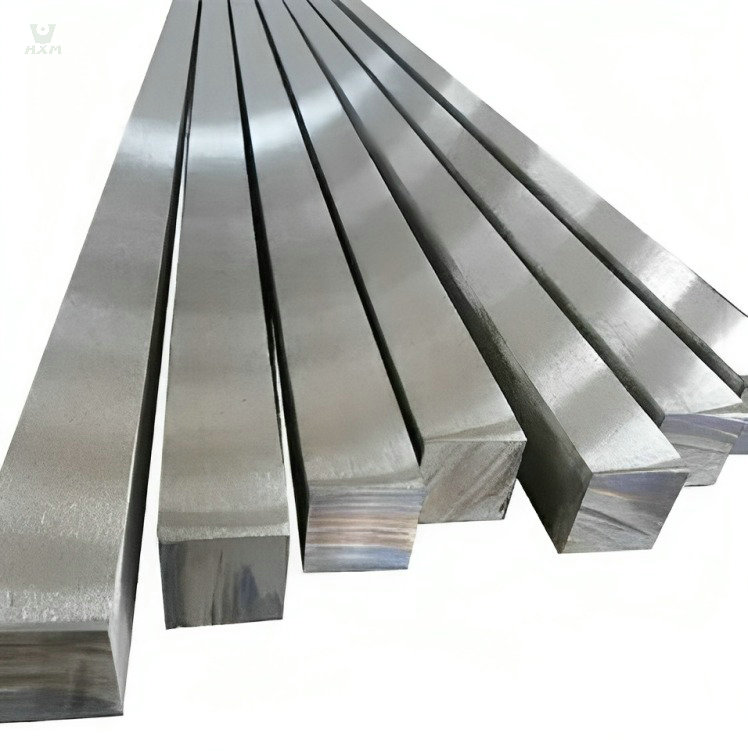

Product Description of Stainless Steel Flat Bar

Stainless steel flat bar is a common stainless steel product, it is a rectangular steel bar made from a stainless steel sheet through the process of cutting, cold drawing, and straightening. Stainless steel flat bars can be semi-finished steel. It includes cold-drawn stainless steel flat bars and hot-rolled stainless steel flat bars. Stainless steel flat bars usually have high straightness, smooth surface, no burrs, and no cracks, and have good mechanical properties and corrosion resistance, and are widely used in construction, machinery, electronics, and other fields.

The material of stainless steel flat steel is usually AISI 201, AISI 304, AISI 316, and other stainless steel materials. Among them, AISI 304 is a common stainless steel material with good corrosion resistance, high strength, and good processability.

The specifications of stainless steel flat bars are generally determined by their thickness and width. Usually, the thickness is 2-8 mm and the width is 10-200 mm. According to different application scenarios and needs, stainless steel flat bars can also be processed into products of different shapes and sizes, such as stainless steel flat sheets, stainless steel flat steel tubes, etc.

Production Range of Stainless Steel Flat Bar

- Standard: ASTM A276/484M, EN 10058/DIN 1017, EN 10278/DIN 174

- Main Grade: 201, 304, 316, 316L, 310s, 430

- Finish: NO.4, HL, 2B, bright, NO.1, mill finish

Thickness | 3mm-40mm, 1/8″ – 5/8″ |

Width | 20mm-120mm, 1″ – 4.1/2″ |

Production Process of Stainless Steel Flat Bar

- Raw Material Procurement: First, raw materials for stainless steel production need to be sourced, including iron ore, chromium, silicon, nickel, molybdenum, and titanium.

- Forming and Shaping of Steel: These raw materials are melted into molten metal, which is then shaped and formed using methods such as hot rolling, cold rolling, extrusion, or forging.

- Heat Treatment Process: Once the desired shape is achieved, heat treatment is often conducted to enhance strength, durability, and certain properties like corrosion resistance or magnetism. This typically involves heating the metal to specific temperatures and then slowly cooling it to reduce brittleness and increase ductility. Heat treatment may also include annealing, which helps relieve any internal stresses caused by prior processing steps like extrusion or forging.

- Production of Flat Bars: Initially, the steel undergoes hot rolling and then annealing (heating the cooled steel) to release stresses. This ensures the highest level of corrosion resistance. The final step is an acid pickling process, where the prepared steel is immersed in a compound solution to remove any marks or scales from the surface.

Inspection Specifications of Stainless Steel Flat Bar

The Appearance Quality of Stainless Steel Flat Bar

- Stainless steel flat bar surface quality standards in the provisions of the general requirements shall not exist for the use of harmful defects, such as stratification, scarring, cracks, and so on.

- The allowable range of geometric deviations is also specified in the standard and generally includes curvatures, edge widths, edge thicknesses, apex angles, theoretical weights, etc., and provides for significant torsion.

General Inspection Specifications

- GB / T2101-89(General Requirements for Acceptance, Packaging, Marking, and Quality Certificates of Section Steel);

- GB9787-88 / GB9788-88 (Dimensions, Shape, Weight, and Permissible Deviation of Hot Rolling);

- JISG3192-94 (Shape of Hot-, Size, weight, and tolerance);

- DIN17100-80 (general structural steel quality standards);

- ГОСТ535-88 (ordinary carbon steel technical conditions).

According to the above standards, should be bundled and delivered, and the lanes and the length of the bundle should meet the requirements. Generally naked delivery, transportation, and storage should pay attention to moisture.

Chemical Composition Inspection

- Component Index: The chemical composition of stainless steel flat steel is a general structure of rolled steel series, the main test indicators for C, Mn, P, S four. According to the different grades, the content is different, with the general range of C <0.08%, Mn: 2.0, P <0.035%, and S <0.03%.

- Test methods: When testing the above chemical composition, the commonly used standard test methods are GB223, JISG1211-1215, BS1837, BS Manual 19, ГОСТ22536 and so on.

Mechanical Property Inspection Method

- Tensile test method. Commonly used standard test methods are GB / T228-87, JISZ2201, JISZ2241, ASTMA370, ГОСТ1497, BS18, DIN50145 and so on;

- Bending test method. Commonly used standard test methods are GB / T232-88, JISZ2204, JISZ2248, ASTME290, ГОСТ14019, DIN50111, and so on.

- Performance Index: The test items of performance evaluation mainly include the tensile test and bending test. Indicators include yield point, tensile strength, elongation, and bending of qualified items.

Application of Stainless Steel Flat Bar

Construction Industry

Stainless steel flat steel is used as various force members according to the composition of different structures, also used for the connection between the steel structure members, widely used in a variety of architectural structures and engineering structures, such as beams, bridges, transmission towers, lifting and transportation machinery, ships, industrial furnaces, reaction towers, container racks and warehouse shelves.

Automotive Manufacturing Industry

Stainless steel flat steel is also widely used in the automotive manufacturing industry, such as brake pads, brake discs and other parts used in the automotive braking system. At the same time, stainless steel flat steel can also be used in the manufacture of automotive chassis, doors, windows, exhaust pipes, steering gear and other structural parts.

Electronic and Electrical Industry

Stainless steel flat steel is also used in the electronic and electrical industry, such as in the production of cell phones, tablet PCs, electronic products shell, monitor frame, motor shaft, wire tubes and other electronic products used in the screen skeleton, battery connection piece, etc., as well as for the production of electrical sockets, plugs, etc.

Food Processing industry

Stainless steel flat steel also has applications in the food processing industry, making food processing equipment, making production line conveyor belts, refrigeration equipment, tableware, kitchenware, etc. Because stainless steel is easy to clean, non-toxic, and will not contaminate food.

FAQ

Stainless steel flat steel has excellent corrosion resistance due to its high content of chromium. The chromium element can combine with oxygen to form a dense chromium oxide film (Cr2O3), and this chromium oxide film prevents the metal surface from continuing to be oxidized and corroded. And when the surface of stainless steel flat steel is scratched or damaged, a new chromium oxide film will be regenerated in a short time to maintain the corrosion resistance of stainless steel flat steel.

In addition, stainless steel flat steel also contains a certain amount of nickel elements, nickel elements can further improve the corrosion resistance of stainless steel flat steel, especially in strong acid and strong alkali environment corrosion performance.

Stainless steel flat bars can be processed in various ways. Stainless steel flat steel has high material hardness and can be processed by hot and cold working for shape processing, cutting, drilling, stamping, welding, riveting and other processing treatments.

In the hot processing, the common processing methods include hot rolling, hot extrusion, hot forging, etc.. These processing methods can change the shape, size and structure of stainless steel flat steel, so that it has the required mechanical properties and surface quality.

In cold processing, the common processing methods include cutting, bending, forming, stretching, deep punching, etc. These processing methods can be used to process stainless steel flat bars into the desired shape and size without changing their chemical composition and physical properties to suit a variety of different application scenarios.

- Polishing: One of the common surface treatment methods for stainless steel flat bars. It makes the surface of stainless steel flat, smooth, and shiny through mechanical grinding and polishing.

- Sandblasting is a surface treatment method in which sand is blasted onto the surface of stainless steel flat steel by high-pressure airflow, resulting in a textured, tactile surface texture.

- Pickling is a surface treatment method that removes oxides and impurities from the surface of stainless steel flat steel by immersing it in a strong acid to make the surface smooth and shiny.

- Electroplating is a surface treatment in which stainless steel flat steel is immersed in an electrolytic solution, and then a metal covering layer is formed on the surface of stainless steel by the action of electric current, thus improving its corrosion resistance and surface quality.

- Painting is the surface treatment method of spraying various paints or coatings on the surface of stainless steel flat steel to improve surface performance, corrosion resistance, aesthetics, etc.

Yes, there are different grades of stainless steel flat bars available. These grades vary in their chemical composition and properties, which determine their suitability for specific applications. It’s important to choose the grade that best matches the requirements of your project. If you have specific grade requirements, you can consult with a stainless steel bar supplier for guidance.

Yes, stainless steel flat bars can often be customized to meet specific size and finish requirements. Stainless steel bar suppliers typically offer a range of sizes and finishing options to accommodate various applications. You can work with a reputable supplier to discuss your customization needs and ensure that the flat bars meet your project specifications.

Yes, stainless steel flat bars can be welded. Stainless steel is known for its weldability, and flat bars are no exception. Welding stainless steel flat bars is achieved using various welding techniques such as TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), or even stick welding, depending on the specific grade and thickness of the flat bar. It’s important to note that proper welding procedures and suitable filler materials must be used to maintain the corrosion resistance and mechanical properties of stainless steel. Therefore, when welding stainless steel flat bars, it’s advisable to consult with a knowledgeable stainless steel bar supplier to ensure the correct procedures and materials are employed to achieve high-quality welds.

Choosing the right grade of stainless steel flat bar for your project is a crucial decision that depends on the specific requirements of your application. Several factors need to be considered:

Corrosion Resistance: Determine the level of corrosion resistance needed for your environment. If your project will be exposed to harsh chemicals or marine conditions, consider corrosion-resistant grades like 316 or 304.

Mechanical Properties: Evaluate the required mechanical properties, such as strength and hardness. Different grades offer varying levels of these properties. For example, 17-4 PH stainless steel provides high strength and hardness.

Temperature Resistance: Consider the temperature range your flat bar will be exposed to. Some stainless steel grades, like 310, offer excellent high-temperature resistance.

Machinability: If your project involves extensive machining or fabrication, select a grade known for good machinability, like 303.

Aesthetic Considerations: For architectural or decorative applications, the appearance of the flat bar may be essential. In such cases, choose a grade that can be easily polished or finished to achieve the desired look.

Budget: Budget constraints may also play a role in your decision. Some grades are more cost-effective than others while still meeting project requirements.

To make an informed choice, it’s advisable to consult with a reputable stainless steel bar supplier who can provide guidance based on your project’s specific needs and recommend the most suitable grade to ensure its success.

The heat treatment process for stainless steel flat bars involves carefully controlled heating and cooling procedures to enhance their mechanical properties and modify their microstructure. The precise process can vary depending on the specific grade of stainless steel and the desired outcome. Below is a generalized explanation:

Annealing (Softening): This process involves heating the stainless steel flat bar to a specific temperature and then gradually cooling it. Annealing relieves internal stresses, increases ductility, and improves machinability. It also softens the material for further processing.

Austenitizing (Hardening): In some cases, stainless steel flat bars are heated to a high temperature, typically above 1,900°F (1,040°C), to transform their microstructure into austenite. This step is followed by rapid quenching, usually in water or oil, to lock in the austenitic structure. This hardening process increases the material’s hardness and strength.

Tempering: After hardening, the stainless steel flat bars are tempered by reheating them to a lower temperature. This step reduces brittleness and internal stresses while maintaining an adequate level of hardness and strength. The exact tempering temperature and time are critical factors that depend on the desired mechanical properties.

Solution Annealing: For stainless steel grades prone to sensitization (such as 304 and 316), a solution annealing treatment may be required. This process involves heating the material to a specific temperature range and then rapidly cooling it to prevent the formation of carbide precipitates, which can cause corrosion issues.

Precipitation Hardening (for PH Grades): Stainless steel flat bars made from precipitation-hardening (PH) grades, like 17-4 PH, undergo a specific heat treatment process to achieve their desired combination of high strength and corrosion resistance. This process involves aging the material at a controlled temperature for a set duration.

Stress Relieving: Stress relieving is often performed to reduce internal stresses that may have accumulated during manufacturing processes like machining or welding. It typically involves heating the flat bars to a specific temperature and then slow cooling.

It’s important to note that the heat treatment process for stainless steel flat bars should be carefully controlled to achieve the desired properties while minimizing the risk of distortion, cracking, or other defects. The expertise of a stainless steel bar supplier is invaluable in ensuring that the correct heat treatment process is applied to meet the specific requirements of your project.

If you need a custom stainless steel flat bar or have any inquiries about stainless steel flat bars, please feel free to contact us, we will reply to your email or message as soon as possible and provide the best service.

Here is our contact information:

Mob/Wechat/WhatsApp: +86-13052085117

Email: [email protected]

other products

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China