Seamless 309s Stainless Steel Pipe Suppliers

- Size Range: From 4mm4mm to 800mm800mm

- Wall Thickness Range: From 1mm to 150mm (SCH10-XXS)

- Length Options: 4000mm, 5800mm, 6000mm, 12000mm, or as required.

- Finish: 2B, BA,4K,8K, NO.1,2D,3#, HL

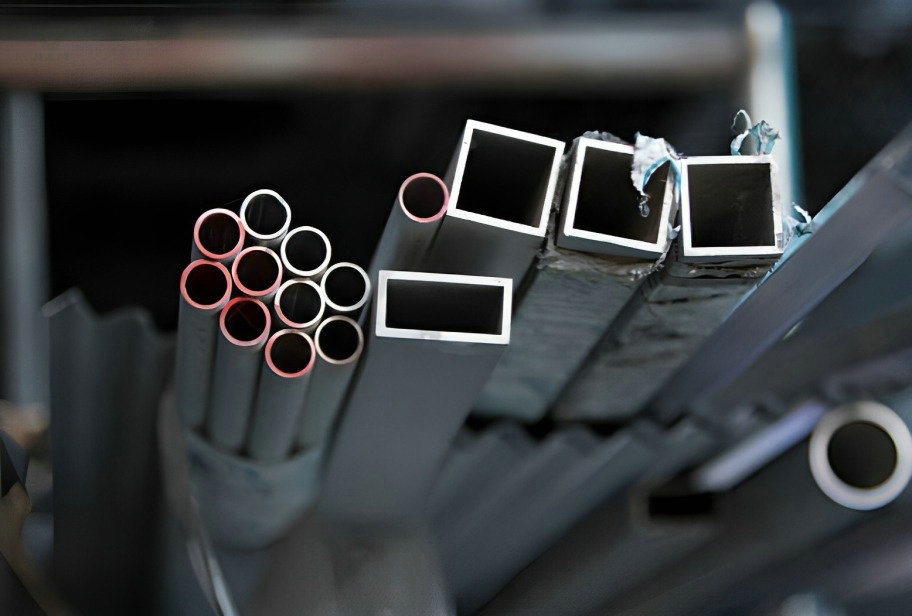

- Type: Round, square, rectangular, hexagonal, flat, angle

- Technique: Cold rolled, hot rolled

Product Description Of Seamless 309s Stainless Steel Pipe

Seamless 309S stainless steel pipe belongs to the family of austenitic chromium-nickel stainless steels, renowned for their exceptional high-temperature performance. With elevated levels of chromium and nickel, this pipe offers remarkable corrosion resistance and outstanding oxidation resistance, making it ideal for applications in extreme heat environments. Its high strength, corrosion resistance, and superior density of 8 grams per cubic centimeter (g/cm³) make it a top choice for demanding industrial needs. Whether you require reliability under intense heat or protection against corrosion, Seamless 309S Stainless Steel Pipe is engineered to deliver outstanding performance.

specification Of Seamless 309s Stainless Steel Pipe

Chemical Components Of Seamless 309s Stainless Steel Pipe

| Element | ASTM A312/A312M-22 |

|---|---|

| Carbon | ≤0.08% |

| Manganese | ≤2.00% |

| Phosphorus | ≤0.045% |

| Sulfur | ≤0.030% |

| Silicon | ≤1.00% |

| Chromium | 18.0-20.0% |

| Nickel | 8.0-11.0% |

| Molybdenum | N/A |

| Nitrogen | N/A |

physical property Of Seamless 309s Stainless Steel Pipe

| Property | Value |

|---|---|

| Density | 7.89 g/cm3 |

| Melting Range | 2500 – 2590°F |

| Electrical Resistivity | 30.7 Microhm-in at 68°C |

| Specific Heat | 0.12 BTU/lb-°F (32 – 212°F) |

| Thermal Conductivity | 9.0 BTU/hr/ ft2/ft /°F |

| Modulus of Elasticity | 28.5 x 106 psi |

mechanical property Of Seamless 309s Stainless Steel Pipe

| Property | Value |

|---|---|

| Tensile Strength | 620 MPa |

| Yield Strength | 310 MPa |

| Elongation at Break | 45% |

| Hardness, Brinell | 147 |

| Hardness, Rockwell B | 85 |

| Hardness, Vickers | 169 |

characteristics Of Seamless 309s Stainless Steel Pipe

Seamless 309S Stainless Steel Pipe boasts an exceptional level of corrosion resistance due to its high chromium and nickel content. Chromium forms a protective oxide layer on the surface, which acts as a barrier, preventing corrosive agents from penetrating the material. This inherent resistance makes it an excellent choice for applications exposed to aggressive environments, including chemical processing, acidic solutions, and saltwater conditions.

Moreover, the nickel content further enhances its resistance to corrosion, ensuring longevity and reliability in challenging settings. Whether facing acidic compounds or saline atmospheres, Seamless 309S Stainless Steel Pipe maintains its structural integrity, minimizing the risk of corrosion-related failures. This outstanding corrosion resistance sets it apart as a preferred material for demanding industrial applications where durability and reliability are paramount.

Seamless 309S Stainless Steel Pipe demonstrates remarkable oxidation resistance, making it well-suited for applications in high-temperature environments. This resistance stems from its high chromium content, which forms a protective chromium oxide layer on the surface when exposed to elevated temperatures. This oxide layer acts as a barrier, preventing further oxidation and maintaining the structural integrity of the pipe.

This exceptional oxidation resistance ensures that Seamless 309S Stainless Steel Pipe remains durable and reliable even when subjected to extreme heat, making it a preferred choice for industries such as aerospace, power generation, and furnace components. Its ability to withstand oxidative stress over time enhances its longevity and minimizes the risk of degradation in demanding applications.

Seamless 309S Stainless Steel Pipe exhibits enhanced sulfidation resistance, particularly in high-temperature environments. This attribute is attributed to its lower nickel content compared to some other stainless steel grades, which paradoxically improves its ability to withstand sulfur attack.

In sulfidation-prone settings, such as those found in petrochemical and industrial applications, the reduced nickel content in 309S minimizes the risk of sulfur-induced corrosion. The alloy forms protective oxides that act as a shield against sulfur compounds, preventing them from causing damage to the pipe.

This enhanced sulfidation resistance makes Seamless 309S Stainless Steel Pipe a reliable choice for industries where exposure to sulfur-containing gases and compounds is prevalent. It ensures the longevity and performance of the pipe, even in challenging sulfidation-prone environments.

Seamless 309S Stainless Steel Pipe possesses remarkable high-temperature strength, making it well-suited for applications in elevated temperature environments. This strength is attributed to its austenitic microstructure and carefully balanced alloy composition.

At elevated temperatures, Seamless 309S Stainless Steel Pipe maintains its structural integrity and mechanical properties. Its ability to resist deformation and maintain strength even under extreme heat conditions is crucial for applications in industries such as furnace components, heat exchangers, and thermal processing.

The high-temperature strength of this stainless steel pipe ensures reliable and long-lasting performance, making it a preferred choice where sustained exposure to elevated temperatures is a requirement. It provides peace of mind in applications where safety, durability, and consistent performance are paramount.

Seamless 309S Stainless Steel Pipe exhibits excellent creep resistance, which is the ability to withstand slow, continuous deformation when exposed to high temperatures and mechanical stress over an extended period.

In applications where the pipe is subjected to elevated temperatures and sustained loads, such as in furnace components, heat exchangers, and high-temperature processing equipment, creep resistance is crucial. Seamless 309S Stainless Steel Pipe’s exceptional creep resistance ensures that it maintains its structural integrity and dimensional stability over time, minimizing the risk of deformation or failure.

This attribute contributes to the longevity and reliability of Seamless 309S Stainless Steel Pipe in demanding high-temperature environments, making it a preferred choice for industries where creep resistance is essential.

application Of Seamless 309s Stainless Steel Pipe

furnaces

Seamless 309S stainless steel pipes find extensive utility in furnaces, where their exceptional heat-resistant properties are indispensable. These pipes play a pivotal role in furnace construction, enduring the extreme heat generated within. Their ability to withstand high temperatures, coupled with outstanding corrosion resistance, ensures prolonged service life in these demanding environments. Whether used in industrial heat treatment furnaces, metal production facilities, or any application requiring controlled high-temperature conditions, Seamless 309S stainless steel pipes contribute to efficient and reliable furnace operations. Their reliability and durability in such environments make them indispensable components for maintaining optimal temperatures and facilitating various heat-related processes.

burners

Seamless 309S stainless steel pipes are vital components in burners, serving a crucial role in high-temperature applications. Burners are essential in various industries, including heating systems, industrial furnaces, and power generation. In these applications, the pipes are subjected to intense heat and thermal stress. Seamless 309S stainless steel pipes excel in this demanding environment due to their exceptional heat resistance and corrosion resistance properties. They maintain their structural integrity even under extreme temperatures, ensuring the reliable and efficient operation of burners. Their ability to withstand thermal cycling and exposure to corrosive elements makes them a preferred choice for ensuring the longevity and performance of burners in a wide range of industrial settings.

kilns

Seamless 309S stainless steel pipes find significant utility in kilns, which are high-temperature industrial ovens used for processes like ceramics and metallurgy. These pipes are employed in kilns due to their remarkable resistance to heat and corrosion, making them well-suited for such extreme environments. Kilns often operate at elevated temperatures, and the pipes' ability to maintain structural integrity in these conditions is crucial. They endure intense thermal stress without degradation, ensuring the sustained functionality and longevity of kilns. Whether in ceramic studios or industrial facilities, Seamless 309S stainless steel pipes play a vital role in supporting the demanding requirements of kiln operations.

annealing equipment

Seamless 309S stainless steel pipes are essential components in annealing equipment, which is used in various industries to heat-treat materials for improved mechanical properties and reduced internal stresses. These pipes play a pivotal role in annealing applications due to their exceptional heat resistance and corrosion resistance. Annealing processes often involve exposing materials to high temperatures in controlled environments, and Seamless 309S stainless steel pipes excel in these conditions. They ensure the uniformity and consistency of heat treatment, contributing to the enhanced performance and durability of materials. Whether in metallurgy, manufacturing, or research settings, these pipes are integral to the success of annealing processes.

gas turbines

Seamless 309S stainless steel pipes find crucial applications in gas turbines, where their exceptional heat resistance and corrosion resistance properties are highly valued. Gas turbines are used in various industries, including aviation, power generation, and oil and gas, to convert energy from fuel into mechanical power by combustion. In these demanding environments, where extreme temperatures and corrosive gases are prevalent, 309S stainless steel pipes play a vital role. They maintain their structural integrity and resist corrosion even at high operating temperatures, ensuring the reliability and longevity of gas turbines. Whether in aircraft engines, power plants, or industrial turbines, these pipes contribute to the efficient and consistent performance of gas turbines, making them a preferred choice for critical components in these applications.

FAQ

Seamless 309S stainless steel pipe and Seamless 309 stainless steel pipe are closely related in terms of their chemical composition and overall properties, but they exhibit subtle differences:

Chemical Composition: Both 309S and 309 stainless steel pipes contain high levels of chromium and nickel for superior corrosion resistance. However, 309S contains a lower carbon content (0.08% max) compared to 309 (0.20% max). This lower carbon content in 309S reduces the risk of sensitization and intergranular corrosion at elevated temperatures, making it better suited for high-temperature applications.

Heat Resistance: The reduced carbon content in 309S enhances its resistance to sensitization and intergranular corrosion when exposed to high temperatures, especially during welding or heating processes. This makes 309S stainless steel pipes a preferred choice for applications in elevated temperature environments.

Weldability: Due to its lower carbon content, Seamless 309S stainless steel pipes generally exhibit better weldability and resistance to sensitization during welding, ensuring long-term performance in high-temperature applications.

Applications: Both 309S and 309 stainless steel pipes find use in similar applications requiring heat and corrosion resistance, such as furnaces, burners, kilns, and other high-temperature industrial processes. However, 309S is often favored when exceptionally high-temperature resistance and weldability are critical, while 309 may be chosen for applications where sensitization is less of a concern.

In summary, the primary difference lies in the carbon content, which impacts sensitization and intergranular corrosion resistance at high temperatures. Seamless 309S stainless steel pipes are typically preferred for their enhanced performance in high-temperature environments, making them a valuable choice for various industrial applications. These pipes adhere to the standards provided by stainless steel pipe suppliers.

Selecting the appropriate specifications for Seamless 309S stainless steel pipes depends on the specific requirements of your application. Here are key factors to consider when choosing the right specifications, in accordance with standards provided by Huaxiao stainless steel pipe suppliers:

Pipe Dimensions: Consider the required outer diameter (OD) and wall thickness (WT) based on the flow rate, pressure, and space constraints of your application.

Material Grade: Ensure that the selected grade is Seamless 309S stainless steel, as it offers superior high-temperature performance.

Length: Determine the required pipe length based on the layout and installation requirements of your project.

Corrosion Resistance: Confirm that the chosen specifications meet the corrosion resistance requirements for your specific environment and the substances the pipe will transport.

Temperature and Pressure: Evaluate the operating temperature and pressure conditions to ensure the selected specifications can handle the intended service conditions.

End Connections: Consider the type of end connections required, whether it’s plain ends, threaded, or flanged, to ensure compatibility with your system.

Standards and Certifications: Verify that the Seamless 309S stainless steel pipes conform to industry standards and certifications for quality and performance, such as ASTM, ASME, or EN standards.

Quantity: Determine the quantity of pipes required for your project or application.

Budget: Keep your budget in mind when selecting specifications, as different dimensions and grades may have varying costs.

Supplier Expertise: Collaborate with a trusted stainless steel pipe supplier like Huaxiao, who can provide guidance and support in choosing the right specifications for your unique requirements.

By carefully assessing these factors and working closely with Huaxiao stainless steel pipe suppliers, you can select the most suitable Seamless 309S stainless steel pipe specifications to ensure optimal performance and longevity in your application.

The manufacturing process for Seamless 309S stainless steel pipes typically involves the following steps, with guidance from Huaxiao stainless steel pipe suppliers:

Raw Material Selection: High-quality stainless steel coils or sheets are selected, with a composition that meets the specifications for 309S stainless steel.

Cutting: The selected material is cut into suitable lengths to begin the manufacturing process.

Forming: The cut stainless steel pieces are then shaped into pipes using various methods, including hot or cold rolling, extrusion, or drawing.

Welding (if applicable): For welded pipes, the edges are prepared and welded together using TIG (Tungsten Inert Gas) or other welding techniques to create a continuous pipe.

Heat Treatment: The pipes are subjected to heat treatment processes such as annealing to relieve stresses and improve mechanical properties.

Cold Working (if necessary): Pipes may undergo cold working processes like cold drawing or cold rolling to achieve the desired dimensions and surface finish.

Cutting to Length: The pipes are cut to the required lengths based on customer specifications.

Inspection: Rigorous quality control and inspection processes are carried out to ensure the pipes meet industry standards and customer requirements.

Surface Finish: The pipes may undergo surface treatment processes like pickling, passivation, or polishing to enhance corrosion resistance and appearance.

Packaging: The finished Seamless 309S stainless steel pipes are carefully packaged to protect them during transportation and storage.

Delivery: The pipes are then shipped to customers or distributors.

Huaxiao stainless steel pipe suppliers adhere to strict quality control measures throughout the manufacturing process to deliver high-quality Seamless 309S stainless steel pipes that meet international standards and customer expectations.

Maintaining and cleaning Seamless 309S stainless steel pipes is essential to preserve their appearance and performance. Here are some general guidelines, with insights from stainless steel pipe suppliers like Huaxiao:

Regular Cleaning: Clean the pipes regularly using a mild detergent, warm water, and a soft cloth or sponge. Avoid abrasive materials that could scratch the surface.

Direction of Cleaning: When cleaning, rub or wipe in the direction of the stainless steel grain to maintain its finish.

Rinse Thoroughly: After cleaning, rinse the pipes thoroughly with clean water to remove any residue from the detergent.

Avoid Harsh Chemicals: Avoid using abrasive cleaners, strong acids, or chlorine-based cleaners, as they can damage the stainless steel surface.

Stain Removal: For stubborn stains, a mixture of baking soda and water or vinegar can be used. Apply gently and rinse thoroughly.

Avoid Scratches: Take care to prevent scratches, as they can diminish the appearance of the pipes. Avoid contact with sharp or abrasive objects.

Passivation: In some cases, it may be beneficial to passivate the stainless steel pipes to enhance corrosion resistance. Consult stainless steel pipe suppliers for guidance on this process.

Routine Inspection: Periodically inspect the pipes for signs of corrosion or damage. Address any issues promptly to prevent further deterioration.

Protective Coatings: Consider applying a protective coating or wax designed for stainless steel surfaces to maintain their shine and minimize fingerprints.

Proper Storage: If storing pipes for an extended period, keep them in a clean, dry, and well-ventilated area, preferably indoors, to prevent environmental exposure.

Following these maintenance and cleaning guidelines, as recommended by stainless steel pipe suppliers like Huaxiao, will help keep your Seamless 309S stainless steel pipes in excellent condition and extend their service life.

Compared to other stainless steel pipes, the price of Seamless 309S stainless steel pipes can vary depending on several factors, including the pipe’s dimensions, specifications, quantity, and market conditions. Huaxiao stainless steel pipe suppliers can provide specific pricing information based on your requirements and current market rates. Generally, 309S stainless steel pipes are known for their exceptional corrosion resistance and high-temperature performance, making them suitable for demanding applications. While they may be priced slightly higher than some other stainless steel grades, their unique properties often justify the investment, especially in environments where corrosion resistance and heat resistance are critical. To get accurate pricing details and quotes for Seamless 309S stainless steel pipes, it’s advisable to contact Huaxiao stainless steel pipe suppliers directly, as prices can fluctuate over time.

Seamless 309S stainless steel pipes are known for their sustainability and recyclability. Stainless steel, in general, is a highly sustainable material due to its durability, long lifespan, and recyclability.

Durability: 309S stainless steel is incredibly durable and can withstand harsh environmental conditions, which extends its service life and reduces the need for frequent replacements.

Recyclability: Stainless steel is one of the most recycled materials globally. When these pipes reach the end of their life cycle, they can be recycled and used to produce new stainless steel products, minimizing waste and conserving resources.

Low Environmental Impact: The production of stainless steel has a relatively low environmental impact compared to some other materials, making it an eco-friendly choice.

Stainless steel pipe suppliers, like Huaxiao, often prioritize sustainability by adhering to responsible production practices and recycling efforts. This makes Seamless 309S stainless steel pipes an environmentally conscious choice for various applications.

Certainly, here are some common considerations and precautions when using Seamless 309S stainless steel pipes:

Temperature Limits: While 309S stainless steel is heat-resistant, it’s important to stay within its specified temperature range to avoid compromising its performance.

Corrosive Environments: Even though it’s corrosion-resistant, exposure to highly corrosive chemicals or environments should be minimized.

Proper Installation: Ensure pipes are installed correctly, with proper support and alignment, to prevent stress and potential leaks.

Regular Inspections: Periodic inspections can help identify any signs of corrosion, wear, or damage early, allowing for timely maintenance.

Cleaning: Keep the pipes clean and free from contaminants that could potentially corrode or degrade the material.

Compatible Fittings: Use fittings and components that are compatible with 309S stainless steel to prevent galvanic corrosion.

Welding Procedures: If welding is required, use suitable welding techniques and materials to maintain the integrity of the pipe.

Avoiding Abrasive Materials: Be cautious when transporting abrasive materials through the pipes, as this can cause wear over time.

Pressure Ratings: Ensure that the pressure ratings of the pipes are not exceeded to prevent ruptures or leaks.

Consult Suppliers: When in doubt or facing specific challenges, consult stainless steel pipe suppliers like Huaxiao for guidance on proper use and maintenance.

By following these guidelines and working with reputable suppliers, users can maximize the longevity and performance of Seamless 309S stainless steel pipes.

other products

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China