Which is Better:

18/8 or 18/10 Stainless Steel?

In the realm of stainless steel, the numerical labels 18/8 and 18/10 stand out prominently. These grades represent specific chemical compositions, and when shopping for housewares, kitchen appliances, cutlery, and various industrial applications, consumers often encounter the dilemma of choosing between these two. The question lingers: Is there a clear winner between 18/8 and 18/10 stainless steel? Let’s delve deeper into their compositions, properties, and real-world applications to unravel which might emerge as the superior choice.

which is better: 18/8 or 18/10 stainless steel?

In determining the superiority between 18/8 and 18/10 stainless steel, the difference primarily lies in their nickel content. 18/8 stainless steel contains approximately 18% chromium and 8% nickel, while 18/10 stainless steel consists of approximately 18% chromium and 10% nickel. The slightly higher nickel content in 18/10 offers marginally improved corrosion resistance compared to 18/8.

chemical components

18/8 or 18/10 stainless steel

Chemical Composition of 18/8 Stainless Steel

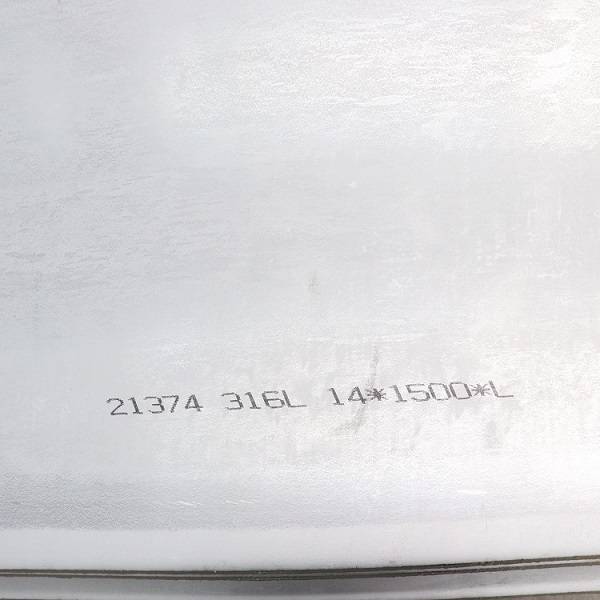

18/8 stainless steel, scientifically known for its composition comprising 18% chromium and 8% nickel, represents a widely utilized grade within the stainless steel spectrum.

At stainless steel factory, the production process involves precise control over the alloy’s composition, ensuring the requisite 18% chromium and 8% nickel content. This balanced composition contributes significantly to the alloy’s robustness against corrosion, oxidation, and rust formation in diverse environments.

Chemical Composition of 18/10 Stainless Steel

18/10 stainless steel, characterized by its composition comprising 18% chromium and 10% nickel, embodies a significant grade within the stainless steel spectrum. This precise combination of elements contributes substantially to the alloy’s enhanced corrosion resistance and suitability for various applications across multiple industries.

Within stainless steel factory, the manufacturing process involves meticulous control over the alloy’s chemical composition to ensure the specified 18% chromium and 10% nickel content. This composition enhances the alloy’s resistance to corrosion, oxidation, and staining, rendering it highly suitable for use in challenging environments.

Impact of Nickel Content Variation on Different Industrial Applications

The variance in nickel content, notably between 18/8 and 18/10 stainless steels, significantly influences their performance in various industrial applications. At stainless steel factories, the nuanced difference in nickel content plays a crucial role in tailoring the alloys for specific industrial uses.

- The lower nickel content in 18/8 stainless steel renders it suitable for applications requiring decent corrosion resistance and moderate durability.

- This grade finds extensive use in household items, architectural elements, and equipment where moderate corrosion resistance is sufficient, offering a cost-effective solution without compromising on quality.

- With a higher nickel content, 18/10 stainless steel exhibits superior corrosion resistance, making it ideal for applications in more demanding environments.

- Its enhanced resistance to corrosion and staining qualifies it for use in kitchenware, cutlery, and industrial equipment exposed to aggressive conditions, ensuring longevity and aesthetic appeal.

The tailored nickel content variations in stainless steel alloys reflect a balance between corrosion resistance, durability, and cost-effectiveness. Stainless steel factory leverage these compositions to meet diverse industrial needs, ensuring that each grade, be it 18/8 or 18/10 stainless steel, is optimized for its intended application, thereby maximizing performance and longevity.

Performance Comparison and Real-world Applications

Performance Comparison

| Properties | 18/8 Stainless Steel | 18/10 Stainless Steel |

|---|---|---|

| Nickel Content (%) | Approximately 8 | Approximately 10 |

| Corrosion Resistance | Moderate resistance to corrosion | Superior resistance to corrosion |

| Strength and Durability | Good mechanical properties | Enhanced strength and durability |

| Industrial Applications | Architectural elements, basic machinery parts | Chemical processing, food production machinery |

| Cost-effectiveness | Cost-effective choice | Slightly higher cost due to increased nickel |

Stainless steel factory consider these performance variations when selecting between 18/8 and 18/10 stainless steel for different industrial manufacturing purposes. While 18/8 serves adequately in environments with milder corrosive conditions, 18/10’s heightened corrosion resistance and durability make it indispensable for applications exposed to aggressive environments, ensuring optimal performance and longevity in diverse industrial settings.

Processing Methods-18/8 or 18/10 stainless steel

- Machining and Forming: The 8% nickel content in 18/8

- Welding Considerations: Weldability is satisfactory, and welding methods are similar to other stainless steels. The alloy’s lower nickel content makes it relatively less prone to sensitization during welding, reducing the risk of corrosion in welded areas.

- Machining and Forming: The 10% nickel content in 18/10 stainless steel slightly increases its work hardening tendencies during machining and forming processes. Precise tooling and slower cutting speeds may be necessary to mitigate work hardening effects.

- Welding Considerations: Weldability is maintained, but greater attention is required to prevent sensitization due to the higher nickel content. Proper welding techniques and post-weld treatments, like annealing, may be necessary to retain corrosion resistance.

Finishing and Surface Treatments-18/8 or 18/10 stainless steel

- Annealing processes: The lower nickel content allows for annealing treatments at slightly lower temperatures, enhancing grain structure and reducing internal stresses without significant risk of grain boundary sensitization.

- Hardening treatments: Hard

- Annealing processes: The higher nickel content might require more precise annealing to prevent sensitization and ensure uniform properties throughout the material.

- Hardening treatments: While limited hardening is achievable, caution is necessary to prevent excessive work hardening, affecting machinability and formability.

Industrial Applications of 18/8 or 18/10 Stainless Steel

18/8 Stainless Steel

- Architectural Sector: In architectural applications, 18/8 stainless steel is often used for exterior facades, roofing, and decorative elements due to its moderate corrosion resistance and cost-effectiveness.

- Household and Food Industry: It finds extensive use in kitchenware, food processing equipment, and utensils owing to its decent corrosion resistance, making it suitable for contact with food without risking contamination.

- Automotive Industry: Components such as trim, exhaust systems, and decorative parts benefit from 18/8 stainless steel's corrosion resistance and moderate strength.

- General Machinery: Basic machinery parts and components that do not necessitate high corrosion resistance often utilize 18/8 stainless steel due to its lower cost and satisfactory mechanical properties.

18/10 Stainless Steel

- Food Processing and Pharmaceutical Industries: 18/10 stainless steel is preferred for food production machinery, pharmaceutical equipment, and storage tanks due to its superior corrosion resistance and hygienic properties, crucial in maintaining product purity.

- Chemical Processing: It's extensively used in chemical plants for pipes, valves, and vessels handling corrosive substances due to its excellent corrosion resistance and durability.

- Marine Equipment: Fittings, fasteners, and marine structures benefit from 18/10 stainless steel's high corrosion resistance in harsh marine environments.

- Aerospace and Medical Equipment: Its superior corrosion resistance and hygiene make it ideal for aerospace components and medical instruments where reliability and hygiene are paramount.

Stainless steel factory recognize these distinct performance characteristics, tailoring the production and processing of 18/8 and 18/10 stainless steel to meet the stringent demands of various industries. The nuanced differences in their composition and properties ensure their suitability across diverse sectors, underscoring their significance in maintaining quality, durability, and functionality across different applications.

conclusion

In the manufacturing process, 18/8 and 18/10 stainless steels differ slightly in chemical composition, mainly in nickel content. 18/8 is suitable for general applications at a lower cost, but has lower corrosion resistance. Whereas 18/10 has a higher nickel content and offers superior corrosion resistance and sanitary properties for industries with higher sanitary requirements, but at a slightly higher cost.

For factories or suppliers, it is recommended to select the right grade of stainless steel based on specific industry needs and customer standards. A good understanding of the product application, industry standards, and customer needs is key to making the right choice. Cost and performance need to be balanced in the decision-making process to ensure that the selected material will meet the expected quality and performance requirements.

In the future, 18/8 and 18/10 stainless steels will continue to play an important role in their respective fields as technology and requirements evolve. Industry’s growing need for hygiene and corrosion resistance will drive more applications for 18/10 stainless steel. However, for general applications, the lower cost 18/8 stainless steel still has some advantages.

In future production, different industries will choose the appropriate grade of stainless steel according to the needs to meet the strict requirements for product performance and hygiene standards, promoting the wide application of stainless steel materials in different fields.

Explore Stainless Steel Products

Get Free Quote: Contact Us