2205 duplex Stainless Steel Bar Supplier In China

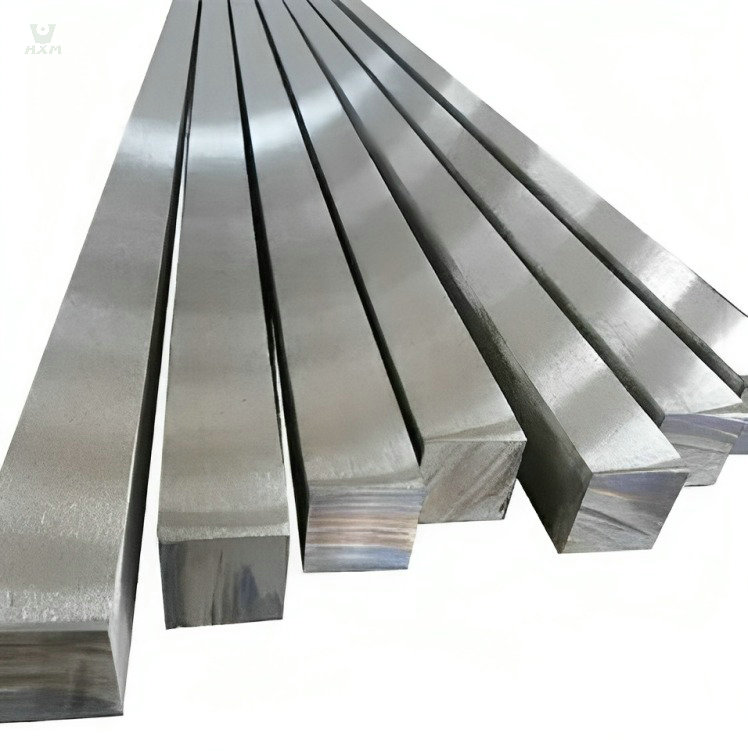

Diameter: 3mm-480mm, 1/8″ to 2 1/4″

Standard: GB1220, ASTM A484/484M, EN 10060/ DIN 1013 ASTM A276, EN 10278, DIN 671

Shape: round, flat, square, angle, hexagonal

Finish: Black, NO.1, mill finish, cold draw, H9, H11

Product Description Of 2205 Stainless Steel Bar

2205 stainless steel bar, a duplex ferritic/austenitic stainless steel, renowned for its superior strength and exceptional corrosion resistance, stands as the most widely used duplex grade. Comprising 21-23% chromium, 4.5-6.5% nickel, 2.5-3.5% molybdenum, and trace elements of carbon, phosphorus, sulfur, and nitrogen. Its advantages encompass excellent weldability, processing capabilities, high resistance to corrosion fatigue, stress corrosion cracking (especially chloride-induced), erosion resistance, and exceptional energy absorption.

Compared to austenitic stainless steels, 2205 stainless steel bar exhibits higher thermal conductivity and a lower coefficient of thermal expansion. Accounting for over 80% of global duplex stainless steel usage, its prevalence arises from superior processability and corrosion resistance. Widely applied in chemical, desalination, material processing, oil and gas extraction, paper, and petrochemical industries. Products wholly or partially made from 2205 stainless steel encompass propellers, cargo tanks, couplings, diaphragm seals, fans, fasteners, heat exchangers, hubs, instrument tubing, fittings, pressure vessels, rotors, screw conveyors, shafts, valve components, among others.

specification Of 2205 Stainless Steel Bar

chemical components of 2205 duplex stainless steel bar

| 2205 | C% | Mn% | Si% | Cr% | Ni% | Mo% | N% | S% | P% |

| ASTM | ≤ 0.03 | ≤ 2.0 | ≤ 1.0 | 22-23 | 4.5-6.5 | 3.0-3.5 | 0.14-0.20 | ≤ 0.02 | ≤ 0.03 |

| EN | ≤ 0.03 | ≤ 2.0 | ≤ 1.0 | 22-23 | 4.5-6.5 | 3.0-3.5 | 0.14-0.20 | ≤ 0.02 | ≤ 0.03 |

| JIS | ≤ 0.03 | ≤ 2.0 | ≤ 1.0 | 21-23 | 4.5-6.5 | 2.5-3.5 | 0.08-0.20 | ≤ 0.03 | ≤ 0.04 |

| GB | ≤ 0.03 | ≤ 2.0 | ≤ 1.0 | 22-23 | 4.5-6.5 | 3.0-3.5 | 0.14-0.20 | ≤ 0.02 | ≤ 0.03 |

physical property of 2205 duplex stainless steel bar

| Property | Value |

|---|---|

| Density | 7.8 g/cm³ |

| Melting Range | 1370°C – 1450°C (2498°F – 2642°F) |

| Thermal Conductivity | 19 W/(m·K) at 100°C (212°F) |

| Coefficient of Thermal Expansion | 13.7 µm/m°C at 20-100°C (68-212°F) |

| Electrical Resistivity | 850 nΩ·m at 20°C (68°F) |

| Modulus of Elasticity (Young’s Modulus) | 200 GPa (29,000 ksi) |

mechanical property of 2205 duplex stainless steel bar

| Property | Value |

|---|---|

| Tensile Strength | 620 – 800 MPa (90,000 – 116,000 psi) |

| Yield Strength | ≥ 450 MPa (65,000 psi) |

| Elongation | ≥ 25% |

| Hardness (Brinell) | ≤ 293 HB |

| Hardness (Rockwell C) | ≤ 31 HRC |

features Of 2205 Stainless Steel Bar

2205 stainless steel bar demonstrates exceptional high strength owing to its microstructure consisting of a dual-phase composition of ferrite and austenite. This duplex structure creates a synergy, offering superior mechanical properties, notably higher yield and tensile strength compared to standard austenitic stainless steels. The balanced mixture of ferritic and austenitic phases allows for the redistribution of stresses within the alloy, enhancing its overall strength performance. This attribute enables 2205 stainless steel bar to withstand heavier loads and harsh operating conditions while retaining structural integrity and durability.

The high energy absorption capability of 2205 stainless steel bar arises from its unique microstructural features and material properties. The alloy’s dual-phase structure, comprising both ferrite and austenite phases, contributes significantly to this attribute. This duplex composition allows for controlled deformation and redistribution of energy under impact or high-stress conditions. The balanced mixture of phases enhances the material’s ability to absorb and dissipate energy, thereby reducing the risk of fractures or structural failure. The alloy’s chemical constituents, including higher chromium, nickel, and molybdenum content, also contribute to its energy absorption capacity, making it suitable for applications requiring superior impact resistance and structural stability.

The outstanding corrosion resistance of 2205 stainless steel bar originates from its chemical composition and dual-phase microstructure. The alloy’s higher chromium, nickel, and molybdenum content, along with a balanced proportion of ferrite and austenite phases, contributes significantly to its superior corrosion resistance. This unique composition forms a protective passive layer on the material’s surface, mitigating corrosion in aggressive environments. Notably, its resistance against stress corrosion cracking, particularly in chloride-laden environments, and erosion resistance, further substantiate its robustness against various forms of corrosion. This attribute makes 2205 stainless steel bar ideal for applications where exposure to corrosive elements is prevalent, ensuring prolonged durability and reliability.

The exceptional corrosion fatigue resistance exhibited by 2205 stainless steel bar is attributed to its unique microstructure and chemical composition. The alloy’s duplex structure, consisting of both ferrite and austenite phases, plays a pivotal role. This dual-phase configuration provides enhanced resistance against cyclic loading in corrosive environments. The balanced combination of constituents, including higher chromium, nickel, and molybdenum content, fortifies the material against the detrimental effects of corrosion-induced fatigue. The synergistic effect of its microstructure allows 2205 stainless steel bar to withstand cyclic stresses in corrosive conditions, ensuring extended service life and reliability in challenging environments subjected to repeated stress and corrosion cycles.

The favorable weldability and processability of 2205 stainless steel bar stem from its balanced dual-phase microstructure and specific chemical composition. The alloy’s duplex nature comprising ferrite and austenite phases provides a beneficial combination for welding and processing. The moderate thermal expansion and balanced phase ratios allow for controlled thermal gradients during welding, reducing the risk of distortion or cracking. Additionally, the alloy’s chemical composition, including higher chromium, nickel, and molybdenum content, promotes favorable weld properties, enabling ease of fabrication and machining processes. This characteristic facilitates the production of intricate structures and components while retaining the material’s mechanical integrity, making it a preferred choice for various fabrication applications.

2205 stainless steel bar exhibits superior thermal conductivity and a lower coefficient of thermal expansion due to its distinct microstructure and elemental composition. The alloy’s duplex structure, containing both ferrite and austenite phases, contributes to these properties. The balanced ratio of these phases allows for improved thermal conductivity, enabling efficient heat transfer within the material. Additionally, the alloy’s chemical constituents, including higher chromium, nickel, and molybdenum content, contribute to its enhanced thermal properties. Moreover, the alloy’s lower coefficient of thermal expansion compared to standard austenitic stainless steels signifies reduced dimensional changes with temperature variations, making it suitable for applications requiring stability under varying thermal conditions.

application Of 2205 Stainless Steel Bar

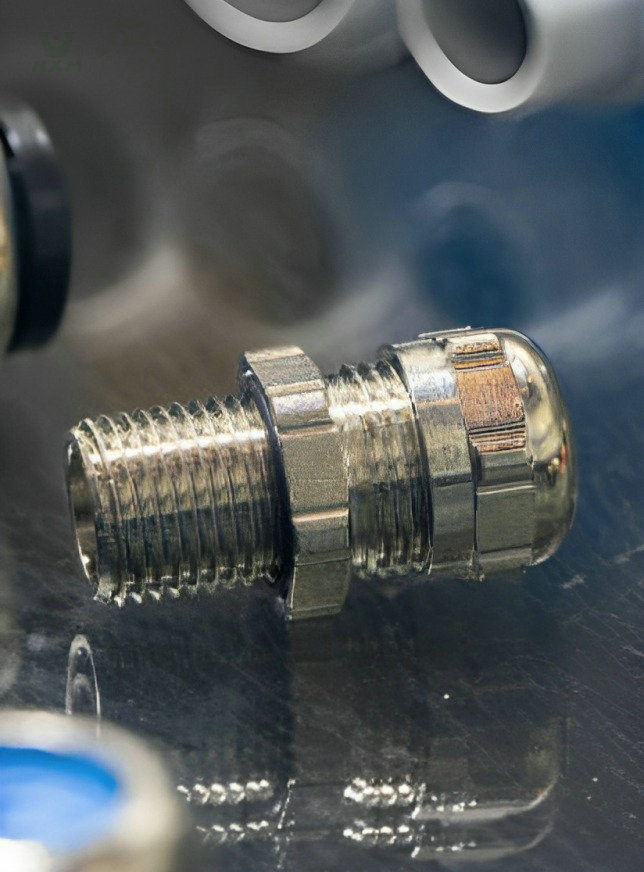

Fasteners

Fasteners constructed from 2205 stainless steel bar offer an optimal solution for demanding environments necessitating superior corrosion resistance and mechanical strength. The alloy's dual-phase microstructure, consisting of ferrite and austenite phases, synergistically contributes to its exceptional properties. This material's higher chromium, nickel, and molybdenum content ensures heightened resistance against corrosive agents like chloride and sulfide environments, while also delivering robust mechanical strength crucial for fastening applications. The combination of these factors enables 2205 stainless steel bar to provide durable, corrosion-resistant fasteners suitable for marine, chemical, and harsh industrial settings.

Pressure Vessels

The utilization of 2205 stainless steel bar in pressure vessels stems from its remarkable combination of corrosion resistance and mechanical strength. The alloy's duplex microstructure, comprising ferrite and austenite phases, contributes significantly to its superior properties. Its higher chromium, nickel, and molybdenum content fortify it against corrosive mediums such as chlorides, enhancing its durability in aggressive environments. Moreover, the alloy's inherent strength and ductility make it an ideal choice for constructing pressure vessels, ensuring reliable performance in demanding applications within chemical plants, offshore installations, and other corrosive settings requiring high-strength containment.

Shafts

2205 stainless steel bar finds extensive application in shafts due to its unique combination of properties. The alloy's dual-phase microstructure, comprising ferrite and austenite phases, contributes to its exceptional mechanical strength and corrosion resistance. Its higher chromium, nickel, and molybdenum content provides enhanced resistance to corrosion, making it suitable for aggressive environments. Additionally, the alloy's superior strength and toughness make it an ideal choice for shafts subjected to high-stress conditions, such as in chemical processing equipment, marine environments, and other demanding industrial applications requiring excellent corrosion resistance and mechanical integrity.

Valve Components

The utilization of 2205 duplex stainless steel bar in valve components is due to its distinct microstructural properties and enhanced corrosion resistance. The alloy's dual-phase composition, combining ferrite and austenite phases, provides exceptional strength and resistance to corrosion in aggressive environments. Its higher chromium, nickel, and molybdenum content imparts superior corrosion resistance, particularly against chloride-induced stress corrosion cracking. This makes it an excellent choice for valve components subjected to corrosive media, such as in chemical processing, offshore, and marine applications, where reliability, durability, and resistance to harsh environments are paramount.

FAQ

The distinction between 2507 stainless steel bar and duplex 2205 stainless steel bar lies in several key aspects:

Chemical Composition:

- 2507 Stainless Steel Bar: Contains higher chromium (25%), molybdenum (7%), and nitrogen (0.25%) than duplex 2205, enhancing its corrosion resistance, especially in aggressive environments.

- Duplex 2205 Stainless Steel Bar: Comprises chromium (22-23%), molybdenum (3-3.5%), and nitrogen (0.14-0.20%), offering excellent corrosion resistance but with lower chromium and molybdenum content compared to 2507.

Corrosion Resistance:

- 2507 Stainless Steel Bar: Demonstrates superior resistance to corrosive environments like seawater, acidic solutions, and chloride-rich conditions, suitable for harsher applications.

- Duplex 2205 Stainless Steel Bar: Offers good corrosion resistance but may not match the elevated performance in aggressive environments exhibited by 2507.

Strength:

- 2507 Stainless Steel Bar: Typically displays higher tensile and yield strengths due to its enhanced alloying elements.

- Duplex 2205 Stainless Steel Bar: Exhibits good strength but may not match the heightened strength levels of 2507.

Applications:

- 2507 Stainless Steel Bar: Preferred in industries demanding exceptional corrosion resistance, such as oil and gas, chemical processing, and marine applications.

- Duplex 2205 Stainless Steel Bar: Widely used in various industries requiring excellent corrosion resistance and moderate strength, like chemical, petrochemical, and pulp and paper industries.

Both types are robust, corrosion-resistant stainless steels, yet the 2507 variant offers superior performance in harsh environments due to its heightened alloy composition. For specific applications requiring higher corrosion resistance and strength, 2507 stainless steel bar might be the preferred choice, while duplex 2205 remains suitable for many general-purpose applications.

Stainless steel bar supplier can provide detailed information on these alloys’ specific properties and applications for tailored industrial needs.

2205 grade stainless steel is a duplex stainless steel alloy primarily composed of chromium, nickel, molybdenum, and nitrogen. It belongs to the duplex family due to its dual-phase microstructure, comprising roughly equal parts of austenitic (chromium-nickel) and ferritic (chromium-molybdenum) structures. This alloy, often denoted as UNS S31803 or UNS S32205, offers excellent corrosion resistance, high strength, and good weldability. It is widely utilized in various industries such as chemical processing, marine environments, oil and gas, and more. Stainless steel bar supplier can offer 2205 stainless steel in different forms, providing tailored solutions for specific industrial applications.

Comparing 2205 stainless steel bar to 316 stainless steel bar involves considering their respective attributes for specific applications:

2205 Stainless Steel Bar:

- Advantages: Offers higher strength and excellent corrosion resistance.

- Usage: Ideal for applications requiring superior strength and resistance to corrosion, especially in aggressive environments.

316 Stainless Steel Bar:

- Advantages: Exhibits good corrosion resistance and excellent weldability.

- Usage: Commonly used in environments with less severe corrosive conditions and where superior strength is not the primary requirement.

Choosing between them depends on the specific application requirements. For applications demanding higher strength and better corrosion resistance, 2205 stainless steel bar might be preferred. Conversely, for applications where corrosion resistance and weldability are more critical factors than high strength, 316 stainless steel bar might be more suitable. Stainless steel bar suppliers can offer guidance based on specific project needs, ensuring the selection of the most appropriate material for the intended application.

Comparing 2205 stainless steel bar to 304 stainless steel bar depends on the intended application:

2205 Stainless Steel Bar:

- Advantages: Offers higher strength and superior corrosion resistance, particularly in aggressive environments.

- Usage: Preferred for applications requiring increased strength and better corrosion resistance, especially in harsh conditions like marine or chemical environments.

304 Stainless Steel Bar:

- Advantages: Demonstrates good corrosion resistance, excellent formability, and weldability.

- Usage: Commonly used in various applications where corrosion resistance and ease of fabrication are crucial, such as in architectural, food processing, and household applications.

The choice between them relies on specific application needs. For environments demanding higher strength and superior corrosion resistance, 2205 stainless steel bar might be preferred. Conversely, for applications prioritizing corrosion resistance, formability, and ease of fabrication, 304 stainless steel bar could be more suitable. Stainless steel bar supplier can assist in selecting the most appropriate material based on the project’s requirements.

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China