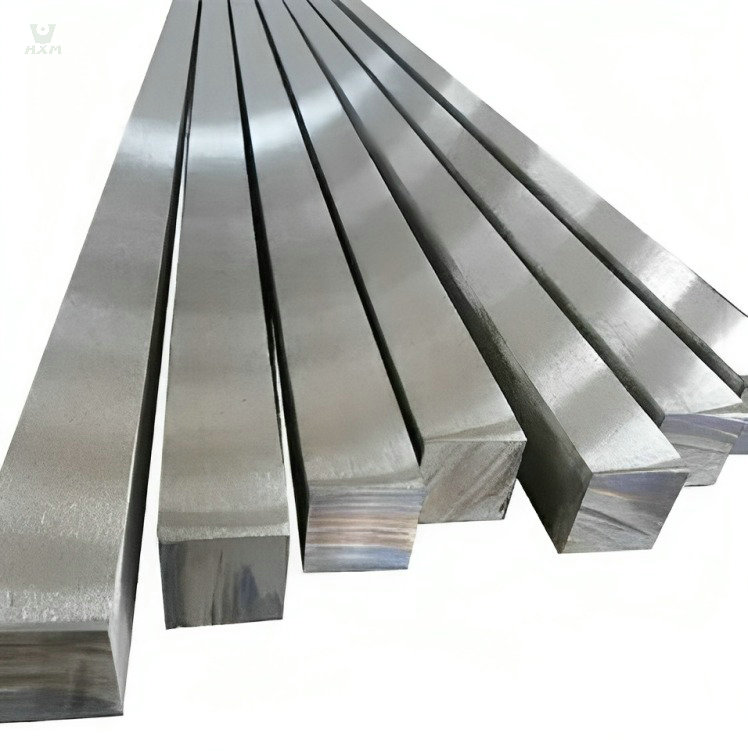

321 Stainless Steel Bar Supplier In China

Diameter: 3mm-480mm, 1/8″ to 2 1/4″

Standard: GB1220, ASTM A484/484M, EN 10060/ DIN 1013 ASTM A276, EN 10278, DIN 671

Shape: round, flat, square, angle, hexagonal

Finish: Black, NO.1, mill finish, cold draw, H9, H11

Product Description Of 321 Stainless Steel Bar

The 321 Stainless Steel Bar, also recognized as UNS S32100 and falling under Grade 321, is an exceptional alloy known for its remarkable qualities. Engineered to cater to a multitude of applications, it boasts an array of key features that make it a sought-after material in various industries.

Foremost among its attributes is its enhanced resistance to inter-granular corrosion, making it a durable and reliable choice for applications exposed to corrosive environments and chemicals. This corrosion resistance is vital in ensuring the longevity and integrity of components made from 321 stainless steel.

What sets the 321 Stainless Steel Bar apart is its titanium content, which stabilizes the alloy against chromium carbide formation. This stabilization is particularly crucial in high-temperature environments where carbide precipitation can compromise the material’s structural integrity.

Compared to the widely used 304 stainless steel, the 321 Stainless Steel Bar offers greater strength, making it suitable for applications subjected to heavier loads and more demanding conditions. This elevated strength ensures the longevity and reliability of components made from this alloy.

Moreover, the 321 Stainless Steel Bar’s ability to withstand high temperatures, up to 1500°F (815°C), renders it ideal for industries where extreme heat is a constant challenge. Its high-temperature suitability opens doors to applications in aerospace, automotive, chemical processing, manufacturing, and more.

specification Of 321 Stainless Steel Bar

Chemical Composition Of 321 Stainless Steel Bar

| Element | Percentage (% by weight) |

|---|---|

| Carbon (C) | ≤ 0.08 |

| Chromium (Cr) | 17.0 – 19.0 |

| Nickel (Ni) | 9.0 – 12.0 |

| Manganese (Mn) | ≤ 2.0 |

| Phosphorus (P) | ≤ 0.045 |

| Silicon (Si) | ≤ 0.75 |

| Sulfur (S) | ≤ 0.03 |

| Titanium (Ti) | 5 x (C + N) – 0.70 |

| Nitrogen (N) | ≤ 0.1 |

physical property Of 321 Stainless Steel Bar

| Property | Value |

|---|---|

| Density | 0.286 lb/in³ (7.89 g/cm³) |

| Melting Point | 2550-2635°F (1400-1450°C) |

| Specific Heat Capacity | 0.12 Btu/lb°F (0.5 J/g°C) |

| Thermal Conductivity | 14.6 Btu-in/hr-ft²-°F (16.8 W/m·K) |

| Electrical Resistivity | 72.0 µΩ·cm |

| Magnetic Permeability | 1.02 (Approximately non-magnetic) |

mechanical property Of 321 Stainless Steel Bar

| Element | Percentage (% by weight) |

|---|---|

| Carbon (C) | ≤ 0.08 |

| Chromium (Cr) | 17.0 – 19.0 |

| Nickel (Ni) | 9.0 – 12.0 |

| Manganese (Mn) | ≤ 2.0 |

| Phosphorus (P) | ≤ 0.045 |

| Silicon (Si) | ≤ 0.75 |

| Sulfur (S) | ≤ 0.03 |

| Titanium (Ti) | 5 x (C + N) – 0.70 |

| Nitrogen (N) | ≤ 0.1 |

features Of 321 Stainless Steel Bar

One of the defining characteristics of the 321 Stainless Steel Bar is its exceptional resistance to inter-granular corrosion, a property that finds its roots in the alloy’s unique composition and scientific principles. Here’s a comprehensive scientific perspective on this noteworthy feature:

Understanding Inter-granular Corrosion:

Inter-granular corrosion, a prevalent concern in various corrosive environments, occurs along the boundaries of metal grains, where the structural integrity of the material can be compromised. It results from the precipitation of chromium carbides in these grain boundaries, rendering the material susceptible to deterioration. In the case of 321 Stainless Steel, the scientific approach to tackling this issue is fundamental.

Titanium’s Crucial Role:

The 321 Stainless Steel Bar incorporates titanium, a strategic alloying element with a profound scientific role. Titanium’s presence serves as a critical stabilizer, preventing the formation of detrimental chromium carbides along the grain boundaries. This scientific strategy ensures that the material remains resistant to inter-granular corrosion, even in aggressive and corrosive environments. The titanium effectively binds with carbon, forming titanium carbides, leaving chromium free to maintain its role in corrosion resistance.

Preservation of Corrosion Resistance:

While titanium’s influence is pivotal, it is complemented by the overall composition of 321 Stainless Steel. The alloy’s chromium content, a fundamental component for corrosion resistance, remains available to form a protective oxide layer on the material’s surface. This layer acts as a barrier against corrosive agents, ensuring that the stainless steel maintains its integrity over time.

Applications and Implications:

The scientific mastery over inter-granular corrosion resistance makes the 321 Stainless Steel Bar an invaluable choice in applications where exposure to aggressive chemicals, high temperatures, or other corrosive factors is common. Industries such as chemical processing, aerospace, and manufacturing benefit from the material’s ability to withstand these challenges, prolonging the lifespan of components and structures.

In conclusion, the improved resistance to inter-granular corrosion in the 321 Stainless Steel Bar is a testament to the precise scientific engineering that underpins its composition. The presence of titanium, its role in stabilizing against chromium carbide formation, and the preservation of corrosion resistance collectively ensure the longevity and reliability of the material in demanding environments. This scientific approach elevates the 321 Stainless Steel Bar to a superior choice for applications where protection against inter-granular corrosion is paramount.

The phenomenon of titanium stabilization for chromium carbide formation in 321 Stainless Steel Bar is a remarkable scientific approach that underlies the material’s unique corrosion-resistant properties. Let’s delve into the intricacies of this feature from a scientific perspective:

Understanding Chromium Carbide Formation: Chromium carbides are detrimental compounds that tend to form in stainless steel along the grain boundaries. When these carbides precipitate, they deplete the chromium content in the material, reducing its corrosion resistance and making it susceptible to inter-granular corrosion. This phenomenon poses a significant challenge in maintaining the integrity of stainless steel in corrosive environments.

Titanium’s Role in Stabilization: The inclusion of titanium in the 321 Stainless Steel Bar serves as a pivotal scientific solution to combat chromium carbide formation. Titanium plays a unique role by preferentially binding with carbon atoms in the alloy, thereby preventing them from reacting with chromium. This preferential binding results in the formation of titanium carbides instead of chromium carbides along the grain boundaries.

Scientific Precision of Titanium Stabilization: The scientific precision of titanium stabilization lies in its ability to outcompete chromium for carbon atoms. Titanium carbides are more thermodynamically stable than chromium carbides, which ensures that the alloy’s chromium remains available for corrosion resistance. This controlled scientific process effectively neutralizes the threat of chromium carbide formation, thus preserving the corrosion resistance of 321 Stainless Steel.

Implications for Corrosion Resistance: The scientific strategy of titanium stabilization has significant implications for corrosion resistance. By safeguarding the chromium content and preventing its depletion due to carbide formation, the 321 Stainless Steel Bar maintains its resistance to corrosive agents and aggressive environments. This ensures the material’s longevity and reliability, making it an excellent choice for applications where corrosion is a constant concern.

Applications and Significance: The titanium stabilization feature elevates the 321 Stainless Steel Bar to a superior material choice, particularly in industries such as chemical processing, aerospace, and manufacturing. Its ability to withstand corrosive environments, even at high temperatures, adds a layer of dependability to components and structures used in these sectors.

In summary, the titanium stabilization for chromium carbide formation in the 321 Stainless Steel Bar is a testament to the precision of materials science. This scientific approach ensures that the material remains impervious to the corrosive threat of chromium carbides, making it an invaluable choice for applications where corrosion resistance is of paramount importance.

The high-temperature suitability of 321 Stainless Steel Bar is a noteworthy characteristic that finds its roots in the material’s unique composition and scientific principles. Let’s delve into the scientific intricacies of this feature:

Understanding High-Temperature Challenges: Exposure to elevated temperatures poses significant challenges to materials. High heat can lead to the degradation of mechanical properties, increased susceptibility to corrosion, and, in some cases, structural failure. In such demanding environments, materials must be scientifically engineered to withstand these challenges.

Scientific Composition for High-Temperature Suitability: The 321 Stainless Steel Bar is specifically designed to thrive in high-temperature settings. Its composition includes a controlled amount of titanium, which serves as a stabilizer, and a higher percentage of chromium and nickel compared to 304 stainless steel. These elements work in unison to provide the scientific basis for the material’s exceptional high-temperature suitability.

Scientific Role of Titanium Stabilization: Titanium’s presence in the alloy not only prevents chromium carbide formation, as previously discussed but also plays a vital role in ensuring the material’s stability at elevated temperatures. This scientific precision aids in maintaining the alloy’s structural integrity and corrosion resistance even when subjected to extreme heat.

Chromium and Nickel Enhancement: The higher content of chromium and nickel in 321 Stainless Steel Bar ensures a robust protective oxide layer on the material’s surface, even at high temperatures. This layer acts as a barrier, safeguarding the material from corrosive agents and ensuring its longevity in demanding applications.

Implications for High-Temperature Environments: The high-temperature suitability of the 321 Stainless Steel Bar holds profound implications for industries that routinely encounter elevated temperatures. Whether in aerospace, manufacturing, or applications where extreme heat is prevalent, this material offers a scientific solution to withstand the challenges posed by such conditions.

Scientific Dependability: The scientific approach to achieving high-temperature suitability underlines the dependability of the 321 Stainless Steel Bar. Its controlled composition and precise engineering ensure that the material maintains its exceptional performance, mechanical strength, and corrosion resistance even when exposed to temperatures as high as 1500°F (815°C).

In conclusion, the high-temperature suitability of the 321 Stainless Steel Bar is a testament to the meticulous scientific engineering that has gone into its development. Its composition, including titanium stabilization, enhanced chromium and nickel content, and the resulting protective oxide layer, positions it as a reliable and durable choice in applications where extreme heat is a constant challenge. This scientific approach ensures that the material not only endures but excels in high-temperature environments, offering longevity and dependability in the face of demanding conditions.

application Of 321 Stainless Steel Bar

Aerospace Industry

In the aerospace sector, the 321 Stainless Steel Bar plays a pivotal role in the construction of critical components. Its remarkable strength, high-temperature resistance, and resistance to oxidation and corrosion make it an ideal material for exhaust systems, where it efficiently handles extreme heat and the corrosive byproducts of combustion. Additionally, it finds application in jet engine parts, with its ability to maintain structural integrity under immense thermal and mechanical stresses. Furthermore, hydraulic lines benefit from the material's corrosion-resistant properties, ensuring the safe and reliable operation of hydraulic systems within aircraft.

Petrochemical Industry

In the petrochemical industry, the 321 Stainless Steel Bar is instrumental in the manufacturing of equipment designed to withstand harsh and corrosive environments. It finds extensive use in heat exchangers, where it endures the rigors of extreme temperatures and corrosive substances. Pressure vessels and storage tanks also rely on 321 stainless steel for its corrosion resistance and structural strength. These applications are critical in ensuring the safe containment and transport of hazardous chemicals and substances.

Manufacturing Industry

The manufacturing industry has embraced 321 Stainless Steel Bar for decades, owing to its versatility and resilience. In the realm of electrical equipment, it serves as a dependable material for components that require resistance to corrosion and high temperatures. Printing presses benefit from its strength and durability, as it can withstand the mechanical stresses and heat generated during operation. Additionally, the dairy equipment industry values 321 stainless steel for its hygienic properties and corrosion resistance, ensuring the quality and safety of dairy products. Machine tools, with their demanding operational conditions, also find a reliable ally in 321 stainless steel, which excels in maintaining structural integrity and longevity under rigorous manufacturing processes.

It’s important to note that while these applications encompass a wide range of industries, the specific usage and requirements may vary based on individual products, manufacturers, and unique project specifications. Nonetheless, the adaptability, strength, and corrosion resistance of 321 Stainless Steel Bar make it a material of choice for numerous critical applications in these diverse sectors.

FAQ

Understanding the resistance of 321 Stainless Steel Bar to inter-granular corrosion necessitates a closer examination of its composition and the scientific principles underpinning this remarkable property. Let’s delve into the intricate details:

Chromium Content: One of the primary contributors to the resistance to inter-granular corrosion in 321 Stainless Steel Bar is its substantial chromium content. Chromium, a critical element in stainless steel, forms a passive oxide layer on the surface of the material when exposed to oxygen. This oxide layer acts as a protective barrier, guarding the underlying steel against corrosive agents.

Nickel Enhancement: 321 Stainless Steel Bar contains a higher percentage of nickel than some other stainless steel grades. Nickel further reinforces the formation and stability of the protective oxide layer. This layer is essential in preventing the penetration of corrosive substances, maintaining the structural integrity of the material.

Manganese and Silicon: The presence of manganese and silicon in the alloy contributes to its overall strength and corrosion resistance. These elements promote the homogeneity of the material, reducing the potential for localized corrosion sites, a crucial factor in preventing inter-granular corrosion.

Titanium Stabilization: A distinguishing feature of 321 Stainless Steel Bar is the inclusion of titanium as a stabilizing element. Titanium’s scientific role is vital in preventing the formation of detrimental chromium carbides along the grain boundaries, which is a common precursor to inter-granular corrosion. The titanium binds with carbon to form titanium carbides, leaving chromium available for the formation of the protective oxide layer.

Preventing Chromium Carbide Formation: The scientific precision in 321 Stainless Steel’s composition ensures that the risk of chromium carbide formation is minimized. By stabilizing the alloy with titanium, carbon atoms preferentially bind with titanium to form titanium carbides instead of chromium carbides. This scientific strategy effectively eliminates a major source of inter-granular corrosion.

Implications for Corrosion Resistance: This controlled composition and the scientific approach underpinning it result in the exceptional resistance of 321 Stainless Steel Bar to inter-granular corrosion. It’s worth noting that the absence of detrimental carbide formation along the grain boundaries preserves the structural integrity and corrosion resistance of the material, even in aggressive and corrosive environments.

Significance for the Stainless Steel Bar Supplier: For stainless steel bar supplier, understanding and maintaining the precise composition of 321 Stainless Steel Bar is crucial. Consistency in the material’s composition is essential to ensure that the corrosion resistance and other valuable properties are upheld, making it a dependable choice for industries where protection against inter-granular corrosion is of utmost importance.

In summary, the resistance of 321 Stainless Steel Bar to inter-granular corrosion is a testament to the meticulous engineering that goes into its composition. The controlled percentages of chromium, nickel, titanium, and other elements, in addition to the scientific strategy of carbide prevention, combine to provide a robust defense against a significant corrosion threat. This scientific approach ensures that 321 Stainless Steel Bar reliably maintains its integrity and corrosion resistance in challenging environments.

While 321 Stainless Steel Bar boasts numerous advantages, it’s essential to explore potential challenges and limitations to gain a comprehensive understanding of its practical applications. Let’s delve into these aspects from a scientific standpoint:

Sensitization at Elevated Temperatures: One of the notable challenges with 321 Stainless Steel Bar is its sensitivity to prolonged exposure at elevated temperatures. Sensitization refers to the formation of chromium carbides along the grain boundaries when the material is subjected to temperatures within the range of approximately 800-1500°F (425-815°C). This phenomenon can compromise the material’s resistance to inter-granular corrosion. To mitigate this, stainless steel bar suppliers should ensure proper heat treatment and processing to reduce the risk of sensitization.

Welding Challenges: Welding 321 Stainless Steel Bar can be more challenging compared to some other stainless steel grades. The titanium stabilization that is a key feature of 321 Stainless Steel can affect the material’s weldability. The presence of titanium can result in the formation of titanium carbides during welding, which may reduce the material’s corrosion resistance in the heat-affected zone. Stainless steel bar suppliers need to employ precise welding techniques and may recommend post-weld heat treatment to minimize these effects.

Cost Considerations: Compared to standard austenitic stainless steel like 304, 321 Stainless Steel Bar can be more expensive due to its specialized composition and the use of titanium. This makes it important for users to carefully assess their specific needs and the cost-effectiveness of choosing 321 Stainless Steel over other materials. For stainless steel bar suppliers, ensuring a consistent supply of 321 Stainless Steel while maintaining competitive pricing can be a challenge.

Varied Mechanical Properties: The mechanical properties of 321 Stainless Steel Bar can vary depending on factors such as the specific heat treatment, manufacturing processes, and the supplier. For users, it’s crucial to understand the mechanical properties of the material they are working with and to ensure that it meets their project requirements.

Supplier Consistency: Maintaining consistent composition and quality across different batches of 321 Stainless Steel Bar can be challenging for stainless steel bar supplier. Users should work with reputable stainless steel bar supplier who follow strict quality control and assurance processes to ensure the reliability of the material.

In conclusion, while 321 Stainless Steel Bar offers exceptional resistance to corrosion and high-temperature suitability, it’s essential to be aware of the challenges and limitations associated with sensitization, welding, cost considerations, mechanical properties, and supplier consistency. Understanding these aspects scientifically allows users and stainless steel bar suppliers to make informed decisions when selecting and working with 321 Stainless Steel Bar in various applications.

The fabricability and weldability of 321 Stainless Steel Bar are essential aspects to consider when evaluating its suitability for various applications. Let’s explore these characteristics from a scientific perspective:

Fabrication Considerations:

Machinability: 321 Stainless Steel Bar exhibits good machinability. The presence of sulfur in some compositions can enhance machinability by forming manganese sulfides. This can aid in the creation of precise components and parts, especially in applications where tight tolerances are critical.

Cold Forming: The material can be cold-formed using standard techniques, making it suitable for processes such as bending, rolling, and cold drawing. This flexibility allows manufacturers to produce a wide range of components with the desired shapes and dimensions.

Hot Forming: 321 Stainless Steel Bar can also be hot-formed, but attention should be paid to the temperature and cooling rate to avoid sensitization. It is critical to control the heat input during hot forming to minimize the risk of carbide precipitation.

Welding Considerations:

Challenges Due to Titanium Stabilization: The titanium stabilization in 321 Stainless Steel Bar can affect its weldability. During welding, there is a potential for the formation of titanium carbides, which may compromise the corrosion resistance of the material in the heat-affected zone. To overcome this challenge, stainless steel bar suppliers and fabricators often employ precise welding techniques and may recommend post-weld heat treatment. The selection of appropriate filler materials is also crucial to mitigate the risk of carbide formation.

Heat-Affected Zone (HAZ): The HAZ in 321 Stainless Steel Bar welds can exhibit varying mechanical properties due to the thermal effects of welding. It is essential to consider the characteristics of the HAZ in applications where consistent mechanical properties are critical.

Avoiding Sensitization: Prolonged exposure to elevated temperatures during welding can lead to sensitization in 321 Stainless Steel Bar, with the potential formation of chromium carbides. To prevent this, suppliers and fabricators should carefully control heat input and employ proper heat treatment methods to restore corrosion resistance.

Supplier Expertise:

Stainless steel bar supplier play a significant role in ensuring the fabricability and weldability of 321 Stainless Steel Bar. Expertise in material composition, heat treatment, and welding procedures is essential to maintain the material’s integrity during fabrication and welding processes.

In conclusion, 321 Stainless Steel Bar offers favorable fabricability and weldability for various applications. The scientific understanding of its composition and the challenges associated with titanium stabilization and sensitization are vital in ensuring successful fabrication and welding. Collaborating with knowledgeable stainless steel bar supplier and fabricators is crucial to maximize the benefits of 321 Stainless Steel Bar in specific applications while mitigating potential challenges.

Understanding the differences between 321 Stainless Steel Bar and 304 Stainless Steel Bar requires a scientific examination of their respective compositions and properties. Let’s explore these distinctions:

Chemical Composition:

Chromium Content:

- 321 Stainless Steel Bar contains a higher percentage of chromium compared to 304 Stainless Steel Bar. Chromium is a critical element that forms a protective oxide layer on the surface of stainless steel, enhancing its corrosion resistance. This higher chromium content in 321 stainless steel contributes to its superior resistance to corrosion in a broader range of environments.

Nickel Content:

- 304 Stainless Steel Bar typically has a higher nickel content than 321 Stainless Steel Bar. Nickel enhances the material’s ductility and impact resistance. In contrast, 321 stainless steel has a slightly lower nickel content but includes the addition of titanium, which stabilizes it against carbide formation. This titanium stabilization is a key feature that prevents sensitization and inter-granular corrosion, especially at elevated temperatures.

Manganese and Silicon:

- Both grades contain manganese and silicon, which contribute to their overall strength and formability. However, the specific ratios and their effects on the materials’ mechanical properties can vary between 321 and 304 stainless steel.

Mechanical Properties:

Strength:

- 321 Stainless Steel Bar is generally stronger than 304 Stainless Steel Bar due to its higher chromium content and titanium stabilization. This enhanced strength makes 321 stainless steel suitable for applications that demand greater structural integrity.

Corrosion Resistance:

- While both grades exhibit good corrosion resistance, 321 Stainless Steel Bar excels in resisting inter-granular corrosion, especially at elevated temperatures, thanks to its titanium stabilization. This property is particularly valuable in applications where corrosion is a concern.

Applications:

321 Stainless Steel Bar:

- Due to its strength, superior corrosion resistance, and high-temperature suitability, 321 Stainless Steel Bar is often chosen for applications in industries such as aerospace, petrochemical, and manufacturing, where these properties are crucial.

304 Stainless Steel Bar:

- 304 Stainless Steel Bar is widely used for various applications and is especially popular in the food and beverage industry, architectural and structural components, and general-purpose manufacturing due to its good corrosion resistance and ease of fabrication.

In summary, the differences between 321 Stainless Steel Bar and 304 Stainless Steel Bar are primarily driven by their chemical compositions, resulting in variations in strength, corrosion resistance, and suitability for specific applications. Stainless steel bar supplier can provide further guidance in selecting the appropriate grade based on the requirements of a particular project.

To differentiate between 321 Stainless Steel Bar and 316 Stainless Steel Bar, we must scientifically examine their compositions and properties. Here is a detailed comparison:

Chemical Composition:

Chromium and Nickel Content:

- 316 Stainless Steel Bar contains a lower percentage of chromium compared to 321 Stainless Steel Bar. Chromium forms a protective oxide layer, enhancing corrosion resistance. 316 stainless steel relies more on the nickel content for its corrosion resistance, making it an excellent choice for applications involving exposure to corrosive environments like seawater.

Molybdenum Content:

- 316 Stainless Steel Bar includes molybdenum, which significantly enhances its corrosion resistance, especially in chloride-rich environments. This makes it well-suited for applications in marine settings and chemical industries. In contrast, 321 stainless steel’s composition does not include molybdenum.

Titanium Stabilization:

- 321 Stainless Steel Bar is stabilized with titanium, which prevents sensitization and inter-granular corrosion, making it an excellent choice for high-temperature applications. This feature is absent in 316 stainless steel.

Mechanical Properties:

Strength:

- 321 Stainless Steel Bar is generally stronger than 316 Stainless Steel Bar due to its higher chromium content and titanium stabilization. Its enhanced strength makes it suitable for applications requiring structural integrity in high-temperature environments.

Corrosion Resistance:

- 316 Stainless Steel Bar excels in corrosion resistance, particularly in chloride-rich environments. Its molybdenum content enhances its resistance to pitting and crevice corrosion, making it a top choice for marine and chemical applications. 321 stainless steel, while corrosion-resistant, is better known for its resistance to inter-granular corrosion and high-temperature suitability.

Applications:

321 Stainless Steel Bar:

- Due to its strength, resistance to inter-granular corrosion, and high-temperature suitability, 321 Stainless Steel Bar is often used in industries such as aerospace, petrochemical, and manufacturing, where these properties are crucial.

316 Stainless Steel Bar:

- 316 Stainless Steel Bar is frequently chosen for applications involving exposure to seawater, marine environments, and chemical processing. It is widely used in industries such as shipbuilding, food and beverage, pharmaceuticals, and chemical processing, where corrosion resistance is paramount.

In summary, the differences between 321 Stainless Steel Bar and 316 Stainless Steel Bar arise from their distinct chemical compositions, leading to variations in strength, corrosion resistance, and suitability for specific applications. When choosing between these grades, stainless steel bar supplier can provide valuable guidance based on the project’s specific requirements and environmental conditions.

recent stainless steel bar products

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China