302 stainless steel bar supplier

Diameter: 3mm-480mm, 1/8″ to 2 1/4″

Standard: GB1220, ASTM A484/484M, EN 10060/ DIN 1013 ASTM A276, EN 10278, DIN 671

Main Grade: 201, 304, 316, 316L, 310s, 430

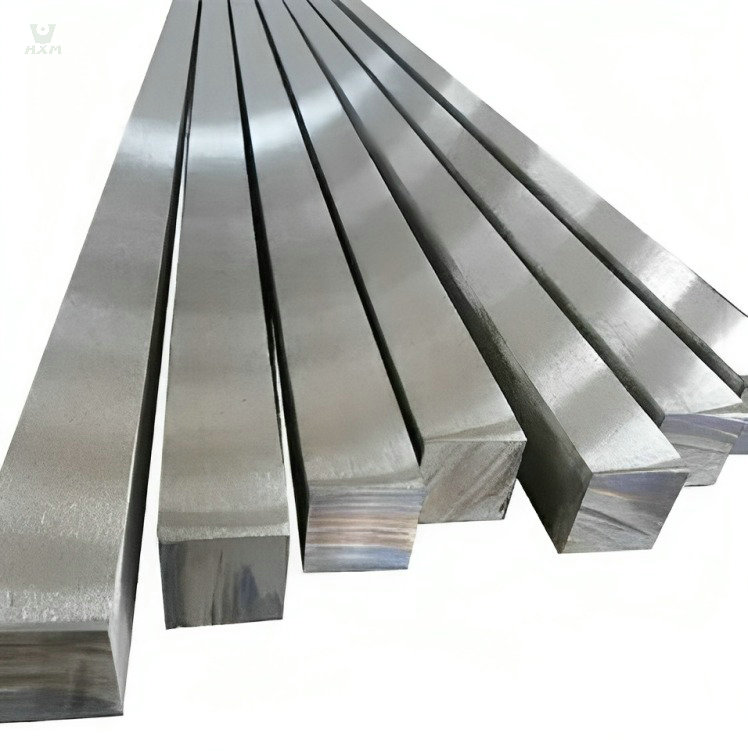

Shape: round, flat, square, angle, hexagonal

Finish: Black, NO.1, mill finish, cold draw, H9, H11

Product Description Of 302 Stainless Steel Bar

Discover the 302 Stainless Steel Bar, a true workhorse across multiple industries. This general-purpose grade stainless steel round bar is prized for its remarkable qualities. It boasts exceptional corrosion resistance, impressive strength, flexibility, and superior weldability. Whether you require it for hot or cold environments, this material delivers without breaking the bank.

One of its standout features is its high corrosion resistance. Industries have long relied on the 302 stainless steel bar for its unwavering durability and ability to withstand the harshest conditions. Despite its robustness, it remains lightweight and incredibly easy to handle.

But that’s not all. What truly sets this stainless steel bar apart is its high fatigue strength, combined with impeccable toughness and outstanding machinability. It’s no wonder that it’s a sought-after choice for a wide range of applications.

Choose the 302 Stainless Steel Bar, a dependable and versatile solution that will meet and exceed your industry needs.

specification Of 302 Stainless Steel Bar

chemical composition of 302 stainless steel bar

| Element | Percentage Composition |

|---|---|

| Chromium (Cr) | 17.0% – 19.0% |

| Nickel (Ni) | 8.0% – 10.0% |

| Manganese (Mn) | 2.0% |

| Silicon (Si) | 1.0% |

| Carbon (C) | 0.15% |

| Phosphorus (P) | 0.045% |

| Sulfur (S) | 0.03% |

physical property of 302 stainless steel bar

| Property | Value |

|---|---|

| Density | 7.93 g/cm³ |

| Melting Point | 1400-1455°C (2552-2651°F) |

| Specific Heat Capacity | 0.50 J/g°C |

| Electrical Conductivity | 1.03 x 10⁶ S/m |

| Thermal Conductivity | 16.2 W/m·K |

| Coefficient of Expansion | 16.3 x 10⁶ /°C |

| Modulus of Elasticity | 193 GPa (28 x 10 |

mechanical property of 302 stainless steel bar

| Property | Value |

|---|---|

| Tensile Strength (Ultimate) | 620 – 795 MPa |

| Tensile Strength (Yield) | 275 – 430 MPa |

| Elongation at Break | 40 – 45% |

| Modulus of Elasticity | 193 – 200 GPa |

| Poisson’s Ratio | 0.29 |

| Hardness (Brinell) | 183 – 215 HB |

| Hardness (Rockwell B) | 85 – 96 HRB |

characteristics Of 302 Stainless Steel Bar

The designation of the 302 stainless steel round bar as a “General-Purpose Grade” underscores its adaptability and suitability for a broad spectrum of industrial and commercial applications. This characteristic can be scientifically explained by examining the following key points:

Versatility: The 302 stainless steel’s chemical composition and mechanical properties are meticulously balanced to provide a versatile material. Its composition typically includes chromium and nickel, which impart corrosion resistance, and other elements contributing to strength and formability. This versatile composition allows it to meet the requirements of various applications.

Material Consistency: Stainless steel 302 is engineered with a consistent composition, ensuring predictable performance and reliability across different applications. Its chemical makeup complies with established industry standards, resulting in a dependable and consistent product.

Application Diversity: Due to its general-purpose nature, the 302 stainless steel round bar finds utility in numerous sectors. Industries ranging from construction and manufacturing to automotive, aerospace, and healthcare benefit from its flexibility, as it can be shaped and employed for different purposes.

Cost-Effective Solution: The 302 stainless steel grade is often favored for its cost-effectiveness. It provides a balanced blend of properties at a reasonable price point, making it an attractive choice for businesses seeking high-performance materials without exceeding their budgets.

Adaptability to Environmental Conditions: This grade exhibits resilience in varying environmental conditions, performing well in both high-temperature and low-temperature settings. Its corrosion resistance ensures longevity, even in challenging surroundings, such as those exposed to moisture, chemicals, or extreme weather conditions.

In conclusion, the designation of “General-Purpose Grade” for the 302 stainless steel bar is based on its chemical composition, consistent performance, wide-ranging applications, cost-effectiveness, and adaptability to diverse environmental conditions. These factors collectively make it a scientifically sound choice for industries requiring a versatile and dependable material.

The exceptional properties of the 302 stainless steel rods are rooted in its precise chemical composition and mechanical characteristics. To scientifically elucidate this feature, let’s delve into the specific attributes that make it a highly regarded material:

Remarkable Corrosion Resistance: The exceptional corrosion resistance of the 302 stainless steel bar can be attributed to its chromium content, typically around 18%. Chromium forms a protective oxide layer on the surface, which acts as a barrier against corrosive elements such as moisture, chemicals, and environmental factors. This property makes it ideal for applications where exposure to corrosive agents is a concern.

Robust Strength: The stainless steel 302 grade boasts robust strength, a quality that results from the careful balance of alloying elements in its composition. This strength is pivotal for applications that require load-bearing components and structural integrity. It can withstand mechanical stress, making it a dependable choice in various industrial settings.

Flexibility: The 302 stainless steel’s composition, which includes nickel and other elements, imparts flexibility to the material. This makes it amenable to forming, bending, and shaping, allowing it to adapt to specific manufacturing requirements. Its ductility is scientifically advantageous, as it ensures ease of fabrication and customization.

Excellent Weldability: Welding is a critical process in many applications, and the 302 stainless steel excels in this aspect. Its composition enables consistent and reliable welds. This characteristic is rooted in the alloy’s metallurgical properties, which support secure joining with other components, contributing to the overall structural integrity of fabricated parts.

Versatility and Cost-Effectiveness: The 302 stainless steel’s remarkable blend of properties—corrosion resistance, strength, flexibility, and weldability—renders it a versatile material suitable for diverse applications. Its cost-effectiveness is scientifically backed by its balance of properties, which allows businesses to meet performance requirements without incurring excessive costs.

Adaptability to Temperature Extremes: Its performance isn’t limited to a specific temperature range. This stainless steel grade maintains its integrity in both high-temperature and low-temperature environments, proving its adaptability. Whether subjected to elevated heat or frigid conditions, it consistently delivers reliable performance.

In summary, the excellent properties of the 302 stainless steel rod, characterized by its corrosion resistance, strength, flexibility, weldability, versatility, and adaptability to temperature extremes, are underpinned by its precise chemical composition. Scientifically, these attributes collectively establish it as a valued material for a wide array of applications, ensuring reliable performance and durability in challenging conditions.

The high corrosion resistance of the 302 stainless steel round bar is a result of its specific chemical composition, primarily featuring a significant chromium content, typically around 18%. This property can be scientifically elucidated as follows:

Chromium’s Protective Role: Chromium plays a pivotal role in rendering the 302 stainless steel highly resistant to corrosion. It reacts with oxygen in the air to form a thin, passive oxide layer on the surface of the material. This layer acts as a protective barrier, preventing further interaction of the steel with the surrounding environment. Scientifically, this phenomenon is known as passivation.

Barrier Against Environmental Factors: The passive oxide layer is highly effective in shielding the steel from the detrimental effects of environmental factors. It serves as a protective shield against moisture, which could lead to rust and corrosion, and also provides resistance to various chemicals, including acids and alkalis. This is especially critical in applications where exposure to corrosive agents is a constant concern.

Long-Term Durability: The formation of this oxide layer is a natural and ongoing process, ensuring long-term durability and corrosion resistance. This layer continuously repairs itself when damaged, further enhancing the stainless steel’s resilience in harsh conditions.

Applications in Corrosion-Prone Environments: Scientifically, the 302 stainless steel’s high corrosion resistance is an essential characteristic, making it well-suited for applications in industries where protection against corrosion is paramount. It is commonly employed in environments where exposure to moisture, chemicals, and other corrosive elements is a routine challenge.

Versatility in Challenging Conditions: The steel’s resistance to corrosion, coupled with its other excellent properties, makes it a versatile choice in applications ranging from architectural and industrial components to marine equipment and more. Its durability and dependability are backed by scientific principles that ensure it performs reliably in challenging conditions.

In conclusion, the high corrosion resistance of the 302 stainless steel bar is a scientifically substantiated attribute stemming from its chromium content and the formation of a protective oxide layer. This resistance is essential for various applications, ensuring the long-term durability and reliability of the material in the face of environmental and chemical challenges.

The lightweight nature of the 302 stainless steel round bar is a characteristic that can be scientifically explained as follows:

Material Density: Stainless steel, in general, is less dense than many other metals, making it inherently lightweight. This property is attributed to its relatively low density, typically around 7.9 g/cm³ for stainless steel, compared to denser materials like carbon steel or iron.

Alloy Composition: The specific alloy composition of the 302 stainless steel contributes to its lightweight nature. This alloy primarily consists of iron, chromium, and nickel, along with small amounts of other elements. Chromium and nickel are less dense than iron, which helps reduce the overall density of the alloy.

Strength-to-Weight Ratio: The lightweight characteristic of the 302 stainless steel does not compromise its strength. It maintains robust strength and durability despite being lightweight. This balance between weight and strength is essential for various applications.

Ease of Handling: Its lightweight nature makes the 302 stainless steel round bar easy to handle, transport, and install. This is particularly advantageous in situations where manual labor is involved, as it reduces the physical strain on workers.

Versatile Applications: The combination of lightweight properties and excellent corrosion resistance, as discussed earlier, makes it a versatile material for numerous applications. Its ease of handling adds to its user-friendliness across industries.

In summary, the lightweight nature of the 302 stainless steel round bar is rooted in the material’s density, alloy composition, and a well-balanced strength-to-weight ratio. This feature enhances its practicality, making it easy to work with in various applications, and is particularly valuable in situations where minimizing physical effort and ensuring ease of handling are key considerations.

The high fatigue strength of the 302 stainless steel round bar is a crucial property that can be scientifically elaborated as follows:

Microstructure and Alloy Composition: The exceptional fatigue strength of this stainless steel grade can be attributed to its microstructure and alloy composition. It consists of primarily iron, chromium, and nickel, which work together to provide strength and durability. Chromium enhances the material’s resistance to corrosion, while nickel contributes to its toughness and fatigue resistance. This combination is critical in withstanding cyclical loading and stress.

Grain Structure: The microstructure of the steel, often characterized by a fine and uniform grain structure, is conducive to high fatigue strength. A refined grain structure minimizes the potential for crack initiation and propagation, which is vital in fatigue resistance.

Heat Treatment: The heat treatment processes used during the manufacturing of 302 stainless steel can further enhance its fatigue strength. Specific heat treatments can modify the material’s microstructure and mechanical properties, making it even more resilient to fatigue.

Machinability: The material’s machinability refers to its ease of being cut, shaped, and customized to meet specific requirements. This property simplifies the process of fabricating components from the 302 stainless steel round bar, which is essential for many applications. The ability to machine the material precisely without compromising its integrity is a valuable characteristic.

Applications: High fatigue strength is particularly important in applications where components undergo repetitive or cyclical loading, such as springs, fasteners, and various mechanical parts. The 302 stainless steel’s ability to withstand these stress cycles without deformation or failure ensures the reliability and longevity of these components.

In conclusion, the high fatigue strength of the 302 stainless steel round bar results from a combination of its alloy composition, microstructure, heat treatment, and exceptional machinability. This property makes it a reliable choice for components and structures exposed to cyclical loading and stress, where longevity and performance are paramount.

application Of 302 Stainless Steel Bar

Stamping, Spinning, Wire Forming

The 302 stainless steel bar plays a vital role in industries where stamping, spinning, and wire forming are integral processes. Its exceptional malleability and durability make it a top choice for manufacturing sectors, allowing efficient stamping, blanking, and forming operations. This stainless steel grade excels in applications requiring precise and intricate designs, producing components like connectors, brackets, and intricate wire forms. Its resistance to corrosion and wear ensures that the resulting products maintain their integrity and performance, making it indispensable in the automotive, aerospace, and electrical industries, among others.

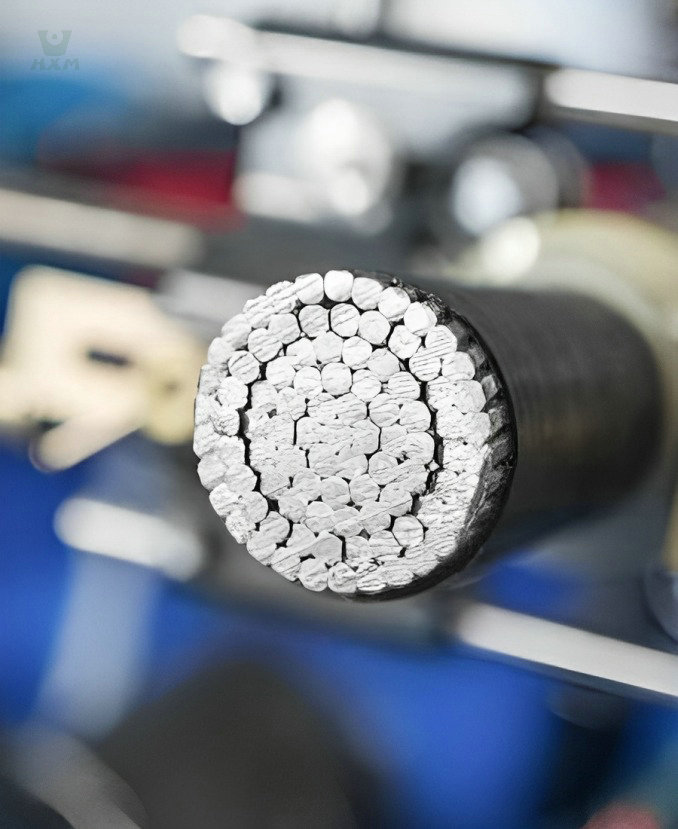

Washers, Springs, Screens, and Cables

The 302 stainless steel rod is a cornerstone in the manufacturing of washers, springs, screens, and cables across various industries. Its remarkable properties, including corrosion resistance, strength, and flexibility, make it an ideal choice for producing high-quality components that require reliability and longevity. In sectors such as automotive, electronics, and telecommunications, this stainless steel grade is essential for creating washers that provide precise spacing and cushioning, springs with consistent resilience, screens that offer durability and visibility, and cables that transmit signals effectively, meeting the stringent demands of modern technology and manufacturing.

Home Appliances

The 302 stainless steel bar plays a crucial role in the manufacturing of home appliances. Due to its outstanding corrosion resistance, flexibility, and excellent machinability, this stainless steel grade is employed in various components within home appliances such as refrigerators, dishwashers, washing machines, and stovetops. It ensures that these appliances withstand the challenges of a home environment, including exposure to moisture, temperature variations, and mechanical stress, while maintaining their functionality and appearance. This versatile material supports the production of durable and reliable home appliances, contributing to their longevity and performance in households worldwide.

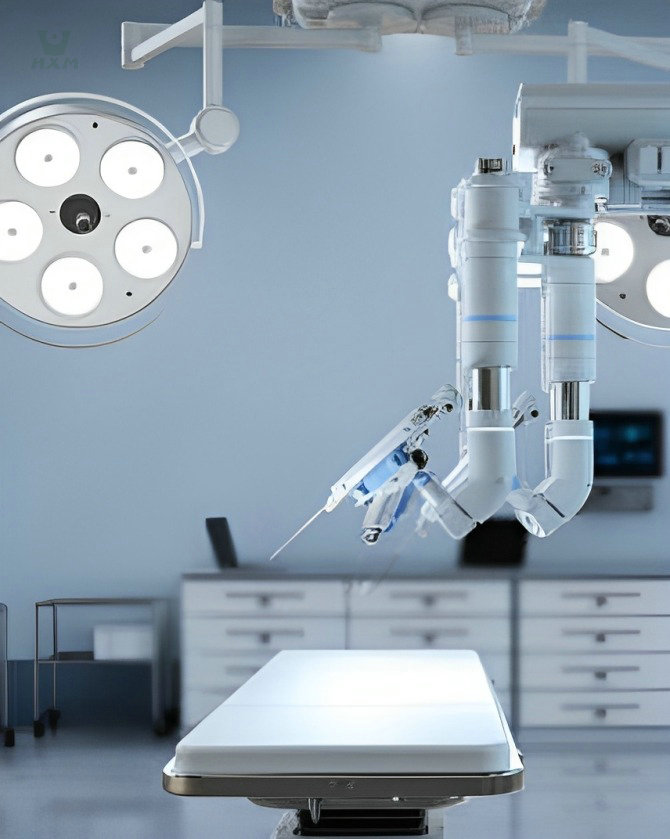

Hospital Equipment

The 302 stainless steel bar finds significant utility in the medical sector for crafting various hospital equipment. Thanks to its remarkable corrosion resistance, strength, and ease of fabrication, it's employed in the production of essential medical devices and instruments. From surgical instruments and diagnostic equipment to hospital furniture and patient handling systems, this stainless steel grade ensures the durability and reliability of these critical tools. Its ability to withstand sterilization processes and harsh hospital environments makes it a trusted choice for maintaining the high standards of hygiene and functionality required in the medical field.

FAQ

The primary distinction between 302 stainless steel bar and 304 stainless steel bar lies in their chemical compositions. Both grades are part of the 300 series of stainless steels and share some similarities in terms of corrosion resistance and mechanical properties. However, 304 stainless steel contains a higher percentage of chromium and nickel compared to 302 stainless steel, making it more corrosion-resistant in certain environments. While 302 stainless steel bar is suitable for general-purpose applications, 304 stainless steel bar is often chosen for its superior corrosion resistance, especially in settings exposed to acids, alkalis, and chloride-rich conditions. Stainless steel bar suppliers can provide both grades to meet specific requirements.

The distinction between 302 stainless steel bar and 316 stainless steel bar mainly arises from differences in their chemical compositions and applications. Both belong to the stainless steel family, but they serve distinct purposes.

Chemical Composition: 316 stainless steel contains more molybdenum than 302 stainless steel, enhancing its corrosion resistance, especially in chloride-rich environments. This makes it suitable for marine and chemical applications.

Corrosion Resistance: 316 stainless steel excels in resisting corrosion, including pitting and crevice corrosion, due to its molybdenum content, making it preferred for aggressive environments.

Applications: While 302 stainless steel is used for general-purpose applications due to its excellent properties, 316 stainless steel is favored in applications requiring superior corrosion resistance, such as marine equipment, chemical processing, and medical devices.

Stainless steel bar suppliers offer both grades, allowing users to select the one that best suits their specific requirements.

Yes, 302 stainless steel bar is generally weldable, thanks to its good weldability. Stainless steel bar suppliers often provide 302 stainless steel bar in various forms, such as round bars, which can be effectively welded using appropriate welding techniques and equipment. However, it’s essential to follow recommended welding procedures and use suitable filler materials to achieve strong and reliable welds with 302 stainless steel.

Certainly, 302 stainless steel bar can be customized to suit specific industrial or commercial applications. Stainless steel bar suppliers offer a range of customization options to tailor the bar’s dimensions, surface finish, and other characteristics to meet the unique requirements of different applications. Whether it’s for specific shapes, sizes, or surface treatments, stainless steel bars can be adapted to ensure they perform optimally in various industries. It’s advisable to consult with stainless steel bar suppliers to discuss the specific customization needs for your application.

Yes, 302 stainless steel bars are typically magnetic. This is due to their composition, which includes iron as the primary element. Magnetic properties make them suitable for various applications, especially where magnetic characteristics are desired. Stainless steel bar suppliers can provide more information about the specific magnetic properties of 302 stainless steel bars for your application.

The dimensions and available forms of 302 stainless steel bars can vary, depending on your specific requirements and the stainless steel bar supplier you choose. Typically, these bars are available in various shapes, such as round, square, hexagonal, or flat, and they come in different sizes and lengths. The specific dimensions, forms, and availability can be obtained from your chosen stainless steel bar supplier, who can provide detailed information based on your needs.

recent stainless steel bar products

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China