Seamless 316L Stainless Steel Pipe Suppliers

- Size Range: From 4mm4mm to 800mm800mm

- Wall Thickness Range: From 1mm to 150mm (SCH10-XXS)

- Length Options: 4000mm, 5800mm, 6000mm, 12000mm, or as required.

- Finish: 2B, BA,4K,8K, NO.1,2D,3#, HL

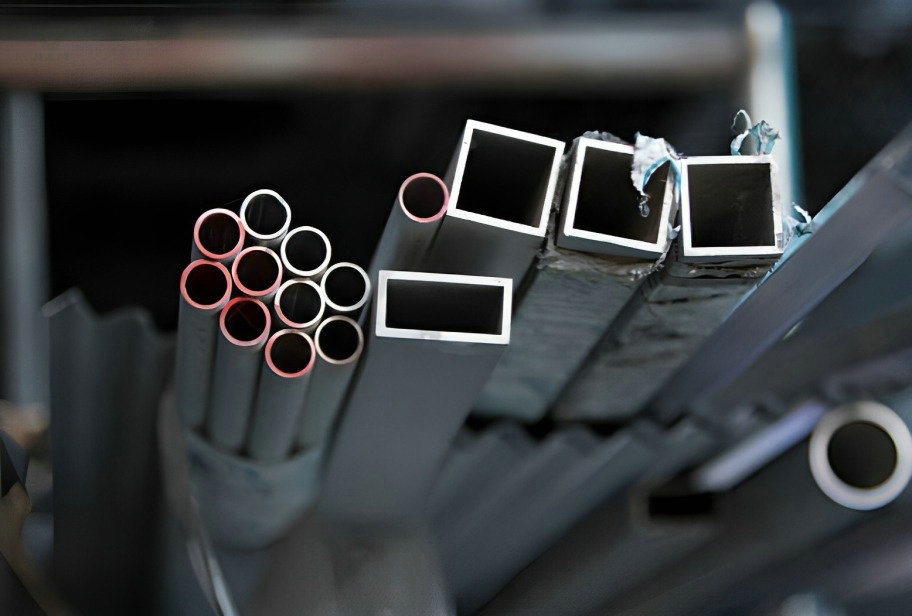

- Type: Round, square, rectangular, hexagonal, flat, angle

- Technique: Cold rolled, hot rolled

Product Description Of Seamless 316L Stainless Steel Pipe

Huaxiao Stainless Steel offers precision with seamless 316L stainless steel pipes, providing superior dimensional accuracy. These pipes exhibit reduced carbide precipitation during welding, minimizing susceptibility to intergranular and localized corrosion. Ranging from ½ inch to 16 inches, they are composed of iron, carbon, chromium, nickel, and molybdenum. Despite similarities in composition between 316 and 316L alloys, subtle differences yield distinct physical properties. The low carbon content of these pipes enhances weldability for various applications. Seamless 316L stainless steel pipes cater to more exacting dimensional requirements. With reduced carbide precipitation during welding, they mitigate intergranular and localized corrosion. Comprising iron, carbon, chromium, nickel, and molybdenum, these elements synergize to create robust and corrosion-resistant stainless steel. Although featuring only two alloy variations (316 and 316L), their minor disparities result in varying physical attributes. The pipes’ low carbon content renders them exceptionally suitable for welding applications. Huaxiao Stainless Steel stands as a reputable supplier, providing quality seamless 316L stainless steel pipes that excel in precision and performance.

specification Of Seamless 316L Stainless Steel Pipe

Chemical Components Of Seamless 316L Stainless Steel Pipe

| Element | ASTM | JIS | EN | GB |

|---|---|---|---|---|

| Chromium | 16.0-18.0% | 16.0-18.0% | 16.5-18.5% | 16.0-18.0% |

| Nickel | 10.0-14.0% | 12.0-15.0% | 10.0-13.0% | 10.0-14.0% |

| Molybdenum | 2.00-3.00% | 2.00-3.00% | 2.00-2.50% | 2.00-3.00% |

| Carbon | ≤0.03% | ≤0.03% | ≤0.03% | ≤0.03% |

| Manganese | ≤2.00% | ≤2.00% | ≤2.00% | ≤2.00% |

| Phosphorous | ≤0.045% | ≤0.045% | ≤0.045% | ≤0.035% |

| Sulfur | ≤0.03% | ≤0.03% | ≤0.015% | ≤0.03% |

| Silicon | ≤1.00% | ≤1.00% | ≤1.00% | ≤1.00% |

physical property Of Seamless 316L Stainless Steel Pipe

| Property | ASTM Standard | JIS Standard | EN Standard | GB Standard |

| Density (g/cm³) | 7.98 | 7.98 | 7.98 | 7.98 |

| Melting Point (℃) | 1399 – 1420 | 1399 – 1420 | 1399 – 1420 | 1399 – 1420 |

| Thermal Conductivity | 16.2 W/m·K | 16.2 W/m·K | 16.2 W/m·K | 16.2 W/m·K |

| Specific Heat Capacity | 500 J/kg·K | 500 J/kg·K | 500 J/kg·K | 500 J/kg·K |

| Electrical Resistivity | 740 Ω·mm²/m | 740 Ω·mm²/m | 740 Ω·mm²/m | 740 Ω·mm²/m |

| Modulus of Elasticity | 193 GPa | 193 GPa | 193 GPa | 193 GPa |

| Poisson’s Ratio | 0.3 | 0.3 | 0.3 | 0.3 |

| Tensile Strength | 485 MPa | 485 MPa | 485 MPa | 485 MPa |

| Yield Strength | 170 MPa | 170 MPa | 170 MPa | 170 MPa |

| Elongation (%) | 40 | 40 | 40 | 40 |

mechanical property Of Seamless 316L Stainless Steel Pipe

| Property | ASTM Standard | JIS Standard | EN Standard | GB Standard |

| Tensile Strength (MPa) | ≥ 485 | ≥ 485 | ≥ 485 | ≥ 485 |

| Yield Strength (MPa) | ≥ 170 | ≥ 170 | ≥ 170 | ≥ 170 |

| Elongation (%) | ≥ 40 | ≥ 40 | ≥ 40 | ≥ 40 |

| Hardness (Brinell) | ≤ 217 | ≤ 217 | ≤ 217 | ≤ 217 |

| Hardness (Rockwell B) | ≤ 95 | ≤ 95 | ≤ 95 | ≤ 95 |

| Impact Toughness (J) | – | – | ≥ 40 | – |

characteristics Of Seamless 316L Stainless Steel Pipe

Enhanced corrosion resistance is a key characteristic of Seamless 316L Stainless Steel Pipe. Thanks to the addition of molybdenum, this type of stainless steel demonstrates exceptional resistance to corrosion from a variety of corrosive agents, including chlorides and acids. This property makes it particularly well-suited for applications in aggressive environments, such as marine, chemical processing, and coastal regions.

The molybdenum content forms a protective barrier on the surface of the steel, preventing the penetration of corrosive elements and minimizing the risk of pitting, crevice corrosion, and stress corrosion cracking. As a result, Seamless 316L Stainless Steel Pipe maintains its structural integrity and aesthetic appearance over extended periods, even when exposed to harsh conditions.

Whether used in pipelines, equipment, or structures subjected to corrosive substances, Seamless 316L Stainless Steel Pipe’s enhanced corrosion resistance ensures longevity, reduced maintenance needs, and cost savings over time.

Reduced carbon precipitation is a significant characteristic of Seamless 316L Stainless Steel Pipe. The low carbon content in this stainless steel grade minimizes the formation of carbide precipitates along grain boundaries during welding or high-temperature exposure. This reduction in carbide precipitation helps to prevent sensitization and the associated susceptibility to intergranular corrosion.

By maintaining the integrity of the microstructure and preventing the formation of chromium-depleted zones, Seamless 316L Stainless Steel Pipe remains highly resistant to corrosion in a wide range of environments. This property is particularly beneficial for applications involving exposure to aggressive media, such as acidic solutions or chloride-containing environments.

The enhanced resistance to intergranular corrosion resulting from reduced carbon precipitation contributes to the longevity and reliability of Seamless 316L Stainless Steel Pipe in various industries, including chemical processing, petrochemical, and marine applications, where corrosion resistance is of utmost importance.

High strength is a notable characteristic of Seamless 316L Stainless Steel Pipe. This stainless steel grade offers excellent mechanical properties, including a higher tensile strength compared to many other austenitic stainless steels. The combination of alloying elements such as chromium, nickel, molybdenum, and a reduced carbon content contributes to the enhanced strength of the material.

The high strength of Seamless 316L Stainless Steel Pipe makes it suitable for applications requiring robust performance under mechanical stress, such as structural components, pressure vessels, and equipment used in various industries. This characteristic ensures the pipe’s ability to withstand challenging conditions while maintaining its integrity and structural integrity over time. Whether used in high-pressure environments, corrosive atmospheres, or demanding mechanical applications, the high strength of this stainless steel grade enhances its suitability for a wide range of industrial and commercial uses.

Excellent weldability is a prominent characteristic of Seamless 316L Stainless Steel Pipe. This stainless steel grade offers exceptional ease and reliability in the welding process, making it a preferred choice for various fabrication and construction applications.

The low carbon content of 316L stainless steel minimizes the risk of sensitization and intergranular corrosion during welding, contributing to the alloy’s enhanced weldability. This property allows for smooth and consistent welding, whether using traditional methods like TIG or MIG welding, or more advanced techniques. The resulting welded joints exhibit strong mechanical integrity and resistance to corrosion.

The excellent weldability of Seamless 316L Stainless Steel Pipe opens up versatile applications in industries such as architecture, marine engineering, food processing, and more. This characteristic ensures that the pipe can be easily incorporated into complex structures and systems while maintaining its corrosion-resistant properties and structural stability.

Superior formability is a standout characteristic of Seamless 316L Stainless Steel Pipe. This grade of stainless steel exhibits exceptional malleability and ductility, allowing it to be easily shaped and formed into various complex geometries without compromising its structural integrity.

The combination of low carbon content and the presence of alloying elements such as chromium and nickel enhances the material’s ability to undergo bending, rolling, and fabrication processes while maintaining its corrosion resistance and mechanical properties. This makes it an ideal choice for applications that require intricate shapes, such as custom fittings, bends, and specialized components.

The superior formability of Seamless 316L Stainless Steel Pipe contributes to its versatility across industries such as automotive, aerospace, architecture, and more. Whether for aesthetic or functional purposes, this characteristic ensures that the pipe can be precisely tailored to meet specific design requirements, offering reliable performance and longevity in various demanding environments.

application Of Seamless 316L Stainless Steel Pipe

- In water treatment, the seamless 316L stainless steel pipe is commonly used for conveying treated water, chemicals, and other fluids. The corrosive nature of certain chemicals and contaminants in water necessitates the use of a material that can withstand such conditions over the long term. The 316L stainless steel's enhanced corrosion resistance ensures that the pipe remains unaffected by the potentially harmful substances present in the treated water.

- In wastewater treatment facilities, where the fluids being transported can be highly corrosive and contain various pollutants, the use of 316L stainless steel pipe is crucial. The pipe's ability to resist the corrosive effects of industrial waste, chemicals, and contaminants ensures the safe and efficient conveyance of wastewater throughout the treatment process. This not only prolongs the lifespan of the infrastructure but also helps in maintaining the overall efficiency of the treatment operations.

- In the petrochemical sector, seamless 316L stainless steel pipe finds extensive use in conveying corrosive chemicals, hydrocarbons, and gases. The pipe's ability to withstand aggressive environments, such as those containing acids, alkalis, and other corrosive substances, is crucial to maintaining the integrity of the infrastructure and ensuring safe operations. The high corrosion resistance of 316L stainless steel prevents material degradation and potential leaks, which can have severe environmental and safety consequences.

- In the chemical industry, where a wide range of corrosive and reactive chemicals are processed and transported, the use of seamless 316L stainless steel pipe is imperative. From transporting raw materials to conveying final products, the pipe's corrosion resistance ensures that it can withstand exposure to chemicals, acids, and bases without compromising its structural integrity. This resilience contributes to the safety of the entire chemical processing operation.

- One of the primary applications of seamless 316L stainless steel pipe in the pharmaceutical sector is for transporting purified water, chemicals, and various fluids used in drug production. The pipe's excellent corrosion resistance ensures that the transported fluids remain uncontaminated and meet stringent purity requirements. This is particularly important in processes where any form of contamination can compromise the quality and efficacy of pharmaceutical products.

FAQ

Seamless 316L stainless steel pipes are manufactured through a process known as seamless tube manufacturing. This involves the following steps:

Material Selection: High-quality 316L stainless steel is selected as the raw material. The composition of 316L stainless steel includes iron, carbon, chromium, nickel, and molybdenum, which contribute to its corrosion resistance and mechanical properties.

Billet Preparation: The selected stainless steel is heated and formed into cylindrical billets. These billets serve as the starting material for the pipe manufacturing process.

Piercing: The billets are then pierced to create a hollow tube. This is done using specialized piercing equipment that creates a hole through the center of the billet.

Hot Rolling: The pierced billet is further elongated and shaped using hot rolling processes. This involves passing the billet through a series of rollers to reduce its diameter and achieve the desired shape.

Heat Treatment: The rolled tube is subjected to heat treatment processes to improve its mechanical properties and remove any residual stresses. This helps enhance the pipe’s strength and durability.

Finishing Processes: The seamless tube undergoes various finishing processes, including straightening, sizing, and cutting, to achieve the desired dimensions and surface quality.

Testing and Inspection: The seamless 316L stainless steel pipes undergo rigorous testing and inspection to ensure they meet industry standards and specifications. This includes dimensional checks, visual inspection, and various mechanical tests.

Final Inspection: The pipes are further examined for surface finish, cleanliness, and overall quality. Any imperfections or defects are addressed before the pipes are ready for shipment.

Packaging and Shipment: The finished seamless 316L stainless steel pipes are carefully packaged to prevent damage during transportation. They are then ready to be shipped to customers, including stainless steel pipe suppliers like Huaxiao.

This manufacturing process results in seamless pipes that have uniform thickness, smooth internal surfaces, and excellent dimensional accuracy. The absence of welding seams ensures enhanced corrosion resistance and structural integrity, making them ideal for various demanding applications.

Please note that the manufacturing process may vary slightly depending on the specific manufacturer and equipment used.

Yes, seamless 316L stainless steel pipes are well-suited for high-temperature environments. Thanks to the alloy’s composition, including elements like chromium, nickel, and molybdenum, these pipes exhibit excellent high-temperature resistance. The presence of these elements contributes to the formation of a stable oxide layer on the surface, which helps protect the pipes from oxidation and corrosion even at elevated temperatures.

Seamless 316L stainless steel pipes are commonly used in applications that involve high-temperature conditions, such as industrial furnaces, heat exchangers, and power generation equipment. They maintain their mechanical properties and corrosion resistance at temperatures well beyond those encountered in typical operating conditions.

Stainless steel pipe suppliers like Huaxiao offer seamless 316L stainless steel pipes that meet industry standards and specifications for high-temperature applications. It’s recommended to consult with suppliers and experts to ensure that the specific pipe dimensions, grades, and specifications are suitable for your intended high-temperature environment.

Yes, seamless 316L stainless steel pipes meet industry standards and specifications. These pipes are manufactured in accordance with various international standards such as ASTM, JIS, EN, and GB, ensuring their quality, performance, and compatibility with a wide range of industrial applications. Reputable 316L stainless steel pipe suppliers, like Huaxiao Stainless Steel, offer pipes that adhere to these industry standards, providing customers with reliable and compliant products for their specific needs.

Proper maintenance of 316L stainless steel pipes involves regular cleaning, inspection, and addressing any signs of corrosion or damage. Cleaning with mild detergents and soft brushes, followed by rinsing and drying, helps prevent dirt buildup. Regular inspections ensure early detection of any corrosion or wear, allowing for timely repairs or replacements. Reputable stainless steel pipe suppliers, such as Huaxiao Stainless Steel, can provide guidance on maintenance practices and recommend suitable cleaning agents to maintain the longevity and performance of 316L stainless steel pipes.

The price of 316L stainless steel pipes can vary depending on factors such as size, quantity, specifications, and market conditions. Reputable stainless steel pipe suppliers, like Huaxiao Stainless Steel, can provide competitive pricing based on these factors. It’s recommended to contact the supplier directly for accurate and up-to-date pricing information tailored to your specific requirements.

Yes, 316L stainless steel pipes are known for their excellent weldability. The low carbon content in 316L reduces the risk of carbide precipitation and sensitization during welding, minimizing the potential for corrosion in the heat-affected zone. Reputable stainless steel pipe suppliers, such as Huaxiao Stainless Steel, can provide guidance on proper welding techniques and offer high-quality 316L pipes suitable for welding applications.

other products

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China