Do you have any questions about our products or are you looking for a professional seamless 310 stainless steel pipes supplier?

Seamless 310 Stainless Steel Pipe Suppliers

Specification: ASTM A312 TP310 Seamless, SA 213 TP310 Seamless pipe, AMS 5572, SS 310S / 310H Pipe & Tubing Seamless, ASTM 310 /310S Seamless Pipe

Size Range: From 4mm4mm to 800mm800mm

Wall Thickness Range: From 1mm to 150mm (SCH10-XXS)

Length Options: 4000mm, 5800mm, 6000mm, 12000mm, or as required.

Finish: 2B, BA,4K,8K, NO.1,2D,3#, HL

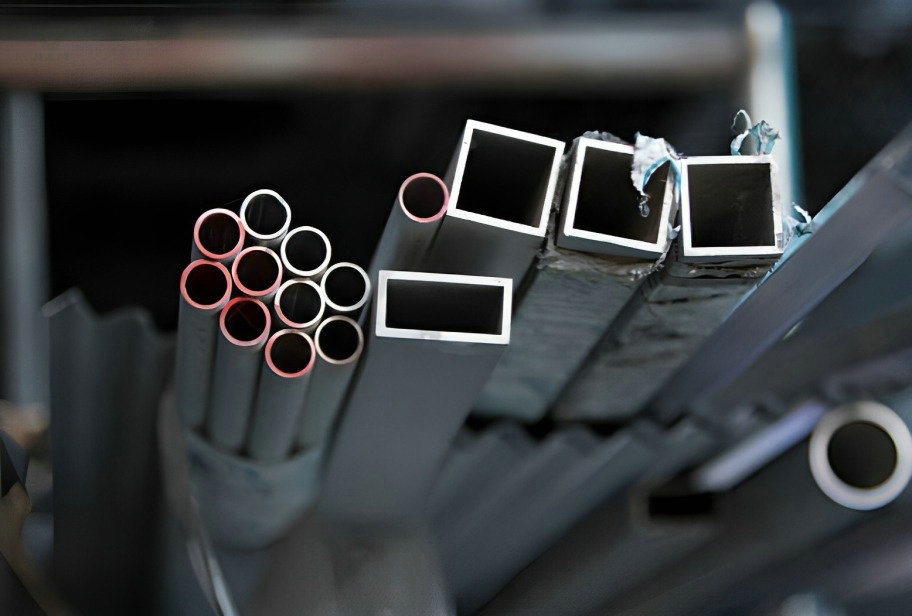

Type: Round, square, rectangular, hexagonal, flat, angle

Technique: Cold rolled, hot rolled

Certification: ISO9001:2015

MOQ: 2MT

Payment method: T/T, LC

Price: Inquiry Factory Price Now

Seamless 310 Stainless Steel Pipe Data Sheet

Chemical Composition Of Seamless 310 Stainless Steel Pipe

| Element | Percentage (%) |

|---|---|

| Chromium (Cr) | 24-26 |

| Nickel (Ni) | 19-22 |

| Carbon (C) | ≤ 0.25 |

| Manganese (Mn) | ≤ 2.00 |

| Silicon (Si) | ≤ 1.50 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.030 |

physical property Of Seamless 310 Stainless Steel Pipe

| Property | Value |

|---|---|

| Density | 7.95 g/cm³ |

| Melting Point | 1402 – 1440°C |

| Specific Heat Capacity | 0.50 J/g°C |

| Thermal Conductivity | 15.6 W/(m·K) |

| Electrical Resistivity | 0.96 × 10⁻⁶ Ω·m |

mechanical property Of 310 Stainless Steel Seamless Pipe

| Property | Value |

|---|---|

| Tensile Strength | 515 MPa (at 20°C) |

| Yield Strength | 205 MPa (at 20°C) |

| Elongation at Break | 40% (in 50mm) |

| Hardness (Brinell) | 217 (in the annealed condition) |

| Modulus of Elasticity | 200 GPa |

Product Description Of Seamless 310 Stainless Steel Pipe

The Seamless 310 Stainless Steel Pipe is a versatile and reliable choice for a wide range of applications. Composed of high-chromium and high-nickel stainless acid-resistant steel, it offers exceptional corrosion resistance, making it suitable for handling aggressive substances. Whether in acidic or alkaline environments, this pipe maintains stability. Its remarkable performance extends to high temperatures, with the ability to endure repeated heating below 980°C. Furthermore, its mechanical properties include high strength, excellent tensile strength, bending resistance, and impact toughness. The ease of cold or hot working makes it a practical choice for various processes. Known for its strength and durability, these pipes are resistant to corrosion, impact, and abrasion, ensuring a long service life. The innovative snap connection system allows for thinner-walled pipes, conserving resources while delivering efficient flow conditions. Widely employed in higher-temperature applications, it excels in heat resistance, oxidation resistance, and carburization resistance, making it ideal for demanding industries.

characteristics Of Seamless 310 Stainless Steel Pipe

The composition of the Seamless 310 Stainless Steel Pipe is a crucial aspect of its exceptional performance. It is crafted from stainless acid-resistant steel with a high chromium and nickel content. This specific alloy adheres to the stringent national standard GB-T, with a digital grade designation of S30920, also known as the new grade 16Cr23Ni13 or the old grade 2Cr23Ni13.

The high chromium and nickel content in this composition is fundamental to its outstanding corrosion resistance and ability to withstand extreme environmental conditions. These elements form a robust protective barrier, making the pipe highly resistant to the corrosive effects of acids, alkalis, and various other substances. Moreover, its compliance with national standards ensures consistent quality and reliability in demanding applications. This composition sets Seamless 310 Stainless Steel Pipe apart as an ideal choice for industries requiring superior resistance to erosion and high-temperature performance.

The Seamless 310 Stainless Steel Pipe exhibits exceptional corrosion resistance, a critical characteristic for its various applications. Its impressive resistance extends to a wide range of corrosive substances, including acids and alkalis. This resistance makes it a highly durable and reliable choice in industries where exposure to such corrosive materials is common.

Notably, this stainless steel pipe goes beyond mere resistance; it also maintains stability even in both acidic and alkaline environments. This dual resistance to acidic and alkaline conditions enhances its versatility and makes it a valuable asset in applications where stability under diverse chemical exposures is crucial. In summary, the Seamless 310 Stainless Steel Pipe’s exceptional corrosion resistance and ability to maintain stability in different chemical environments ensure its suitability for a wide array of demanding applications.

The High-Temperature Performance of the Seamless 310 Stainless Steel Pipe is a vital attribute, particularly in applications where exposure to elevated temperatures is common. This characteristic encompasses several key aspects:

Low-Temperature Performance: The pipe demonstrates excellent performance even at low temperatures. This quality is essential for applications in various industries where temperature fluctuations can be substantial.

Strength, Plasticity, Toughness, and Cold Formability: In addition to its high-temperature resistance, the pipe exhibits good strength, plasticity, and toughness. This means it can withstand mechanical stress and deformation, making it a reliable choice for demanding conditions. Its cold formability allows for various shaping and fabrication processes.

Repeatability of Heating: One of the most impressive aspects is its ability to withstand repeated heating below 980°C. This quality ensures that the pipe can maintain its structural integrity and performance even in high-temperature environments. It is an invaluable characteristic in applications that involve frequent heating and cooling cycles.

In summary, the High-Temperature Performance of the Seamless 310 Stainless Steel Pipe makes it suitable for industries and applications where exposure to elevated temperatures and varying temperature conditions is a critical requirement. Its strength, plasticity, and ability to withstand repeated heating further enhance its value in these demanding environments.

The Mechanical Qualities of the Seamless 310 Stainless Steel Pipe encompass several crucial attributes that contribute to its exceptional performance in demanding applications:

Endurance Under High Pressure and Heavy Loads: This stainless steel pipe is engineered to endure high-pressure conditions and heavy mechanical loads. It can withstand the forces exerted by pressurized fluids and the weight of various structures, making it a reliable choice for applications where structural integrity is paramount.

Good Tensile Strength: Tensile strength refers to the material’s ability to resist a force attempting to stretch or pull it apart. The 310 stainless steel pipe possesses excellent tensile strength, which is crucial for applications that involve tension and stretching forces.

Bending Resistance: Bending resistance is essential for applications that require the pipe to conform to specific shapes or angles. This characteristic ensures that the pipe maintains its structural integrity during bending without deformation.

Impact Toughness: Impact toughness reflects the material’s ability to absorb energy and resist fracture upon sudden impact. The 310 stainless steel pipe demonstrates good impact toughness, which is particularly important in applications where it may be subjected to unexpected mechanical shocks.

In summary, the Mechanical Qualities of the Seamless 310 Stainless Steel Pipe make it a robust and reliable choice for various applications. Its ability to endure high pressure, exhibit excellent tensile strength, resist bending, and withstand impacts positions it as a valuable material for industries where structural integrity and performance are critical.

Processability is a critical characteristic of the Seamless 310 Stainless Steel Pipe that contributes to its versatility and usability in various applications:

Cold Working: This stainless steel pipe is amenable to cold working processes. Cold working involves shaping and forming the material at or near room temperature, making it a suitable choice for applications requiring precise dimensional accuracy and intricate designs. The pipe can be bent, rolled, and shaped to meet specific requirements without compromising its structural integrity.

Hot Working: The 310 stainless steel pipe is also conducive to hot working methods. Hot working involves processing the material at elevated temperatures, allowing for more extensive deformation and shaping. This characteristic enables the pipe to be forged, extruded, or otherwise manipulated at higher temperatures, offering flexibility in manufacturing processes.

Forming: The pipe’s processability extends to forming operations, such as bending and rolling. These methods are essential for adapting the pipe to complex geometries and configurations, ensuring it can seamlessly integrate into a wide range of applications.

Welding: Weldability is another notable aspect of the pipe’s processability. It can be easily welded using various techniques, facilitating the assembly of complex structures and systems. This welding capability is especially valuable for applications where multiple sections of pipe need to be joined securely.

Machining: Machining is the final dimension of processability, allowing the stainless steel pipe to be accurately cut, drilled, and shaped to meet precise specifications. This feature ensures that the pipe can be tailored to the specific needs of various industries.

In summary, the Seamless 310 Stainless Steel Pipe’s exceptional processability empowers manufacturers and engineers to employ a wide range of working methods, from cold and hot forming to welding and machining. This adaptability makes it a preferred material for applications demanding precision and customization.

The Strength and Longevity of the Seamless 310 Stainless Steel Pipe are fundamental attributes that underpin its reliability and durability in demanding applications:

Corrosion Resistance: This stainless steel pipe exhibits exceptional resistance to corrosion, making it suitable for use in environments exposed to aggressive substances, such as acids and alkalis. Its ability to withstand chemical attack safeguards against premature degradation and maintains structural integrity over time.

Impact Resistance: The pipe’s robustness against impact is a key feature, ensuring it can endure physical stresses and external forces without compromising its performance. This resistance to impact is vital in applications where the pipe may be subjected to mechanical loads and potential collisions.

Abrasion Resistance: The 310 stainless steel pipe is adept at resisting abrasion, which is crucial for applications involving the flow of abrasive materials or particles. Its durability against wear and tear minimizes the risk of surface damage and maintains the pipe’s longevity.

Stress Tolerance: This stainless steel pipe is designed to withstand stress and pressure, enabling its use in high-pressure systems and applications. Its ability to endure mechanical stress without deformation or failure ensures the integrity of the overall system.

Long Service Life: The seamless 310 stainless steel pipe’s resistance to corrosion, impact, and stress contributes to its extended service life. It remains structurally sound and maintains its functionality over many years, reducing the need for frequent replacements and maintenance.

In summary, the Seamless 310 Stainless Steel Pipe’s combination of corrosion resistance, impact resistance, abrasion resistance, and stress tolerance ensures its long-term performance and service life. These characteristics are crucial for applications where durability and reliability are paramount.

The Efficiency in Pipe Usage feature of the Seamless 310 Stainless Steel Pipe is a significant advantage, driven by innovative design principles:

Snap Connections: The absence of traditional threads in the pipe’s design streamlines installation and maintenance processes. Snap connections offer a secure and efficient way to join sections of the pipe, reducing the time and labor required for assembly and disassembly.

Thin-Walled Pipes: The elimination of threading allows for the use of thin-walled pipes without compromising structural integrity. Thin-walled pipes are lighter and more cost-effective, making them an eco-friendly choice and minimizing material usage.

Inner Diameter Expansion: Simultaneously, snap connections expand the pipe’s inner diameter while maintaining the same nominal diameter. This expansion optimizes flow conditions within the pipe, enhancing fluid conveyance efficiency. It reduces pressure drops and improves the overall performance of the pipeline system.

In summary, the Seamless 310 Stainless Steel Pipe’s efficiency in pipe usage combines the benefits of snap connections, thin-walled pipe utilization, and inner diameter expansion. These features contribute to cost savings, reduced environmental impact, and improved fluid flow, making it a practical choice for a wide range of industrial applications.

application Of Seamless 310 Stainless Steel Pipe

Chemical Processing, Petrochemical, and Offshore Industries

In the Chemical Processing, Petrochemical, and Offshore Industries, the 310 Stainless Steel Seamless Pipe plays a pivotal role. Its outstanding corrosion resistance, particularly in hostile environments, is of paramount importance in these sectors. This exceptional resistance extends to guarding against oxidation, scaling, and corrosion induced by a range of aggressive substances such as acids, alkalis, and industrial gases. As a result, it stands as an indispensable component in chemical processing, petrochemical operations, and offshore applications. Whether countering the corrosive effects of acids or withstanding the rigors of offshore environments, the 310 Stainless Steel Pipe's unwavering performance ensures optimal productivity and longevity in these demanding industrial settings.

Oil Refineries, Power Generation Plants, Food Processing Facilities

310 stainless steel seamless pipes are a cornerstone in the operations of Oil Refineries, where the demand for robust, high-temperature-resistant materials is paramount. In the extreme conditions of power generation plants, they play a vital role, ensuring efficient and long-lasting performance. Additionally, their presence is felt in food processing facilities, where the need to meet stringent standards for hygiene and durability makes them an ideal choice. The capability to withstand extreme temperatures and harsh chemical conditions is a testament to their reliability and resilience in these demanding industrial environments.

Petrochemical Processing, Power Generation, Heat Exchangers, and Boilers

In Petrochemical Processing, these pipes are indispensable. Their exceptional resistance to high temperatures, corrosion, and oxidation, thanks to their significant chromium and nickel content, is a hallmark feature. They find extensive use in the power generation sector, ensuring efficient operations in the face of extreme conditions. These pipes are also the materials of choice for critical equipment such as heat exchangers and boilers, where their remarkable resistance to high-temperature corrosion and oxidation significantly enhances their suitability. Seamless 310 Stainless Steel Pipes exemplify the perfect combination of strength and durability, making them invaluable in these challenging industrial applications.

FAQ

Seamless 310 stainless steel pipes are manufactured using a specialized process. Stainless steel suppliers begin by melting the raw materials, including iron ore, chromium, and nickel, in an electric arc furnace. The molten metal is then refined to achieve the desired composition and cleanliness. Next, it’s continuously cast into large-diameter billets. These billets are then heated and pierced to create hollow shells. Following this, the shells are elongated and reduced in diameter through a series of hot rolling processes. The resulting seamless pipe is then cold-drawn and heat-treated to achieve the required mechanical properties and dimensions. Stainless steel suppliers play a crucial role in sourcing and processing the high-quality stainless steel used in this manufacturing process.

Yes, 310 stainless steel is generally considered food-grade and safe for the food industry. Its composition, which includes high chromium and nickel content, makes it resistant to corrosion and staining. However, it’s essential to ensure that the specific 310 stainless steel used meets the relevant food-grade standards and regulations. Stainless steel pipe suppliers can provide certified materials suitable for food processing and handling applications. It’s advisable to consult with suppliers to verify that the stainless steel products conform to the required food safety standards to guarantee the safety of food products and processes.

Yes, 310 stainless steel seamless pipes are generally weldable and machinable. These pipes are designed for ease of fabrication, making them suitable for welding processes such as TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and other common welding techniques. Machining processes, including cutting, drilling, and threading, can also be applied to these pipes to meet specific industrial needs. Stainless steel pipe suppliers can provide guidance on the best welding practices and machining techniques for seamless 310 stainless steel pipes to ensure optimal results in various applications.

Seamless 310 stainless steel pipes and 304 stainless steel pipes have some key differences:

Composition: 310 stainless steel contains more chromium (24-26%) and nickel (19-22%) compared to 304 stainless steel (18-20% chromium and 8-10.5% nickel). This higher chromium and nickel content in 310 stainless steel enhances its high-temperature performance and corrosion resistance.

High-Temperature Resistance: 310 stainless steel is specifically designed for high-temperature applications and can withstand repeated heating below 980°C. In contrast, 304 stainless steel has lower resistance to high temperatures.

Corrosion Resistance: Both 310 and 304 stainless steel offer excellent corrosion resistance, but 310 stainless steel excels in aggressive environments due to its higher alloy content. It is highly resistant to oxidation, scaling, and corrosion caused by acids, alkalis, and industrial gases.

Applications: 310 stainless steel is typically chosen for applications requiring superior heat resistance, such as in furnaces, heat treatment equipment, and high-temperature industrial settings. On the other hand, 304 stainless steel is more versatile and widely used in various industries, including food processing, chemical processing, and construction.

Stainless steel pipe suppliers can provide guidance on selecting the most suitable stainless steel pipe based on specific application requirements and environmental conditions.

Seamless 310 stainless steel pipes and 309 stainless steel pipes share similarities but also have key differences:

Composition: Both 310 and 309 stainless steel contain high chromium and nickel content, but 310 stainless steel typically has a slightly higher chromium content (24-26%) compared to 309 stainless steel (22-24%). This higher chromium content enhances the high-temperature resistance of 310 stainless steel.

High-Temperature Performance: 310 stainless steel is specifically designed for high-temperature applications and can withstand repeated heating below 980°C. While 309 stainless steel also offers good high-temperature performance, it may not be as heat-resistant as 310 stainless steel.

Corrosion Resistance: Both 310 and 309 stainless steel provide excellent corrosion resistance in various environments. However, 310 stainless steel may exhibit better resistance to oxidation and scaling, especially in aggressive settings with exposure to acids, alkalis, and industrial gases.

Applications: 310 stainless steel is typically chosen for applications requiring superior heat resistance, such as in furnaces, heat treatment equipment, and high-temperature industrial settings. 309 stainless steel is well-suited for applications where high-temperature corrosion resistance is required but may not need the extreme heat resistance of 310 stainless steel.

Stainless steel pipe suppliers can offer guidance on selecting the most appropriate stainless steel pipe based on specific application needs, ensuring optimal performance and durability.

Seamless 310 stainless steel pipes and 316 stainless steel pipes are distinct in their compositions and applications:

Composition:

- 310 Stainless Steel: Contains about 25% chromium and 20% nickel, with added elements like manganese and silicon. It’s specifically designed for high-temperature applications.

- 316 Stainless Steel: Comprises about 16-18% chromium, 10-14% nickel, and molybdenum. This composition offers excellent corrosion resistance, especially in chloride-rich environments.

Corrosion Resistance:

- 310 Stainless Steel: While it provides good corrosion resistance, its primary strength lies in its high-temperature resistance and oxidation resistance.

- 316 Stainless Steel: Known for its superior corrosion resistance, making it suitable for a wide range of applications, including those involving exposure to saltwater and chemicals.

High-Temperature Performance:

- 310 Stainless Steel: Engineered for extreme heat and can withstand repeated heating below 980°C.

- 316 Stainless Steel: Not as heat-resistant as 310 steel but excels in standard and high-temperature applications where corrosion resistance is crucial.

Applications:

- 310 Stainless Steel: Mainly used in applications demanding exceptional heat resistance, such as furnace parts, heat treatment equipment, and high-temperature industrial processes.

- 316 Stainless Steel: Widely used in industries like marine, chemical processing, food and beverage, and pharmaceuticals, where corrosion resistance is a top priority.

Stainless steel pipe suppliers can assist in choosing the right stainless steel pipe based on your specific needs and application requirements. Both 310 and 316 stainless steel pipes have their unique strengths, and the choice depends on the intended use.

other seamless stainless steel pipe products

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WeChat: +86 13381673250

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China