Seamless 316H Stainless Steel Pipe Suppliers

- Size Range: From 4mm4mm to 800mm800mm

- Wall Thickness Range: From 1mm to 150mm (SCH10-XXS)

- Length Options: 4000mm, 5800mm, 6000mm, 12000mm, or as required.

- Finish: 2B, BA,4K,8K, NO.1,2D,3#, HL

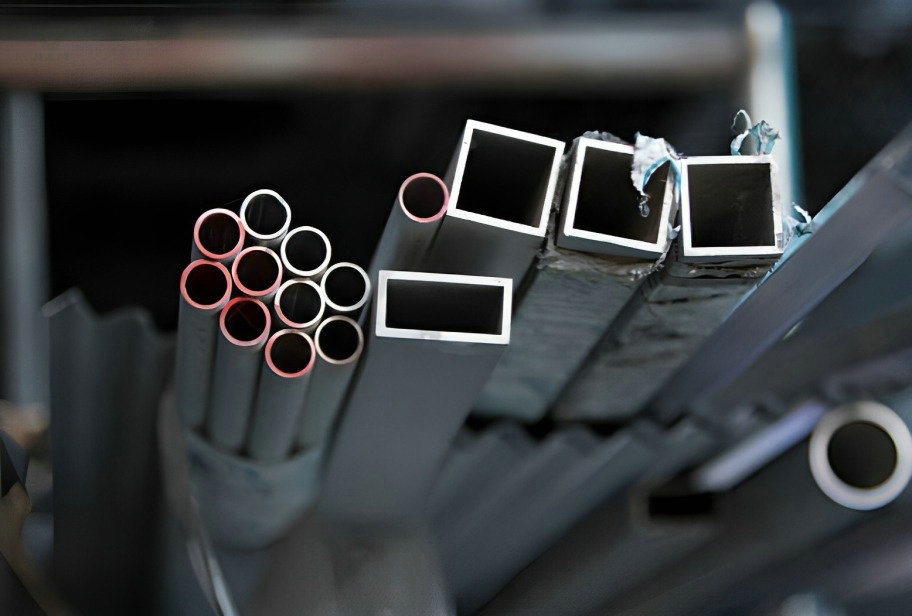

- Type: Round, square, rectangular, hexagonal, flat, angle

- Technique: Cold rolled, hot rolled

Product Description Of Seamless 316H Stainless Steel Pipe

Seamless 316H Stainless Steel Pipe is engineered from a specialized austenitic stainless steel alloy. With its composition of 16-18% chromium, 10-14% nickel, 2-3% molybdenum, and a maximum of 0.08% carbon, this pipe exhibits remarkable resistance to general corrosion, pitting, and crevice corrosion. Outperforming conventional chromium-nickel austenitic stainless steels like 304, it excels in challenging environments. Moreover, it boasts superior properties, including increased creep, stress-to-rupture, and tensile strength, especially at elevated temperatures. This makes Seamless 316H Stainless Steel Pipe an exceptional choice for applications demanding exceptional corrosion resistance and robust performance under varying conditions.

Product Description Of Seamless 316H Stainless Steel Pipe

Chemical Components Of Seamless 316H Stainless Steel Pipe

| Standard | C, ≤ | Si, ≤ | Mn, ≤ | P, ≤ | S, ≤ | Cr | Ni | Mo |

|---|---|---|---|---|---|---|---|---|

| ASTM A276/A276M | 0.04-0.10 | 1.00 | 2.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

physical property Of Seamless 316H Stainless Steel Pipe

| Property | Value (Metric) | Value (Imperial) | Standard |

|---|---|---|---|

| Density | 8.00 g/cm³ | 0.289 lb/in³ | ASTM A240, ASME SA240 |

| Melting Point | 1375-1400°C | 2507-2552°F | ASTM A240, ASME SA240 |

| Thermal Conductivity | 16.3 W/(m·K) | 113 BTU/(hr·ft·°F) | ASTM A240, ASME SA240 |

| Specific Heat Capacity | 0.5 J/g·K | 0.12 BTU/lb·°F | ASTM A240, ASME SA240 |

| Electrical Resistivity | 0.74 μΩ·m | 29.1 μΩ·in | ASTM A240, ASME SA240 |

| Modulus of Elasticity | 193 GPa | 28 x 10^6 psi | ASTM A240, ASME SA240 |

mechanical property Of Seamless 316H Stainless Steel Pipe

| Property | Value (Metric) | Value (Imperial) | Standard |

|---|---|---|---|

| Tensile Strength | 515-690 MPa | 74.7-100 ksi | ASTM A312, ASME SA312 |

| Yield Strength (0.2%) | ≥205 MPa | ≥29.7 ksi | ASTM A312, ASME SA312 |

| Elongation | ≥40% | ≥40% | ASTM A312, ASME SA312 |

| Hardness (Brinell) | ≤217 HB | ≤217 HB | ASTM A312, ASME SA312 |

| Hardness (Rockwell B) | ≤95 HRB | ≤95 HRB | ASTM A312, ASME SA312 |

| Impact Strength (Charpy) | N/A | N/A | ASTM A312, ASME SA312 |

characteristics Of Seamless 316H Stainless Steel Pipe

“Superior Corrosion Resistance” in Seamless 316H Stainless Steel Pipe refers to its exceptional ability to withstand various forms of corrosion. This stainless steel pipe’s unique alloy composition, including a high percentage of chromium and molybdenum, provides an effective barrier against corrosion. It exhibits remarkable resistance to general corrosion, which includes the gradual deterioration of the material when exposed to aggressive environments. Additionally, it excels in resisting pitting corrosion, which involves the formation of localized holes or pits on the surface. Its resistance to crevice corrosion, which occurs in tight, confined spaces, further emphasizes its durability. This superior corrosion resistance ensures the longevity and reliability of the pipe in challenging and corrosive applications, making it an excellent choice for critical industries and environments.

“High-Temperature Performance” in Seamless 316H Stainless Steel Pipe signifies its exceptional capability to maintain structural integrity and strength when exposed to elevated temperatures. This stainless steel pipe’s composition, which includes higher levels of chromium and molybdenum, ensures its resistance to thermal degradation. It can withstand high temperatures without significant deformation or loss of mechanical properties, making it a reliable choice for applications where exposure to heat is a constant factor. Whether in industrial processes, power generation, or other high-temperature environments, Seamless 316H Stainless Steel Pipe excels, providing longevity and dependability under extreme heat conditions.

“Creep Strength” refers to the ability of a material, in this context, Seamless 316H Stainless Steel Pipe, to resist deformation and maintain its structural integrity when subjected to prolonged exposure to high temperatures and constant stress.

In high-temperature applications, materials may experience a slow, time-dependent deformation phenomenon known as “creep.” This deformation occurs over an extended period and can compromise the material’s mechanical properties if not adequately resistant to it.

Seamless 316H Stainless Steel Pipe exhibits excellent creep strength, meaning it can withstand and maintain its shape under elevated temperatures without excessive deformation. This property is crucial in industries such as power generation, where components like pipes and tubes must endure prolonged exposure to high temperatures while maintaining their structural reliability and safety.

“Resistance to Stress Corrosion Cracking” in the context of Seamless 316H Stainless Steel Pipe refers to its ability to withstand a specific form of corrosion-related failure known as stress corrosion cracking (SCC).

Stress corrosion cracking is a type of corrosion that occurs when a material is exposed to a corrosive environment while simultaneously experiencing tensile stress. This stress can be caused by various factors, such as mechanical loads or temperature fluctuations. SCC is a particularly insidious form of corrosion because it can lead to sudden and catastrophic failures in materials.

Seamless 316H Stainless Steel Pipe demonstrates a high resistance to stress corrosion cracking. Its unique alloy composition, which includes a significant amount of chromium and molybdenum, forms a protective barrier against the corrosive effects of the environment, even under stress. This resistance ensures the structural integrity and longevity of the pipe, making it a reliable choice for critical applications in corrosive environments where stress is a concern.

“Enhanced Tensile Strength” in the context of Seamless 316H Stainless Steel Pipe highlights its superior ability to withstand tensile forces without undergoing deformation or failure.

Tensile strength is a critical mechanical property that measures a material’s resistance to a force trying to pull it apart. Enhanced tensile strength means that this stainless steel pipe can endure higher levels of tensile stress before experiencing permanent deformation or rupture.

Seamless 316H Stainless Steel Pipe’s composition, including increased chromium and molybdenum content, contributes to this enhanced tensile strength. This characteristic ensures that the pipe can reliably withstand mechanical loads and stresses, making it suitable for applications where strength and structural integrity are paramount, such as in construction, high-pressure systems, and various industrial settings.

application Of Seamless 316H Stainless Steel Pipe

Architectural Construction

Seamless 316H Stainless Steel Pipe finds versatile applications in architectural construction. It serves as a fundamental component in the construction industry due to its unique properties. This stainless steel pipe is commonly used for structural supports, forming the backbone of buildings by creating sturdy columns and beams. Its high tensile strength and corrosion resistance ensure the longevity and structural integrity of architectural projects. Additionally, it's utilized for crafting aesthetic elements like handrails and balustrades, offering not only durability but also an elegant finish to architectural designs.

Household Appliances

Seamless 316H Stainless Steel Pipe is a valuable component in the manufacturing of household appliances. Its corrosion resistance and aesthetic appeal make it an ideal choice for various applications in this industry. It is commonly used in the construction of appliance frames and structural components, ensuring durability and longevity. Additionally, its sleek and modern appearance enhances the overall look of appliances, contributing to their visual appeal. From ovens and refrigerators to dishwashers and range hoods, Seamless 316H Stainless Steel Pipe plays a crucial role in both the structural and aesthetic aspects of household appliance design, meeting the high standards of quality and reliability expected in this sector.

Industrial Artwork

Seamless 316H Stainless Steel Pipe also finds its place in the world of industrial artwork. Artists and craftsmen appreciate its versatile characteristics, including its malleability and aesthetic appeal. The pipe serves as a canvas for creative minds, allowing them to sculpt and shape it into unique and captivating industrial art pieces. Its corrosion resistance ensures the artwork's longevity, even when displayed in outdoor or challenging environments. Whether used in large-scale sculptures or intricate, detailed pieces, Seamless 316H Stainless Steel Pipe provides artists with a robust and visually appealing material to bring their creative visions to life, merging the worlds of art and industry.

Food and Beverage Industry

Seamless 316H Stainless Steel Pipe plays a crucial role in the food and beverage industry, where hygiene and corrosion resistance are paramount. It is extensively used for various applications in this sector, including the construction of piping systems, storage tanks, and equipment components. The stainless steel's inherent resistance to corrosion and ability to withstand the demanding conditions of food processing make it an ideal choice. Its smooth, non-reactive surface ensures product purity and prevents contamination, meeting stringent industry standards. Additionally, it can endure exposure to cleaning agents and high-temperature processes, making it a reliable and long-lasting material for maintaining the integrity and safety of food and beverage production.

Pharmaceutical and Chemical Industry

Seamless 316H Stainless Steel Pipe holds a significant presence in the pharmaceutical and chemical industry, where its unique attributes are indispensable. It is employed extensively for constructing critical components, including pipelines, reactors, and storage vessels. The stainless steel's exceptional corrosion resistance and durability ensure the safe transport and containment of highly reactive and corrosive chemicals, adhering to strict industry regulations. Moreover, its resistance to high temperatures and extreme chemical environments makes it suitable for the rigorous processes involved in pharmaceutical and chemical manufacturing. Seamless 316H Stainless Steel Pipe contributes to the integrity, purity, and safety of these industries, where precision and reliability are paramount.

FAQ

There are some key differences between Seamless 316H Stainless Steel Tubing and 316 Stainless Steel Tubing, mainly in the following areas:

- Carbon Content: 316H tubing has a slightly higher carbon content than 316 tubing. 316H stainless steel typically contains a maximum of 0.08% carbon, while 316 stainless steel has a lower carbon content, typically no more than 0.03%. This difference gives 316H better creep resistance in high temperature environments.

- High Temperature Performance: Due to its slightly higher carbon content, 316H stainless steel performs better in high temperature conditions. It has higher creep strength, stress embrittlement strength and tensile strength, so it is more reliable in high temperature environment.

- Applications: 316H is mainly used in high temperature environments, such as high temperature chemical reactions, high temperature processing and high temperature corrosive environments. While 316 stainless steel is usually used in general corrosion resistant applications, such as food processing and chemical industry.

- Price: As 316H stainless steel is more superior in high temperature performance, it is usually slightly more expensive than 316 stainless steel.

In summary, 316H stainless steel seamless tubing performs better in high temperature environments and is suitable for applications that require higher heat resistance, while 316 stainless steel is more commonly used in general corrosion resistant applications. The choice of material depends on the specific application needs and engineering requirements.

316H stainless steel pipe exhibits excellent performance in high temperature environments, which makes it ideal for many high temperature applications. The following are the performance characteristics of 316H stainless steel pipe in high temperature environments:

- High Creep Strength: 316H stainless steel has excellent creep strength, which means that it is not prone to deformation at high temperatures and high stresses. This makes it suitable for applications that need to withstand high temperatures and high stresses for extended periods of time, such as high temperature reactors and piping systems.

- Stress Corrosion Cracking Resistance: 316H stainless steel has good resistance to Stress Corrosion Cracking (SCC), which is critical in high temperature and corrosive environments.

- High Tensile Strength: At high temperatures, 316H stainless steel maintains high tensile strength, so it can be used in applications that require high tensile loads, such as high-temperature piping and pressure vessels.

- Oxidation Resistance: 316H stainless steel has excellent oxidation resistance to resist oxidation and corrosion at high temperatures, so it is suitable for high temperature atmospheres and chemical environments.

Overall, 316H stainless steel tubing exhibits excellent performance in high-temperature environments and is widely used in refining, chemical, power, food processing and other high-temperature applications. The high temperature resistance of this tubing allows it to operate stably for long periods of time under extreme conditions.

To ensure the quality of Seamless 316H stainless steel pipe, you can consider the following key measures, which include working closely with suppliers such as Huaxiao stainless steel pipe suppliers:

- Choose a reliable supplier: It is critical to work with a reputable and experienced stainless steel pipe supplier. Make sure the supplier has the necessary certifications and quality control systems in place to meet your needs.

- Material certifications: Require suppliers to provide material certifications, including chemical composition, physical properties and dimensions. This helps verify that the pipe meets the required specifications and standards.

- Quality control systems: Ensure that your suppliers have rigorous quality control systems in place, including raw material inspections, manufacturing process monitoring and final product testing. This helps ensure the consistency and quality of the pipe.

- Standards Compliance: Ensure that Seamless 316H Stainless Steel Tubing meets international and industry standards such as ASTM, ASME, etc. This helps ensure product quality and performance. This helps ensure product quality and performance.

- Non-destructive testing: Require suppliers to perform non-destructive testing, such as ultrasonic testing, radiographic testing, etc., to check the internal quality of the tubes.

- Dimensional and Geometric Inspection: Perform dimensional and geometric inspections of tubes to ensure that they meet specifications and requirements.

- Tracking and Recording: Suppliers are required to track and record key parameters of the production process in order to trace and verify the quality of the product.

- Customer feedback: Establish an active line of communication with suppliers to resolve any quality issues or change requests in a timely manner.

By taking these steps, you can ensure that the quality of Seamless 316H stainless steel tubing meets your requirements and meets the demands of high-temperature applications. Working with a reliable supplier is key to achieving this goal.

To select the right size of Seamless 316H stainless steel pipe, you can consider the following factors:

Application requirements: The first step is to determine what application the pipe will be used for. Different applications may require pipes of different diameters, wall thicknesses and lengths.

Operating Environment: Consider the environmental conditions to which the pipe will be subjected, including temperature, pressure and corrosivity. Ensure that the specifications selected meet the requirements of these environments.

Fluid Properties: If the pipe will be used to transport a specific type of fluid, such as an acidic or alkaline solution, it is important to ensure that the pipe material and specifications are suitable for the fluid.

Budget: Consider the project budget to determine available pipe sizes. Prices may vary between pipe sizes.

Standards and regulations: Ensure that the selected specifications comply with applicable international standards and regulations.

Mechanical properties: If the pipe will be subjected to high pressures or temperatures, select a specification with adequate strength and temperature resistance.

Dimensional accuracy: Consider the dimensional accuracy requirements of the pipe, especially if the pipe needs to fit tightly with other components.

Supplier recommendations: Work with stainless steel pipe suppliers to consult them on the best pipe specifications for a particular application.

Huaxiao Stainless Steel pipe suppliers can advise you on Seamless 316H Stainless Steel Tube specifications and customize the product to meet your needs. Speak with your supplier to get a detailed understanding of your project needs to ensure the right specification is selected.

Translated with DeepL

Huaxiao stainless steel pipe suppliers’ production cycle will vary depending on the specific requirements, quantity and complexity of the order. Typically, the production cycle includes the stages of material preparation, manufacturing, quality inspection and delivery.

Typically, producing a batch of Seamless 316H Stainless Steel Tubes can take anywhere from a few weeks to a few months, depending on the supplier’s production capacity and the size of the order. In order to obtain accurate information on production lead times, it is recommended to contact your Huaxiao stainless steel pipe suppliers directly and provide them with your specific order requirements so that they can provide you with a customized production plan and delivery schedule. This will ensure that your project is completed on time and delivered as planned.

Translated with DeepL

In order to maintain and clean Seamless 316H stainless steel pipe, the following are some common recommendations:

- Regular Cleaning: Clean stainless steel pipe with a mild detergent and a soft cloth, then rinse with water and wipe dry. Avoid abrasive or highly chlorinated cleaners that may scratch or corrode the stainless steel surface.

- Avoid Salt and Chemicals: If stainless steel tubes are exposed to environments containing salt or chemicals, clean them promptly to prevent corrosion.

- Gentle cleaning tools: Use a soft brush or sponge to clean the stainless steel tube, avoid using wire brushes or hard brushes to avoid scratching the surface.

- Avoid squeezing and collision: Avoid excessive squeezing pressure or collision on the stainless steel tube to prevent deformation or scratches.

- Prevent buildup: When cleaning stainless steel tubes, pay attention to removing dirt from corners and seams to prevent buildup.

- Regular inspection: Regularly inspect the surface of stainless steel tubes, and if corrosion, scratches, or other damage is found, take timely measures to repair it.

- Use polish: If needed, stainless steel polish can be used to maintain the luster of stainless steel pipe.

Most importantly, develop a maintenance program based on actual use and environment. If there are special cleaning or maintenance needs, it is recommended to consult with Huaxiao stainless steel pipe suppliers who can provide detailed advice on maintenance and cleaning to ensure the long-term performance and appearance of stainless steel tubes.

The price of Seamless 316H Stainless Steel Pipe may vary compared to other stainless steel pipes, as the price is affected by a number of factors, including the pipe’s specification, size, quality grade, market supply and demand, and the supplier’s pricing strategy.

In general, 316H stainless steel pipe is usually relatively expensive due to its high temperature performance and corrosion resistance. Compared to lower cost stainless steel pipe materials, 316H stainless steel pipe may have a higher price.

To obtain accurate pricing information, it is recommended to contact Huaxiao Stainless Steel Pipe suppliers with your specific requirements so that they can provide you with a customized quote. The supplier will consider your requirements and provide relevant pricing information to meet your project budget and requirements.

Seamless 316H Stainless Steel Pipe offers some advantages in terms of sustainability and recyclability:

Corrosion resistance: 316H stainless steel pipe has excellent corrosion resistance and can be used for a long time in harsh environments, reducing the frequency of pipe replacement and helping to reduce resource consumption.

Long life: Due to its high temperature performance and corrosion resistance, 316H stainless steel pipe has a relatively long service life, which reduces the frequency of the need to produce and replace piping, helping to reduce resource waste.

Recyclability: Stainless steel is a recyclable material, waste 316H stainless steel pipe can be recycled, reducing the need for new raw materials, helping to reduce waste and resource waste.

Energy saving: 316H Stainless Steel Pipe has excellent performance in high temperature environments, which can reduce energy consumption and lower energy costs for production and operations.

In summary, Seamless 316H Stainless Steel Tubing has positive characteristics in terms of sustainability and recyclability, helping to reduce resource waste, lower environmental impact and improve the sustainability of piping systems.

The manufacturing process for Seamless 316H Stainless Steel Pipe typically involves the following steps:

- Raw Material Selection: High-quality stainless steel materials, specifically 316H stainless steel, are chosen for production.

- Billet Formation: The selected stainless steel is heated and formed into cylindrical billets.

- Piercing: The billets are pierced to create hollow tubes.

- Hot Rolling: The pierced billets are hot rolled to reduce their diameter and achieve the desired pipe size.

- Annealing: The pipes are subjected to heat treatment (annealing) to relieve stress and improve mechanical properties.

- Cold Working: Cold working processes such as cold drawing or cold rolling may be used to further refine the pipe’s dimensions and surface finish.

- Testing: Rigorous quality testing is performed to ensure the pipe meets industry standards for dimensions, mechanical properties, and corrosion resistance.

- Finishing: The pipes are finished, which may include surface treatments like pickling and passivation to enhance corrosion resistance.

- Cutting and Inspection: The pipes are cut to the required lengths and thoroughly inspected for quality.

- Packaging and Shipping: The finished pipes are packaged and prepared for shipping to customers.

It’s important to note that the manufacturing process may vary slightly depending on the specific requirements of the seamless 316H stainless steel pipes and the practices of the stainless steel pipe supplier.

other products

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China