What Is Colored Stainless Steel Sheet?

Vibrant, durable colored stainless steel sheets

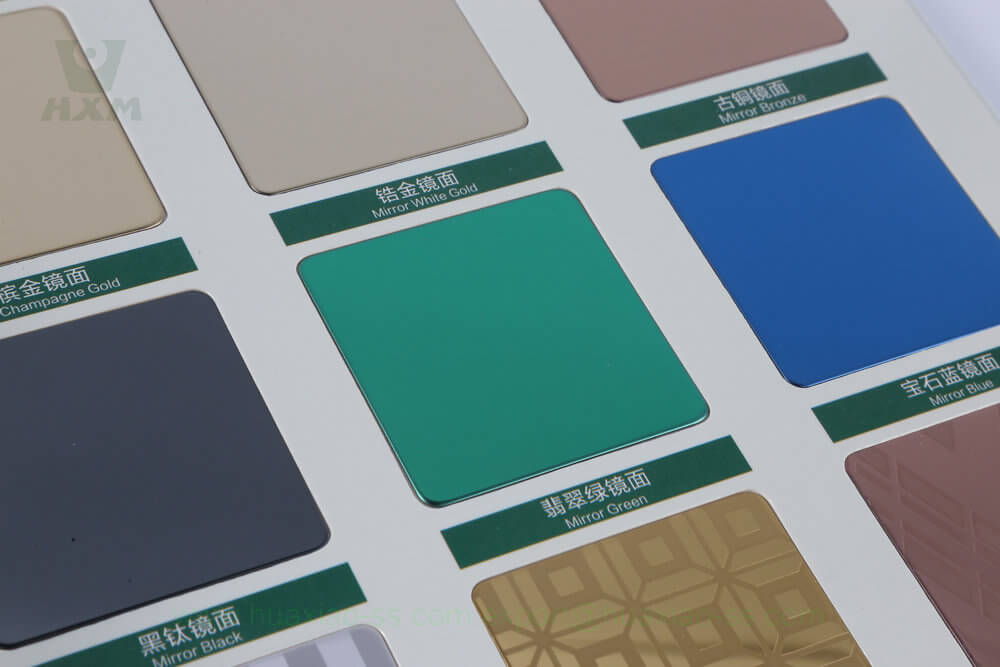

for striking designs

In today’s world, the development of material science is changing rapidly, bringing us countless surprises. Among them, colored stainless steel sheet is undoubtedly one of the most remarkable. With its unique color and texture, this amazing material is gradually changing our living and working environment, becoming a new favorite in the field of modern decoration and design. The appearance of colored stainless steel sheet not only enriches our visual experience, but also changes our perception of traditional metal materials to some extent. It combines the solidity of metal and the splendor of color, and skillfully combines modern technology and art. So, what is colored stainless steel sheet?

What Is Colored Stainless Steel Sheet?

Huaxiao Metal colored stainless steel sheet supplier

Stainless steel colored sheet is a kind of stainless steel products that add coatings to the surface of stainless steel or change its color to achieve decorative effect through special treatment process.

From a scientific point of view, the main component of colored stainless steel sheet is stainless steel, which is a metal material with high strength, corrosion and wear resistance. The surface of stainless steel is usually silver-white or yellowish, which is due to a thin layer of oxide film on its surface.

In order to change the color of stainless steel and give it a more decorative effect, a variety of treatment processes have been developed. One common method is electroplating, by plating a layer of metal or alloy on the surface of stainless steel, it can change its color and increase its corrosion resistance. In addition, stainless steel can also be colored by chemical treatment, coating and other methods.

Stainless steel colored sheets have a wide range of applications and can be used in many fields such as building facades, interior decoration, furniture making and so on. Because of its high strength, corrosion resistance, wear resistance, easy to clean and other advantages, it is favored by the majority of users.

Manufacturing technology of colored stainless steel sheets

When it comes to the manufacturing process of stainless steel colored sheets, making them and the surface treatment techniques are crucial. Let’s take an in-depth look at the process of making colored coatings, stainless steel sheets surface treatment techniques, and how these techniques ensure color stability and longevity.

color coating production process

Colored stainless steel sheets color coating production process is a complex process involving chemistry, physics and materials science and other multidisciplinary fields. The following is a scientific explanation of the color coating production process of colored stainless steel sheet:

- Pre-treatment: first of all, the stainless steel sheets need to be pre-treated, including cleaning, degreasing, descaling and other steps. The purpose of these steps is to remove impurities and contaminants on the surface of the stainless steel sheets to ensure that the coating can be firmly attached to the substrate.

- Chemical conversion film treatment: After pre-treatment, the stainless steel sheets will undergo chemical conversion film treatment. The purpose of this step is to form a dense layer of oxidized film on the surface of stainless steel, to improve the corrosion resistance of the substrate and adhesion. Commonly used chemical conversion film treatment methods include chromate treatment, phosphate treatment and so on.

- Coating preparation: After the chemical conversion film treatment, the preparation of color coatings begins. This step usually involves a complex chemical reaction and physical deposition process. Depending on the desired color and effect, different coating preparation methods can be used, such as electroplating, chemical plating, spraying and so on.

Electroplating is a commonly used coating preparation method, in which metal ions are deposited on the surface of stainless steel to form a metal film by the action of an electric current. During electroplating, different metal ions and plating processes can be selected as needed to obtain the desired color and effect.

Chemical plating, on the other hand, reduces and deposits metal ions on the surface of stainless steel through chemical reactions. Compared with electroplating, chemical plating has more flexible selectivity and can prepare coatings with different structures and properties.

Spray coating is a method of spraying paint onto the surface of stainless steel by means of a spray gun. This method allows for the preparation of coatings with a wide range of colors and textures, as well as faster production speeds and lower costs.

- Post-treatment: After the coating has been prepared, post-treatment is often required to further improve the properties and stability of the coating. Post-treatment may include heat treatment, curing, passivation and other steps to improve the coating's hardness, corrosion resistance, weatherability and other properties.

It should be noted that the process of making color coatings for colored stainless steel sheets may vary depending on the requirements of specific products and applications. In addition, rigorous quality control and performance testing is usually required to ensure the quality and performance of the coating.

Overall, the color coating production process of colored stainless steel sheet is a comprehensive technical process involving knowledge and applications in multiple subject areas. Through scientific methods and technical means, colored stainless steel sheets with excellent performance and decorative effects can be prepared.

How colored stainless steel sheets stay color stable and durable

- Chemical Stability: Color coatings are usually subjected to rigorous chemical treatment during the preparation process in order to provide a high degree of bonding and stability with the stainless steel substrate. This treatment allows the coating to form a chemical bond with the substrate, reducing the possibility of interfacial diffusion and chemical corrosion, thus ensuring the stability and durability of the color.

- Physical Protection: Colored coatings typically have high hardness and abrasion resistance, which provides effective resistance to physical abrasion and scratches. By introducing high hardness materials in the coating or increasing the thickness of the coating, its physical protection properties can be further improved, thus extending the durability of the color of colored stainless steel sheet.

- Corrosion Resistance: Color coatings usually have good corrosion resistance, and can effectively resist corrosive substances in the atmosphere, such as oxygen, moisture, salt and so on. By selecting the appropriate coating material and preparation process, it can further improve its anti-corrosion properties, thereby extending the stability and durability of the colored stainless steel sheet color.

- Environmental Adaptability: Colored coatings usually have good environmental adaptability to various climatic conditions and environmental factors. For example, some coatings containing organotin compounds can resist the effects of ultraviolet radiation and climate change; while some coatings containing chromates have good corrosion resistance and can resist corrosive substances in the atmosphere. These characteristics can improve the stability and durability of colored stainless steel sheet color.

Advantages and limitations of colored stainless steel sheet

advantages

-

Colored stainless steel sheet can present various colors and textures through special coating treatment, making its appearance more beautiful and fashionable.

The combination of color coating and stainless steel substrate makes the overall appearance more harmonious and unified. -

Durability: Stainless steel itself is a metal material with high strength and corrosion resistance, and has excellent durability and weather resistance.

The addition of the color coating further enhances its durability and weather resistance, enabling it to adapt to a variety of harsh environmental conditions. -

Environmental Protection: Colored stainless steel sheet is usually produced with environmentally friendly coating materials and processes, which reduces the impact on the environment.

Compared with other traditional materials, colored stainless steel plate has lower energy consumption and less waste emissions, in line with the concept of green environmental protection.

limitations

-

Cost: The manufacturing process of colored stainless steel sheet is relatively complex and requires several processing steps, so its manufacturing cost is usually higher than that of ordinary stainless steel sheet.

Special coating materials and processes also increase its cost. -

Special Manufacturing Requirements: The manufacture of colored stainless steel sheet requires specialized equipment and processes to ensure the uniformity and stability of the coating.

Higher performance and stability requirements for coating materials require strict quality control and technical support.

application of colored stainless steel sheet

- Construction and interior decoration: Colored stainless steel sheet has a wide range of applications in the field of construction and interior decoration. It is often used as outdoor walls, railings, curtain walls, etc. due to its corrosion resistance, weather resistance and aesthetics. By choosing different coating colors and textures, colored stainless steel plate can blend harmoniously with the surrounding environment and add unique visual effects to the building. In interior decoration, colored stainless steel plate can also be used for floor, wall, furniture, etc., bringing a sense of modernity and fashion to the interior space.

- Art and design: Colored stainless steel sheet also has unique applications in the field of art and design. Artists and designers can use its rich colors and textures to create a variety of visually striking works. For example, some artists cut colored stainless steel plate into various shapes and sizes, and then through the process of splicing, welding, etc., to create unique sculptures and installations. In addition, colored stainless steel sheets can also be used to make jewelry, watches and other high-grade accessories, showing its noble and elegant quality.

- Automotive and electronic products: In the field of automotive and electronic products, colored stainless steel plate also plays an important role. Automobile body, interior parts and electronic products shell often use colored stainless steel plate as material. This material is not only corrosion-resistant, wear-resistant properties, but also can resist a variety of harsh environmental conditions, to ensure the quality and durability of the product. At the same time, the appearance of colored stainless steel plate is beautiful, stylish, can enhance the overall texture of the product, to meet the consumer demand for high quality and high performance.

Conclusion

After understanding the definition, characteristics and applications of colored stainless steel sheet, we can have a deeper understanding of its value and potential. With its unique color, texture and stability, colored stainless steel sheets bring a new visual experience and practicality to modern architecture, interior decoration, art and design, as well as automotive and electronic products.

For buyers, when choosing colored stainless steel sheets, they should first clarify their needs and budget, and then make a comprehensive assessment based on the quality, performance and price of the product.

In the pursuit of innovation and quality, we, Huaxiao Metal, as a professional supplier of colored stainless steel sheet, create an excellent product experience for you with exquisite technology and first-class service.

Our colored stainless steel sheets cover a wide range of specifications and varieties, from regular sizes to customized needs. Using advanced production processes and high-quality raw materials, our colored stainless steel sheets have excellent corrosion resistance and durability, providing long-lasting protection for your building or product design.