stainless Steel's Resistance

Stainless steel’s unrivaled corrosion resistance is a result of meticulous engineering by stainless steel manufacturers. At its core, this alloy is primarily composed of iron, but its secret weapon against corrosion lies in the inclusion of chromium, which typically makes up at least 10.5% of its composition.

Chromium is the unsung hero here. When stainless steel is exposed to oxygen, a natural reaction occurs. The chromium in the alloy reacts with oxygen to form a thin, transparent layer known as chromium oxide. This layer acts as an impenetrable shield, effectively sealing the underlying metal from the harmful effects of moisture, air, and various corrosive agents.

The key to this process is the remarkable self-repairing property of the chromium oxide layer. If it gets scratched or damaged, it instantly reforms in the presence of oxygen. This continuous, invisible shield is what grants stainless steel its exceptional durability and resistance to corrosion, even in challenging environments.

Role of the Protective Chromium Oxide Layer

The protective chromium oxide layer is the linchpin of stainless steel’s corrosion resistance. It not only prevents rust and staining but also maintains the alloy’s signature luster. This layer is exceptionally thin, measuring only a few nanometers, yet its impact is profound.

Crucially, the composition of this chromium oxide layer is remarkably stable, even in extreme conditions, such as exposure to saltwater, acids, or high temperatures. This stability ensures that the underlying stainless steel retains its structural integrity and performance over time.

In essence, the chromium oxide layer is the unsung guardian of stainless steel, preserving its pristine appearance and functional qualities in the face of countless challenges. Understanding the science behind this protective layer allows us to appreciate the resilience of stainless steel and its ability to withstand the test of time and harsh environments.

manufacturing process of stainless steel

What causes stainless steel to turn green?

Smelting: Converting Raw Materials

Rolling: Shaping and Forming

Processing: Enhancing Properties

Causes of stainless steel turning green

What causes stainless steel to turn green?

Stainless steel, prized for its corrosion resistance, can occasionally exhibit a greenish tint on its surface, a phenomenon often linked to the presence of copper oxide. Despite stainless steel’s resilience, it can still succumb to corrosion when exposed to specific substances like iron oxide, chloride ions, and copper oxide. This is especially pronounced in humid environments.

Copper oxide, the main culprit behind the greenish appearance, typically arises when stainless steel interacts with copper-containing materials such as copper products, bronze, or copper piping. When these copper-based materials come into contact with stainless steel, they release copper ions. These ions, in the presence of oxygen and water molecules on the stainless steel’s surface, initiate a chemical reaction, resulting in the formation of a thin layer of copper oxide. This layer, with its distinctive green hue, is commonly referred to as “copper green.”

While copper green doesn’t significantly compromise stainless steel’s corrosion resistance, it does affect its aesthetic appeal. Understanding these underlying causes of surface discoloration is vital, as it allows for informed material selection and maintenance decisions. Stainless steel manufacturers are valuable resources in choosing the right stainless steel grade and finish for various applications, ensuring both functionality and visual appeal.

Environmental factors cause stainless steel to turn green

Environmental factors are one of the main causes of stainless steel turning green. The phenomenon of stainless steel turning green occurs when the stainless steel surface is exposed to certain specific environments, such as humid environments or environments containing chlorides, sulfides and acids.

This phenomenon is caused by the chemical reaction of oxidation and corrosion. When the surface of stainless steel is oxidized or corroded, the element chromium is converted into a green compound called chromate. This compound forms a green oxide layer that covers the surface of the stainless steel, which causes the stainless steel to turn green.

It is important to note that this green oxide layer does not destroy the overall structure of the stainless steel, but is simply a surface covering. Moreover, this green layer actually has a certain anti-corrosion and anti-oxidation effect, which can prevent the stainless steel from further erosion and damage by the environment.

Stainless steel manufacturers play a pivotal role in guiding material selection based on environmental considerations, ensuring the alloy’s resilience and durability even in green-tinged conditions.

Chemical factors that cause stainless steel to turn green

In addition to environmental factors, chemical factors may also cause stainless steel to turn green. The most common of these is the action of acid.

Stainless steel is acid-resistant, but if the surface of stainless steel is exposed to a high concentration of acidic solutions for a long time, it can lead to chromium being dissolved away, resulting in the formation of chromate and a green oxide layer on the surface, causing stainless steel to turn green.

In addition, strong alkaline solutions and chlorine-containing solutions, etc. may also lead to a chemical reaction on the surface of stainless steel and turn green.

Therefore, in order to protect the color and quality of the stainless steel surface, it is necessary to avoid exposing stainless steel to strong acids, alkalis, or chlorine-containing environments. If stainless steel needs to be used in such an environment, appropriate measures need to be taken, such as applying protective agents or using acid and alkali-resistant stainless steel materials.

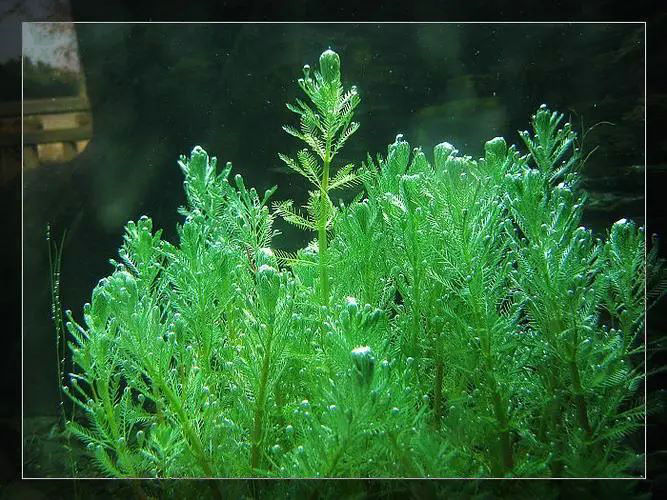

bacteria and algae cause stainless steel to turn green

In addition to environmental and chemical factors, bacteria and algae can also cause stainless steel surfaces to turn green. This phenomenon usually occurs on stainless steel surfaces that are exposed to wet environments, such as stainless steel equipment used in the ocean, swimming pools or other humid environments.

Bacteria and algae can form a biofilm on the surface of stainless steel, which can release compounds such as organic acids and ammonia, which can react with elements such as iron, chromium and nickel on the surface of stainless steel to form a green oxide layer, causing the stainless steel to turn green.

To prevent the growth and reproduction of bacteria and algae, stainless steel surfaces can be cleaned regularly with disinfectants and cleaners. On some stainless steel equipment that is exposed to moisture for long periods of time, special anti-fouling agents or preservatives can be used to protect the surface from bacteria and algae.

How to prevent stainless steel from turning green

What causes stainless steel to turn green?

When it comes to stainless steel’s propensity to turn green, preventive measures and maintenance play a pivotal role in preserving its appearance. Stainless steel manufacturers emphasize the importance of these strategies to minimize the likelihood of green discoloration and sustain the alloy’s visual appeal.

-

Regular Cleaning:

Frequent and gentle cleaning is paramount in maintaining stainless steel's pristine appearance. A neutral cleaner and a soft cloth are recommended for this task, especially after exposure to water or chemicals. The goal is to remove any potential contaminants that may accelerate corrosion or oxidation. -

Beware of Harsh Chemicals:

Exercise caution when selecting cleaning agents. Avoid cleaners containing chlorine or acidic substances, as these can harm the stainless steel surface and exacerbate the formation of oxidation and corrosion. Opt for mild, non-abrasive cleaning solutions to ensure the longevity of your stainless steel products. -

Consider the Environment:

Assessing the operating environment is crucial. For instance, high-molybdenum stainless steels exhibit exceptional corrosion resistance, making them suitable for marine applications. They are well-suited for equipment and components exposed to saltwater environments. On the other hand, low-carbon stainless steels are advantageous for welding processes due to their reduced carbide formation. -

Extended Service Life:

Opting for the right stainless steel material isn't just about preventing green discoloration; it's also an investment in longevity. Choosing a material that aligns with the application's specific requirements can extend the service life of your equipment and reduce maintenance and replacement costs in the long run.

By collaborating with stainless steel manufacturers and considering the environmental demands, you can ensure that your stainless steel material is not only resistant to turning green but also optimized for your application’s performance and durability.

Conclusion

What causes stainless steel to turn green?

In conclusion, our exploration into the intriguing phenomenon of stainless steel turning green has revealed the science behind this transformation and shed light on the factors and conditions involved. Through the guidance of stainless steel manufacturers, we have gained valuable insights into this enigmatic process.

We began our journey by acknowledging the significance of understanding the science behind stainless steel patina. We learned that stainless steel’s corrosion resistance is attributed to the protective chromium oxide layer. We delved into the conditions that lead to green patina, emphasizing the roles of moisture, oxygen, and specific chemicals.

One of the pivotal discoveries was the chromate conversion process, which elucidated how interactions between iron oxide and chromium give rise to the distinct green hue on stainless steel surfaces. We also explored the varying susceptibilities of stainless steel grades to this transformation, highlighting the crucial influence of chromium content and why marine-grade stainless steel is less prone to turning green.

Our journey further extended to real-world examples and applications, where we saw how this phenomenon impacts various industries and contexts. We discussed practical strategies for preventing green discoloration and maintaining the appearance of stainless steel, underlining the importance of regular cleaning and selecting the right materials.

In closing, our exploration of stainless steel’s green transformation empowers us with knowledge that demystifies a phenomenon that might perplex many. With this understanding, we can make informed decisions and ensure the longevity and aesthetic appeal of stainless steel in diverse applications. This journey illustrates how science and industry expertise intersect to unveil the mysteries of everyday occurrences, equipping us to navigate the world of stainless steel with confidence and clarity.