410&410S Stainless Steel Coil Supplier

- Thickness: 0.2mm – 200mm

- Width: 300mm – 2000mm, the narrowed products pls check in strip products

- Length: 500mm-12000mm

- Finish: 2B, 2D, Black, NO.1, Anneal pickling

- MOQ: 2MT

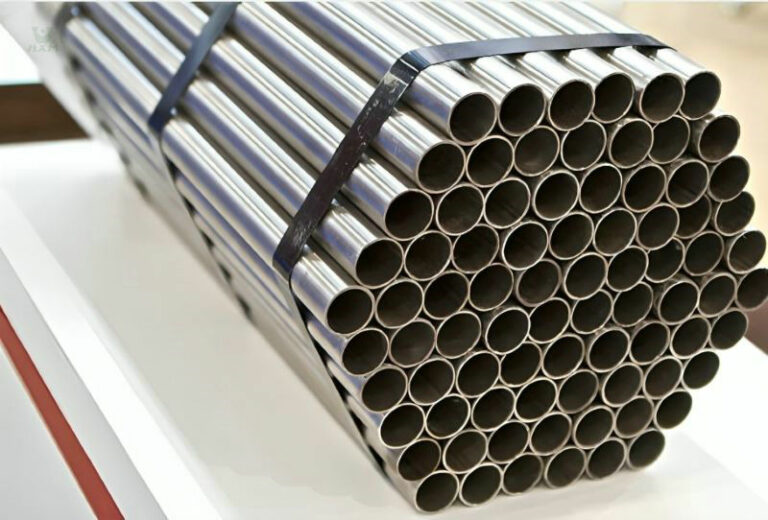

Product Description of 410/410s stainless steel coil

410 and 410S Stainless Steel Coil is a high-strength, corrosion-resistant stainless steel material that is widely used in a variety of industrial applications. This stainless steel material has excellent processing performance and durability, and can maintain long-term stability under complex environmental conditions.

410 Stainless Steel Coil contains high chromium and silicon elements, which have better corrosion resistance and high temperature strength. It has better resistance to corrosive media such as oxidizing and organic acids, and can be used in some acidic environments. In addition, 410 stainless steel coil also has good processing performance, can be cut, bending, welding and other processing operations, convenient to manufacture a variety of parts.

410S stainless steel coil is a kind of 410 series stainless steel, after special heat treatment and processing technology, its corrosion resistance and high temperature strength has been further improved. 410S stainless steel coil can still maintain good mechanical properties and stability in high temperature environment, suitable for manufacturing parts and components need to withstand high temperature and corrosive environment.

Production Range of 410/410s stainless steel coil

-410 410S Cold Rolled Stainless Steel coil, Cold rolled 410 410S coil, 410 410S CRC.

- · Thickness: 0.2mm – 8.0mm

- · Width: 600mm – 2000mm, the narrowed products pls check in strip products

- · Max coil weight: 25MT

- · Coil ID: 508mm, 610mm

- · Finish: 2B

-410 410S Hot Rolled Stainless Steel coil, Hot Rolled 410 410S coil, 410 410S HRC.

- · Thickness: 1.2mm – 16mm

- · Width: 600mm – 2000mm, the narrower products please check in strip products

- · Max coil weight: 40MT

- · Coil ID: 508mm, 610mm

- · Finish: NO.1

specification of 410/410s stainless steel coil

chemical composition of 410 stainless steel coil

| Element | Carbon (C) | Chromium (Cr) | Manganese (Mn) | Silicon (Si) | Phosphorus (P) | Sulfur (S) |

|---|---|---|---|---|---|---|

| Composition | 0.08–0.15% | 11.5–13.5% | 1.0% max | 1.0% max | 0.04% max | 0.03% max |

chemical composition of 410s stainless steel coil

| Element | Carbon (C) | Chromium (Cr) | Manganese (Mn) | Silicon (Si) | Phosphorus (P) | Sulfur (S) |

|---|---|---|---|---|---|---|

| Composition | 0.08% max | 11.5–13.5% | 1.0% max | 1.0% max | 0.040% max | 0.030% max |

410 steel mechanical properties in different standard

410 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | 205 | 450 | 20 | – | 96 | 217 | – |

JIS | 205 | 440 | 20 | – | 93 | 201 | 210 |

GB | 205 | 450 | 20 | – | 96 | 217 | 210 |

410S steel mechanical property in different standard

410S | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | 205 | 450 | 20 | – | 96 | 217 | – |

JIS | 205 | 440 | 20 | – | 93 | 201 | 210 |

GB | 205 | 450 | 20 | – | 96 | 217 | 210 |

application of 410 and 410s stainless steel coil

410 Stainless Steel Coil Applications

- Cutting Tools: Due to its high hardness and wear resistance, 410 stainless steel is commonly used to manufacture cutting tools such as knives, scissors, and saw blades.

- Automotive Components: In the automotive industry, 410 stainless steel is used for manufacturing certain non-critical components due to its strength and corrosion resistance, such as fasteners and decorative parts.

- Home Appliances and Household Items: With its strength and corrosion resistance, 410 stainless steel is also used to manufacture the outer shells and internal components of home appliances, as well as decorative and fixing components in households.

410s Stainless Steel Coil Applications

- High-Temperature Applications: 410S stainless steel belongs to the martensitic stainless steel category, featuring excellent oxidation resistance and high-temperature strength, making it suitable for manufacturing high-temperature furnaces, heat treatment equipment, and other components that operate in high-temperature environments.

- Chemical Industry: In chemical processing, 410S stainless steel is often used to manufacture corrosion-resistant pipes, valves, and containers due to its excellent corrosion resistance.

- Energy and Power Industry: In power generation and energy transmission systems, 410S stainless steel may be used to manufacture heat exchangers, pipelines, and boiler components due to its high-temperature and corrosion-resistant properties.

differences between 410 and 410s stainless steel coil

- 410 Stainless Steel Coil: Due to its high strength and hardness, it is commonly used in applications that require wear resistance, such as tools, cutlery, and other parts that require high hardness and strength to resist wear.

- 410S Stainless Steel Coil: In addition to inheriting the uses of 410, due to its excellent machinability, it is also particularly suitable for applications that require a lot of cutting or welding, such as precision machine parts, kitchenware, medical equipment and so on.

- 410 Stainless Steel Coil: Due to its high carbon content, it has high strength and hardness. This means that it excels in resisting external stresses (e.g. bending, tensile, etc.).

- 410S Stainless Steel Coil: In addition to inheriting the strength and hardness of 410, it has improved cutting and machining properties and welding properties due to the addition of sulfur and copper. This makes operations such as cutting, bending and welding easier during fabrication.

- 410 Stainless Steel Coil: Although it has some corrosion resistance, it may not be as corrosion resistant as 410S in certain corrosive environments.

- 410S Stainless Steel Coil: Due to its specific chemical composition, it has better corrosion resistance when facing certain acidic and oxidizing environments.

- 410 stainless steel coil: mainly contains iron, chromium and small amounts of carbon, silicon and other elements. Among them, the content of carbon (C) is relatively high, which helps to improve the strength and hardness of steel.

- 410S stainless steel coil: on the basis of 410, its processing properties are improved by adjusting the chemical composition, especially by increasing the content of sulfur (S) and copper (Cu). The addition of sulfur and copper enhances the steel’s machinability and weldability.

After exploring the extensive applications and outstanding performance of 410 and 410S stainless steel coils, we deeply understand their indispensability in multiple industries. Whether it’s cutting tools, automotive components, or applications in high-temperature environments, they demonstrate extraordinary durability and stability.

As a professional exporter of stainless steel products, Huaxiao Metal always upholds the principle of quality first. We have SGS certification guarantees, and each batch of products comes with MTC for inspection, ensuring that every coil of stainless steel you purchase meets the standards. Furthermore, equipped with multiple production lines, we can meet your diverse needs for different grades and sizes.

If you have any purchasing requirements, please feel free to contact us.

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China