Seamless 409L Stainless Steel Pipe Suppliers

- Size Range: From 4mm4mm to 800mm800mm

- Wall Thickness Range: From 1mm to 150mm (SCH10-XXS)

- Length Options: 4000mm, 5800mm, 6000mm, 12000mm, or as required.

- Finish: 2B, BA,4K,8K, NO.1,2D,3#, HL

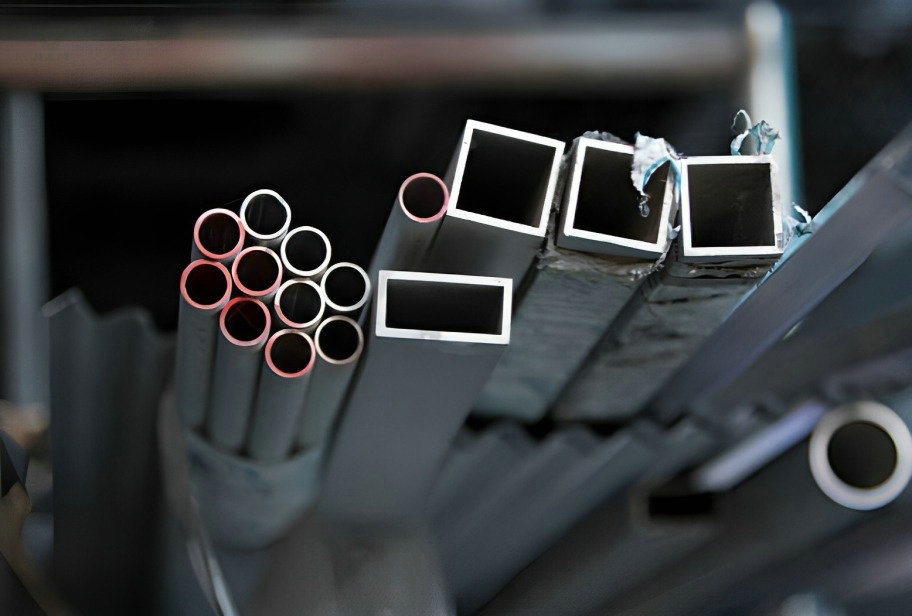

- Type: Round, square, rectangular, hexagonal, flat, angle

- Technique: Cold rolled, hot rolled

Product Description Of Seamless 409L Stainless Steel Pipe

Seamless 409L Stainless Steel Pipe is available in economical stainless steel grades and is an iron alloy designed for corrosion resistance. Consisting of 11% chromium, 0.5% to 1.0% manganese, and 0.75% silicon, it is resistant to rust during welding, making it ideal for engine and turbine components that need protection from sulfur-induced oxidative damage. It is also significantly more cost-effective than 304 and 316L series because of the different chemical elements.

Commonly used in applications requiring high temperatures and corrosion-resistant environments, 409L stainless steel seamless pipe is derived from alloy 409L, which has lower levels of chromium, nickel, and other elements, making it a cost-effective alternative to other stainless steel grades. Their seamless design eliminates potential weak points and is ideal for high pressure applications. They are highly resistant to oxidation and decarburization and excel in challenging chemical environments. Because they can be fabricated and customized to meet specific requirements, they are popular in the automotive, construction and transportation sectors. 409L seamless stainless steel tubes offer an optimal balance between performance and cost-effectiveness, making them ideal for a wide range of industrial needs.

specification Of Seamless 409L Stainless Steel Pipe

Chemical Components Of Seamless 409L Stainless Steel Pipe

| 409L | C % | Si% | Mn % | P % | S % | Ni % | Cr % | N % | Ti % |

| ASTM | 0.03 | 1 | 1 | 0.04 | 0.02 | 0.5 | 10.5-11.7 | 0.03 | 6*(C+N)-0.5 |

| DIN/EN | 0.03 | 1 | 1 | 0.04 | 0.015 | – | 10.5-12.5 | – | 6*(C+N)-0.65 |

| JIS | 0.03 | 1 | 1 | 0.04 | 0.03 | – | 10.5-11.7 | – | 6*C% – 0.75 |

| GB | 0.03 | 1 | 1 | 0.04 | 0.02 | – | 10.5-11.7 | 0.03 | Ti≥8*(C+N) |

mechanical property Of Seamless 409L Stainless Steel Pipe

| 409L | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

| ASTM | 170 | 380 | 20 | – | 88 | 179 | – |

| JIS | 175 | 360 | 25 | 162 | 80 | – | 175 |

| GB | 170 | 380 | 20 | – | 88 | 179 | 200 |

physical property Of Seamless 409L Stainless Steel Pipe

| Property | Value |

|---|---|

| Density (kg/m³) | 7800 |

| Elastic Modulus (GPa) | 200 |

| Mean Coefficient of Thermal Expansion (μm/m/°C) | 11.0 (0-100°C), 11.7 (0-315°C), 12.4 (0-538°C) |

| Thermal Conductivity (W/m.K) | 25.8 (at 100°C), 27.5 (at 500°C) |

| Specific Heat 0-100°C (J/kg.K) | 460 |

| Electrical Resistivity (nΩ.m) | 600 |

characteristics Of Seamless 409L Stainless Steel Pipe

Seamless 409L stainless steel pipe exhibits remarkable corrosion resistance attributed to its unique composition and inherent properties. The presence of 11% chromium within the alloy forms a protective layer of chromium oxide on the surface, commonly known as a passive film. This passive film acts as a barrier, shielding the underlying metal from direct contact with corrosive agents, such as moisture, chemicals, and pollutants. The combination of chromium, together with the presence of silicon and manganese, enhances the pipe’s resistance to both general and localized corrosion phenomena.

Furthermore, the seamless manufacturing process minimizes potential crevices or discontinuities in the pipe’s structure, reducing the sites where corrosion initiation could occur. This aspect is especially crucial when the pipe is exposed to aggressive environments. The result is a stainless steel pipe that offers sustained performance and durability, even when subjected to challenging conditions.

Overall, the corrosion resistance of seamless 409L stainless steel pipe is a product of its carefully balanced chemical composition, passive film formation, and seamless design. This combination ensures that the pipe can effectively withstand the corrosive influences present in various applications, making it a reliable choice for industries where protection against corrosion is paramount.

The welding stability of seamless 409L stainless steel pipe is a notable characteristic stemming from its chemical composition and microstructure. This attribute contributes to the ease and reliability of welding processes involving this material.

The lower carbon content in 409L stainless steel reduces the likelihood of sensitization, a condition where chromium carbides form at grain boundaries, leading to reduced corrosion resistance. As a result, during welding, the risk of chromium depletion near the weld area is minimized, preserving the material’s corrosion-resistant properties.

Additionally, the presence of stabilizing elements, such as titanium and niobium, aids in preventing carbide precipitation during welding and subsequent cooling, enhancing the pipe’s resistance to intergranular corrosion. This feature is crucial when the material is subjected to high-temperature welding processes.

Moreover, the seamless design of the pipe ensures uniform mechanical properties across its length, which plays a vital role in maintaining welding stability. The absence of welded joints in the pipe’s structure eliminates potential weak points that could compromise the overall weld quality and structural integrity.

In summary, the welding stability of seamless 409L stainless steel pipe is achieved through careful material composition, the presence of stabilizing elements, and its seamless construction. This stability simplifies welding processes and ensures that the pipe maintains its corrosion resistance and mechanical strength even after joining operations, making it suitable for a variety of fabrication and construction applications.

The cost-effectiveness of seamless 409L stainless steel pipe is a significant advantage that arises from its composition and manufacturing process. This stainless steel grade, designed to offer corrosion resistance while maintaining affordability, presents several factors that contribute to its cost-effectiveness.

The lower content of expensive alloying elements like nickel within the composition of 409L stainless steel contributes to a more economical raw material. This reduced reliance on costly elements helps to lower production costs without compromising essential properties.

Furthermore, the efficient manufacturing process of seamless pipes, such as hot rolling or cold drawing, contributes to cost savings due to minimized material waste and reduced machining requirements. The seamless construction also ensures fewer potential points of weakness, enhancing durability and reducing the need for maintenance and replacements, thus reducing long-term costs.

In various applications, where the corrosion resistance and mechanical properties of stainless steel are essential, seamless 409L stainless steel pipe offers an economically viable solution that balances performance and affordability. Its ability to meet the requirements of specific applications while being a cost-effective option makes it an attractive choice for industries seeking high-value materials for various projects.

Seamless 409L stainless steel pipe demonstrates exceptional suitability for high-temperature applications owing to its specific composition and inherent properties. This stainless steel grade has been engineered to withstand elevated temperatures without compromising its structural integrity.

The presence of 11% chromium in 409L stainless steel forms a protective chromium oxide layer on the surface, even at high temperatures. This layer acts as a barrier against oxidation and corrosion, ensuring the material’s resistance to degradation in challenging environments.

Additionally, the alloy’s low carbon content minimizes the formation of harmful carbides, preserving the material’s mechanical properties even when exposed to elevated temperatures. This aspect is crucial for maintaining the structural strength and durability of the pipe under thermal stress.

Furthermore, the seamless design of the pipe eliminates potential weak points, enhancing its reliability when subjected to varying thermal expansion and contraction. This seamless construction ensures uniform properties throughout the pipe’s length, crucial for consistent performance in high-temperature conditions.

In conclusion, seamless 409L stainless steel pipe’s composition, passive film formation, and seamless structure collectively contribute to its suitability for high-temperature applications. Its ability to withstand thermal stress, oxidation, and corrosion makes it a valuable choice for industries requiring dependable performance in environments with elevated temperatures.

The seamless design of stainless steel pipes, including the seamless 409L stainless steel pipe, is a distinctive feature that offers several advantages due to its manufacturing method and resulting structural characteristics.

Seamless pipes are crafted without the need for welding joints or seams, which eliminates potential weak points that can be present in welded pipes. This seamless construction ensures uniform mechanical properties along the entire length of the pipe, contributing to enhanced structural integrity and reliability.

The absence of welded seams eliminates the risk of defects that can occur during welding processes, ensuring a smoother inner surface. This characteristic is particularly beneficial in applications where smooth flow is crucial, such as fluid transport systems.

Seamless pipes also exhibit superior dimensional accuracy, contributing to tighter tolerances and consistent sizing. This accuracy is essential in industries where precise measurements are critical for compatibility and performance.

Furthermore, the seamless manufacturing process minimizes material waste compared to welded pipes, resulting in a more efficient use of resources and potentially lower production costs.

In summary, the seamless design of stainless steel pipes, exemplified by seamless 409L stainless steel pipes, offers advantages such as uniform properties, smoother inner surfaces, precise dimensions, and reduced waste. These qualities make seamless pipes a preferred choice in industries where structural integrity, fluid flow efficiency, and precise measurements are paramount.

Seamless 409L stainless steel pipe exhibits notable oxidation and decarburization resistance due to its carefully balanced composition and inherent properties, making it suitable for applications in challenging environments.

The presence of 11% chromium within the alloy forms a protective chromium oxide layer on the surface, even when exposed to elevated temperatures and harsh conditions. This passive film acts as a barrier against oxidation, preventing the direct interaction of the metal with oxygen and preventing the formation of detrimental oxides.

Furthermore, the low carbon content in 409L stainless steel minimizes the risk of decarburization—a process in which carbon atoms diffuse out of the material’s surface during exposure to high temperatures. This helps maintain the mechanical properties of the pipe, ensuring its stability and performance in demanding conditions.

The seamless design of the pipe further contributes to its oxidation and decarburization resistance. The absence of welded joints eliminates potential sites for oxidation and decarburization to initiate, ensuring consistent performance and durability.

In conclusion, seamless 409L stainless steel pipe’s composition, passive film formation, and seamless construction collectively offer remarkable oxidation and decarburization resistance. These attributes enhance the material’s longevity and suitability for applications where resistance to high temperatures and aggressive chemical environments is crucial.

application Of Seamless 409L Stainless Steel Pipe

engine components and turbo parts

Seamless 409L Stainless Steel Pipe excels in engine components and turbo parts due to its exceptional resistance to rust during welding. This feature is crucial in safeguarding against oxidation damage caused by sulfur-rich environments prevalent in engines. The 11% chromium content forms a protective layer that shields against corrosive effects of sulfur compounds. By resisting rust formation during welding and exposure to combustion byproducts, this stainless steel grade ensures prolonged durability and performance integrity. It's a reliable choice, addressing corrosion challenges while contributing to the efficiency and longevity of engine components and turbo assemblies.

High-Temperature Environments

Seamless 409L Stainless Steel Pipe is frequently employed in environments characterized by elevated temperatures due to its inherent ability to withstand thermal stress. The presence of 11% chromium forms a protective layer that remains effective even in high-temperature conditions. This passive film mitigates oxidation and corrosion, ensuring the pipe's durability and structural integrity. The low carbon content minimizes the risk of carbide precipitation, preserving mechanical properties in extreme heat. These attributes collectively make seamless 409L stainless steel pipe a reliable choice for applications such as exhaust systems, industrial furnaces, and other settings where resistance to high temperatures is essential for sustained performance.

corrosive environments

Seamless 409L Stainless Steel Pipe is well-suited for corrosive environments owing to its robust alloy composition. With 11% chromium content, it forms a protective chromium oxide layer, effectively shielding against corrosive agents. This passive film remains intact in challenging conditions, offering superior resistance to corrosion and rust. Its suitability for corrosive environments extends its application to industries like chemical processing, marine, and coastal installations. Whether exposed to saltwater, chemicals, or acidic compounds, the seamless 409L stainless steel pipe reliably maintains its integrity, making it a trusted choice for projects demanding long-lasting performance in harsh and corrosive surroundings.

high-pressure applications

The seamless design of 409L stainless steel pipe makes it particularly well-suited for high-pressure applications due to its inherent structural integrity. Unlike welded pipes, seamless pipes lack joints or weak points, ensuring uniform strength throughout their length. This construction minimizes the risk of leaks or failures under high pressure. Seamless 409L stainless steel pipe's composition, including 11% chromium, enhances its corrosion resistance, further contributing to its reliability in demanding environments. This makes it a preferred choice for industries like oil and gas, where high-pressure conditions demand materials capable of withstanding substantial stress, making seamless 409L stainless steel pipe a reliable solution for critical high-pressure applications.

FAQ

Seamless 409L stainless steel pipe exhibits excellent corrosion resistance due to its rational compositional design and special manufacturing process. The 11% chromium content forms a protective chromium oxide layer that effectively insulates it from external corrosive factors. This layer is known as the passive film of the protective layer in a variety of environments are excellent performance, including humid climate, chemical corrosion and high temperature environment.

At the same time, the low carbon content of 409L stainless steel pipe reduces the generation of carbides, which helps prevent grain boundary corrosion. This resistance to corrosion in harsh conditions is critical to ensuring the stability and durability of the pipe over the long term.

In summary, Seamless 409L stainless steel pipe’s rational composition, passive film protection mechanism, and low carbon content are designed to provide superior corrosion resistance in a variety of environments, making it widely used in applications involving corrosion issues.

Seamless 409L stainless steel pipe excels in high temperature environments due to its unique chemical composition and manufacturing process. The 11% chromium content in it forms a shield, called a chromium oxide layer, which effectively stops oxidation and corrosion at high temperatures. This protective film is stabilized at high temperatures and provides the material with heat resistance.

The low carbon content reduces the formation of carbides at high temperatures, thus maintaining the mechanical properties of 409L stainless steel tubing. This design allows it to maintain structural strength and durability in high-temperature applications, making Seamless 409L stainless steel tubing a reliable choice for use in high-temperature environments such as engine components and industrial furnaces. Stainless steel pipe suppliers expertise ensures you get proven materials for high temperature applications.

Seamless 409L stainless steel pipe has excellent mechanical properties that ensure adequate strength. Its specific composition and processing give the pipe excellent durability and structural strength. Stainless steel pipe suppliers carry out stringent quality control on the pipes they produce to ensure that they meet international standards and deliver consistent performance.

Through its low carbon content and suitable added elements, 409L stainless steel pipe maintains stable mechanical properties at high temperatures and in corrosive environments. Its excellent corrosion and oxidation resistance does not compromise its strength. Supplier expertise and quality assurance ensure that Seamless 409L Stainless Steel Pipe is strong and durable in a variety of applications.

Seamless 409L stainless steel pipe demonstrates exceptional suitability for high-temperature applications owing to its specific composition and inherent properties. This stainless steel grade has been engineered to withstand elevated temperatures without compromising its structural integrity.

The presence of 11% chromium in 409L stainless steel forms a protective chromium oxide layer on the surface, even at high temperatures. This layer acts as a barrier against oxidation and corrosion, ensuring the material’s resistance to degradation in challenging environments.

Additionally, the alloy’s low carbon content minimizes the formation of harmful carbides, preserving the material’s mechanical properties even when exposed to elevated temperatures. This aspect is crucial for maintaining the structural strength and durability of the pipe under thermal stress.

Furthermore, the seamless design of the pipe eliminates potential weak points, enhancing its reliability when subjected to varying thermal expansion and contraction. This seamless construction ensures uniform properties throughout the pipe’s length, crucial for consistent performance in high-temperature conditions.

In conclusion, seamless 409L stainless steel pipe’s composition, passive film formation, and seamless structure collectively contribute to its suitability for high-temperature applications. Its ability to withstand thermal stress, oxidation, and corrosion makes it a valuable choice for industries requiring dependable performance in environments with elevated temperatures.

Compared to other stainless steel materials, Seamless 409L stainless steel pipe offers distinct advantages. Its notable advantage lies in its cost-effectiveness, making it a preferred choice for various applications. With a composition optimized for corrosion resistance, this grade maintains its durability while being more economical. Additionally, its specific characteristics, such as resistance to oxidation, suitability for high-temperature environments, and applicability in corrosive settings, enhance its versatility. Stainless steel pipe suppliers ensure access to a high-quality product that combines performance with affordability, catering to diverse industry needs effectively.

Yes, Seamless 409L stainless steel pipes supplied by Huaxiao stainless steel pipe suppliers conform to international standards and certifications. These pipes are manufactured to meet rigorous quality and performance criteria set by recognized industry standards. Huaxiao’s commitment to providing high-quality products ensures that their Seamless 409L stainless steel pipes adhere to the required specifications, making them a reliable choice for various applications that demand compliance with international standards and certifications.

During the manufacturing process, Seamless 409L stainless steel pipes undergo specific heat treatment steps to enhance their properties. These steps typically include annealing, which involves heating the pipes to a specific temperature and then gradually cooling them to improve their mechanical characteristics and eliminate stresses. The exact details of the heat treatment may vary based on the desired final properties of the pipes.

Stainless steel pipe suppliers like Huaxiao ensure that the heat treatment process follows industry standards and guidelines to achieve the desired material properties, such as improved corrosion resistance and mechanical strength. This meticulous approach to heat treatment guarantees that Seamless 409L stainless steel pipes meet the required specifications for various applications.

Yes, reputable stainless steel pipe suppliers like Huaxiao adhere to relevant quality assurance and testing standards to ensure the quality of Seamless 409L stainless steel pipes. These standards encompass various aspects of production, including material composition, manufacturing processes, and final product properties.

Common quality assurance measures involve compliance with international standards such as ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization). Rigorous testing methods, including mechanical property testing, chemical analysis, and non-destructive testing, are conducted to verify the integrity and performance of the pipes.

By adhering to these established quality assurance and testing standards, suppliers ensure that Seamless 409L stainless steel pipes meet the required specifications, offering customers a reliable and high-quality product for their diverse applications.

other products

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China