Seamless 347H Stainless Steel Pipe Supplier

- Size Range: From 4mm4mm to 800mm800mm

- Wall Thickness Range: From 1mm to 150mm (SCH10-XXS)

- Length Options: 4000mm, 5800mm, 6000mm, 12000mm, or as required.

- Finish: 2B, BA,4K,8K, NO.1,2D,3#, HL

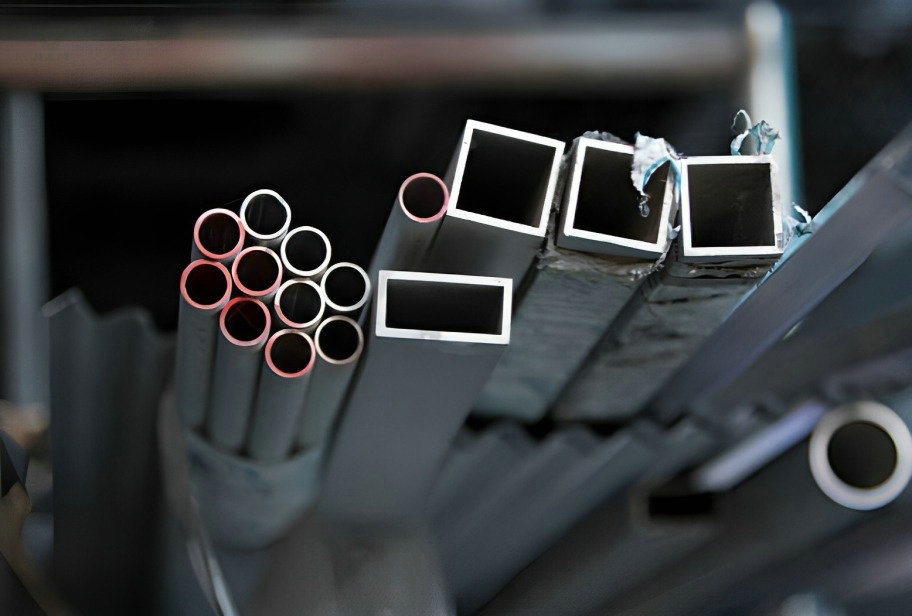

- Type: Round, square, rectangular, hexagonal, flat, angle

- Technique: Cold rolled, hot rolled

Product Description Of Seamless 347H Stainless Steel Pipe

Seamless 347H Stainless Steel Pipe is a remarkable member of the stainless steel family, celebrated for its exceptional high-temperature performance, corrosion resistance, and versatility in demanding applications. Operating within a temperature range of 800 to 1500°F (427 to 816°C), Seamless 347H Stainless Steel Pipe stands as a stalwart performer in elevated heat environments. Its higher carbon content imparts robust high-temperature strength, making it indispensable in industries where extreme heat is a constant challenge.

The increased carbon content in 347H stainless steel elevates its high-temperature capabilities. This carbon enrichment enables it to thrive in applications where standard 347 stainless steel might falter. Its ability to withstand intense heat ensures the reliability and longevity of critical systems.

The inclusion of niobium as a stabilizing element further enhances its performance. Niobium grants this stainless steel grade the invaluable ability to resist intergranular corrosion, thereby strengthening its overall durability.

specification Of Seamless 347H Stainless Steel Pipe

Chemical Components Of Seamless 347H Stainless Steel Pipe

| Element | 347H |

|---|---|

| Chromium | 17.0–19.0 |

| Nickel | 9.0–13.0 |

| Carbon | 0.04–0.10 |

| Manganese | 2.00 |

| Phosphorus | 0.045 |

| Sulfur | 0.03 |

| Niobium | See Spec |

| Nitrogen | – |

| Iron | Balance |

physical property Of Seamless 347H Stainless Steel Pipe

| Property | Value |

|---|---|

| Density, g/cm³ | 7.96 |

| Melting Range, °C (°F) | 1398 – 1446 (2550 – 2635) |

| Specific Heat Capacity, J/kg·K (Btu/lb ·°F) | 500 (0.12) at 20 °C |

| Electrical Resistivity, μΩ·m | 72 at 20 °C |

| Modulus of Elasticity, GPa (10⁶ psi) | 193 (28) |

| Thermal Conductivity, W/m·K (Btu/ft · h ·°F) | 16.3 (9.3) at 100 °C (212 °F) |

| Coefficient of Thermal Expansion, 10⁻⁶/K (μin./in. ·°F) | 16.0 (9.2) at 0-100 °C (32-212 °F), 18.9 (10.5) at 0-600 °C (32-1112 °F), 20.5 (11.4) at 0-1000 °C (32-1832 °F) |

mechanical property Of Seamless 347H Stainless Steel Pipe

| Property | Value |

|---|---|

| Tensile Strength, Ultimate | 480 MPa (69600 psi) |

| Tensile Strength, Yield | 205 MPa (29700 psi) |

| Rupture Strength (@750°C/1380°F, time 100,000 hours) | 38 – 39 MPa (5510 – 5660 psi) |

| Elastic Modulus | 190 – 210 GPa (27557 – 30458 ksi) |

| Poisson’s Ratio | 0.27 – 0.30 |

| Elongation at Break | 29% |

| Hardness, Brinell | 187 |

characteristics Of Seamless 347H Stainless Steel Pipe

The Seamless 347H Stainless Steel Pipe exhibits exceptional high-temperature resistance, making it a standout choice for applications in demanding heat-intensive environments. This remarkable characteristic can be attributed to several key factors:

High Carbon Content: 347H stainless steel contains a higher carbon content compared to standard 347 stainless steel. This elevated carbon level enhances the material’s strength and high-temperature performance¹.

Operating Range: The 347H stainless steel pipe is designed to operate effectively within a temperature range of 800 to 1500°F (427 to 816°C)². This range encompasses many high-temperature industrial processes, including those in the petrochemical, chemical, and aerospace industries.

Creep Resistance: The higher carbon content in 347H provides improved resistance to creep, which is the gradual deformation of materials under prolonged exposure to high temperatures and stress³. This resistance ensures the pipe retains its structural integrity over extended periods of use.

Oxidation Resistance: The alloy’s composition also offers good oxidation resistance, protecting it against damage caused by the reaction with oxygen at high temperatures. This is crucial in preventing the formation of oxide scales that can compromise the material’s performance⁴.

Thermal Stability: The stable austenitic microstructure of 347H stainless steel maintains its integrity even when subjected to extreme heat, ensuring the pipe’s dimensional stability and mechanical properties over time¹.

Applications: Its exceptional high-temperature resistance makes Seamless 347H Stainless Steel Pipe highly suitable for use in a wide range of applications, including furnace components, heat exchangers, chemical processing equipment, and exhaust systems in aircraft and high-performance automobiles.

In summary, the outstanding high-temperature resistance of Seamless 347H Stainless Steel Pipe is a result of its high carbon content, enabling it to withstand extreme heat, creep, and oxidation. This exceptional characteristic ensures the reliable and long-lasting performance of the pipe in various demanding industries.

Seamless 347H Stainless Steel Pipe offers comparable resistance and corrosion protection to Alloy 321, making it a highly reliable choice for applications demanding robust resistance against corrosive environments. This characteristic can be attributed to the following factors:

Similar Alloy Composition: Both 347H and Alloy 321 are stabilized austenitic stainless steels that contain titanium as a stabilizing element. This stabilizing element prevents chromium carbide precipitation and subsequent intergranular corrosion at elevated temperatures, ensuring excellent corrosion resistance¹.

Intergranular Corrosion Resistance: The addition of niobium in both 347H and Alloy 321 enhances their resistance to intergranular corrosion. This is particularly important after exposure to temperatures within the chromium carbide precipitation range, which typically occurs in the 800 to 1500°F (427 to 816°C) range². The niobium forms niobium carbides, preventing the formation of chromium carbides and preserving the material’s corrosion resistance.

Acidic and Oxidizing Environments: Both alloys excel in resisting corrosion in acidic and oxidizing environments. This property makes them suitable for applications in chemical processing, petrochemical, and pharmaceutical industries where exposure to aggressive chemicals and elevated temperatures is common.

Weldability: Both 347H and Alloy 321 exhibit excellent weldability, maintaining their corrosion resistance in the heat-affected zones of welded joints. This makes them ideal for applications requiring fabrication and welding processes³.

Heat Resistance: The alloys are designed to withstand high-temperature environments, which is vital in applications such as exhaust systems, furnace components, and heat exchangers.

In summary, Seamless 347H Stainless Steel Pipe shares a similar alloy composition and intergranular corrosion resistance profile with Alloy 321. This ensures that it provides excellent protection against corrosion and maintains its integrity even in challenging environments, making it a reliable choice for various industrial applications.

Seamless 347H Stainless Steel Pipe finds extensive use in heavy welded equipment due to its unique characteristics, making it a preferred material for applications where extreme durability and corrosion resistance are essential. Here’s a detailed exploration of its usage in heavy welded equipment:

High-Temperature Resistance: One of the primary reasons for using Seamless 347H Stainless Steel Pipe in heavy welded equipment is its exceptional high-temperature resistance. This alloy can withstand temperatures ranging from 800 to 1500°F (427 to 816°C)². In heavy machinery and equipment that operate under elevated temperatures, such as heat exchangers and industrial ovens, 347H stainless steel maintains its structural integrity, ensuring long-term reliability.

Corrosion Resistance: Heavy welded equipment often encounters aggressive environments where corrosion is a significant concern. Seamless 347H Stainless Steel Pipe offers excellent corrosion resistance, even in corrosive chemical processes. Its resistance to intergranular corrosion, particularly in the heat-affected zones of welded joints, makes it an ideal choice for critical applications in the chemical, petrochemical, and pharmaceutical industries.

Weldability: When heavy equipment requires intricate fabrication and welding, the weldability of the material becomes crucial. 347H stainless steel exhibits exceptional weldability, and welded joints maintain their corrosion resistance properties. This allows for the construction of complex, welded components and structures with confidence in their long-term performance.

Strength and Durability: The inherent strength and durability of Seamless 347H Stainless Steel Pipe are essential attributes for heavy equipment subjected to substantial mechanical stress. This alloy retains its mechanical properties even under high-temperature and high-pressure conditions, ensuring the longevity of critical components.

Applications: Heavy welded equipment encompasses a wide range of industrial machinery, including pressure vessels, heat exchangers, reactors, and piping systems. In these applications, 347H stainless steel’s combination of high-temperature resistance and corrosion resistance makes it indispensable for ensuring operational safety and reliability.

In conclusion, Seamless 347H Stainless Steel Pipe is a favored choice for heavy welded equipment due to its ability to withstand high temperatures, resist corrosion in demanding environments, offer excellent weldability, and provide the necessary strength and durability. These characteristics make it an essential material for critical industrial applications where equipment performance and safety are paramount.

Seamless 347H Stainless Steel Pipe exhibits excellent oxidation resistance, making it an ideal material for applications in environments where exposure to high temperatures and oxidative agents is prevalent. Here, we delve into the details of this exceptional oxidation resistance:

1. High-Temperature Performance: Seamless 347H Stainless Steel Pipe demonstrates remarkable performance under high-temperature conditions, with the ability to withstand temperatures ranging from 800 to 1500°F (427 to 816°C)². This property is vital for applications involving intense heat, such as in industrial furnaces, exhaust systems, and aerospace components.

2. Resistance to Oxidation: When exposed to elevated temperatures, most materials are susceptible to oxidation, which can lead to surface degradation and a loss of mechanical properties. However, 347H stainless steel maintains its structural integrity and surface quality even in oxygen-rich environments. This resistance to oxidation results from the alloy’s high chromium and niobium content, which forms a protective oxide layer on the surface, preventing further oxidation.

3. Longevity in Challenging Environments: Industries such as petrochemical, power generation, and metal processing often operate in harsh conditions with elevated temperatures and exposure to combustion gases. In these environments, the outstanding oxidation resistance of 347H stainless steel ensures that critical components and piping systems maintain their performance and durability over time.

4. Reduced Maintenance: The ability of Seamless 347H Stainless Steel Pipe to resist oxidation means reduced maintenance and replacement costs for equipment and pipelines. This makes it a cost-effective choice for industries where minimizing downtime and maintenance expenses is essential.

5. Versatility: The alloy’s resistance to oxidation extends its usability to a wide range of applications, including heat exchangers, automotive exhaust systems, and chemical processing equipment. In each of these scenarios, 347H stainless steel’s oxidation resistance ensures longevity and reliability.

In conclusion, the oxidation resistance of Seamless 347H Stainless Steel Pipe is a crucial factor in its suitability for high-temperature applications and harsh environments. Its ability to withstand oxidative agents, maintain surface quality, and provide long-term performance makes it a preferred material in industries where reliability and durability are paramount.

The high-temperature creep properties of Seamless 347H Stainless Steel Pipe are a defining characteristic that sets it apart in high-temperature applications. Here’s a detailed explanation:

1. Creep Resistance: Creep refers to the tendency of materials to deform plastically and slowly under the influence of mechanical stress at high temperatures, typically above 500°C (932°F). Seamless 347H Stainless Steel Pipe exhibits remarkable resistance to creep deformation, making it an excellent choice for applications subjected to long-term mechanical loads at elevated temperatures.

2. Elevated Temperatures: In industries such as petrochemical, power generation, and aerospace, components and structures are often exposed to extreme temperatures. At these elevated temperatures, materials may undergo deformation over time if they lack proper creep resistance. However, 347H stainless steel can maintain its dimensional stability and structural integrity in these conditions.

3. Enhanced Carbon Content: The higher carbon content in 347H stainless steel, compared to its 347 counterpart, contributes to its superior creep resistance. This elevated carbon content enhances the alloy’s ability to withstand creep deformation, even at higher temperatures.

4. Applications: The exceptional high-temperature creep properties of Seamless 347H Stainless Steel Pipe make it an ideal choice for applications such as gas turbine components, boiler tubing, and heat exchanger tubes, where prolonged exposure to high temperatures and mechanical stress is common.

5. Longevity and Reliability: Components made from 347H stainless steel can operate reliably for extended periods at elevated temperatures without suffering from excessive deformation or failure. This longevity reduces downtime, maintenance costs, and the need for frequent replacements, making it a cost-effective solution in industries requiring dependable high-temperature performance.

In summary, the high-temperature creep properties of Seamless 347H Stainless Steel Pipe make it an invaluable material for industries demanding stability and reliability at elevated temperatures. Its ability to resist creep deformation ensures that critical components and structures maintain their integrity and performance, even under prolonged exposure to extreme heat and mechanical stress.

Seamless 347H Stainless Steel Pipe exhibits impressive thermal cycling resistance, making it a valuable material in applications where temperature fluctuations are frequent. Here’s a detailed explanation of this characteristic:

1. Thermal Cycling: Thermal cycling refers to the process of repeated heating and cooling of a material or component. In various industries such as aerospace, power generation, and petrochemical, equipment and structures often experience rapid and significant temperature changes. Seamless 347H Stainless Steel Pipe is designed to withstand these extreme thermal cycles without undergoing significant deformation or deterioration.

2. Resistance to Thermal Shock: When subjected to sudden temperature changes, some materials can crack or develop stress-related issues due to differential expansion and contraction. However, 347H stainless steel, with its enhanced carbon content and stable alloy composition, maintains its structural integrity and dimensional stability during rapid temperature fluctuations.

3. Applications: The impressive thermal cycling resistance of 347H stainless steel makes it well-suited for applications like exhaust systems, heat exchangers, and furnace components where rapid heating and cooling cycles are part of the operational requirements. In these applications, the material’s ability to endure repeated thermal stresses ensures long-lasting performance.

4. Reduced Maintenance: By using Seamless 347H Stainless Steel Pipe in equipment and systems subjected to thermal cycling, industries can significantly reduce maintenance costs and downtime. The material’s durability under such conditions minimizes the need for frequent inspections, repairs, and replacements.

5. Enhanced Durability: Components and structures made from 347H stainless steel can maintain their functionality and structural integrity over an extended service life, even in environments characterized by extreme temperature fluctuations. This enhanced durability contributes to the overall reliability of critical systems.

In conclusion, Seamless 347H Stainless Steel Pipe’s impressive thermal cycling resistance is a valuable asset in applications where temperature fluctuations are frequent and severe. Its ability to withstand these thermal stresses ensures the longevity and reliable performance of equipment and structures, making it a preferred choice in industries demanding exceptional durability in dynamic temperature environments.

Seamless 347H Stainless Steel Pipe is known for its high strength and hardness, making it a valuable material in various demanding applications. Here’s a detailed explanation of this characteristic:

1. High Tensile Strength: One of the primary attributes of 347H stainless steel is its exceptional tensile strength, which measures its resistance to a stretching force. This high tensile strength allows the material to withstand heavy loads and mechanical stresses without experiencing deformation or failure.

2. Elevated Hardness: 347H stainless steel exhibits increased hardness compared to standard austenitic stainless steel grades like 304 or 316. This hardness is a result of its higher carbon content and the stabilizing alloying elements, such as niobium. The elevated hardness contributes to its resistance to wear, abrasion, and deformation, particularly under high-temperature conditions.

3. Impact Resistance: The combination of high strength and hardness in 347H stainless steel results in enhanced impact resistance. This makes it suitable for applications where the material may be subjected to sudden shocks or impacts without experiencing significant damage.

4. Creep Resistance: In addition to its tensile strength, 347H stainless steel also demonstrates excellent creep resistance. Creep is the tendency of a material to deform slowly under constant stress at elevated temperatures. The enhanced creep resistance of 347H stainless steel makes it a reliable choice for components operating in high-temperature environments, such as steam generators and exhaust systems.

5. Structural Stability: The high strength and hardness of Seamless 347H Stainless Steel Pipe contribute to its structural stability. It maintains its shape and integrity even when exposed to challenging conditions, ensuring the long-term reliability of critical components.

6. Versatility: Due to its combination of strength and hardness, 347H stainless steel finds applications in various industries, including aerospace, chemical processing, power generation, and petrochemical. It is commonly used in equipment subjected to high-pressure, high-temperature, and corrosive environments.

In conclusion, Seamless 347H Stainless Steel Pipe’s high strength and hardness are key attributes that make it suitable for demanding applications where resistance to mechanical stresses, wear, and elevated temperatures is essential. Its structural stability and versatility have earned it a reputation as a robust material choice for critical components in various industries.

application Of Seamless 347H Stainless Steel Pipe

Water Supply System

Seamless 347H Stainless Steel Pipe plays a critical role in water supply systems, particularly in applications requiring robust and corrosion-resistant piping. For instance, it is commonly employed in municipal water treatment plants for transporting chemically treated water. Its exceptional corrosion resistance ensures that the water remains uncontaminated and safe for consumption. Additionally, in desalination plants, where highly saline water is processed into fresh water, the corrosion-resistant properties of Seamless 347H Stainless Steel Pipe make it an ideal choice for handling the challenging, corrosive environment involved in desalination processes, ensuring the durability and reliability of the water supply system.

Oil and Gas Refineries

Seamless 347H Stainless Steel Pipe finds vital applications in oil and gas refineries, where its exceptional high-temperature strength and resistance to oxidation are indispensable. It is extensively used in the construction of piping systems for transporting crude oil and refined petroleum products within the refinery. Additionally, in high-temperature processing units such as catalytic cracking units and reforming units, Seamless 347H Stainless Steel Pipe is chosen for its ability to withstand the extreme conditions, ensuring the safe and efficient processing of hydrocarbons. Its resistance to corrosion and oxidation guarantees the integrity and longevity of critical infrastructure in the oil and gas industry.

Pulp and Paper Industry

The Pulp and Paper Industry relies on Seamless 347H Stainless Steel Pipe due to its exceptional mechanical properties. This stainless steel pipe is extensively used in various processes within pulp and paper mills, such as in the construction of pipelines and equipment handling corrosive chemicals and high-temperature fluids. It withstands the harsh and demanding conditions of chemical pulping, bleaching, and paper manufacturing, ensuring a reliable and corrosion-resistant solution. The high-temperature resistance and corrosion protection of Seamless 347H Stainless Steel Pipe make it a preferred choice, contributing to the efficiency and longevity of equipment in the pulp and paper industry.

Pharmaceuticals Equipment

Seamless 347H Stainless Steel Pipe finds crucial applications in the Pharmaceuticals Equipment industry due to its exceptional resistance to corrosion. It is widely used for manufacturing pharmaceutical equipment that comes into contact with various chemicals, high-temperature substances, and corrosive environments. This stainless steel pipe ensures the integrity and hygiene of pharmaceutical processes, making it ideal for applications like the production of drug manufacturing vessels, storage tanks, and piping systems. Its resistance to intergranular corrosion and outstanding high-temperature performance contribute to the reliability and safety of pharmaceutical equipment, meeting stringent industry standards and regulations.

FAQ

Seamless 347H Stainless Steel Pipe differs from other stainless steel pipes in several ways, primarily due to its composition and performance characteristics. Here’s a comparison with some specific stainless steel grades:

Alloy Composition: Unlike standard 304 or 316 stainless steel pipes, Seamless 347H Stainless Steel Pipe contains higher levels of niobium (also known as columbium). This addition of niobium enhances its resistance to intergranular corrosion in high-temperature environments.

High-Temperature Strength: When compared to stainless steel grade 321, which is stabilized with titanium, 347H exhibits better high-temperature strength due to the presence of niobium.

Operating Temperature Range: Seamless 347H Stainless Steel Pipe can withstand a wider temperature range (from 800 to 1500°F or 427 to 816°C) compared to standard stainless steels like 304 or 316, which have lower maximum operating temperatures.

Corrosion Resistance: The niobium content in 347H provides exceptional resistance to intergranular corrosion following exposure to temperatures within the chromium carbide precipitation range. This makes it highly suitable for applications involving high-temperature and corrosive environments.

Oxidation Resistance: Similar to most austenitic stainless steels, Seamless 347H Stainless Steel Pipe offers good oxidation resistance, allowing it to maintain its properties in challenging high-temperature conditions.

Creep Resistance: Its higher carbon content also provides better resistance to high-temperature creep deformation, making it a reliable choice for applications involving sustained elevated temperatures.

In summary, Seamless 347H Stainless Steel Pipe stands out due to its unique composition, which includes niobium, and its exceptional performance in high-temperature and corrosive environments. These qualities make it suitable for a wide range of demanding applications, including those where standard stainless steel grades like 304 or 316 may not perform as effectively. When sourcing this pipe, it’s advisable to consult stainless steel pipe suppliers for specific grade comparisons and recommendations tailored to your project requirements.

The Seamless 347H Stainless Steel Pipe has an impressive maximum temperature range, making it suitable for high-temperature applications. It can operate within the temperature range of 800 to 1500°F (427 to 816°C). This wide temperature tolerance is one of its key advantages, allowing it to perform exceptionally well in environments with extreme heat. For more detailed information and specifications regarding its temperature capabilities, it’s advisable to consult stainless steel pipe suppliers who can provide specific data and recommendations for your particular application.

Yes, there are specific welding considerations when working with Seamless 347H Stainless Steel Pipe. Due to its composition and intended use in high-temperature environments, it’s important to follow proper welding practices to maintain its properties and corrosion resistance. Stainless steel pipe suppliers can offer guidance on the following aspects:

Matching Filler Material: Select the appropriate filler material with a similar composition to 347H stainless steel for welding to ensure compatibility and maintain corrosion resistance.

Preheating: Preheating the pipe and adjacent material before welding can help prevent cracking and maintain proper weld integrity.

Welding Process: Consider using welding processes like TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) for better control over the heat input and weld quality.

Post-Weld Heat Treatment: Depending on the application and welding process, post-weld heat treatment may be necessary to restore mechanical properties and relieve residual stresses.

Weld Purging: Implement weld purging techniques to protect the backside of the weld from oxidation, especially in critical applications.

Avoid Contamination: Prevent contamination of the weld area by ensuring cleanliness and avoiding contact with materials that could introduce impurities.

Proper Passivation: After welding, the stainless steel should be passivated to remove any impurities and restore its corrosion resistance.

Stainless steel pipe suppliers can provide detailed recommendations and guidelines for welding Seamless 347H Stainless Steel Pipe, ensuring the best results for your specific welding application. It’s crucial to follow these recommendations to maintain the integrity and performance of the pipe in high-temperature environments.

The price of Seamless 347H Stainless Steel Pipe can vary depending on factors like the size, wall thickness, and specific requirements of the project. Typically, 347H stainless steel is considered a higher grade due to its exceptional high-temperature properties and corrosion resistance compared to some other stainless steel grades. As a result, it may be priced slightly higher than lower-grade stainless steel pipes like 304 or 316.

For accurate pricing information and to compare the cost of Seamless 347H Stainless Steel Pipe to other grades, it’s recommended to contact reputable stainless steel pipe suppliers like Huaxiao. They can provide detailed pricing based on your specific needs and quantities, ensuring you get the most accurate cost estimate for your project. Keep in mind that the price can also be influenced by market conditions and fluctuations in raw material costs, so it’s advisable to request a quote for the most up-to-date pricing.

The manufacturing process for Seamless 347H Stainless Steel Pipe typically involves the following steps:

Raw Material Selection: High-quality stainless steel billets or ingots are chosen as the starting material. These materials should meet the specific chemical composition requirements for 347H stainless steel.

Heating and Piercing: The selected billets are heated to a high temperature and then pierced to create a hollow tube.

Rotary Piercing: In this method, a solid billet is rotated while a pointed mandrel is forced into the center, forming a hollow tube.

Hot Extrusion: The pierced or rotary-pierced tube is then extruded through a die to reduce its diameter and achieve the desired dimensions.

Heat Treatment: The pipe is subjected to heat treatment processes like annealing to relieve stress, improve mechanical properties, and ensure uniform grain structure.

Cold Drawing: The pipe is drawn through a series of dies to further reduce its diameter and improve its surface finish and dimensional accuracy.

Cutting and Finishing: The pipe is cut to the desired lengths, and its ends are prepared for welding or other connections.

Testing: Various quality tests are conducted to ensure the pipe meets the required standards, including tests for dimensions, mechanical properties, corrosion resistance, and non-destructive testing.

Pickling and Passivation: The pipe’s surface is pickled and passivated to remove any impurities and improve its corrosion resistance.

Packaging and Delivery: The finished pipes are packaged according to customer requirements and delivered to the end-users or distributors.

For specific details on the manufacturing process of Seamless 347H Stainless Steel Pipe provided by Huaxiao stainless steel pipe suppliers, it’s advisable to contact the supplier directly, as they may have variations in their production methods and quality control processes.

other products

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: export82@huaxia-intl.com

Address: RM557, NO.1388 Jiangyue Road, Shanghai China