Seamless 304H Stainless Steel Pipe Suppliers

- Size Range: From 4mm4mm to 800mm800mm

- Wall Thickness Range: From 1mm to 150mm (SCH10-XXS)

- Length Options: 4000mm, 5800mm, 6000mm, 12000mm, or as required.

- Finish: 2B, BA,4K,8K, NO.1,2D,3#, HL

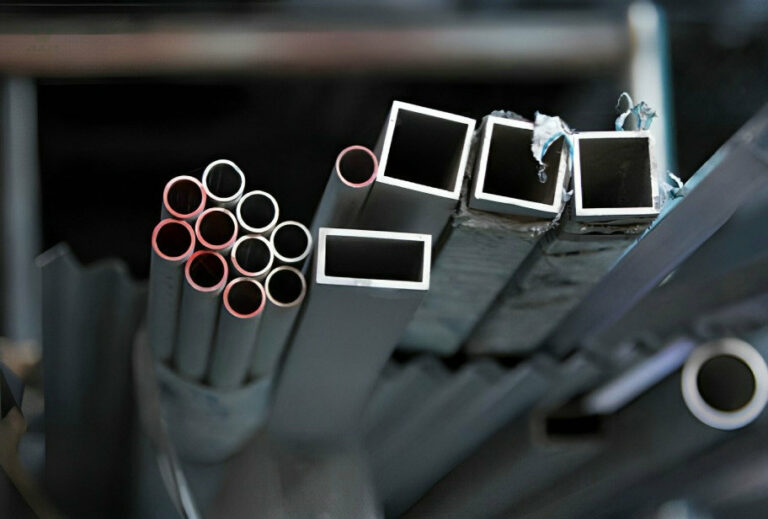

- Type: Round, square, rectangular, hexagonal, flat, angle

- Technique: Cold rolled, hot rolled

Product Description Of Seamless 304H Stainless Steel Pipe

Our Seamless 304H Stainless Steel Pipe is crafted from austenitic stainless steel alloy, boasting a chromium content of 18-19% and a nickel content of 8-11%. With a maximum carbon content of just 0.08%, it represents one of the most versatile and widely used members of the stainless steel family.

This stainless steel pipe exhibits exceptional corrosion resistance, remarkable strength, ease of machining, and outstanding formability. Its robust properties make it an ideal choice for a myriad of applications, where reliability and durability are paramount. Whether in the chemical industry, construction, or various engineering projects, our Seamless 304H Stainless Steel Pipe promises the highest quality and performance.

specification Of Seamless 304H Stainless Steel Pipe

Chemical Components Of Seamless 304H Stainless Steel Pipe

| Standard | C, ≤ | Si, ≤ | Mn, ≤ | P, ≤ | S, ≤ | Cr | Ni |

|---|---|---|---|---|---|---|---|

| ASTM A276/A276M | 0.04-0.10 | 1.00 | 2.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-11.0 |

physical property Of Seamless 304H Stainless Steel Pipe

| Property | ASTM A312 | JIS G3459 | EN 10217-7 | GB/T 14976 |

|---|---|---|---|---|

| Density (g/cm³) | 7.93 | 7.93 | 7.93 | 7.93 |

| Melting Point (°C) | 1400-1450 | 1400-1450 | 1400-1450 | 1400-1450 |

| Thermal Conductivity (W/m·K) | 16.2 (100°C) | 16.2 (100°C) | 16.2 (100°C) | 16.2 (100°C) |

| Specific Heat (J/g·K) | 0.50 (0-100°C) | 0.50 (0-100°C) | 0.50 (0-100°C) | 0.50 (0-100°C) |

| Electrical Resistivity (Ω·m) | 0.72 (20°C) | 0.72 (20°C) | 0.72 (20°C) | 0.72 (20°C) |

| Modulus of Elasticity (GPa) | 193 | 193 | 193 | 193 |

mechanical property Of Seamless 304H Stainless Steel Pipe

| Property | ASTM A312 | JIS G3459 | EN 10217-7 | GB/T 14976 |

|---|---|---|---|---|

| Tensile Strength (MPa) | ≥ 515 | ≥ 520 | ≥ 520 | ≥ 520 |

| Yield Strength 0.2% Offset (MPa) | ≥ 205 | ≥ 205 | ≥ 205 | ≥ 205 |

| Elongation (%) | ≥ 35 | ≥ 35 | ≥ 35 | ≥ 35 |

| Hardness (Brinell) | ≤ 201 | ≤ 201 | ≤ 201 | ≤ 201 |

characteristics Of Seamless 304H Stainless Steel Pipe

Seamless 304H Stainless Steel Pipe exhibits exceptional corrosion resistance, making it highly suitable for demanding environments. This corrosion resistance is attributed to its chromium content, typically ranging from 18% to 20%, which forms a protective oxide layer on the surface of the steel. This oxide layer acts as a shield, preventing the underlying metal from reacting with corrosive substances. As a result, 304H Stainless Steel Pipe maintains its integrity and performance even when exposed to various corrosive agents, including acids, alkalis, and saline solutions. It excels in applications where resistance to corrosion is paramount, making it a reliable choice for industries such as chemical processing, marine, and food production.

Seamless 304H Stainless Steel Pipe is renowned for its exceptional strength properties, making it a preferred material in a wide range of applications. This high strength is primarily attributed to its unique composition, which includes chromium (typically 18-20%) and nickel (approximately 8-10.5%). These alloying elements enhance the steel’s structural integrity and mechanical properties. As a result, 304H Stainless Steel Pipe exhibits impressive tensile and yield strength, allowing it to withstand substantial loads and pressures. This characteristic makes it an ideal choice for applications in industries such as construction, aerospace, and automotive, where structural integrity and reliability are paramount. Its robust strength combined with excellent corrosion resistance further solidifies its position as a versatile and high-performance material in various demanding environments.

Seamless 304H Stainless Steel Pipe boasts exceptional ease of fabrication as one of its prominent features. This attribute stems from its unique alloy composition, typically comprising 18-20% chromium and 8-10.5% nickel. These alloying elements lend themselves to excellent workability and formability, making it effortless for manufacturers and fabricators to shape and mold the steel into various intricate designs and structures.

The material’s malleability and ductility allow for a wide array of fabrication techniques, including cutting, welding, bending, and machining. Whether it’s constructing complex components or straightforward installations, this ease of fabrication simplifies the manufacturing process and enhances the overall efficiency of projects.

This characteristic positions Seamless 304H Stainless Steel Pipe as a preferred choice in industries where precision and customization are paramount, such as construction, architecture, and manufacturing. Its versatility in fabrication makes it an ideal material for projects that demand intricate designs and tailored solutions while maintaining the steel’s exceptional strength and corrosion resistance.

Seamless 304H Stainless Steel Pipe exhibits low conductivity as one of its notable characteristics. This feature is a result of its specific alloy composition, primarily composed of 18-20% chromium and 8-10.5% nickel, with minimal carbon content.

Low electrical and thermal conductivity makes this stainless steel pipe suitable for various applications where heat transfer or electrical conduction is not desirable. The reduced conductivity minimizes the risk of heat loss or gain in systems, ensuring temperature stability. It also prevents unwanted electrical currents from passing through, contributing to safety in certain applications.

This property expands the range of applications for Seamless 304H Stainless Steel Pipe, particularly in situations where insulation or containment of heat and electricity is crucial. It is commonly employed in industries like petrochemical, aerospace, and construction, where minimizing heat exchange or electrical interference is essential for optimal performance and safety.

Seamless 304H Stainless Steel Pipe possesses magnetic properties, which is another noteworthy characteristic. These properties are a result of its specific alloy composition.

Despite being part of the stainless steel family, which is generally known for its non-magnetic nature, Seamless 304H Stainless Steel Pipe exhibits some level of magnetism due to its higher carbon content compared to other stainless steel grades. This mild magnetism can be advantageous in certain applications where magnetic properties are required, such as in industries involving magnetic sensors or components.

However, it’s important to note that the magnetic properties of 304H stainless steel are relatively weak compared to common ferromagnetic materials like carbon steel. As a result, its magnetism is often not a primary consideration, and it maintains the corrosion resistance and other stainless steel properties that make it valuable in various industrial applications.

Application of Seamless 304H Stainless Steel Pipe

Structural Supports in Construction

Seamless 304H Stainless Steel Pipe finds extensive application in the construction sector, primarily as a reliable material for structural supports. Its exceptional strength, corrosion resistance, and adaptability make it a crucial choice for ensuring the stability, safety, and durability of various construction projects. Whether used in beams, columns, or other structural components, Seamless 304H Stainless Steel Pipe plays a fundamental role in upholding the integrity of buildings and infrastructure. Its ability to withstand harsh environmental conditions and corrosive elements makes it an ideal solution for long-lasting structural support in the demanding field of construction.

Manufacturing Household Appliances

Seamless 304H Stainless Steel Pipe is also utilized in the manufacturing of household appliances. Its corrosion resistance and durability make it an excellent choice for applications such as the production of kitchen appliances, including stoves, refrigerators, sinks, and dishwashers. The stainless steel's ability to withstand high temperatures and exposure to moisture ensures that these appliances remain reliable and aesthetically pleasing for an extended period. Additionally, its hygienic properties make it suitable for appliances used in food preparation and storage, contributing to the overall safety and convenience of households.

Industrial Artwork Production

Seamless 304H Stainless Steel Pipe finds its application in the production of industrial artwork. This stainless steel's versatility, corrosion resistance, and durability make it a preferred material for creating various forms of artistic installations and sculptures in industrial settings. Artists and designers often choose it for its ability to withstand outdoor conditions and resist corrosion, ensuring that the artwork maintains its aesthetic appeal over time. Whether used for large outdoor sculptures or intricate indoor designs, Seamless 304H Stainless Steel Pipe provides the structural integrity and visual appeal needed for industrial art projects.

Food and Beverage Industry

Seamless 304H Stainless Steel Pipe is widely utilized in the food and beverage industry due to its exceptional corrosion resistance and hygienic properties. This stainless steel pipe is a preferred choice for various applications within this sector, such as food processing equipment, beverage production, and storage tanks. Its resistance to corrosion, even in contact with acidic or alkaline substances, ensures the integrity of food and beverage handling and storage systems. Additionally, its smooth surface finish makes it easy to clean and maintain the highest levels of hygiene, meeting the stringent requirements of this industry. Seamless 304H Stainless Steel Pipe plays a critical role in preserving the quality and safety of food and beverages, making it an essential material in this field.

Pharmaceutical and Chemical Industry

Seamless 304H Stainless Steel Pipe plays a vital role in the pharmaceutical and chemical industries. Its exceptional corrosion resistance and durability make it ideal for pharmaceutical equipment, chemical storage, reactors, and pipelines. This stainless steel's resistance to corrosion ensures product purity and prevents contamination. Additionally, it withstands high temperatures and can be easily customized for various applications, contributing to the safety and efficiency of pharmaceutical and chemical processes.

FAQ

Seamless 304H Stainless Steel Pipe is a versatile and widely used stainless steel grade known for its excellent corrosion resistance, high-temperature strength, and ease of fabrication. When compared to other stainless steel grades, such as 316 or 321, Seamless 304H has some distinct differences and advantages:

- Corrosion Resistance: Seamless 304H Stainless Steel Pipe exhibits excellent corrosion resistance in a wide range of environments, including acidic and chloride-rich conditions. It is well-suited for applications involving exposure to various chemicals and corrosive substances.

- High-Temperature Strength: 304H Stainless Steel has elevated carbon content, which enhances its high-temperature strength. This makes it suitable for applications where elevated temperatures are a concern, such as industrial heating systems and exhausts.

- Ease of Fabrication: Compared to some other stainless steel grades, 304H is relatively easy to fabricate and weld. It can be formed into various shapes and sizes, making it a versatile choice for manufacturing processes.

- Cost-Effective: In terms of cost, 304H Stainless Steel is often more budget-friendly than higher nickel-content stainless steels like 316 or 321. This makes it a cost-effective choice for applications where extreme corrosion resistance isn’t necessary.

- Magnetic Properties: Unlike some stainless steel grades that are non-magnetic, 304H Stainless Steel is weakly magnetic. This can be advantageous in certain applications where magnetic properties are desired.

- Wider Availability: Seamless 304H Stainless Steel Pipe is widely available and commonly stocked, making it readily accessible for various industries and projects.

It’s important to note that the choice of stainless steel grade depends on the specific requirements of the application. While 304H offers many advantages, other grades may be more suitable for specialized uses. Consulting with stainless steel suppliers or experts can help determine the best grade for a particular project.

The strength of Seamless 304H Stainless Steel Pipe significantly influences its suitability for various applications, and this characteristic makes it a versatile choice in several industries. Here’s how its strength profile affects its application:

- High-Temperature Strength: One of the key advantages of 304H Stainless Steel is its enhanced high-temperature strength. The elevated carbon content in 304H provides improved creep resistance and resistance to sensitization when exposed to high temperatures. This makes it an excellent choice for applications in industrial heating systems, such as boilers and heat exchangers, where materials must withstand extreme heat.

- Structural Applications: Due to its good tensile strength and yield strength, Seamless 304H Stainless Steel Pipe finds use in structural applications. It is employed in construction, architectural designs, and infrastructure projects where the material must provide both strength and corrosion resistance.

- Pressure Vessels: The combination of corrosion resistance and high-temperature strength makes 304H Stainless Steel suitable for use in the fabrication of pressure vessels. These vessels can withstand internal pressure and maintain their structural integrity even in demanding environments.

- Exhaust Systems: In the automotive and aerospace industries, where exhaust systems are exposed to high temperatures and corrosive gases, Seamless 304H Stainless Steel Pipe’s strength and heat resistance make it a preferred choice.

- Chemical and Petrochemical Industry: For applications involving the transport of corrosive chemicals and gases at elevated temperatures, 304H Stainless Steel’s strength and corrosion resistance are valuable properties.

- Industrial Equipment: Various industrial equipment and machinery components, such as shafts, valves, and fasteners, benefit from 304H Stainless Steel’s strength, especially in demanding or high-temperature environments.

In summary, the high-temperature strength of Seamless 304H Stainless Steel Pipe makes it well-suited for applications where materials need to maintain their structural integrity and resist corrosion at elevated temperatures. Its versatility and reliability in diverse environments contribute to its widespread use across multiple industries. Collaborating with stainless steel pipe suppliers can help identify the best grade for specific applications based on their strength requirements.

Yes, Seamless 304H Stainless Steel Pipe is designed to withstand high temperatures and corrosive environments, making it a highly suitable choice for a wide range of industrial applications. Here’s how it excels in these conditions:

- High-Temperature Resistance: Seamless 304H Stainless Steel Pipe is specifically formulated to offer excellent high-temperature resistance. The “H” in 304H stands for high carbon content, which enhances its ability to withstand elevated temperatures. It resists scaling and retains its mechanical properties at temperatures well above 1000°C (1832°F). This property makes it ideal for applications involving industrial heating systems, such as boilers, heat exchangers, and furnaces.

- Corrosion Resistance: 304H Stainless Steel exhibits outstanding corrosion resistance, particularly in a wide range of corrosive environments. It effectively resists attack from acids, alkalis, and chlorides, making it suitable for use in chemical processing industries, where exposure to corrosive substances is common.

- Creep Resistance: This alloy has excellent creep strength, which means it can withstand prolonged exposure to high temperatures without deformation or failure. This property is vital for applications like pressure vessels, where sustained high temperatures are involved.

- Oxidation Resistance: Seamless 304H Stainless Steel Pipe also offers good oxidation resistance, protecting it from oxygen-induced corrosion, even at high temperatures.

- Durability: Thanks to its robust combination of high-temperature and corrosion resistance, Seamless 304H Stainless Steel Pipe boasts exceptional durability, ensuring a long service life in challenging conditions.

- Versatility: The versatility of 304H Stainless Steel extends its use to a broad range of industries, including petrochemical, chemical, food and beverage processing, pharmaceuticals, and more. It’s well-suited for applications where both temperature and corrosion challenges exist.

Collaborating with stainless steel pipe suppliers who specialize in high-temperature and corrosion-resistant materials can help ensure the appropriate selection and customization of Seamless 304H Stainless Steel Pipe for specific applications.

Yes, Seamless 304H Stainless Steel Pipe is known for its excellent weldability. This property is essential in various industries where welding is a common joining method. Here’s why it is easily weldable:

- Low Carbon Content: Seamless 304H Stainless Steel Pipe has a low carbon content, typically around 0.04-0.10%. This low carbon content minimizes the risk of carbide precipitation, which can occur during welding and lead to intergranular corrosion. As a result, 304H Stainless Steel remains corrosion-resistant after welding.

- Austenitic Structure: It belongs to the austenitic stainless steel family, which is renowned for its favorable welding characteristics. The austenitic structure provides good ductility and prevents the formation of brittle phases during welding.

- Wide Range of Welding Methods: Seamless 304H Stainless Steel Pipe can be welded using various common welding techniques, including TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), and shielded metal arc welding (SMAW). The choice of welding method depends on the specific application and requirements.

- Post-Weld Heat Treatment: While 304H Stainless Steel is generally easy to weld without issues, it can benefit from post-weld heat treatment (PWHT) in certain situations to further improve its properties. PWHT can help relieve residual stresses and enhance the material’s performance.

- Welding Precautions: Although 304H Stainless Steel Pipe is highly weldable, it’s essential to follow proper welding practices, such as using appropriate filler materials and maintaining proper shielding gas conditions, to ensure high-quality welds.

Collaborating with experienced stainless steel pipe suppliers who are knowledgeable about welding procedures and can provide guidance on welding techniques and materials is advisable for achieving reliable and durable welds in Seamless 304H Stainless Steel Pipe.

Maintaining Seamless 304H Stainless Steel Pipe is essential to ensure its longevity and optimal performance. Here are recommended maintenance practices:

- Regular Cleaning: Clean the surface of the stainless steel pipe regularly to remove dirt, dust, and contaminants. Use mild detergent solutions or stainless steel-specific cleaners with a soft cloth or sponge. Avoid abrasive materials that can scratch the surface.

- Passivation: Periodically passivate the pipe to restore its corrosion resistance. Passivation is a chemical process that removes contaminants and enhances the passive oxide layer on the stainless steel’s surface. It’s especially important after welding or exposure to corrosive environments.

- Avoid Chloride Exposure: Minimize contact with chloride-containing substances, such as salt or certain cleaning agents, as they can promote pitting corrosion in stainless steel. If exposure occurs, promptly rinse and clean the affected area.

- Prevent Contamination: Ensure that the stainless steel pipe does not come into contact with iron or steel particles, which can lead to rust staining. Keep the work area clean and free from potential sources of contamination.

- Inspect for Damage: Regularly inspect the pipe for signs of damage, including cracks, dents, or corrosion. Address any issues promptly to prevent further deterioration.

- Proper Storage: If the pipe is not immediately installed, store it in a dry and covered area to protect it from moisture and environmental contaminants.

- Avoid Mixing Metals: When connecting or fastening the pipe, use compatible materials and avoid mixing different types of metals to prevent galvanic corrosion.

- Temperature Considerations: If the pipe is exposed to high-temperature environments, ensure that it is adequately supported and insulated to prevent stress corrosion cracking.

- Consult Stainless Steel Experts: For specific maintenance guidelines or if you encounter any challenges, consult with stainless steel experts or stainless steel pipe suppliers. They can provide tailored advice based on your application and environmental conditions.

- Routine Inspections: Implement a routine inspection schedule to assess the condition of the stainless steel pipe, particularly in critical applications. Early detection of issues can prevent costly repairs or replacements.

By following these maintenance practices and working closely with reputable stainless steel pipe suppliers, you can maximize the lifespan and performance of Seamless 304H Stainless Steel Pipe in various applications.

Yes, Huaxiao stainless steel pipe suppliers offer a wide range of sizes and dimensions for Seamless 304H Stainless Steel Pipe, and many of these pipes can be customized to meet specific project requirements. This flexibility in sizing and customization allows you to select the ideal pipe dimensions for your application, ensuring a precise fit and optimal performance in your project. Whether you need standard sizes or specialized dimensions, Huaxiao stainless steel pipe suppliers can work with you to provide the seamless stainless steel pipe that meets your exact specifications.

Seamless 304H Stainless Steel Pipe is typically manufactured through a multi-step process, ensuring high-quality and reliable pipes. The key steps in its production, with the involvement of Huaxiao stainless steel pipe suppliers, include:

- Raw Material Selection: High-quality stainless steel ingots with the appropriate composition, such as 18-20% chromium and 8-10.5% nickel, are selected as the raw materials. These elements contribute to the corrosion resistance and durability of the final product.

- Melting and Casting: The selected stainless steel ingots are melted in a furnace and then cast into billets or slabs of the desired size.

- Hot Rolling or Forging: The billets or slabs are heated and then hot rolled or forged into the desired shape, typically into seamless pipes. This process enhances the mechanical properties and dimensions of the pipes.

- Heat Treatment: The pipes may undergo heat treatment processes like annealing or solution annealing to relieve stresses and improve their properties.

- Surface Finish: The pipes’ surfaces can be finished through processes like pickling, passivation, or polishing to achieve the desired appearance and corrosion resistance.

- Quality Control: Stringent quality control measures are taken to ensure that the pipes meet the required standards and specifications. This includes testing for dimensions, mechanical properties, and corrosion resistance.

- Cutting and Inspection: The seamless pipes are cut to the desired lengths and thoroughly inspected for any defects or imperfections.

- Packaging and Delivery: The final pipes are packaged and prepared for shipping to customers, including Huaxiao stainless steel pipe suppliers.

The collaboration with Huaxiao stainless steel pipe suppliers ensures that these processes are carried out to industry standards, delivering high-quality Seamless 304H Stainless Steel Pipes for various applications.

The main difference between seamless 304H stainless steel pipe and 304 stainless steel lies in their carbon content.

- 304 Stainless Steel: It is a standard “18-8” stainless steel with 18% chromium and 8% nickel. It has a low carbon content, typically around 0.08%.

- 304H Stainless Steel: It is a high-carbon variant of 304, containing higher carbon content, usually in the range of 0.04%-0.10%. This increased carbon content provides better high-temperature strength.

Due to its higher carbon content, 304H stainless steel has improved high-temperature performance compared to 304 stainless steel. This makes it suitable for applications involving elevated temperatures, such as in high-temperature processing or boiler systems. However, the higher carbon content may make it slightly more susceptible to sensitization and intergranular corrosion in certain environments. Stainless steel pipe suppliers can provide both variants to meet specific application requirements.

other products

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China