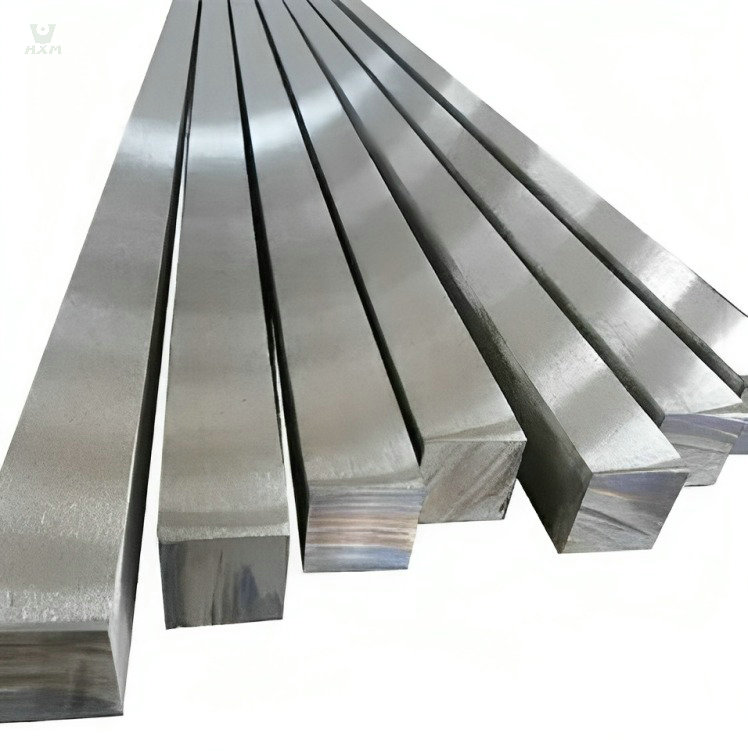

17-4PH stainless steel bar supplier in China

Diameter: 3mm-480mm, 1/8″ to 2 1/4″

Standard: GB1220, ASTM A484/484M, EN 10060/ DIN 1013 ASTM A276, EN 10278, DIN 671

Shape: round, flat, square, angle, hexagonal

Finish: Black, NO.1, mill finish, cold draw, H9, H11

product description of 17-4PH stainless steel bar

17-4PH stainless steel bar is a martensitic stainless steel precipitation hardened by copper and niobium. The mechanical properties of this stainless steel are significantly improved after heat treatment, and the compressive strength can reach 1100-1300 MPa (160-190 ksi). However, it cannot be used above 300°C (572°F) or at very low temperatures. The material has good corrosion resistance to atmospheric conditions, dilute acids or salts, and its corrosion performance is comparable to that of 304 and 430.

In addition, 17-4PH is a martensitic precipitation-hardening stainless steel with easily adjustable strength levels. The main means of strengthening is martensitic transformation and aging treatment to form precipitation hardening phase. This stainless steel has good resistance to corrosion fatigue and fracture resistance.

In industrial applications, 17-4PH is used in the manufacture of shafts, turbine components and so on.

17-4 PH Industry Standards

- UNS S17400

- AMS 5643

- ASTM A564

- ASTM A693 Grade 630

- NACE MR0175/MR0103 (H-1150D Condition)

specification of 17-4PH stainless steel bar

chemical components of 17-4PH stainless steel bar

| Element | Composition (%) |

|---|---|

| Chromium (Cr) | 15.0 – 17.5 |

| Nickel (Ni) | 3.0 – 5.0 |

| Copper (Cu) | 3.0 – 5.0 |

| Manganese (Mn) | ≤1.00 |

| Silicon (Si) | ≤1.00 |

| Columbium (Cb) | 0.15 – 0.45 |

| Phosphorus (P) | ≤0.040 |

| Sulfur (S) | ≤0.030 |

| Carbon (C) | ≤0.07 |

| Iron (Fe) | Balance |

physical property of 17-4PH stainless steel bar

| Property | Value |

|---|---|

| Density | 7.8 g/cm³ |

| Melting Range | 2560-2625°F (1404-1440°C) |

| Specific Heat Capacity | 0.12 BTU/lb-°F (0-100°C) |

| Thermal Conductivity | 17.9 BTU/hr-ft-°F (100°C) |

| Electrical Resistivity | 780 nΩ·m (20°C) |

| Magnetic Permeability | < 1.05 μT (Approx.) |

| Modulus of Elasticity (Young’s Modulus) | 190 GPa (27.6 x 10^6 psi) |

| Poisson’s Ratio | 0.272 |

| Thermal Expansion Coefficient | 10.8 x 10^-6/°F (20-100°C) |

mechanical property of 17-4PH stainless steel bar

| Property | Value |

|---|---|

| Tensile Strength (Ultimate) | 190,000 – 210,000 psi (1310 – 1450 MPa) |

| Yield Strength (0.2% offset) | 170,000 – 190,000 psi (1170 – 1310 MPa) |

| Elongation at Break | 6 – 10% |

| Hardness (Rockwell C) | HRC 36 – 40 |

| Impact Toughness | 15 – 20 ft-lb (20°C) |

features of 17-4PH stainless steel bar

In addition to its high strength and excellent corrosion resistance, 17-4PH stainless steel bar has the following key features:

- Good machinability and weldability: 17-4PH stainless steel can be easily machined and welded operations, which makes it highly productive in the manufacturing process.

- Heat and oxidation resistance: 17-4PH stainless steel can maintain good properties over a range of temperatures while also resisting oxidation. This makes it better suited for certain high temperature applications.

- Good corrosion resistance: 17-4PH stainless steel has good corrosion resistance to atmospheric conditions, dilute acids or salts, etc. This allows it to maintain good stability and durability in many corrosive environments.

- Precipitation hardening: Through aging treatment, 17-4PH stainless steel can obtain higher strength and hardness, and also improve its corrosion fatigue and fracture resistance.

- Beautiful luster: chromium is one of the main components in 17-4PH stainless steel, which gives this stainless steel a unique luster and makes it highly attractive in appearance.

In conclusion, 17-4PH stainless steel bar is a kind of stainless steel material with excellent comprehensive performance, which is suitable for a variety of different applications.

application of 17-4PH stainless steel bar

17-4PH stainless steel bar is widely used in the following scenarios:

- Offshore platforms: the high strength and excellent corrosion resistance of 17-4PH stainless steel bar make it ideal for offshore facilities and platforms.

- Food industry: Due to its good corrosion resistance and sanitary properties, 17-4PH stainless steel bar is commonly used in food processing equipment, food conveying and storage equipment, etc.

- Pulp and paper industry: paper machines require corrosion and abrasion resistant materials, 17-4PH stainless steel bar can meet these requirements, while also providing an aesthetic appearance.

- Aerospace industry: 17-4PH stainless steel bar is used in the manufacture of turbine blades and other aerospace components, and its high strength, corrosion resistance and oxidation resistance have important applications in the aerospace industry.

- Mechanical components: Because 17-4PH stainless steel bar has good mechanical properties, corrosion resistance and beautiful luster, it is commonly used in the manufacture of various mechanical components.

In short, the 17-4PH stainless steel bar has a wide range of applications in many fields, and its excellent performance and adaptability make it maintain good stability and durability in various environments, which is suitable for various applications.

Huaxiao Metal, a prominent entity in metal material exports, stands out with a vast inventory of 1 million tons, ensuring prompt dispatch of readily available stock within 15 days. Our customizable surface finishes and film coatings meet diverse preferences, enabling tailored solutions for our valued clientele. Committed to unparalleled service, we prioritize client satisfaction, offering swift global distribution and bespoke options to meet varied industrial requirements.

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China