Decorative Stainless Steel Factory

Stainless steel decorative plate we can call it decorative stainless steel sheet. The colorful stainless steel decorative plate is a very good decorative material with brilliant colors. It is decorated with elegant and luxurious quality. The colorful ss plate has strong corrosion resistance and mechanical properties. The colored surface layer will not tarnish or fade for a long time, and the color will change with the light angle. The colored ss sheet and the colored surface layer can withstand the temperature of 200 ℃, the salt spray corrosion resistance is better than ordinary stainless steel, and the color stainless steel plate is wear-resistant.

Colored stainless plates are generally used to decorate walls. It not only maintains the advantages of the original stainless steel plate but also looks more beautiful, which is very suitable for decoration. And stainless steel decorative plate is a general term, it is divided into sandblasted stainless steel plate, ss sheet mirror finish, embossed metal sheet decorative, etched stainless steel sheet, No.4 finish stainless steel, BA stainless steel sheets, etc.

Surface Classification of Stainless steel Decorative Sheets

No.4 SS Plates are divided into oily stainless steel shortline plates and dry stainless steel shortline plates. The plates are made by high-speed grinding using special polishing oil as the medium in the production process. The surface of the product is intermittently silky, with smooth surface, clear texture and soft texture. It is widely used in all kinds of decoration appliances and stainless steel appliances.

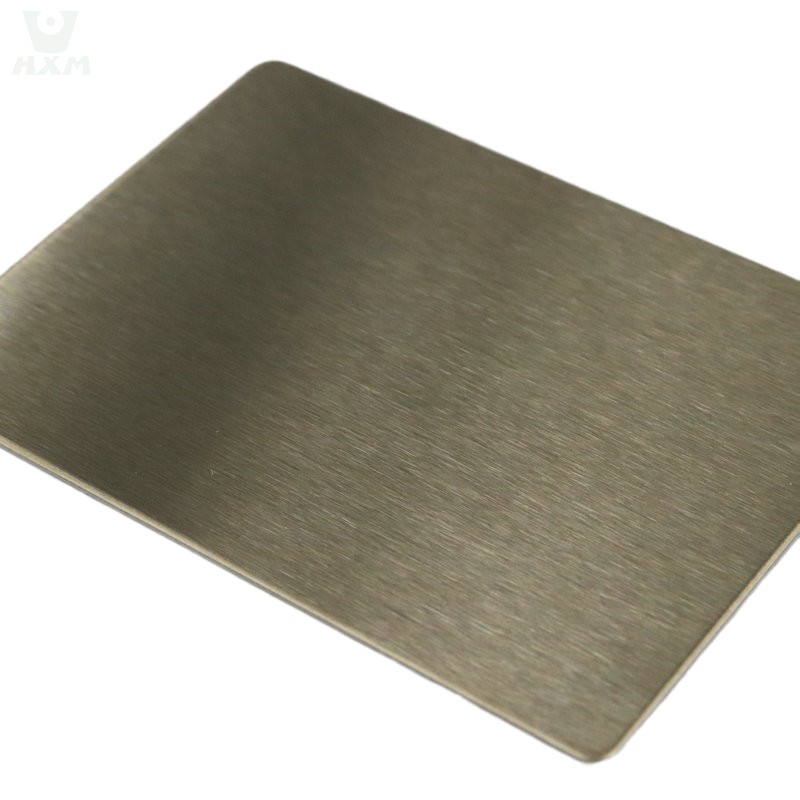

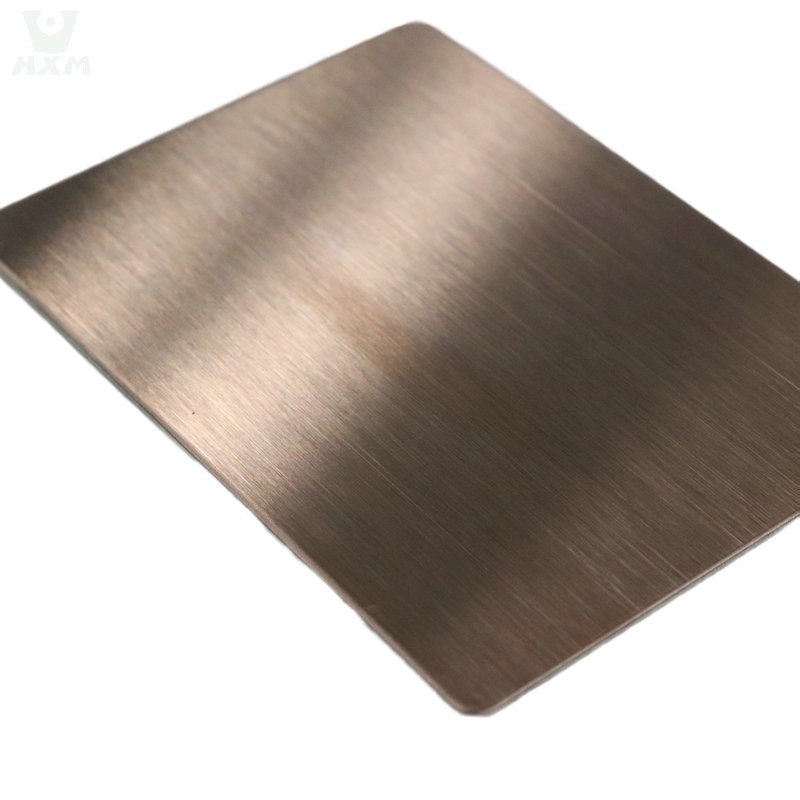

Brushed Stainless Steel Plate, also called hairline, because the lines are like hair slender and straight. Its surface resembles a wire-like texture, which is a processing technique of stainless steel. The surface is matt, and there is a trace of texture on it carefully, but it can’t be felt.

The Stainless Steel Etching Sheet is based on the mirror panel, wire drawing plate, and sandblasting plate. The surface is chemically corroded to various patterns and patterns for deep processing; the local pattern of the etching plate, drawing, gold embedded, titanium, etc. The complex process, finally achieves the effect of bright and dark patterns and brilliant colors.

The 8K Stainless Steel Sheet is also called the mirror panel. The surface of the stainless steel plate is polished by polishing equipment with a grinding fluid to make the surface brightness as clear as a mirror, and then electroplated and colored.

Stainless Steel Embossed Plates are embossed patterns on the surface of the steel plate, used in places that require smoothness and ornamentation. When embossing is rolled, patterned work rolls are used.

The zirconium beads for the Sandblasting Board are processed on the stainless steel surface by mechanical equipment, so that the surface of the board presents a fine bead-like sand surface, forming a unique decorative effect. Then electroplating

the production process of stainless steel decorative sheets

A. Electroplating

The process of attaching the metal film to the surface of the decorative stainless steel plate through electrolysis is called electroplating. Due to the metal film on the surface, stainless steel can prevent corrosion, improve wear resistance, conductivity, and light reflection, and enhance aesthetics.

B. Water Plating

It does not rely on an external power source in the aqueous solution. It is a process that relies on the reducing agent in the plating solution to perform a chemical reduction reaction so that the metal ions are continuously reduced on the autocatalytic surface to form a metal coating.

C. Fluorocarbon Paint

Refers to coatings with fluoro resin as the main film-forming substance; also known as fluorocarbon paint, fluoro coating, fluoro resin coating.

D. Spray Paint

Use compressed air to spray the paint into a mist and apply it to the stainless steel plate to form different colors.

Specifications of Decorative Stainless Steel Sheet

Item | Decorative stainless steel sheets(Decorative stainless sheet, ss decorative plate, ss decorative sheets, Stainless steel decorative sheet) |

Standard | ASTM A240, JIS G4304, G4305, GB/T 4237, GB/T 8165, etc |

Material | 304 ba stainless steel, SS 304, 304L, 316, 316L, etc |

Thickness | 5 mm,1-2 mm,3-4 mm,4-5 mm,2-3 mm,0-1 mm. as customers’ request |

Size | 8×4, 10×4, 10×5 & More as per size |

Manufacturer: | Tisco steel, Posco steel, Ttss,Bao steel, etc |

Features of Decorative Stainless Steel Sheets

Decorative stainless steel sheet has very good corrosion resistance and can be used in wet, acidic, or alkaline environments for a long time, not easy to rust.

The surface of decorative stainless steel sheet can be treated in many ways, such as mirror, silk, sandblasting, etc., to achieve different appearance effects.

In addition to the traditional silver-white color, decorative stainless steel sheets can also be made into a variety of colors through chemical reactions or coating pigments, etc.

The strength of decorative stainless steel sheet is higher than many other metal materials, which can meet the needs of different applications.

The surface of the decorative stainless steel plate is smooth and flat, does not easy to adhere to dirt and dust, easy to clean and maintain.

Decorative stainless steel sheet does not release harmful substances, which meets the requirements of environmental protection and health.

Decorative stainless steel sheet has a unique metallic luster and texture, which can be used for various indoor and outdoor decorations, such as walls, ceilings, staircase handrails, doors and windows, etc.

Applications of Stainless Steel Decorative Sheet

Before the application of decorative stainless steel industry, traditional decorative materials such as wood, stone, ceramics, etc. have been dominant. However, these materials are often vulnerable to pollution, easy to damage, difficult to process, high maintenance costs and other problems. With the continuous progress of technology and techniques, decorative stainless steel materials have gradually been widely used because of their high quality, high reliability, low cost and other advantages. In terms of design and manufacturing, the processing technology of decorative stainless steel materials is becoming more and more mature, and various new materials are emerging, thus providing customers with more choices. In terms of market, decorative stainless steel materials have high added value, high demand and high returns, and have become a part of the decorative materials market that cannot be ignored.

Construction Industry

Furniture Industry

Automotive Industry

Cultural and Creative Industries

Why Choose Huaxiao?

Cooperation Flexibility

We know that our current stock is not enough to satisfy customers with innovative ideas. We need stainless steel decorative panels with different patterns and colors to apply to the decoration of various industries. Therefore, we accept customer requirements and can professionally produce stainless steel products that customers need. We have a professional service team, experienced engineers, and a full set of production lines. Huaxiao can solve any stainless steel product problems for you.

Stable Quality

We export ss decorative sheets with various patterns and materials. All the production machinery in our factory is the most advanced, and equipment testing will be carried out before production. Carry out pre-production sample confirmation to ensure compliance with customer requirements.

Moderate Price

Our stainless steel suppliers have professional operators, skilled skills, and strict cost control to maintain quality. Because we know that any customer, including us, takes profitability as the main goal. So our job is not only to provide customers with high-quality products but also to understand that saving stainless steel costs is also very important.

Excellent service

We provide a variety of contact information so that customers can get in touch with us at any time if they encounter any problems or questions. We also promise accurate delivery times and keep our customers updated on the status of their orders. If there is any problem with the order, we will immediately communicate with the customer and provide a solution.

How to install stainless steel decorative sheet?

1. Install the Dragon Skeleton: The installation process of the basic dragon skeleton can refer to the construction process of the wooden keel or light steel keel, and repeat the check for verticality and flatness.

2. Fixed Bottom Plate: The bottom plate is generally 5-12mm thick plywood. The construction method and requirements are the same as the construction of ordinary wooden cover panels, but when the keel is a light steel keel or angle steel keel, first use an electric drill to drill the keel, Use self-tapping screws to fix the bottom plate on the keel, and the screw head cannot be higher than the bottom plate surface

3. Fixed Panel: The color stainless steel decorative panel should be made into a finished product shape according to the design size and modeling requirements before installation. When there is a bottom plate, apply universal glue on the bottom plate and the back of the stainless steel respectively, and gently paste the prepared stainless steel plate on the bottom plate. When there is no bottom plate, fix the pre-processed stainless steel plate on the light steel keel with stainless steel screws.

4. Edge Finishing: Edge finishing treatment, filling sealant, pressing stainless steel grooves, etc. at the interface between stainless steel or at the internal and external corners, finishing and decorative treatment

5. Use a soft dry cloth to wipe clean the surface of the colored stainless steel and tear off the protective film.

The above is about the introduction of stainless steel decorative panels and some installation and construction steps. You can use this common sense to have more professional knowledge when decorating, especially when installing, and you have the confidence to avoid construction errors. If you want to know more about the home improvement knowledge of stainless steel decorative panels, please contact us.

How to distinguish between etching and embossing sS sheets?

1. Strictly speaking, there are two explanations for stainless steel embossed plates, one is punching with abrasive tools, and the other is embossing with tape. One is sheet processing and the other is tape processing. One is local force and the other is average force. Abrasive stamping is to frequently stamp one pattern next to another pattern on the plate, and the tape embossing is the whole roll rolling through the unwinding machine, embossing roller, and winding machine.

Therefore, the depth and three-dimensional effect of the stamping pattern of the abrasive tool are stronger than the embossing of the tape. However, the flatness of the stamped plate is worse than that of the embossed plate.

2. The stainless steel etching plate is to make a patchwork pattern on the plate through chemical corrosion. Compared with the embossed plate, the pattern of the etching plate can be customized according to customer requirements, and the patterns are diverse. Most of the general etching boards are currently used in the decoration industry, such as elevators and hotel lobbies.

The embossing process is a process that uses a concave-convex mold to deform the stainless steel coil under a certain pressure, thereby performing artistic processing on the surface of the stainless steel. The embossed stainless steel surface presents patterns and textures of different depths and has obvious relief three-dimensionality, which enhances the artistic appeal of stainless steel plates. It is mainly used in architectural decoration, elevator decoration, countertops, kitchen countertops, etc.