304 Stainless Steel Bar Supplier

Diameter: 3mm-480mm, 1/8″ to 2 1/4″

Standard: GB1220, ASTM A484/484M, EN 10060/ DIN 1013 ASTM A276, EN 10278, DIN 671

Main Grade: 201, 304, 316, 316L, 310s, 430

Finish: Black, NO.1, mill finish, cold draw, H9, H11

Product Description Of 304 stainless steel bar

The 304 stainless steel bar, also known as UNS S30400, is a widely recognized and frequently utilized member of the stainless steel family. It belongs to the austenitic alloy category, characterized by its composition of iron, 18% chromium, and 8% nickel. The ‘L’ designation in 304/L signifies a lower carbon content, enhancing its corrosion resistance during welding. This material boasts exceptional qualities such as good strength, formability, and remarkable corrosion resistance, making it ideal for a wide range of applications where durability and anti-corrosive properties are crucial. It’s a cost-effective and versatile choice suitable for various industries.

specification Of 304 stainless steel bar

chemical components of 304 stainless steel bar

304 | C % | Si % | Mn % | P % | S % | Ni % | Cr % | Mo % | N % | Cu % |

ASTM | 0.08 | 0.75 | 2.00 | 0.045 | 0.030 | 8.0 – 10.5 | 18.0 – 20.0 | – | 0.10 | – |

DIN/EN | 0,07 | 1,00 | 2,00 | 0,045 | 0,015 | 8,0 – 10,5 | 17,5 – 19,5 | – | 0,10 | – |

JIS | 0.08 | 1.00 | 2.00 | 0.045 | 0.030 | 8.0 – 10.5 | 18.0 – 20.0 | – | – | – |

GB | 0.08 | 1.00 | 2.00 | 0.045 | 0.030 | 8.0 – 10.0 | 18.0 – 20. 0 | – | – | – |

physical property of 304 stainless steel bar

| 304 | Density (g/cm³) | Melting point (℃) | Thermal conductivity (W/m-K) | Coefficient of thermal expansion (10^-6/K) | Elastic Modulus(GPa) | Poisson’s Ratio |

| ASTM | 7.93 | 1398-1454 | 16.2-24.9 | 17.3-17.8 | 200 | 0.3 |

| JIS | 7.93 | 1398-1454 | 16.2-24.9 | 17.3-17.8 | 193 | 0.3 |

| EN | 7.9 | 1400-1450 | 15-21.5 | 17.0-17.5 | 193 | 0.3 |

| GB | 7.9 | 1398-1454 | 16.2-24.9 | 17.3-17.8 | 193 | 0.3 |

mechanical property of 304 stainless steel bar

304 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | 205 | 515 | 40 | – | 92 | 201 | – |

JIS | 205 | 520 | 40 | 187 | 90 | – | 200 |

GB | 205 | 515 | 40 | – | 92 | 201 | 210 |

characteristics Of 304 stainless steel bar

304 stainless steel, particularly the variant denoted as 304/L with its lower carbon content, exhibits exceptional corrosion protection properties. This attribute is especially prominent during welding processes.

The significance of this corrosion protection lies in the prevention of localized corrosion, such as pitting and crevice corrosion, which can occur in aggressive environments. The reduced carbon content minimizes the formation of carbides, thereby preserving the material’s corrosion resistance.

In practical terms, this means that 304 stainless steel can withstand exposure to various corrosive elements, making it suitable for applications in industries where resistance to rust and corrosion is crucial. Whether it’s facing chemical solutions, acidic environments, or exposure to moisture, the 304 stainless steel bar’s corrosion protection ensures its durability and longevity.

This feature makes 304 stainless steel an ideal choice for a wide array of applications, from kitchen appliances and architectural components to industrial equipment and structural supports, where maintaining structural integrity in corrosive conditions is imperative.

The 304 stainless steel bar is widely recognized and acclaimed in various industries for its exceptional attributes. It has earned its reputation as one of the most familiar and frequently used alloys within the stainless steel family.

This recognition is attributed to its versatility and reliability across a broad spectrum of applications. Engineers, manufacturers, and designers across industries acknowledge the 304 stainless steel bar for its impressive combination of strength, formability, and outstanding corrosion resistance.

Moreover, its wide recognition extends to its ease of fabrication, making it a preferred choice for countless projects and products. Whether in the construction of architectural components, manufacturing of kitchen appliances, or crafting industrial equipment, the 304 stainless steel bar is a trusted and widely embraced material.

This widespread recognition is not only a testament to its performance but also a reflection of its cost-effectiveness. Industries have come to rely on 304 stainless steel for its ability to provide durable support, corrosion resistance, and excellent value, making it a top choice in numerous applications.

The composition of the 304 stainless steel bar, also known as UNS S30400, is primarily characterized by its austenitic structure. This alloy is composed of a precise combination of elements that contribute to its exceptional properties:

Iron (Fe): Iron is the base metal of the alloy, forming the structural foundation.

Chromium (Cr): With a chromium content of approximately 18%, 304 stainless steel gains its corrosion-resistant properties. Chromium forms a passive oxide layer on the surface, safeguarding against rust and corrosion.

Nickel (Ni): Nickel, constituting around 8% of the alloy, enhances its corrosion resistance and provides stability in various environments.

Carbon (C): The ‘L’ in 304/L signifies a lower carbon content compared to standard 304 stainless steel. This reduced carbon content minimizes the risk of sensitization and intergranular corrosion during welding, making it suitable for welded applications.

Manganese (Mn): Manganese is present in small amounts, contributing to the alloy’s overall strength and workability.

Silicon (Si): Silicon aids in deoxidizing the steel and enhancing its resistance to scaling at high temperatures.

Phosphorus (P): Phosphorus is present in minimal quantities and primarily serves as an impurity control.

Sulfur (S): Sulfur is also present in trace amounts and helps improve machinability.

This precisely balanced composition is the key to the 304 stainless steel bar’s outstanding corrosion resistance, mechanical strength, formability, and weldability. It is this harmonious blend of elements that makes it a highly sought-after material across various industries.

Certainly, let’s discuss the impressive qualities of the 304 stainless steel bar:

Corrosion Resistance: The 304 stainless steel bar offers exceptional resistance to corrosion, making it suitable for various applications in corrosive environments. Its chromium content forms a protective oxide layer on the surface, preventing rust and corrosion.

Versatility: This alloy is one of the most versatile materials in the stainless steel family. It finds applications in a wide range of industries, including construction, automotive, food processing, and more, due to its ability to perform well in diverse conditions.

Weldability: Thanks to its lower carbon content (indicated by the ‘L’ in 304/L), the 304 stainless steel bar exhibits excellent weldability. It can be easily welded without the risk of sensitization or intergranular corrosion.

Strength: Despite being non-hardenable by heat treatment, 304 stainless steel maintains good strength and durability. It offers reliable mechanical performance for structural and load-bearing applications.

Formability: This alloy is easy to shape and form, making it a preferred choice for various manufacturing processes, including machining, bending, and fabrication.

Longevity: The 304 stainless steel bar’s resistance to rust and corrosion ensures a long lifespan, reducing maintenance costs and enhancing the durability of components.

Cost-Effective: It is a cost-effective material due to its widespread availability, ease of manufacturing, and longevity, making it an economical choice for many applications.

These impressive qualities collectively make the 304 stainless steel bar a popular and dependable material in numerous industries, offering solutions for a wide range of engineering challenges.

The tensile strength of the 304 stainless steel bar is one of its notable qualities. It exhibits impressive tensile strength, which is the maximum stress it can endure while being stretched or pulled before breaking. This high tensile strength makes it suitable for applications where robust structural support and load-bearing capabilities are required. Whether in construction, automotive, or other industries, the 304 stainless steel bar’s ability to withstand significant tensile forces contributes to its reliability and versatility.

Application Of 304 stainless steel bar

Food Handling and Processing Equipment

Food Handling and Processing Equipment: The 304 stainless steel bar plays a crucial role in the food industry. Its exceptional corrosion resistance and ease of cleaning make it ideal for manufacturing food handling and processing equipment. From conveyor systems to storage tanks and food preparation surfaces, this stainless steel variant ensures the hygienic processing and safe handling of food products. Its resistance to corrosion from acidic foods and cleaning agents, coupled with its durability, minimizes contamination risks. This is why it's the top choice for everything from industrial kitchen appliances to sterile food processing environments, upholding the highest sanitary standards.

Screws and Machinery Parts

Screws and Machinery Parts: The 304 stainless steel bar finds extensive use in manufacturing screws and various machinery components. Its remarkable strength, corrosion resistance, and ease of machining make it an ideal material for these applications. In the world of machinery, where reliability and longevity are paramount, 304 stainless steel stands out. Whether it's fasteners, gears, or structural components, this stainless steel alloy ensures that machinery operates smoothly and withstands the rigors of daily use. Its resistance to corrosion in various environments, including those with exposure to moisture and chemicals, further enhances its suitability for these critical applications.

Architectural Field

Architectural Field: In the architectural realm, the 304 stainless steel bar plays a vital role. Thanks to its aesthetic appeal, corrosion resistance, and durability, it's a top choice for various architectural applications. It's frequently used for exterior accents such as water features, fire installations, and decorative elements. The steel's ability to withstand weathering ensures these architectural embellishments maintain their visual appeal for years. Whether it's adorning modern buildings, enhancing outdoor spaces, or adding a touch of sophistication to interior designs, the 304 stainless steel bar's versatility and reliability make it an indispensable material in the world of architecture.

FAQ

304 stainless steel is a popular choice in the stainless steel family, but it has distinct differences when compared to other grades, such as 316 stainless steel:

Corrosion Resistance: Both 304 and 316 stainless steel offer excellent corrosion resistance. However, 316 stainless steel has a higher resistance to chlorides, making it more suitable for marine and coastal environments.

Composition: 304 stainless steel contains 18% chromium and 8% nickel, while 316 stainless steel contains 16% chromium, 10% nickel, and 2% molybdenum. The presence of molybdenum in 316 enhances its corrosion resistance, especially in acidic and chloride-rich conditions.

Use in Saline Environments: 316 stainless steel is preferred for applications involving exposure to saltwater or saline solutions due to its superior resistance to pitting and crevice corrosion.

Temperature Resistance: 316 stainless steel exhibits better high-temperature resistance compared to 304, making it suitable for applications in elevated-temperature environments.

Cost: 304 stainless steel is generally more cost-effective than 316, making it a popular choice for a wide range of applications where extreme corrosion resistance is not required.

Weldability: Both grades are weldable, but 316 stainless steel may require special considerations during welding to prevent carbide precipitation and maintain corrosion resistance.

While 304 stainless steel is versatile and widely used, the choice between 304 and 316 depends on the specific application and the level of corrosion resistance required. Consulting with a stainless steel bar supplier can help determine the best grade for your needs.

Yes, 304 stainless steel bars can be heat-treated to increase their strength. The most common heat treatment process for 304 stainless steel is annealing. Annealing involves heating the material to a specific temperature (usually around 1900°F or 1040°C) and then cooling it slowly. This process helps relieve internal stresses, improve ductility, and enhance the material’s mechanical properties, including its strength.

However, it’s important to note that 304 stainless steel is not a heat-treatable grade in the same way as some other stainless steel alloys, like 17-4 PH stainless steel, which can be significantly hardened through heat treatment. Heat treatment of 304 stainless steel primarily focuses on stress relief and improving its formability and machinability.

For applications where higher strength is a critical requirement, you might consider using a different stainless steel grade that is specifically designed for heat treatment and offers superior strength properties when heat-treated. Consulting with a stainless steel bar supplier can help you choose the most suitable material and heat treatment process for your specific needs.

The machining capabilities of 304 stainless steel bars are quite good, making them a popular choice for various machining processes. Some key machining features of 304 stainless steel include:

Excellent Formability: 304 stainless steel is known for its ease of formability, which allows it to be machined into a wide range of shapes and components.

Machinability: It exhibits good machinability, especially in annealed or low-carbon versions like 304L. This means it can be easily cut, drilled, and machined with standard machining tools and techniques.

Cutting: It can be efficiently cut into various lengths and shapes using cutting methods like sawing, shearing, or laser cutting.

Drilling: 304 stainless steel can be drilled using standard twist drills, although carbide or cobalt drill bits are recommended for extended tool life.

Turning and Milling: It is suitable for turning and milling operations, making it versatile for manufacturing components.

Welding: While not a machining process, 304 stainless steel also offers good weldability, allowing components to be joined using various welding techniques.

Surface Finish: 304 stainless steel can achieve a wide range of surface finishes, from rough to high-polish, depending on the desired aesthetics and functional requirements.

Tolerance Control: It allows for tight tolerance control in machining operations, ensuring precise dimensions and high-quality parts.

It’s important to note that the specific machining parameters and techniques can vary depending on the grade of 304 stainless steel being used (e.g., 304 vs. 304L) and the machining equipment and tools employed. Consulting with a stainless steel bar supplier or machining expert can provide valuable guidance for optimizing machining processes with 304 stainless steel bars.

304 stainless steel and 316 stainless steel are two common stainless steel grades, and they differ primarily in their chemical composition and some properties. Here’s a comparison between the two:

Chemical Composition:

304 Stainless Steel: It is also known as 18-8 stainless steel, containing 18% chromium and 8% nickel. It’s an austenitic stainless steel with good general corrosion resistance and excellent forming and welding characteristics.

316 Stainless Steel: It contains 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. The addition of molybdenum enhances its corrosion resistance, especially in chloride-rich environments. As a result, 316 stainless steel is often referred to as “marine-grade” stainless steel.

Corrosion Resistance:

304 Stainless Steel: It offers good corrosion resistance, making it suitable for various applications, including indoor and outdoor use. However, it may not be as corrosion-resistant as 316 stainless steel in highly corrosive environments.

316 Stainless Steel: Due to the presence of molybdenum, it provides superior corrosion resistance, particularly in marine and chloride-exposed environments. It’s ideal for applications like coastal structures, chemical processing, and marine equipment.

Applications:

304 Stainless Steel: Commonly used in a wide range of applications, including kitchen appliances, food processing equipment, architectural components, and fasteners.

316 Stainless Steel: Preferred for applications requiring exceptional corrosion resistance, such as marine equipment, pharmaceutical equipment, chemical processing, and medical devices.

Price:

304 Stainless Steel: Generally more cost-effective than 316 stainless steel, making it a popular choice for various applications where extreme corrosion resistance is not necessary.

316 Stainless Steel: Due to its superior corrosion resistance and molybdenum content, 316 stainless steel is typically more expensive than 304 stainless steel.

In summary, the choice between 304 and 316 stainless steel depends on the specific application and the level of corrosion resistance required. A stainless steel bar supplier can provide guidance on selecting the appropriate grade based on your project’s needs.

304 stainless steel bars are available in various forms to suit different applications and manufacturing processes. Common forms of 304 stainless steel bars include:

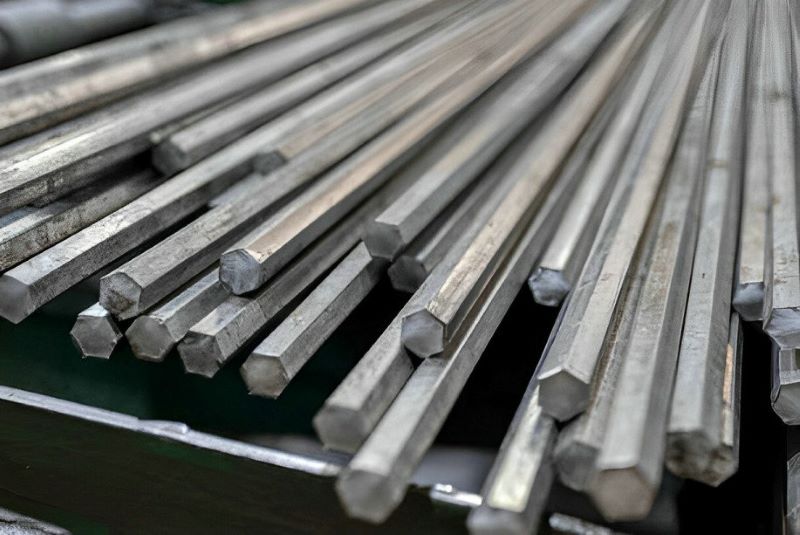

Round Bars: These are cylindrical bars with a circular cross-section. Round bars are widely used in various applications, including shafts, fasteners, and general fabrication.

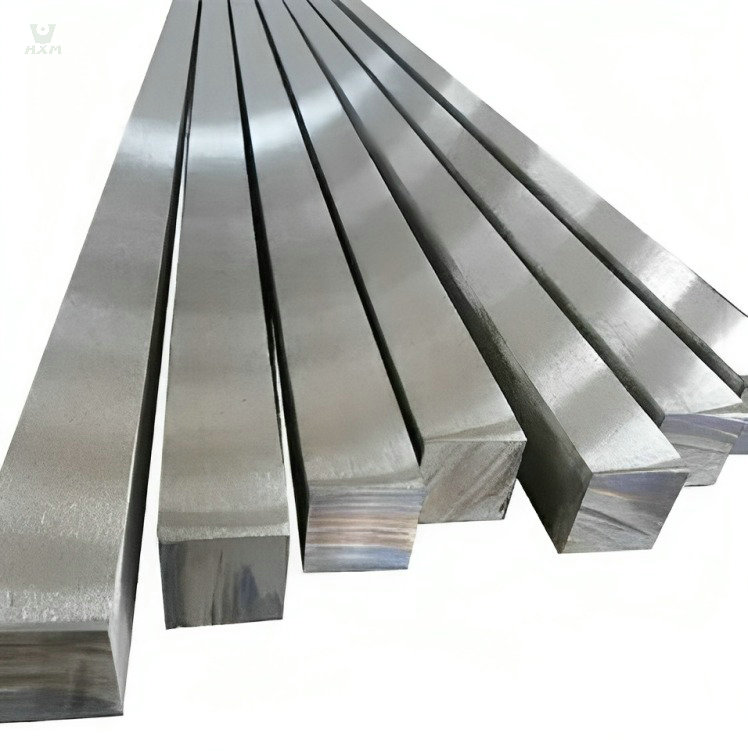

Square Bars: Square bars have a square cross-section, making them suitable for applications where square or sharp edges are required, such as architectural details and decorative elements.

Hexagonal Bars: Hexagonal bars have a hexagonal (six-sided) cross-section. They are often used in applications where increased strength and rigidity are needed, such as in construction and machinery.

Flat Bars: Flat bars have a rectangular cross-section with sharp edges. They are commonly used for architectural and structural purposes, as well as in manufacturing and fabrication.

Angle Bars: Angle bars have an L-shaped cross-section, with two legs at a 90-degree angle. They are used in structural and architectural applications, such as framing and supports.

Channel Bars: Channel bars have a U-shaped cross-section and are commonly used in construction and architectural applications, especially for framing and support structures.

Half-Round Bars: Half-round bars have a semicircular cross-section. They are used in applications where a smooth, rounded edge is required, such as in handrails and decorative trim.

Precision Ground Bars: Precision ground bars are carefully machined to achieve precise dimensions and a smooth surface finish. They are often used in high-precision applications, such as in the manufacturing of machinery and equipment components.

Threaded Bars: Threaded bars have threads cut into their surface, allowing for easy attachment to other components using nuts or threaded fasteners. They are used in various construction and assembly applications.

Hollow Bars: Hollow bars have a tubular cross-section and are used in applications where lightweight and structural integrity are essential, such as in the manufacture of conveyor systems and automotive components.

These different forms of 304 stainless steel bars cater to a wide range of industries and applications, from construction and manufacturing to aerospace and food processing. A stainless steel bar supplier can provide these bars in various sizes, lengths, and finishes to meet specific project requirements.

You can purchase high-quality 304 stainless steel bars from Huaxiao, a reputable stainless steel bar supplier known for providing top-notch stainless steel products. Huaxiao offers a wide range of stainless steel bars in various forms, sizes, and finishes to meet your specific needs. Whether you require round bars, square bars, flat bars, or any other form of 304 stainless steel, Huaxiao is a trusted source for reliable stainless steel products. Their commitment to quality and customer satisfaction makes them a preferred choice for stainless steel bars and other stainless steel materials.

other products

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China