Seamless 410s Stainless Steel Pipe Suppliers

- Size Range: From 4mm4mm to 800mm800mm

- Wall Thickness Range: From 1mm to 150mm (SCH10-XXS)

- Length Options: 4000mm, 5800mm, 6000mm, 12000mm, or as required.

- Finish: 2B, BA,4K,8K, NO.1,2D,3#, HL

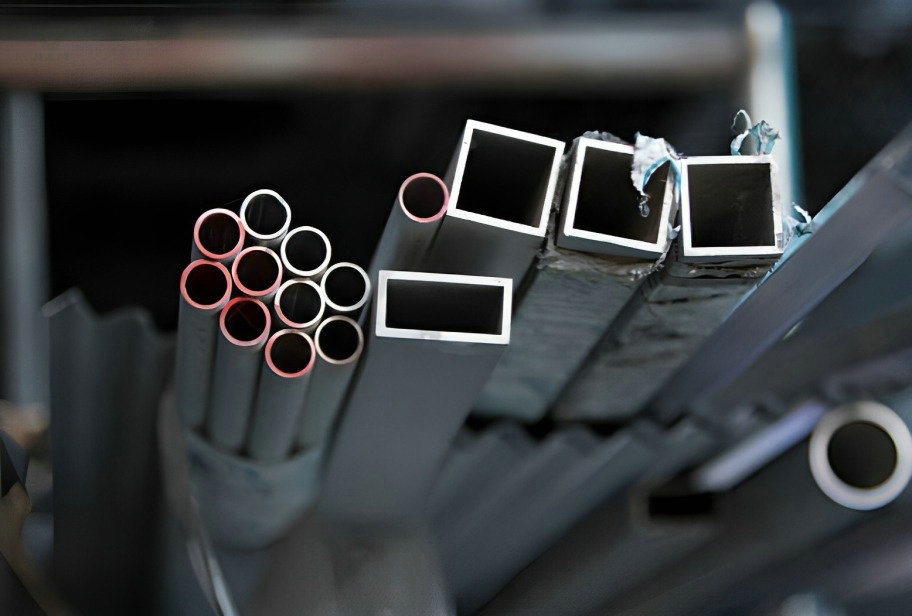

- Type: Round, square, rectangular, hexagonal, flat, angle

- Technique: Cold rolled, hot rolled

Product Description Of Seamless 410s Stainless Steel Pipe

Seamless 410S Stainless Steel Pipe – A versatile corrosion-resistant solution. Low-carbon 410S stainless steel offers exceptional high-temperature performance. With its reduced risk of intergranular corrosion and carbide precipitation, it’s ideal for elevated temperature applications. The pipe’s excellent oxidation resistance from its high chromium content (11.5%-13.5%) makes it suitable for challenging environments. Moderate nickel content (0.75%-1.25%) enhances strength and overall durability. Widely used in heat exchangers, boilers, pressure vessels, and chemical industries. Explore the reliability of Seamless 410S stainless steel pipe for diverse industrial needs.

specification Of Seamless 410s Stainless Steel Pipe

Chemical Components Of Seamless 410s Stainless Steel Pipe

| 410S | C % | Si% | Mn % | P % | S % | Ni % | Cr % |

| ASTM | 0.08 | 1 | 1 | 0.04 | 0.03 | 0.6 | 11.5-13.5 |

| DIN/EN | 0,08 | 1,00 | 1,00 | 0,040 | 0,015 | – | 12,0-14,0 |

| JIS | 0.08 | 1 | 1 | 0.04 | 0.03 | – | 11.5-13.5 |

| GB | 0.08 | 1 | 1 | 0.04 | 0.03 | 0.6 | 11.5-13.5 |

physical property Of Seamless 410s Stainless Steel Pipe

| Property | Value |

|---|---|

| Density (kg/m³) | 7800 |

| Elastic Modulus (GPa) | 200 |

| Mean Coefficient of Thermal Expansion (μm/m/°C) | 9.6 (0-100°C) |

| Thermal Conductivity (W/m.K) | 26.9 (at 100°C) |

| Specific Heat 0-100°C (J/kg.K) | 460 |

| Electrical Resistivity (nΩ.m) | 600 |

characteristics Of Seamless 410s Stainless Steel Pipe

Seamless 410S stainless steel pipe showcases a distinctive characteristic in its low carbon modification. This modification involves deliberately reducing the carbon content within the alloy to levels lower than conventional stainless steels. The strategic limitation of carbon (typically 0.08% or less) imparts several advantages.

Firstly, the minimized carbon content significantly reduces the susceptibility to intergranular corrosion—a type of corrosion occurring at the grain boundaries of the metal. By mitigating the formation of chromium carbides along these boundaries, the risk of localized corrosion and mechanical degradation is markedly diminished. This is particularly relevant in environments with elevated temperatures, where traditional stainless steels might succumb to sensitization and subsequent intergranular corrosion.

Secondly, the absence of excessive carbon prevents the formation of large carbide precipitates, thereby maintaining the material’s mechanical properties and preventing brittleness. This is pivotal in ensuring the material’s structural integrity and reliability, especially when exposed to dynamic or high-stress conditions.

In essence, the low carbon modification of seamless 410S stainless steel pipe enhances its overall corrosion resistance, especially in critical intergranular contexts, and safeguards its mechanical strength and durability, making it a versatile choice for various demanding applications.

Seamless 410S stainless steel pipe exhibits remarkable versatile corrosion resistance owing to its unique composition and structure. The high chromium content within the alloy (ranging from 11.5% to 13.5%) plays a pivotal role in this attribute. Chromium forms a protective passive oxide layer on the surface of the material upon exposure to oxygen, creating a barrier against corrosive agents.

This passive oxide layer, predominantly composed of chromium oxide (Cr2O3), effectively shields the underlying metal from various corrosive environments, including moisture, chemicals, and aggressive substances. This versatile corrosion resistance extends to both acidic and alkaline conditions, rendering the material suitable for a wide spectrum of industrial applications.

Furthermore, the seamless construction of the pipe minimizes crevices and potential weak points that could promote localized corrosion. This ensures uniform protection along the entire length of the pipe, contributing to its reliable performance in challenging settings.

In summary, the versatile corrosion resistance of seamless 410S stainless steel pipe, facilitated by its high chromium content and seamless design, makes it an ideal choice for diverse industries where protection against a range of corrosive agents is paramount.

Seamless 410S stainless steel pipe demonstrates exceptional high-temperature performance due to its specific composition and metallurgical characteristics. The alloy’s low carbon modification, coupled with its significant chromium content (11.5%-13.5%), is integral to this attribute.

At elevated temperatures, the low carbon content minimizes the formation of chromium carbides along grain boundaries, effectively preventing sensitization and intergranular corrosion. This phenomenon maintains the material’s structural integrity, preventing brittleness and maintaining its mechanical properties.

The high chromium content, in turn, forms a protective oxide layer on the surface of the pipe, even at high temperatures. This layer, composed primarily of chromium oxide (Cr2O3), acts as a barrier against oxidation and prevents corrosion. The oxide layer remains stable across a range of temperatures, preserving the material’s resistance to oxidation even in challenging thermal environments.

In applications where temperatures can escalate significantly, such as in exhaust systems and high-temperature processing, the high-temperature performance of seamless 410S stainless steel pipe ensures sustained reliability and durability, making it a preferred choice for industries requiring steadfast operation under demanding thermal conditions.

Seamless 410S stainless steel pipe exhibits a unique non-hardening characteristic, which stems from its specific alloy composition and metallurgical properties. The non-hardening behavior refers to the absence of significant hardening or embrittlement upon cooling from high temperatures, particularly during heat treatment processes.

This attribute is primarily attributed to the low carbon modification in the alloy, which curtails the formation of carbides, thereby preventing the detrimental effects of carbide precipitation, such as reduced ductility and mechanical toughness. This non-hardening behavior ensures that the material maintains its desired mechanical properties and resilience across a range of thermal processes.

The non-hardening nature of seamless 410S stainless steel pipe enhances its suitability for various fabrication and heat treatment procedures. It enables manufacturers to achieve desired material properties without the drawbacks of excessive hardness or brittleness. This characteristic also contributes to the pipe’s enhanced weldability and machinability.

In summary, the non-hardening trait of seamless 410S stainless steel pipe underscores its adaptability to thermal processes while preserving its mechanical integrity, making it an excellent choice for applications requiring controlled heat treatments and consistent material performance.

application Of Seamless 410s Stainless Steel Pipe

Heat Exchangers

Seamless 410S stainless steel pipes find vital use in heat exchangers, where their exceptional corrosion resistance and high-temperature stability shine. The pipes efficiently facilitate the transfer of heat between fluids in various industries, including power generation, chemical processing, and HVAC systems. The non-hardening characteristic of 410S stainless steel ensures durability under thermal cycling, while its low carbon modification mitigates the risk of intergranular corrosion, crucial for sustained performance in heat exchanger environments. These pipes reliably contribute to efficient heat exchange processes, ensuring the integrity and longevity of heat exchangers across diverse applications.

boiler

Seamless 410S stainless steel pipes play a crucial role in boiler applications, excelling in high-temperature and corrosive environments. These pipes are integral components in steam generation systems, ensuring the efficient transfer of heat in power plants, industrial facilities, and heating systems. The alloy's non-hardening property maintains its mechanical integrity under extreme temperature fluctuations, while the low carbon modification mitigates the risk of intergranular corrosion. This unique combination of attributes makes Seamless 410S stainless steel pipes a reliable choice for boilers, contributing to their longevity, safety, and optimal performance in critical heat generation processes.

Pressure Vessels

Seamless 410S stainless steel pipes find essential application in pressure vessels, where their corrosion resistance and high-temperature capabilities are vital. These pipes are employed to contain and transport gases or liquids under elevated pressures in various industries, including chemical processing, oil and gas, and manufacturing. The non-hardening characteristic of 410S stainless steel ensures structural integrity in fluctuating conditions, while its low carbon content reduces susceptibility to intergranular corrosion. These pipes contribute to the safe and reliable operation of pressure vessels, ensuring containment of contents and the prevention of leaks or failures, even in demanding environments.

Food Processing

Seamless 410S stainless steel pipes have a significant role in food processing industries. Due to their corrosion resistance and hygienic qualities, they are utilized for conveying fluids and materials within the food production and processing environments. The low carbon modification of 410S stainless steel reduces the risk of contamination and maintains the material's integrity in contact with food substances. These pipes ensure the safety and quality of processed food products by providing a reliable and durable conduit for various fluids, contributing to the overall efficiency and compliance of food processing operations.

FAQ

Seamless 410S stainless steel stands apart from other stainless steel materials due to its unique attributes. Notably, its low-carbon, non-hardening modification sets it apart from traditional 410 stainless steel. This alteration enhances corrosion resistance while maintaining mechanical integrity. Comparatively, its higher chromium content (11.5%-13.5%) and lower carbon content contribute to its suitability for high-temperature applications. When compared to other alloys, like the 300 series, its lower cost, coupled with adept resistance to oxidation and intergranular corrosion, provides a distinct advantage. While maintaining compatibility with common stainless steel fabrication practices, Seamless 410S stainless steel, available through stainless steel pipe suppliers, is favored for its corrosion resistance and cost-effective performance.

Seamless 410S stainless steel pipes are well-suited for high-temperature environments due to their specific composition and properties. The alloy’s low carbon modification minimizes the risk of sensitization and intergranular corrosion, crucial factors in sustaining performance under elevated temperatures. Additionally, the high chromium content (11.5%-13.5%) forms a protective oxide layer on the pipe’s surface, enhancing resistance to oxidation even at high temperatures. This oxide layer remains stable, preserving the material’s integrity in challenging thermal conditions. This unique combination of low carbon, high chromium content, and stable oxide layer ensures that Seamless 410S stainless steel pipes, available through stainless steel pipe suppliers, offer reliable and durable performance in applications requiring exposure to extreme heat.

Seamless 410S stainless steel pipes possess notable corrosion-resistant characteristics. These pipes, available through stainless steel pipe suppliers, showcase enhanced resistance to corrosion owing to their specific composition. The alloy’s substantial chromium content (11.5%-13.5%) forms a protective chromium oxide layer on the surface, guarding against corrosive agents. This oxide layer acts as a barrier, preventing the penetration of moisture, chemicals, and harsh substances that can cause corrosion. Additionally, the low carbon modification mitigates the risk of intergranular corrosion, further bolstering the material’s resilience in various corrosive environments. These combined attributes contribute to the durability and longevity of Seamless 410S stainless steel pipes in applications prone to corrosion challenges.

Quality assurance and testing of Seamless 410S stainless steel pipes, available through stainless steel pipe suppliers, involve rigorous processes to ensure optimal performance and reliability. These measures include:

- Chemical Composition Analysis: Rigorous testing is conducted to verify the precise composition of the alloy, ensuring it meets specified standards.

- Mechanical Properties Testing: Tensile strength, yield strength, and elongation tests are performed to evaluate the material’s mechanical integrity.

- Corrosion Resistance Testing: Corrosion tests assess the pipes’ ability to withstand various corrosive environments, confirming their suitability for diverse applications.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and radiographic examination detect internal flaws and ensure the pipes’ structural soundness.

- Dimensional Inspection: Comprehensive measurements verify the pipes’ adherence to specified dimensions and tolerances.

- Heat Treatment Verification: Heat treatment processes are verified to ensure the desired material properties are achieved.

- Surface Quality Examination: Visual and surface inspection techniques confirm the pipes’ surface quality, eliminating defects.

- Hydrostatic and Pressure Testing: Pipes are subjected to hydrostatic and pressure tests to ensure their integrity under pressure.

- Certification and Documentation: Comprehensive documentation, including material certificates, test reports, and quality assurance records, ensures transparency and traceability.

Through these stringent quality assurance and testing procedures, stainless steel pipe suppliers ensure that Seamless 410S stainless steel pipes meet the highest standards, guaranteeing their performance and suitability for critical applications.

The Seamless 410S stainless steel pipes exhibit favorable welding performance, a crucial attribute for their diverse applications. These pipes, available through reputable stainless steel pipe suppliers, offer good weldability due to their low carbon modification. The reduced carbon content minimizes the risk of sensitization and intergranular corrosion during welding processes, preserving the material’s corrosion resistance.

Moreover, the alloy’s specific composition, including a higher chromium content (11.5%-13.5%), contributes to solidifying the weld joint and prevents the formation of detrimental carbides. This ensures the integrity and longevity of welded connections. Stainless steel pipe suppliers offer Seamless 410S stainless steel pipes that maintain their structural soundness and corrosion resistance after welding, making them suitable for various fabrication and construction applications.

To prevent oxidation and maintain the integrity of Seamless 410S stainless steel pipes, proper handling and storage procedures are essential. Stainless steel pipe suppliers recommend the following measures:

- Cleanliness: Ensure that the pipes are free from contaminants such as dirt, oil, and grease before storage or installation. Cleaning with a mild detergent and water is usually sufficient.

- Dry Storage: Keep the pipes in a dry environment to prevent moisture buildup. Moisture can accelerate oxidation and promote corrosion.

- Protection from Weather: If pipes are stored outdoors, provide weatherproof covering or protection to shield them from rain, snow, and humidity.

- Ventilation: Adequate ventilation can help prevent condensation, which can contribute to oxidation. Ensure proper airflow in storage areas.

- Avoid Contact with Corrosive Substances: Keep the pipes away from chemicals, acids, and other corrosive materials that can cause surface damage.

- Avoid Abrasive Cleaning: Use non-abrasive cleaning methods to maintain the pipes’ surface finish and prevent scratches that can lead to localized oxidation.

- Proper Handling: During installation, handle the pipes with clean gloves to prevent contamination from oils and fingerprints.

By following these precautions, provided by stainless steel pipe suppliers, you can help ensure the long-term durability and corrosion resistance of Seamless 410S stainless steel pipes.

other products

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China