Seamless 304 Stainless Steel Pipe Suppliers

- Size Range: From 4mm4mm to 800mm800mm

- Wall Thickness Range: From 1mm to 150mm (SCH10-XXS)

- Length Options: 4000mm, 5800mm, 6000mm, 12000mm, or as required.

- Finish: 2B, BA,4K,8K, NO.1,2D,3#, HL

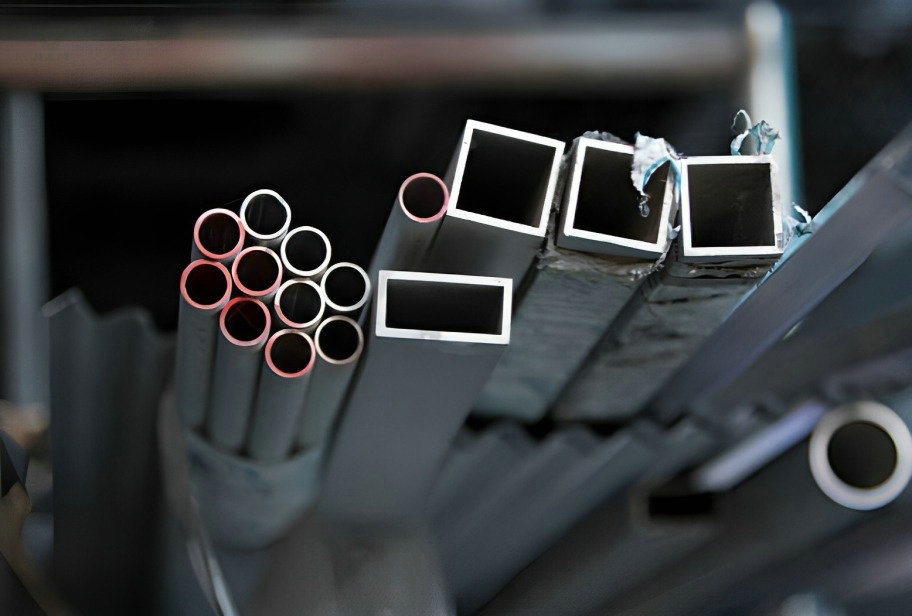

- Type: Round, square, rectangular, hexagonal, flat, angle

- Technique: Cold rolled, hot rolled

Product Description Of Seamless 304 Stainless Steel Pipe

Seamless 304 stainless steel pipe embodies the epitome of quality. Crafted from an austenitic alloy enriched with metallic nickel and chromium, it shines with exceptional anti-corrosion and anti-oxidation traits. This makes it an optimal pick for environments demanding top-tier corrosion resistance. Moreover, its remarkable attributes extend to seamless welding and streamlined production processes, cementing its stature as a pinnacle of performance and reliability. Choose Seamless 304 stainless steel pipe for a seamless fusion of durability and excellence.

Product Description Of Seamless 304 Stainless Steel Pipe

304 Grade Description in Different Standards

ISO Name | ASTM | DIN / EN | JIS | GB | Other |

X5CrNi18-10 | S30400 / 304 | 1.4301 | SUS304 | S30408/ | 06Cr19Ni10 0Cr18Ni9 |

304 Grade Chemical Components in the Different Standards

304 | C % | Si % | Mn % | P % | S % | Ni % | Cr % | Mo % | N % | Cu % |

ASTM | 0.08 | 0.75 | 2.00 | 0.045 | 0.030 | 8.0 – 10.5 | 18.0 – 20.0 | – | 0.10 | – |

DIN/EN | 0,07 | 1,00 | 2,00 | 0,045 | 0,015 | 8,0 – 10,5 | 17,5 – 19,5 | – | 0,10 | – |

JIS | 0.08 | 1.00 | 2.00 | 0.045 | 0.030 | 8.0 – 10.5 | 18.0 – 20.0 | – | – | – |

GB | 0.08 | 1.00 | 2.00 | 0.045 | 0.030 | 8.0 – 10.0 | 18.0 – 20. 0 | – | – | – |

304 Mechanical Properties in Different Standards

304 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | 205 | 515 | 40 | – | 92 | 201 | – |

JIS | 205 | 520 | 40 | 187 | 90 | – | 200 |

GB | 205 | 515 | 40 | – | 92 | 201 | 210 |

304 Physical Properties in Different Standards

| 304 | Density (g/cm³) | Melting point (℃) | Thermal conductivity (W/m-K) | Coefficient of thermal expansion (10^-6/K) | Elastic Modulus(GPa) | Poisson’s Ratio |

| ASTM | 7.93 | 1398-1454 | 16.2-24.9 | 17.3-17.8 | 200 | 0.3 |

| JIS | 7.93 | 1398-1454 | 16.2-24.9 | 17.3-17.8 | 193 | 0.3 |

| EN | 7.9 | 1400-1450 | 15-21.5 | 17.0-17.5 | 193 | 0.3 |

| GB | 7.9 | 1398-1454 | 16.2-24.9 | 17.3-17.8 | 193 | 0.3 |

characteristics Of Seamless 304 Stainless Steel Pipe

Seamless 304 stainless steel pipe embodies the epitome of quality. Crafted from an austenitic alloy enriched with metallic nickel and chromium, it shines with exceptional anti-corrosion and anti-oxidation traits. This makes it an optimal pick for environments demanding top-tier corrosion resistance. Moreover, its remarkable attributes extend to seamless welding and streamlined production processes, cementing its stature as a pinnacle of performance and reliability. Choose Seamless 304 stainless steel pipe for a seamless fusion of durability and excellence.

The Seamless 304 stainless steel pipe stands out with its hallmark feature: superior corrosion resistance. This quality arises from its composition rich in chromium and nickel, creating a protective layer that shields the pipe from corrosive agents. As a result, this pipe excels in environments prone to corrosion, ensuring sustained performance and durability over time. Whether exposed to moisture, chemicals, or varying temperatures, its exceptional corrosion resistance ensures that it remains a reliable choice for diverse applications.

The Seamless 304 stainless steel pipe showcases an exceptional attribute: high oxidation resistance. This characteristic stems from its composition, which includes a substantial content of chromium and nickel. These elements form a protective oxide layer on the surface, shielding the pipe from the detrimental effects of high temperatures and oxidative environments. As a result, this pipe maintains its structural integrity and appearance even in conditions where oxidation would typically pose a challenge. Its elevated oxidation resistance makes it a reliable choice for applications involving elevated temperatures and exposure to air and other oxidizing agents.

The Seamless 304 stainless steel pipe distinguishes itself through its seamless construction, signifying a continuous and uniform composition. This manufacturing method results in a pipe devoid of welded seams or joints, which can be points of vulnerability in terms of strength and corrosion resistance. The seamless structure ensures a smooth and uninterrupted flow path, reducing friction and turbulence. This feature is especially crucial in applications requiring optimal fluid dynamics, such as conveying liquids or gases in industries ranging from petrochemicals to pharmaceuticals.

Durable Performance is a hallmark of the Seamless 304 stainless steel pipe. Engineered with precision and resilience, this pipe excels under challenging conditions, maintaining its structural integrity and functionality over time. Its resistance to corrosion, oxidation, and wear ensures consistent performance, making it a reliable choice for demanding environments. Whether subjected to high pressures, extreme temperatures, or corrosive substances, the Seamless 304 stainless steel pipe consistently delivers durability and unwavering performance, embodying longevity and reliability in every application.

The Seamless 304 stainless steel pipe embodies hygienic excellence, thanks to its smooth and polished surface. This feature prevents the accumulation of contaminants and facilitates easy cleaning, making it ideal for applications where cleanliness is paramount. In industries such as food and beverage, pharmaceuticals, and healthcare, the pipe’s hygienic properties ensure compliance with stringent sanitation standards. Its ability to maintain a high level of cleanliness contributes to a safer and healthier environment, making it a preferred choice for applications that require uncompromising hygiene.

Application Of Seamless 304 Stainless Steel Pipe

high-temperature environments

Seamless 304 stainless steel pipes find extensive application in high-temperature environments due to their exceptional heat resistance. They are utilized in diverse sectors including power plants for conveying steam and gases, industrial furnaces for heat conduction, chemical and petroleum industries for transporting high-temperature media, and aerospace for fluid transmission. Their ability to withstand elevated temperatures while maintaining structural integrity makes them a reliable choice in critical applications such as heat exchangers, power generation, and industrial processing, ensuring consistent performance under challenging thermal conditions.

chemical processing industry

In the chemical processing industry, Seamless 304 stainless steel pipes play a pivotal role due to their exceptional attributes. These pipes are utilized for conveying corrosive chemicals, acids, and reactive substances at various temperatures. Their superior corrosion resistance ensures safe and efficient transportation of chemicals without compromising structural integrity. Whether used in reactors, pipelines, or chemical storage facilities, Seamless 304 stainless steel pipes provide the reliability and durability necessary to withstand the harsh chemical environments, contributing to the efficiency and safety of chemical processing operations.

food and beverage processing industry

Seamless 304 stainless steel pipes are indispensable in the food and beverage processing industry, ensuring uncompromised hygiene and product quality. These pipes, sourced from reliable stainless steel pipe suppliers, are utilized to convey consumables in a sanitary manner, preserving taste and purity. Their non-reactive surfaces prevent contamination, making them a trusted choice for dairy, beverage, and pharmaceutical applications, meeting stringent standards while upholding product safety and integrity.

FAQ

Manufacturing Process:

- Seamless Pipes: Seamless pipes are produced from a solid cylindrical steel billet. The billet is heated, pierced, and then elongated to form a hollow tube. This process creates a pipe without any welded seams or joints.

- Welded Tubes: Welded tubes are manufactured by joining two or more pieces of steel together through welding. The edges of the steel plates or strips are heated, fused, and welded to form the tube.

Appearance:

- Seamless Pipes: Seamless pipes have a smooth and consistent appearance due to their uninterrupted structure. They lack the visible seams present in welded tubes.

- Welded Tubes: Welded tubes have visible weld seams along their length, which can impact their appearance, especially in applications where aesthetics matter.

Strength and Integrity:

- Seamless Pipes: Seamless pipes generally have better structural integrity due to the absence of welds. They are more resistant to pressure and can handle higher stress levels.

- Welded Tubes: While modern welding techniques have improved the strength of welded tubes, there might still be slightly reduced strength around the weld seams compared to seamless pipes.

Size and Availability:

- Seamless Pipes: The manufacturing process of seamless pipes allows for a broader range of sizes, especially larger diameters and thicker walls. They are often available in longer lengths.

- Welded Tubes: Welded tubes are available in a wide range of sizes and thicknesses, including both smaller and larger dimensions. They might be more readily available and cost-effective for certain applications.

Applications:

- Seamless Pipes: Due to their superior strength and integrity, seamless pipes are commonly used in high-pressure and high-temperature applications, such as oil and gas transmission, petrochemical industries, and power generation.

- Welded Tubes: Welded tubes are used in various industries including construction, automotive, furniture, and structural applications, where specific design considerations or cost-effectiveness are important.

In summary, the choice between stainless steel seamless pipes and welded tubes depends on factors like the intended use, budget, aesthetic requirements, and specific application demands. Each option has its own advantages and considerations that should be evaluated based on the project’s requirements.

Seamless 304 Stainless Steel Pipe offers a number of advantages that make it highly desirable in many applications:

- Excellent Corrosion Resistance: 304 stainless steel has excellent corrosion resistance, making Seamless 304 stainless steel pipe perform well in a wide range of corrosive environments for industries such as chemical processing, petroleum, food and beverage, and more.

- Excellent High Temperature Resistance: Seamless 304 Stainless Steel Pipe maintains stable performance in high temperature environments, making it suitable for high temperature industrial applications such as power plants, chemical equipment, and heat exchangers.

- Sanitation and Cleanliness: The smooth surface of stainless steel makes Seamless 304 Stainless Steel Pipe easy to clean and suitable for food processing, pharmaceutical and medical applications where strict sanitation standards are required.

- Superior Mechanical Properties: Seamless 304 Stainless Steel Pipe has good strength and toughness while being easy to machine and weld for a wide range of structural and engineering applications.

- Heat Resistance: Seamless 304 Stainless Steel Pipe is not easily deformed at high temperatures, making it suitable for industries that need to withstand high temperatures, such as energy production and metallurgy.

- Versatility: Due to its corrosion resistance, high temperature resistance and mechanical properties, Seamless 304 Stainless Steel Pipe can be used in a wide range of applications, from chemical to construction, from food processing to automotive manufacturing.

- Environmentally Friendly and Recyclable: Stainless steel is a 100% recyclable material, and the use of Seamless 304 Stainless Steel Pipe contributes to sustainable development and reduces the need for new raw materials.

In summary, Seamless 304 stainless steel tubing demonstrates multiple advantages in a wide range of applications due to its excellent corrosion resistance, high temperature resistance, hygiene and mechanical properties, making it an ideal choice for a number of industries.

There are some differences between Seamless 304 stainless steel pipe and 316 stainless steel pipe, mainly related to their chemical composition, corrosion resistance, and areas of application:

- Chemical Composition:

304 Stainless Steel Pipe: Containing 18% chromium and 8% nickel, it is a common austenitic stainless steel. It has good corrosion resistance and mechanical properties at room temperature.

316 Stainless Steel Pipe: Contains 16% chromium, 10% nickel and 2% molybdenum. This added molybdenum provides higher corrosion resistance, especially in chloride environments, allowing it to perform better in harsher corrosive conditions.

- Corrosion Resistance:

304 Stainless Steel Pipe: Suitable for general corrosive environments such as indoor applications, natural environments, and low concentrations of acids and alkalis.

316 Stainless Steel Pipe: has higher corrosion resistance, especially in chloride and salt water environments. It performs better in harsh environments such as seawater, chemical processing and offshore installations.

- Areas of Application:

304 Stainless Steel Pipe: Suitable for many general industrial and commercial applications such as construction, food and beverage processing, HVAC, etc.

316 Stainless Steel Pipe: More commonly used in chemical, marine, pharmaceutical, offshore exploration and highly chlorinated environments due to its excellent corrosion resistance.

In summary, the difference between Seamless 304 stainless steel pipe and 316 stainless steel pipe mainly lies in the chemical composition and corrosion resistance. Choosing the right material for a specific application can ensure that the pipe will perform well in a particular environment.

- Material Selection and Preparation: Firstly, high quality stainless steel 304 material is selected and supplied by reliable stainless steel pipe suppliers. This ensures the quality and performance of the pipe.

- Billet heating and piercing: The manufacturing process begins with the heating of the stainless steel billet to make it easy to work with. In a piercing machine, a hollow tube is formed by passing a conical tool through the center of the billet.

- Drawing and Rolling: The punched billet is drawn and rolled several times to gradually reduce the diameter, increase the length, and achieve the desired wall thickness and outside diameter dimensions.

- Heat treatment: In order to improve the mechanical properties and corrosion resistance of Seamless 304 Stainless Steel Pipe, the billet is heat treated, which is a key step.

- Terminal shaping and cutting: The finished billet is terminally shaped and cut to obtain the exact size and shape required.

- Pickling and Cleaning: To remove surface oxides and impurities, the tubes are pickled or chemically cleaned to keep their surfaces smooth and clean.

- Inspection and Testing: The finished pipe undergoes a series of inspections and tests to ensure its quality and performance. This includes non-destructive and physical property tests.

- Marking and Packaging: The finished pipe will be marked to identify its specification, material and production batch, and then packaged appropriately to prevent damage before being delivered to the customer by stainless steel pipe suppliers.

This manufacturing process is strictly controlled and monitored to ensure the production of high quality, seamless and reliable Seamless 304 Stainless Steel Pipe for various applications.

Seamless 304 stainless steel pipe comes in a wide range of sizes, which is part of what stainless steel pipe suppliers can offer. They can be customized to meet the needs of different applications and generally include the following ranges:

- Outside diameter: ranging from small diameters (such as 1/8 inch or 3.18 mm) to large diameters (over 24 inches or 609.6 mm).

- Wall Thickness: From thin-walled tubing to thick-walled tubing, depending on the pressure and needs of the application.

- Lengths: Standard lengths are usually random lengths (e.g., 6 to 12 meters), but custom lengths are also available upon request.

Stainless steel pipe suppliers are usually able to offer Seamless 304 stainless steel pipe in a variety of sizes and specifications to meet the requirements of different industries and applications. When selecting pipe sizes, it is often necessary to consider the pressure, temperature, flow rate and structural requirements of the application to ensure optimum performance and safety.

other products

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China