Seamless 410 Stainless Steel Pipe Suppliers

- Size Range: From 4mm4mm to 800mm800mm

- Wall Thickness Range: From 1mm to 150mm (SCH10-XXS)

- Length Options: 4000mm, 5800mm, 6000mm, 12000mm, or as required.

- Finish: 2B, BA,4K,8K, NO.1,2D,3#, HL

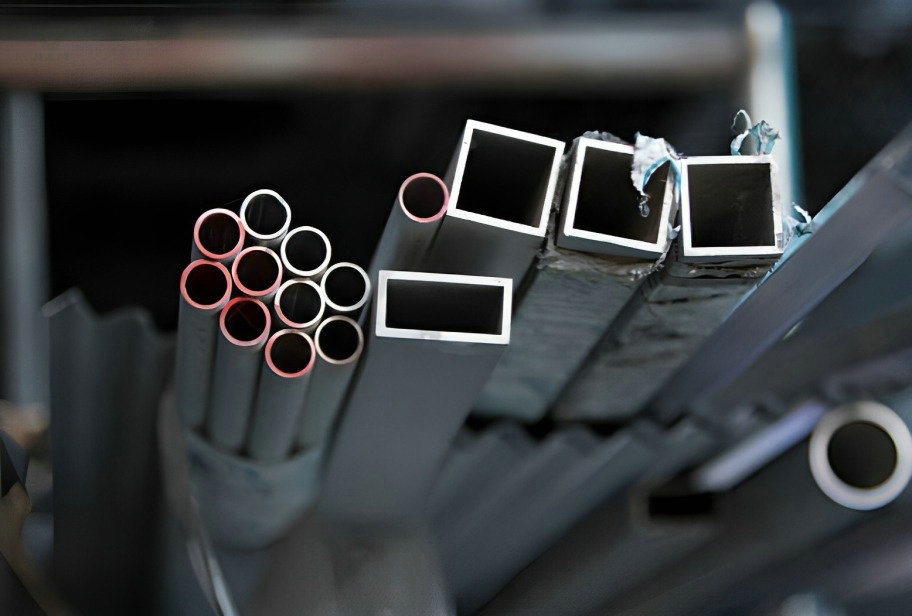

- Type: Round, square, rectangular, hexagonal, flat, angle

- Technique: Cold rolled, hot rolled

Product Description of Seamless 410 Stainless Steel Pipe

410 Stainless Steel Seamless Tubing is a martensitic stainless steel commonly used where high strength, hardness, and moderate corrosion resistance are required. It is a cost-effective choice and is commonly used for cutlery, dental and surgical instruments, nozzles, valve parts, and hardened steel balls and seats for oil well pumps.410 Stainless Steel typically consists of a chemical composition of 11.5%-13.5% chromium, 0.15% carbon, and 1% manganese, resulting in good corrosion resistance and high strength.

specification of Seamless 410 Stainless Steel Pipe

Chemical Components Of Seamless 410 Stainless Steel Pipe

| Element | ASTM | JIS | EN | GB |

| Chromium | 11.5-13.5% | 11.5-13.5% | 12.0-14.0% | 11.5-13.5% |

| Nickel | – | – | – | – |

| Manganese | ≤1.00% | ≤1.00% | ≤1.50% | ≤1.00% |

| Carbon | 0.08-0.15% | 0.08-0.15% | 0.08-0.15% | 0.08-0.15% |

| Phosphorous | ≤0.040% | ≤0.040% | ≤0.040% | ≤0.035% |

| Sulfur | ≤0.030% | ≤0.030% | ≤0.015% | ≤0.030% |

| Silicon | ≤1.00% | ≤1.00% | ≤1.00% | ≤1.00% |

mechanical property Of Seamless 410 Stainless Steel Pipe

| Property | Value |

|---|---|

| Tensile Strength | 540 MPa (Minimum) |

| Yield Strength | 450 MPa (Minimum) |

| Elongation | 20% (Minimum) |

| Hardness (Rockwell C) | HRC 20 (Maximum) |

| Impact Toughness | 40 J (Minimum) at -20°C (-4°F) |

| Modulus of Elasticity | 200 GPa (29,000 ksi) |

| Density | 7.75 g/cm³ (0.279 lb/in³) |

| Thermal Conductivity | 24 W/m·K (16.7 BTU/hr·ft·°F) |

| Electrical Conductivity | 25% IACS (International Annealed Copper Standard) |

physical property Of Seamless 410 Stainless Steel Pipe

| Property | Value |

|---|---|

| Density | 7.75 g/cm³ (0.279 lb/in³) |

| Melting Point | 1480 – 1530°C (2696 – 2786°F) |

| Thermal Expansion | 10.4 x 10^-6 /°C (20-100°C) |

| Specific Heat Capacity | 460 J/kg·K (0.11 BTU/lb·°F) |

| Electrical Resistivity | 0.57 μΩ·m (microhm·cm) |

| Magnetic Properties | Ferromagnetic |

| Thermal Conductivity | 24 W/m·K (16.7 BTU/hr·ft·°F) |

characteristics of Seamless 410 Stainless Steel Pipe

The Seamless 410 Stainless Steel Pipe is engineered from martensitic stainless steel, a class of stainless steel known for its exceptional strength and hardness characteristics. The unique microstructure of martensitic steel contributes to its remarkable mechanical properties, making it an ideal choice for applications that require enduring strength and hardness. This property ensures that the Seamless 410 Stainless Steel Pipe can withstand challenging conditions and heavy loads, offering reliability and longevity in demanding environments.

One of the standout features of the Seamless 410 Stainless Steel Pipe is its commendable corrosion resistance, which enhances its durability and ensures a prolonged service life. While not as corrosion-resistant as some other stainless steel types like austenitic stainless steels, the Seamless 410 Stainless Steel Pipe is designed to effectively withstand corrosion in various environments, including mildly corrosive ones. This characteristic makes it particularly suitable for applications where exposure to moisture, chemicals, and other corrosive agents is a concern. By maintaining its structural integrity over time, the Seamless 410 Stainless Steel Pipe minimizes the need for frequent replacements, thereby reducing maintenance costs and enhancing the overall reliability of your projects.

The adaptability of the Seamless 410 Stainless Steel Pipe sets it apart, as it finds its utility across a wide spectrum of industries. Its robust mechanical properties and corrosion resistance make it a versatile choice for numerous applications. In the culinary world, it’s a staple for crafting durable cutlery that withstands constant use. In dentistry and surgical instrumentation, its strength and corrosion resistance ensure precision and hygiene. It’s a key component in nozzles, where its hardness maintains performance under high pressure. Valve components benefit from its reliability, and even in the oil and gas sector, it serves as hardened steel balls and seats for oil well pumps. This broad spectrum of applications showcases the adaptability and reliability of the Seamless 410 Stainless Steel Pipe, making it an optimal solution across diverse industrial domains.

The Seamless 410 Stainless Steel Pipe stands as a testament to the balance between affordability and performance. While offering exceptional mechanical properties and corrosion resistance, it also presents a cost-effective solution. This unique combination ensures that you don’t have to compromise on quality to meet budget constraints. Industries seeking reliable materials for their projects can confidently turn to the Seamless 410 Stainless Steel Pipe, knowing that they’re investing in a product that delivers exceptional value. This cost-effectiveness opens avenues for a wider range of applications without sacrificing the high standards of performance and durability that your projects demand.

The craftsmanship behind the Seamless 410 Stainless Steel Pipe is characterized by meticulous attention to detail and adherence to rigorous industry standards. Each step of its manufacturing process is executed with precision, ensuring that the final product meets and often exceeds the stringent quality benchmarks set by the industry. This commitment to precision extends from the selection of raw materials to the final stages of fabrication. The result is a stainless steel pipe that not only embodies superior mechanical properties and corrosion resistance but also demonstrates consistent quality across every unit produced. By adhering to such high standards, the Seamless 410 Stainless Steel Pipe offers you the assurance of a product that you can rely on for your critical applications, contributing to the overall success and durability of your projects.

application of Seamless 410 Stainless Steel Pipe

steam turbines, gas turbines, and nuclear reactors

The Seamless 410 Stainless Steel Pipe plays a crucial role in various energy generation sectors including steam turbines, gas turbines, and nuclear reactors. It finds application in manufacturing essential components and equipment for these systems. With its exceptional strength, hardness, and corrosion resistance, the pipe is well-suited to endure the challenging conditions within steam turbines, gas turbines, and nuclear reactors. It contributes to the structural integrity, longevity, and overall performance of these power generation technologies. Whether in crafting turbine blades, pressure vessels, or other critical parts, the Seamless 410 Stainless Steel Pipe ensures reliability and efficiency, making it an indispensable material for advancing energy production across these vital industries.

Forged valves, fasteners, shafting, pump parts and machine parts

The application of Seamless 410 Stainless Steel Pipe extends to various industrial sectors, including forged valves, fasteners, shafting, pump parts, and machine parts. Its exceptional strength, hardness, and corrosion resistance make it an ideal choice for crafting components that require durability and reliability. In forged valves, it ensures robust performance under high pressure and temperature conditions. As fasteners, it provides secure connections in critical assemblies. For shafting, its resilience contributes to the smooth operation of rotating machinery. In pump parts, its corrosion resistance and mechanical properties maintain efficiency. Additionally, the Seamless 410 Stainless Steel Pipe is vital in machine parts, ensuring structural integrity and functionality. Its versatility and enduring properties make it an indispensable material for various applications, contributing to the performance and longevity of industrial equipment across these diverse sectors.

heat exchangers

The Seamless 410 Stainless Steel Pipe finds critical application in the realm of heat exchangers. Its remarkable attributes, including high strength, corrosion resistance, and thermal stability, make it an excellent choice for constructing heat exchange components. In this context, the pipe serves as a conduit for transferring heat between fluids while withstanding elevated temperatures and corrosive environments. Its durability ensures prolonged service life in various heat exchange systems, contributing to their efficiency and reliability. Whether used in shell-and-tube or plate heat exchangers, the Seamless 410 Stainless Steel Pipe maintains structural integrity, minimizes maintenance needs, and optimizes heat transfer performance. As a fundamental element in heat exchanger construction, it underscores its importance in facilitating efficient heat management across a wide range of industrial applications.

fertilizer industry

Seamless 410 Stainless Steel Pipe also finds application in the fertilizer industry. Its inherent strengths, such as superior corrosion resistance and robustness, make it a valuable choice for various applications within this sector. Whether used for conveying corrosive chemicals, constructing equipment, or fabricating components, the pipe's properties ensure durability and reliability in fertilizer production processes. Its resistance to corrosion from fertilizers and chemicals helps maintain the integrity of critical systems, while its exceptional strength and hardness contribute to the longevity of equipment. In the fertilizer industry, where harsh environments and chemical exposures are common, the Seamless 410 Stainless Steel Pipe serves as a reliable material that upholds operational efficiency and product quality, reinforcing its significance in supporting this vital sector.

FAQ

Yes, Seamless 410 Stainless Steel Pipe exhibits stable performance in steam and high temperature environments. Its special martensitic crystal structure gives it excellent high temperature stability and strength properties. Under steam and high temperature operating conditions, this seamless stainless steel tube maintains its structural integrity and is not prone to deformation or loss of strength. This makes it ideal for use in the manufacture of steam turbines, gas turbines and other high-temperature equipment.

The oxidation resistance of Seamless 410 Stainless Steel Seamless Tubing makes it effective against the effects of oxidation, corrosion and thermal stress in high temperature environments. Its retention of hardness and strength at high temperatures ensures the durability of components, thereby extending the life of the equipment. As a result, it offers excellent suitability in applications requiring high-temperature stability and reliability, such as blades for steam turbines and components for gas turbines. In short, Seamless 410 Stainless Steel Seamless Tubing’s superior performance in steam and high temperature environments provides a reliable solution for a variety of industrial applications.

One of the standout features of the Seamless 410 Stainless Steel Pipe is its commendable corrosion resistance, which enhances its durability and ensures a prolonged service life. While not as corrosion-resistant as some other stainless steel types like austenitic stainless steels, the Seamless 410 Stainless Steel Pipe is designed to effectively withstand corrosion in various environments, including mildly corrosive ones. This characteristic makes it particularly suitable for applications where exposure to moisture, chemicals, and other corrosive agents is a concern. By maintaining its structural integrity over time, the Seamless 410 Stainless Steel Pipe minimizes the need for frequent replacements, thereby reducing maintenance costs and enhancing the overall reliability of your projects.

The heat treatment process of 410 stainless steel seamless pipe usually includes annealing, solution treatment and quenching. First, with annealing treatment, the material is heated to a higher temperature and then cooled slowly to reduce internal stresses and improve workability. Second, solution treatment heats the stainless steel to a specific temperature to evenly distribute the alloying elements and then cools it rapidly to maintain the solid solution structure. Finally, quenching is a critical step that cools the material rapidly to form a martensitic structure that provides superior hardness and strength.

These heat treatment steps can alter the organization and properties of 410 stainless steel to meet specific mechanical and physical property requirements. As stainless steel pipe suppliers, understanding these heat treatment processes is critical to providing high quality Seamless 410 stainless steel seamless pipe.

Seamless 410 stainless steel pipe offers several advantages when comparing it to other stainless steel materials. First, it has a high degree of hardness and strength, which makes it excel in abrasion-resistant and high-stress environments. Second, 410 stainless steel also excels in corrosion resistance, and while not as good as some austenitic stainless steels, it is still reliable in general corrosive environments. In addition, 410 stainless steel exhibits good stability in high temperature and high pressure environments, making it suitable for a variety of industrial applications.

As stainless steel pipe suppliers, understanding these advantages of Seamless 410 stainless steel seamless pipe can help you provide your customers with more comprehensive solutions for different applications. Whether it’s for mechanical applications where strength is important or for corrosion-resistant applications where high corrosion resistance is required, this seamless pipe provides reliable performance.

Yes, Seamless 410 Stainless Steel Pipe typically meets multiple international standards and certification requirements. These standards may include ASTM, ASME, EN, JIS, and others. These standards define the chemical composition, mechanical properties, and processing requirements of stainless steel materials to ensure their quality and performance in various applications.

As a Huaxiao Stainless Steel Pipe Suppliers, understanding and ensuring that Seamless 410 Stainless Steel Seamless Tubing meets the relevant international standards and certification requirements is key to delivering high quality materials. This helps you provide your customers with reliable material options that meet the technical and quality requirements of their projects.

As a Huaxiao stainless steel pipe supplier, it is critical to ensure the quality and consistency of Seamless 410 stainless steel pipe. Here are some key measures:

Rigorous material selection and sourcing: Ensure sourcing of high quality stainless steel sheets from reliable raw material suppliers to ensure the quality of Seamless 410 Stainless Steel Pipes.

Precise manufacturing process control: Control process parameters during manufacturing, including heating, rolling, piercing and annealing, to ensure product consistency and stability.

Non-destructive testing: Non-destructive testing such as ultrasonic, radiographic or eddy current testing is performed to inspect the internal and external quality of the seamless tubes to detect any defects.

Chemical composition analysis: Each batch of raw material is analyzed for its chemical composition to ensure that it meets the standard requirements.

Mechanical property tests: Mechanical property tests such as tensile, hardness and impact are carried out on the finished seamless tubes to verify that they meet the design requirements.

Dimensional Inspection: Ensure that the dimensions and geometry of the seamless tubes comply with the specified standards.

Certification and Inspection: Ensure that the products comply with relevant international standards and certifications, such as ASTM, ASME, etc.

Continuous Improvement: Continuous optimization of manufacturing processes, feedback and experience to improve product quality and consistency.

Through the above measures, Huaxiao Stainless Steel Pipe Suppliers is able to provide high quality, consistent and reliable Seamless 410 Stainless Steel Tubing to meet the requirements and expectations of our customers.

The manufacturing process of Seamless 410 Stainless Steel Pipe involves several steps to ensure its quality and performance. A typical manufacturing process includes the following major steps:

Material Preparation: High quality 410 stainless steel sheet is obtained from reliable raw material suppliers to ensure that it meets the chemical composition and quality requirements.

Cold Drawing or Hot Rolling: The raw material is cold drawn or hot rolled into a billet, which typically requires multiple steps to achieve the desired size and shape.

Piercing: A piercing machine is used to pierce the billet into a hollow tube. The piercing process improves the internal surface quality and dimensional accuracy of the tube.

Solution Annealing: Solution treatment of the pipe at a certain temperature to achieve a uniform distribution of alloying elements, followed by rapid cooling to maintain the solid solution structure.

Quenching: Rapid cooling of solid solution treated tubing to form a martensitic structure that provides superior hardness and strength.

Finishing: Tubes are finished to ensure dimensional and cosmetic quality, such as removal of cosmetic oxide layers.

Non-destructive testing: Non-destructive testing such as ultrasonic, radiographic or eddy current testing is performed to check the internal and external quality of the tube.

Mechanical property tests: Mechanical property tests such as tensile, hardness, impact, etc. are carried out to verify that the performance meets the requirements.

Surface treatment: Polishing, pickling and other surface treatment can be carried out to improve the appearance quality and corrosion resistance.

As stainless steel pipe suppliers, understanding these steps in the manufacturing process ensures that you can provide high-quality Seamless 410 Stainless Steel Seamless Pipe to meet the needs of different applications.

other products

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China