Seamless 304L Stainless Steel Pipe Suppliers

- Size Range: From 4mm4mm to 800mm800mm

- Wall Thickness Range: From 1mm to 150mm (SCH10-XXS)

- Length Options: 4000mm, 5800mm, 6000mm, 12000mm, or as required.

- Finish: 2B, BA,4K,8K, NO.1,2D,3#, HL

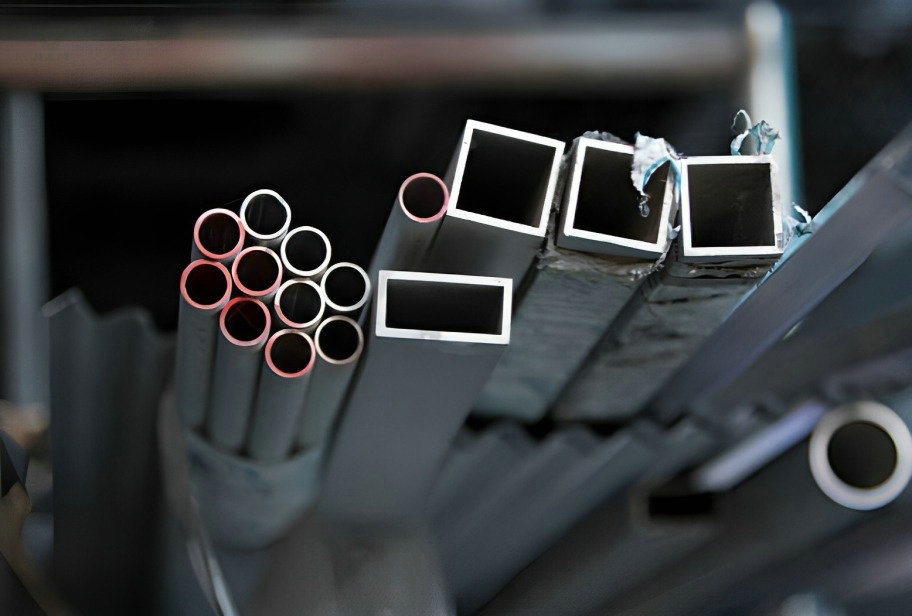

- Type: Round, square, rectangular, hexagonal, flat, angle

- Technique: Cold rolled, hot rolled

Product Description Of Seamless 304L Stainless Steel Pipe

304L Stainless Steel Seamless Pipe is a type of stainless steel pipe that is made from a single raw material with no welded seams. It is a low carbon version of 304 steel, also known as ultra-low carbon stainless steel.

The seamless 304L stainless steel pipe is a premium choice crafted from a singular billet, ensuring structural integrity devoid of welded seams. Derived from the esteemed 18-8 austenitic stainless steel, it stands as one of the world’s most widely used materials. Its distinctive feature lies in its lower carbon composition, facilitating extensive welding while mitigating localized corrosion.

Whether you seek reliability for industrial or creative endeavors, the seamless 304L stainless steel pipe from Huaxiao stainless steel pipe suppliers promise enduring performance and robust solutions to elevate your projects.

Product Description Of Seamless 304L Stainless Steel Pipe

304L Grade Description in Different Standards

ISO Name | ASTM | DIN / EN | JIS | GB | Other |

X2CrNi19-11 | S30403 304L | 1.4306 | SUS304L | S30403 | 022Cr19Ni10 00Cr19Ni10 |

304L Grade Chemical Components in Different Standards

304L | C % | Si % | Mn % | P % | S % | Ni % | Cr % | Mo % | N % | Cu % |

ASTM | 0.03 | 0.75 | 2.00 | 0.045 | 0.030 | 8.0-12.0 | 18.0-20.0 | – | 0.10 | |

DIN/EN | 0,03 | 1,00 | 2,00 | 0,045 | 0,015 | 10,0-12,0 | 18,0-20,0 | – | 0,10 | – |

JIS | 0.03 | 1.00 | 2.00 | 0.045 | 0.030 | 9.0-13.0 | 18.0-20.0 | – | – | – |

GB | 0.03 | 0.75 | 2.00 | 0.045 | 0.030 | 8.00-12.0 | 18.0-20.0 | – | 0.10 | – |

304L Mechanical Property in Different Standards

304L | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | 170 | 485 | 40 | – | 92 | 201 | – |

JIS | 175 | 480 | 40 | 187 | 90 | – | 200 |

GB | 170 | 480 | 40 | – | 92 | 201 | 210 |

304L Physical Property in Different Standards

| 304L | Density (g/cm³) | Melting point (℃) | Thermal conductivity (W/m-K) | Coefficient of thermal expansion (10^-6/K) |

| ASTM | 7.93 | 1400-1450 | 16.3 | 17.2 |

| JIS | 7.93 | 1400-1450 | 16.3 | 17.2 |

| EN | 7.93 | 1400-1450 | 16.3 | 17.2 |

| GB | 7.93 | 1400-1450 | 16.3 | 17.2 |

characteristics Of Seamless 304L Stainless Steel Pipe

Seamless 304L stainless steel pipes offer heightened strength due to their absence of welded seams. This unique construction contributes to the material’s enhanced structural integrity. Specifically, the minimum yield strength of the 304L stainless steel is 205 megapascals (MPa). This measurement represents the point at which the material will begin to deform plastically under stress. The minimum tensile strength, on the other hand, stands at 515 MPa, indicating the maximum load the material can bear without breaking.

This combination of yield strength and tensile strength underscores the robustness and reliability of 304L seamless stainless steel pipes. Their seamless design ensures a consistent distribution of material properties throughout the pipe’s length, translating into dependable performance in various applications, including those subjected to high-pressure environments or mechanical stress. Whether used in structural components, industrial processes, or critical systems, the elevated strength of seamless 304L stainless steel pipes ensures long-lasting durability and safety.

The superior corrosion resistance of 304L stainless steel seamless tubing stems from its chemical composition and microstructure. Its high chromium (Cr) content of approximately 18%, as well as its nickel (Ni) composition, make it highly resistant to oxidation. This oxidation resistance allows it to excel in most atmospheric environments without the need for additional protective measures.

In addition, the low carbon (C) content of 304L stainless steel seamless tubes helps reduce the risk of intergranular corrosion. Intergranular corrosion is a phenomenon that occurs in the intergranular regions of stainless steel at high temperatures. Low carbon content helps reduce the risk of intergranular corrosion under these conditions, thereby increasing the service life and reliability of the tube.

The continuous structure of seamless tubing also helps to prevent the expansion of cracks and corrosion. Since the seamless manufacturing process eliminates welded seams, this reduces the point at which corrosion can begin and lowers the risk of the pipe being subjected to corrosion. This allows 304L stainless steel seamless pipe to perform well in a wide range of corrosive media, including acidic media in the chemical industry, salt water in the marine environment, and corrosive liquids in many industrial processes.

In summary, 304L stainless steel seamless pipe can remain stable in a wide range of environments with its excellent corrosion resistance, providing a long-lasting and reliable piping solution.

The excellent processability of 304L stainless steel seamless tubing stems from its carefully engineered chemical composition, which includes the key elements of chromium (Cr), nickel (Ni) and molybdenum (Mo). The presence of these elements provides multiple advantages to the tubing, resulting in excellent performance during processing, forming and fabrication.

First, the presence of chromium gives 304L stainless steel seamless tubes excellent corrosion resistance. Chromium reacts with oxygen to form a dense oxide film called a passivation layer, which helps prevent further corrosion and oxidation. This property allows the pipe to maintain its appearance and performance for a long time in wet or corrosive environments.

Secondly, the addition of nickel improves the toughness and plasticity of 304L stainless steel seamless pipe. This makes it easier to adjust the shape of the pipe during processing and forming while maintaining its mechanical properties. This excellent malleability means that complex shapes and sizes can be manufactured to meet the needs of a variety of applications.

Finally, the presence of molybdenum improves the corrosion and heat resistance of the tubing. Molybdenum increases the corrosion resistance of tubes, especially in corrosive media such as salt water or chemical solutions. In addition, molybdenum improves the stability of the tubing in high temperature environments, making it suitable for applications with large temperature variations.

In summary, the ease of processing of 304L stainless steel seamless tubes is given by their optimized chemical composition. The synergy of chromium, nickel, and molybdenum provides simultaneous excellent corrosion resistance, strength, and machinability, making it ideal for a wide range of applications. Whether in manufacturing, construction or industry, all can benefit from its ease of processing.

The low carbon content of 304L stainless steel is one of the keys to its unique properties, especially in welding and high temperature environments. Low carbon content means that the material contains a relatively low amount of carbon, typically below 0.03%.

During welding, high carbon content stainless steel may produce intergranular corrosion in the heat-affected zone (around the weld), due to the fact that the elemental carbon combines with chromium to form carbides, which reduces the chromium content and makes the area susceptible to the effects of corrosion. The low carbon content of 304L stainless steel helps to reduce the formation of such carbides, thereby reducing the risk of intergranular corrosion.

In addition, the low carbon content improves the corrosion resistance of 304L stainless steel in high temperature environments. At high temperatures, stainless steels with high carbon content may form a large number of carbides that reduce the effective chromium content, thus reducing corrosion resistance. And 304L stainless steel due to the low carbon content, more able to maintain its corrosion resistance in high temperature environment, suitable for many high temperature industrial environment.

In summary, the low carbon content of 304L stainless steel makes it have superior welding and corrosion resistance. This makes it perform well in different applications, especially when it needs to be welded frequently or used in high temperature environments.

characteristics Of Seamless 304L Stainless Steel Pipe

304L Stainless Steel Seamless Pipe is a type of stainless steel pipe that is made from a single raw material with no welded seams. It is a low carbon version of 304 steel, also known as ultra-low carbon stainless steel. 304L stainless steel’s low carbon content minimizes harmful or deleterious carbide deposits after welding. As a result, 304L can be “welded” in severe corrosive environments and eliminates the need for annealing.304L stainless steel seamless tubes are used in a wide range of applications in the following areas:

chemical and petrochemical processing

Seamless 304L stainless steel tubes play an integral role in several key applications in chemical and petrochemical processing. First and foremost, they are widely used in pressure vessels and storage tanks, where their superior corrosion resistance makes them ideal for storing corrosive chemicals and liquids. In addition, these pipes also play an important role in heat exchangers, where they are used to transfer heat efficiently while maintaining their corrosion resistance and ensuring reliable fluid heat transfer. Piping systems are vital in the chemical industry and the corrosion and pressure resistance of 304L stainless steel pipes make them an ideal option for piping systems to ensure safe transfer of fluids and stable operation. In addition, these pipes are also widely used in equipment such as flanges, fittings, valves and pumps, which often require superior corrosion and pressure resistance to safeguard the smooth running of processes. Notably, these seamless 304L Stainless Steel Pipes are sourced from reliable stainless steel pipe suppliers, whose premium quality materials and superb manufacturing processes ensure the quality and performance of the pipes.

food and beverage processing sector

Seamless 304L Stainless Steel Pipes offered by reliable stainless steel pipe suppliers are widely used in the food and beverage processing sector for their excellent corrosion resistance and hygienic properties. To begin with, these pipes are able to withstand corrosive substances associated with food and beverage processing due to their superior corrosion resistance, ensuring long-lasting and stable pipes that do not require frequent maintenance and replacement. In addition, the stainless steel 304L seamless pipe's stainless surface as well as its smooth internal structure make it easy to clean and free from adhering bacteria, microorganisms, and foreign matter, thus helping to ensure the hygiene and safety of food and beverages. This makes it ideal for handling and transporting food liquids, helping to avoid cross-contamination and food safety hazards. Seamless 304L stainless steel tubes also play a key role in food and beverage storage facilities. Its corrosion resistance and hygienic properties make it suitable for use in the manufacture of storage tanks, conveying piping and handling equipment, ensuring the quality and hygiene of food and beverages during storage and processing.

medical device industry

Seamless 304L Stainless Steel Pipes offered by reliable stainless steel pipe suppliers are widely used in the medical device industry. These tubes play a vital role in medical devices such as surgical instruments, syringes, catheters and more. To begin with, 304L stainless steel seamless pipes have excellent corrosion and drug resistance, which makes them ideal for manufacturing medical devices. They are able to withstand the chemical effects of contact with drugs, disinfectants and body fluids, ensuring the durability and reliability of the instruments. Second, the stainless steel 304L seamless pipe's stainless surface and smooth internal structure make it easy to clean and sterilize, helping to maintain the hygiene and safety of medical devices. This is especially important for devices that come into contact with the human body, helping to prevent cross-infection and maintain patient health. In addition, 304L stainless steel seamless tubing has excellent machinability and can be fabricated into a variety of shapes and sizes to meet the diverse needs of medical device design.

indoor and outdoor decoration projects

In the building decoration industry, 304L Stainless Steel Seamless Pipe from reliable stainless steel pipe suppliers is widely used in indoor and outdoor decoration projects, such as staircase handrails, balustrades, guardrails and so on. First of all, 304L Stainless Steel Seamless Pipe adds modernity and sophistication to architectural decoration with its smooth and stainless appearance. Its surface texture and corrosion resistance enable it to withstand harsh weather and environmental influences in outdoor environments and maintain long-lasting beauty. Second, the malleability and workability of 304L stainless steel seamless tubing makes it suitable for fabricating decorative elements in a variety of shapes and designs. From delicate stair railings to creative balustrades, it can fulfill the creative needs of architects and designers to infuse buildings with a unique style. In addition, 304L Stainless Steel Seamless Tubes also excel in interior decoration, with its hygienic properties and durability making it ideal for public places such as shopping malls and hotels. Its easy-to-clean nature helps maintain the hygiene and comfort of interior spaces.

FAQ

The main difference between 304L stainless steel pipe and 304 stainless steel pipe lies in their carbon content. 304L stainless steel is a low-carbon variation of 304 stainless steel, which means it has a lower carbon content. This reduced carbon content in 304L minimizes the risk of sensitization – a phenomenon where the material becomes susceptible to intergranular corrosion when exposed to high temperatures. Due to its lower carbon content, 304L stainless steel is often used in applications where welding is involved, as it reduces the likelihood of carbide precipitation and subsequent corrosion. While both 304 and 304L stainless steel pipes share similar corrosion resistance and other mechanical properties, the difference in carbon content makes 304L a preferred choice for certain applications that require welding and resistance to sensitization.

Choosing seamless 304L stainless steel pipe over a welded tube offers several advantages.

- Strength and Integrity: Seamless pipes are generally stronger and have greater structural integrity compared to welded tubes due to their uninterrupted grain structure. This is particularly beneficial in high-pressure or critical applications.

- Corrosion Resistance: Seamless pipes have no welded seams that could potentially become weak points prone to corrosion. This makes them better suited for environments where corrosion resistance is crucial, such as in corrosive chemicals or marine environments.

- Smooth Interior Surface: Seamless pipes have a smooth interior surface with no weld bead or seam, which reduces the likelihood of particles getting trapped and makes them suitable for applications where cleanliness and flow are important.

- Reduced Risk of Defects: Welded tubes can have potential defects along the weld line, whereas seamless pipes are manufactured without welding, minimizing the risk of defects that could compromise the pipe’s structural integrity.

- Pressure and Temperature Tolerance: Seamless pipes can handle higher pressure and temperature levels due to their uniform thickness and absence of welds, making them suitable for applications involving extreme conditions.

- Aesthetic Considerations: The absence of welds in seamless pipes provides a more visually appealing and smoother appearance, making them preferred for applications where aesthetics matter, such as architectural and decorative uses.

- Consistency: Seamless pipes are produced using a continuous extrusion process, ensuring consistent dimensions and properties throughout the entire length of the pipe.

In essence, choosing seamless 304L stainless steel pipe provides improved durability, corrosion resistance, and overall performance, making it a suitable choice for critical and demanding applications where welded tubes might have limitations.

The corrosion resistance of 304L stainless steel pipe is excellent, making it well-suited for various applications in corrosive environments. 304L stainless steel is a low-carbon variation of the 304 grade, which enhances its resistance to sensitization and intergranular corrosion when exposed to elevated temperatures. This property makes it suitable for applications involving welding and thermal processes.

304L stainless steel contains chromium, which forms a passive oxide layer on its surface. This oxide layer acts as a protective barrier, preventing direct contact between the metal and corrosive agents, such as moisture, chemicals, and chlorides. As a result, 304L stainless steel exhibits impressive resistance to general corrosion, pitting corrosion, and crevice corrosion.

Its corrosion resistance allows 304L stainless steel pipe to perform well in various environments, including industrial settings, chemical processing plants, marine applications, and exposure to moderately aggressive chemicals. However, it’s important to note that while 304L stainless steel offers robust corrosion resistance, the suitability of the material for specific applications should be determined based on factors such as temperature, concentration of corrosive agents, and mechanical stresses involved.

Maintaining and caring for your 304L seamless stainless steel pipe, with guidance from stainless steel pipe suppliers, is crucial to ensure its longevity and performance. Here’s a comprehensive approach:

- Regular Cleaning: Clean the pipe’s surface using mild soap, warm water, and a soft cloth. Consult stainless steel pipe suppliers for recommended cleaning agents that won’t compromise the material’s integrity.

- Avoid Abrasives: Use non-abrasive cleaning tools to prevent scratching the surface. Suppliers can provide suitable cleaning brushes or sponges.

- Thorough Rinsing: After cleaning, thoroughly rinse the pipe with clean water to remove any residue from cleaning agents.

- Prevent Contamination: Avoid contact with substances containing chlorides, which can lead to corrosion. Seek advice from suppliers on suitable protective coatings if needed.

- Regular Inspection: Periodically inspect the pipe for signs of corrosion, pitting, or discoloration. Address issues promptly and consult suppliers for professional assessment if necessary.

- Ventilation: Ensure proper ventilation in storage areas to prevent moisture buildup, a potential cause of corrosion.

- Proper Handling: During transport and installation, handle the pipe carefully to avoid dents, scratches, and stress points that could lead to corrosion vulnerabilities.

- Suitable Storage: Store spare pipes in a covered, dry area to shield them from environmental elements.

- Professional Maintenance: Consider engaging stainless steel pipe suppliers for periodic professional inspections and maintenance, especially for critical applications.

- Supplier Recommendations: Rely on your stainless steel pipe suppliers for specific care instructions tailored to their products, as different alloys and finishes might require unique maintenance approaches.

By following these guidelines and collaborating with stainless steel pipe suppliers, you can ensure the long-term performance and durability of your 304L seamless stainless steel pipe across various applications.

304L Stainless Steel Seamless Pipe is a type of stainless steel pipe that is made from a single raw material with no welded seams. It is a low carbon version of 304 steel, also known as ultra-low carbon stainless steel. 304L stainless steel’s low carbon content minimizes harmful or deleterious carbide deposits after welding. As a result, 304L can be “welded” in severe corrosive environments and eliminates the need for annealing. 304L stainless steel seamless tubing offers the following advantages:

- Strength: Due to the absence of welded seams, 304L stainless steel seamless pipe has high strength.

- Corrosion resistance: 304L stainless steel seamless pipe has excellent corrosion resistance and can resist most atmospheric conditions and many corrosive media.

- Ease of processing: 304L stainless steel seamless pipe is mainly composed of chromium, nickel and molybdenum. The presence of these three elements makes 304L stainless steel seamless pipe has excellent corrosion resistance, strength and easy processing.

- Low carbon content: 304L stainless steel is a low carbon version of the 18-8 austenitic stainless steel material (the most widely used in the world). The low carbon content prevents localized corrosion during welding.

Other products

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China