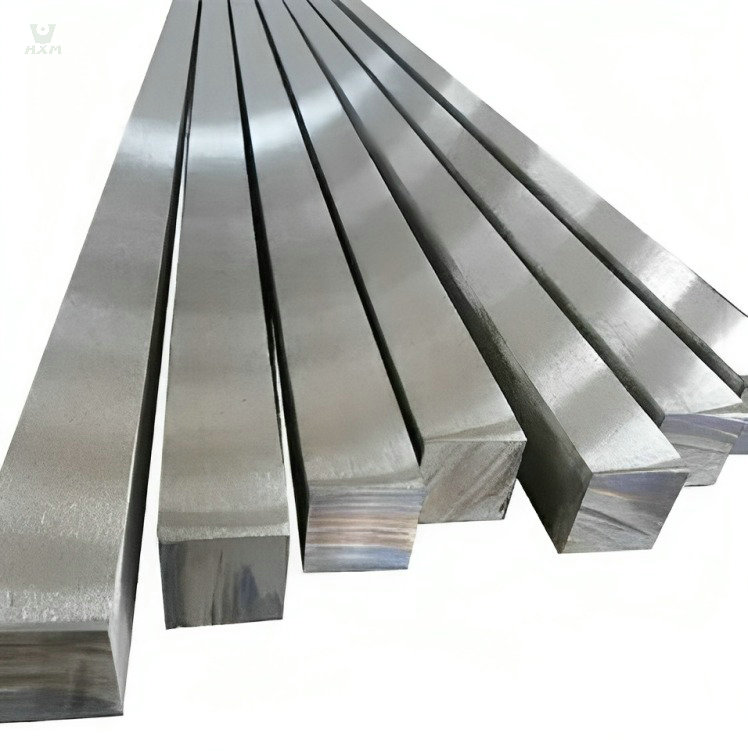

316 Stainless Steel Bar Supplier

Diameter: 3mm-480mm, 1/8″ to 2 1/4″

Standard: GB1220, ASTM A484/484M, EN 10060/ DIN 1013 ASTM A276, EN 10278, DIN 671

Main Grade: 201, 304, 316, 316L, 310s, 430

Finish: Black, NO.1, mill finish, cold draw, H9, H11

Product Description Of 316 Stainless Steel Bar

Introducing our premium 316 Stainless Steel Bar, also known as UNS S31600, renowned for its exceptional corrosion resistance and versatile applications. As a molybdenum-bearing grade, it stands as a testament to durability and performance in challenging environments.

This stainless steel bar outshines many counterparts, thanks to the unique properties bestowed by molybdenum. It offers superior corrosion resistance, especially in chloride-rich settings, making it a top choice for industries like chemical processing, textile processing, paper and pulp production, and heat exchangers. In these demanding environments, 316 stainless steel excels, ensuring longevity and reliability.

One of its standout features is its impressive ductility and formability, allowing for easy fabrication and adaptability to various shapes and designs. Whether you’re crafting intricate components or robust structures, 316 stainless steel delivers exceptional results.

Furthermore, this grade’s weldability is a boon for manufacturers, as it can be conveniently welded without compromising its corrosion-resistant properties. This opens up a world of possibilities for custom projects and complex assemblies.

Notably, 316 Stainless Steel Bar retains its non-magnetic nature, in line with all austenitic steels. While it cannot be hardened through heat treatment, its inherent strength and resilience more than compensate, ensuring it remains a top choice for critical applications.

specification Of 316 Stainless Steel Bar

chemical composition of 316 Stainless Steel Bar

| Element | Composition (%) |

|---|---|

| Carbon (C) | ≤ 0.08 |

| Silicon (Si) | ≤ 1.00 |

| Manganese (Mn) | ≤ 2.00 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.030 |

| Chromium (Cr) | 16.00 – 18.00 |

| Nickel (Ni) | 10.00 – 14.00 |

| Molybdenum (Mo) | 2.00 – 3.00 |

| Nitrogen (N) | ≤ 0.10 |

mechanical property of 316 Stainless Steel Bar

| Property | Value |

|---|---|

| Tensile Strength | 580 – 800 MPa |

| Yield Strength (0.2%, Rp0.2) | ≥ 250 MPa |

| Elongation at Break (in 50mm) | ≥ 40% |

| Modulus of Elasticity | 193 GPa |

| Hardness (Brinell) | ≤ 217 HBW |

| Hardness (Rockwell B) | ≤ 95 HRB |

| Impact Strength | ≥ 50 J (20°C) |

physical property of 316 Stainless Steel Bar

| Property | Value |

|---|---|

| Density | 8.00 g/cm³ |

| Melting Point | 1370 – 1400°C (2500 – 2550°F) |

| Electrical Resistivity | 7.4 x 10⁻⁷ Ω·m |

| Thermal Conductivity | 16.3 W/(m·K) |

| Thermal Expansion Coefficient | 15.9 x 10⁻⁶/°C (20-100°C) |

| Specific Heat Capacity | 500 J/(kg·K) |

| Magnetic Susceptibility | Non-magnetic |

characteristics Of 316 Stainless Steel Bar

316 Stainless Steel Bar boasts an exceptional level of corrosion resistance that sets it apart in demanding environments. This property arises from its high chromium and molybdenum content, granting it an inherent ability to withstand corrosion, particularly in chloride-rich surroundings. Its stainless nature remains unyielding, ensuring longevity and reliability, making it a top choice for applications exposed to harsh chemical, marine, and industrial conditions. The robust resistance to corrosion positions 316 Stainless Steel Bar as a stalwart guardian against the deteriorating effects of the elements, ensuring structural integrity and performance over extended periods.

Molybdenum, an essential component within 316 Stainless Steel Bar, plays a vital protective role in safeguarding against corrosion. This remarkable element acts as a shield, enhancing the steel’s resistance to various corrosive agents, especially in challenging environments laden with chlorides. By forming a resilient barrier, molybdenum ensures the longevity and reliability of 316 Stainless Steel Bar, making it an ideal choice for applications where exposure to corrosive substances is a constant challenge. Molybdenum’s protective prowess elevates the performance and durability of this stainless steel grade, ensuring it remains a stalwart material in the face of adversity.

Weldability and formability are hallmarks of 316 Stainless Steel Bar, making it a versatile and sought-after material in various industries. This stainless steel grade exhibits exceptional weldability, allowing for efficient and secure joining in diverse applications. Its high ductility and formability further enhance its adaptability, enabling the fabrication of intricate components and structures with ease. Whether it’s crafting precision parts or constructing robust assemblies, 316 Stainless Steel Bar’s weldability and formability provide the flexibility and reliability needed for a wide range of projects, cementing its position as a favored choice in engineering and manufacturing.

Heat treatment characteristics of 316 Stainless Steel Bar align with its austenitic nature, as it cannot be hardened through conventional heat treatment methods. Unlike some other steel types, it retains its optimal properties without the need for heat-induced hardening. This non-heat-treatable quality is advantageous in applications where maintaining corrosion resistance and ductility is paramount. Additionally, 316 Stainless Steel Bar remains non-magnetic, a testament to its stable structure. Its heat treatment characteristics emphasize its reliability and suitability for environments demanding consistent performance and resistance to deterioration.

The non-magnetic nature of 316 Stainless Steel Bar is a distinctive feature attributed to its austenitic structure. This property, shared with other austenitic stainless steels, renders it impervious to magnetic forces. This non-magnetic quality is highly advantageous in applications where magnetism is undesired or could interfere with the functionality of equipment. It ensures the integrity of sensitive instruments and components that rely on a magnetically neutral environment. In addition, 316 Stainless Steel Bar’s non-magnetic nature aligns with its exceptional corrosion resistance and makes it an ideal choice for industries and settings where both non-magnetism and durability are essential.

application Of 316 Stainless Steel Bar

Food Preparation Equipment

316 Stainless Steel Bar finds an indispensable role in the domain of food preparation equipment, notably in environments rich in chloride compounds. Its remarkable resistance to corrosion, particularly in the presence of chlorides, ensures the highest standards of hygiene and safety in food handling and processing. The non-reactive nature of this stainless steel grade safeguards the purity of food products, preventing contamination and preserving their quality. Its innate strength and formability enable the fabrication of precision components for food processing machinery, from cutting blades to mixing elements. In food preparation equipment, 316 Stainless Steel Bar emerges as the backbone, guaranteeing longevity, sanitation, and impeccable performance.

Laboratory Benches & Equipment

316 Stainless Steel Bar is a cornerstone material in the construction of laboratory benches and equipment, driven by its exceptional resistance to corrosion and ease of maintenance. In laboratory settings where precision and cleanliness are paramount, this stainless steel grade thrives. Its innate resistance to corrosive agents ensures the longevity of laboratory fixtures and equipment, even in challenging chemical environments. The non-reactive nature of 316 Stainless Steel Bar preserves the integrity of experiments and analyses, preventing contamination. Moreover, its formability allows for the creation of custom-fit laboratory components. Thus, 316 Stainless Steel Bar underpins the reliability, safety, and hygiene crucial in laboratory benches and equipment.

Boat Fittings

316 Stainless Steel Bar plays a pivotal role in boat fittings, thanks to its formidable strength and exceptional resistance to corrosion. In the demanding marine environment, where exposure to saltwater and harsh weather conditions is constant, this stainless steel grade excels. Its robustness ensures that boat fittings, from railings to anchor components, withstand the rigors of marine life, offering durability and longevity. What sets 316 Stainless Steel Bar apart is its heightened resistance to chloride-induced corrosion, safeguarding critical fittings from deterioration. Its non-reactive nature ensures compatibility with marine ecosystems, making it an ideal choice for boat fittings, contributing to safety and reliability on the water.

Threaded Fasteners

316 Stainless Steel Bar proves indispensable in the realm of threaded fasteners, owing to its exceptional strength and unwavering resistance to corrosion. In various industries and applications, where the security and longevity of connections are paramount, this stainless steel grade thrives. Its formidable tensile strength ensures the reliability of threaded connections, even under substantial loads and stress. Moreover, its exceptional corrosion resistance, particularly in chloride-rich environments, ensures the longevity of fasteners, preventing structural compromise due to rust and deterioration. The non-reactive nature of 316 Stainless Steel Bar guarantees the integrity of fastened joints, making it the preferred choice for threaded fasteners across a spectrum of demanding applications.

FAQ

The differences between 316 Stainless Steel Bar and 304 Stainless Steel Bar lie primarily in their chemical compositions and corrosion resistance properties.

316 Stainless Steel Bar, supplied by Huaxiao stainless steel bar supplier, contains molybdenum, which imparts superior corrosion resistance, especially in chloride-rich environments, such as marine and coastal applications. It exhibits remarkable resistance to pitting and crevice corrosion, making it suitable for aggressive conditions.

On the other hand, 304 Stainless Steel Bar, while corrosion-resistant in many environments, lacks the molybdenum content found in 316. Consequently, it may be more susceptible to corrosion in chloride-heavy settings.

In summary, the key distinction between the two lies in their resistance to corrosion, with 316 Stainless Steel Bar being the preferred choice for applications demanding exceptional corrosion resistance, while 304 Stainless Steel Bar is suitable for less demanding environments.

Molybdenum, an essential component within 316 Stainless Steel

Maintaining and cleaning 316 Stainless Steel Bar, supplied by Huaxiao stainless steel bar supplier, is essential to ensure its longevity and appearance. Here are some steps to follow:

Regular Cleaning: Wipe down the surface with a soft, damp cloth to remove dust, dirt, and surface contaminants. For stubborn stains, use a mild detergent or a mixture of water and vinegar.

Avoid Abrasive Cleaners: Do not use abrasive cleaners, steel wool, or scouring pads, as they can scratch the stainless steel surface.

Directional Cleaning: When cleaning, follow the grain or brushed finish of the stainless steel for a smoother and more effective result.

Rinse Thoroughly: After cleaning with a detergent, make sure to rinse the surface thoroughly with clean water to remove any residue.

Avoid Chlorides: Avoid contact with chloride-containing substances, as they can cause corrosion. If contact occurs, rinse promptly.

Passivation: In harsh environments, consider passivating the stainless steel to enhance its corrosion resistance. This process removes contaminants and restores the protective oxide layer.

Protective Coatings: Apply a stainless steel cleaner or protectant to maintain the shine and protect against fingerprints and stains.

Avoid Hard Water Stains: If you have hard water, dry the stainless steel surface after cleaning to prevent mineral deposits and water spots.

Regular cleaning and proper maintenance will help keep your 316 Stainless Steel Bar in optimal condition and preserve its corrosion resistance properties.

Bar, plays a vital protective role in safeguarding against corrosion. This remarkable element acts as a shield, enhancing the steel’s resistance to various corrosive agents, especially in challenging environments laden with chlorides. By forming a resilient barrier, molybdenum ensures the longevity and reliability of 316 Stainless Steel Bar, making it an ideal choice for applications where exposure to corrosive substances is a constant challenge. Molybdenum’s protective prowess elevates the performance and durability of this stainless steel grade, ensuring it remains a stalwart material in the face of adversity.

No, 316 Stainless Steel Bar, provided by Huaxiao stainless steel bar supplier, is not magnetic. It belongs to the austenitic stainless steel family, characterized by its non-magnetic nature. This property is a result of its specific crystalline structure, where the atoms are arranged in a manner that does not create a magnetic field. While some stainless steel alloys may exhibit slight magnetism due to cold working or other factors, 316 Stainless Steel Bar remains non-magnetic under normal conditions. This makes it suitable for applications where magnetic interference must be minimized, such as in certain scientific and medical equipment.

Correctly welding 316 Stainless Steel Bar, supplied by Huaxiao stainless steel bar supplier, requires specific techniques to ensure a strong and durable weld while preserving its corrosion-resistant properties. Here are the steps for proper welding:

Select the Right Filler Metal: Choose a filler metal that matches the composition of 316 Stainless Steel, such as 316L for maximum corrosion resistance. The low carbon content in 316L reduces the risk of carbide precipitation, which can lead to corrosion.

Preparation: Ensure the surfaces to be welded are clean and free from contaminants, including oils, grease, and oxides. Use a stainless steel wire brush or pickling paste to remove any surface impurities.

Welding Process: Use a welding method suitable for stainless steel, such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding. These methods provide precise control over heat input.

Shielding Gas: Employ a shielding gas, typically argon or helium, to protect the weld pool from atmospheric contamination. This helps maintain the corrosion-resistant properties of the stainless steel.

Maintain Interpass Temperature: Control the interpass temperature (the temperature between welding passes) to avoid overheating, which can lead to carbide precipitation and reduced corrosion resistance.

Post-Weld Passivation: After welding, passivate the weld area with a citric acid-based solution or a pickling paste to remove any oxide layers and restore the stainless steel’s protective passive film.

Avoid Overloading: Be mindful of stress and strain on the weld joint, as excessive loading can compromise its integrity.

Inspection: Perform non-destructive testing, such as dye penetrant testing or radiographic inspection, to ensure the weld quality meets the required standards.

Heat Treatment: In some cases, a solution annealing heat treatment may be necessary to restore the stainless steel’s corrosion resistance after welding.

By following these steps and using proper welding techniques, you can achieve strong and corrosion-resistant welds when working with 316 Stainless Steel Bar.

The pricing and availability of 316 Stainless Steel Bar from Huaxiao stainless steel bar supplier can vary depending on factors such as the market demand, quantity required, dimensions, and surface finish. Stainless steel prices are subject to market fluctuations, so it’s advisable to contact Huaxiao stainless steel bar supplier directly for current pricing and availability information. They can provide you with specific details tailored to your requirements and offer competitive pricing based on the quantity and specifications of the bars you need. Additionally, they can inform you about lead times and any special order considerations.

The manufacturability of 316 Stainless Steel Bar from Huaxiao stainless steel bar supplier is excellent, making it a preferred choice for a wide range of applications. Here are some key points regarding its manufacturability:

Formability: 316 Stainless Steel Bar is highly ductile and formable, allowing it to be easily shaped into various profiles, including rounds, squares, hexagons, and more. This versatility makes it suitable for a broad spectrum of manufacturing processes.

Machinability: This stainless steel grade exhibits good machinability, enabling efficient cutting, drilling, and milling operations. It maintains its dimensional stability during machining.

Weldability: 316 Stainless Steel Bar can be readily welded using standard welding techniques, such as TIG or MIG welding. Proper procedures should be followed to preserve its corrosion-resistant properties during welding.

Heat Treatment: While 316 Stainless Steel Bar cannot be hardened by heat treatment, it can undergo solution annealing to optimize its properties after welding or forming processes.

Surface Finish: It is available in various surface finishes, including polished, brushed, and mill finishes, allowing manufacturers to choose the most suitable finish for their specific applications.

Corrosion Resistance: Its exceptional corrosion resistance ensures that the material remains durable and reliable even in aggressive environments, reducing the risk of premature failure.

Availability: 316 Stainless Steel Bar is widely available in different sizes and forms, providing manufacturers with options to meet their production needs.

Overall, the manufacturability of 316 Stainless Steel Bar makes it a versatile and reliable material for a wide range of manufacturing processes and applications, particularly those requiring corrosion resistance and durability.

Recycling and reuse of 316 Stainless Steel Bar from Huaxiao stainless steel bar supplier are integral parts of sustainable stainless steel production. Here’s how recycling and reuse are managed for this stainless steel grade:

Collection and Sorting: Used stainless steel bars are collected from various sources, including industrial sites, construction projects, and end-of-life products. They are then sorted based on their type and alloy composition.

Melting and Refining: The collected 316 Stainless Steel Bars are melted down in specialized furnaces to recover the raw material. During this process, impurities are removed, and the stainless steel is refined to meet quality standards.

Alloy Separation: Stainless steel is often alloyed with other metals like nickel, chromium, and molybdenum. Alloy separation is performed to ensure that the recycled material retains its original alloy composition.

Reproduction: Once the stainless steel is purified and separated, it can be used to produce new 316 Stainless Steel Bars. This recycled material is typically combined with virgin stainless steel to create products with the desired properties.

Reduced Environmental Impact: Recycling stainless steel reduces the environmental impact associated with mining and refining raw materials. It conserves energy and minimizes greenhouse gas emissions, making it an environmentally responsible choice.

Reuse: In some cases, 316 Stainless Steel Bars can be refurbished and reused in their existing form. This is common in applications where the material remains structurally sound, such as in architectural elements or industrial equipment.

Certification and Standards: Manufacturers and suppliers adhere to industry standards and certifications to ensure the quality and traceability of recycled stainless steel products.

By implementing effective recycling and reuse practices, Huaxiao stainless steel bar supplier contributes to the sustainability of stainless steel production and minimizes the environmental footprint associated with stainless steel manufacturing.

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China