Stainless Steel High Pressure Heater Tube Supplier

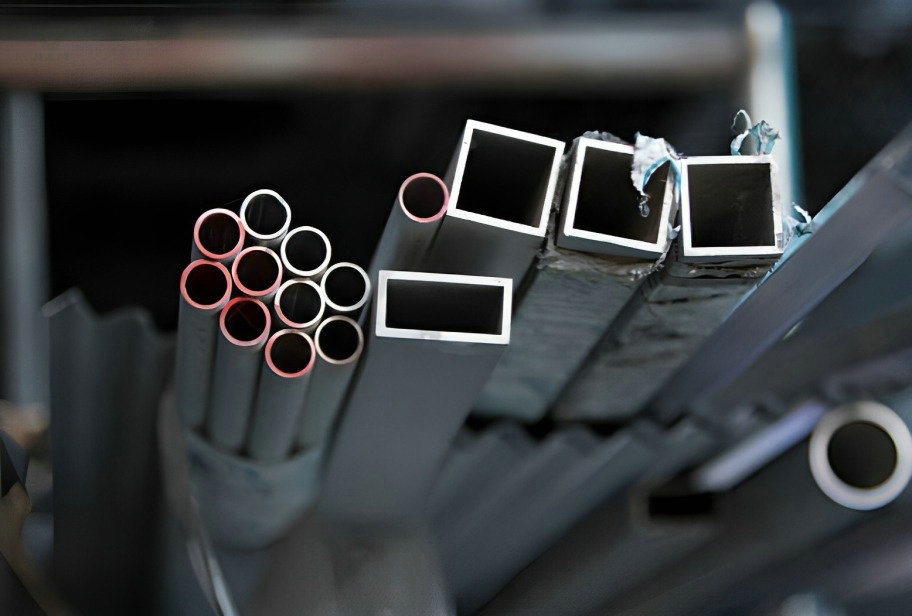

Huaxiao provides a full range of stainless steel seamless tubes for heat exchangers made of stainless steel for various environments. Our tubes can be straight, curved, smooth, or finned. Every order is unique and every tube delivered is produced, inspected, and packaged.

Product Description of Stainless Steel High Pressure Heater Tube

Introducing our Stainless Steel High Pressure Heater Tube, a pinnacle of engineering designed to thrive in the most demanding environments. This specialized tube is meticulously crafted to excel under high-pressure conditions, making it an indispensable component for critical industrial applications.

Crafted from premium quality stainless steel, this heater tube guarantees exceptional corrosion resistance, ensuring a prolonged service life even in harsh and corrosive operating conditions. Its robust construction enables it to withstand the rigors of elevated pressures, making it ideal for use in boilers, heat exchangers, and other systems where reliable heat transfer is paramount.

The advanced design of the Stainless Steel High Pressure Heater Tube prioritizes both performance and longevity. Its smooth internal surface enhances heat conductivity and minimizes the potential for fouling or scaling, maintaining optimal efficiency over extended periods of operation.

With a focus on precision engineering, this heater tube delivers consistent and reliable performance, contributing to the seamless operation of your industrial processes. Whether in power generation, petrochemicals, or other high-pressure applications, this tube stands as a testament to durability and excellence.

Choose our Stainless Steel High Pressure Heater Tube to elevate your systems to new levels of efficiency and reliability. Backed by a legacy of quality, this tube is a testament to our commitment to providing solutions that endure the harshest conditions while delivering exceptional performance. Invest in durability and precision – elevate your operations today.

specification of Stainless Steel High Pressure Heater Tube

Production Standard

ASME SA688 Welded Austenitic Stainless Steel Tube for Feed Water Heater

ASTM A312, JIS G3459, GB/T 12771, EN 10217-7,etc.

Main grade description in different standard

ASTM | DIN / EN | JIS | GB | ISO Name | Other |

S20100 201 | 1.4372 | SUS201 | S35350 | X12CrMnNiN17–7-5 | J1 L1 LH 201J1 |

S20200 202 | 1.4373 | SUS202 | S35450 | X12CrMnNiN18–9-5 | 202 L4, 202 J4, 202 J3 |

S30400 304 | 1.4301 | SUS304 | S30408 | X5CrNi18-10 | 06Cr19Ni10 0Cr18Ni9 |

S31603 316L | 1.4404 | SUS316L | S31603 | X2CrNiMo17-12-2 | 022Cr17Ni12Mo2 00Cr17Ni14Mo2 |

S40900 409 | – | SUH409 | S11168 | X5CrTi12 | 0Cr11Ti |

S40910 409L | 1.4512 | SUH409L | S11163 | X2CrTi12 | 00Cr11Ti 022Cr11Ti |

S41008 410S | 1.4000 | SUS410S | S11306 | X6Cr13 | – |

S43000 430 | 1.4016 | SUS430 | 10Cr17 | X6Cr17 | 1Cr17 |

characteristics of Stainless Steel High Pressure Heater Tube

The Stainless Steel High Pressure Heater Tube stands as a testament to its exceptional corrosion resistance. Crafted from high-quality stainless steel alloys, this tube exhibits remarkable durability even in the face of harsh and corrosive environments. Its corrosion-resistant properties ensure that it remains unaffected by corrosive fluids, chemicals, and adverse atmospheric conditions, making it a dependable choice for industries where protection against corrosion is paramount. Whether used in marine, chemical, or industrial applications, this tube’s high corrosion resistance guarantees long-lasting performance, reduced maintenance needs, and consistent operational efficiency. Trust in its ability to withstand the challenges posed by corrosive elements, safeguarding your systems and processes with unwavering reliability.

The Stainless Steel High Pressure Heater Tube boasts exceptional strength that sets it apart in demanding industrial environments. Engineered from premium stainless steel alloys, this tube is purpose-built to withstand rigorous conditions, including high pressures and mechanical stresses. Its robust construction ensures structural integrity, enabling it to effectively handle the challenges of various applications. Whether in power generation, petrochemical processing, or other high-pressure systems, this tube’s exceptional strength provides the foundation for reliable and consistent performance. Count on its durability to meet the demands of your operations, delivering unmatched strength that contributes to the efficiency and longevity of your processes.

The Stainless Steel High Pressure Heater Tube excels in optimized heat transfer, making it a superior choice for critical industrial applications. Its design prioritizes efficient heat conductivity, allowing for seamless and rapid heat exchange within systems. The smooth internal surface of the tube enhances thermal efficiency by minimizing resistance and fouling, ensuring consistent and reliable heat transfer. Whether used in boilers, heat exchangers, or other heat-intensive processes, this tube’s optimized heat transfer capabilities contribute to improved system performance, reduced energy consumption, and enhanced overall efficiency.

The Stainless Steel High Pressure Heater Tube is characterized by its remarkable durability under pressure, making it an invaluable asset for rigorous industrial environments. Engineered to withstand elevated pressures and extreme conditions, this tube maintains its structural integrity and performance integrity even when subjected to substantial pressure differentials. Its robust construction and premium stainless steel composition ensure that it remains resilient and dependable under demanding circumstances. Whether used in power generation, petrochemical processing, or other high-pressure applications, this tube’s durability under pressure guarantees consistent performance and longevity, providing peace of mind in critical operations.

The Stainless Steel High Pressure Heater Tube is synonymous with longevity and reliability, making it an optimal choice for industrial applications. Crafted from premium stainless steel, this tube’s exceptional durability ensures a prolonged service life even in challenging operating conditions. Its resistance to corrosion, mechanical stresses, and high pressures translates to reduced maintenance needs and enhanced operational continuity. Whether utilized in power plants, chemical processing, or other demanding sectors, the tube’s longevity and reliability contribute to cost savings and uninterrupted performance. Rely on its enduring nature to provide consistent results and peace of mind, enabling your systems to operate efficiently and effectively over the long term.

Toggle ContentThe Stainless Steel High Pressure Heater Tube offers seamless integration into various industrial systems, enhancing their functionality and efficiency. Designed with compatibility in mind, this tube easily integrates into existing setups, whether in power generation, petrochemical processing, or other applications. Its standardized dimensions and precise engineering ensure a smooth fit, minimizing installation complexities. By seamlessly integrating into your systems, this tube optimizes performance, minimizes downtime, and enhances overall operational productivity. Trust in its ability to seamlessly assimilate, contributing to streamlined processes and maximizing the value of your industrial infrastructure.

Production process of Stainless Steel High Pressure Heater Tube

High-pressure pipes’ production process: heating of perforation of billets, billets, and billets, and expansion of steel pipes.

The rolling of high-pressure pipes, the sizing, and decrease in steel pipes, the heating, and finishing of steel pipes, or the heating and perforation of steel blanks, hot rolling, pickling, cold-drawn carbon burning, along with the final product, a seamless steel pipe manufacturing method, Is characterized by the installation of a mandrel-type seamless tube rolling mill where a rolling rack with a plurality of rolls and a plurality of successively arranged rolling instructions different from each other are set up,

and the seamless steel tubing is rolled on this type of production line Then, measure the wall thickness at the circumferential direction of the wrapped steel pipe at multiple points, and according to the measurement outcome, at least to control the positions of both ends of each axis of the rolls onto the last rolling stand of the mandrel-type smooth pipe rolling mill. To be able to lessen the wall thickness.

application of Stainless Steel High Pressure Heater Tube

chemical injection and sample piping

Stainless Steel High Pressure Heater Tubes play a key role in chemical injection and sample piping. Its corrosion resistance and high pressure performance make it ideal for chemical processing and sample transfer. In the chemical industry, this tube can withstand a wide range of chemicals, ensuring safe transfer and handling at high pressures. At the same time, its superior corrosion resistance ensures long-term stability in corrosive environments. Our stainless steel pipe suppliers will provide you with high-quality piping solutions to ensure you get excellent performance and reliability in chemical injection and sample piping applications.

test benches and waterjet cutting

Stainless Steel High Pressure Heater Tubes play an important role in test benches and waterjet cutting. Its excellent pressure and corrosion resistance makes it ideal for test benches and waterjet cutting equipment. In test environments, the tubes are able to withstand high pressures and mechanical stresses to ensure consistent performance. In waterjet cutting, the pipe resists corrosion from the cutting fluid and coolant environment, ensuring system reliability. Our stainless steel pipe suppliers will provide you with professional piping solutions to meet the high pressure requirements of test benches and waterjet cutting equipment.

surface and subsea applications

Stainless Steel High Pressure Heater Tube plays an important role in surface and subsea applications. Its high pressure and corrosion resistance makes it the pipe of choice for a wide range of surface and subsea applications. In these applications, the tubes are used for conveying media, cooling and heating systems to meet the demands of diverse deep-sea and marine environments. Whether faced with the corrosive environments of the sea or surface applications where high pressures are required, these pipes provide reliable performance and long-lasting durability. Our stainless steel pipe suppliers will provide you with expert support to ensure superior piping solutions for surface and subsea applications.

hydraulic systems

Stainless Steel High Pressure Heater Tubes play an important role in hydraulic systems. Its excellent pressure and corrosion resistance makes it ideal for hydraulic machinery and equipment. In hydraulic systems, high pressure is the norm, and this tubing ensures reliable operation by steadily transferring high-pressure fluids. Their corrosion resistance guarantees the pipe's stability in hydraulic fluids and other liquid media, thus supporting the efficient operation of hydraulic machinery. Our stainless steel pipe suppliers will provide you with professional piping solutions to meet the needs of hydraulic systems in high pressure environments.

FAQ

Stainless Steel High Pressure Heater Tubes offer a variety of advantages, including:

- Corrosion Resistance: Constructed from high-quality stainless steel, these tubes offer excellent corrosion resistance for long, stable operation in harsh environments.

- High Pressure Resistance: Designed to withstand high-pressure working environments, they maintain stability and safety for a variety of high-pressure applications.

- Superior Strength: Due to the high strength of the material, these pipes are able to maintain their structural integrity under high pressure, avoiding deformation or rupture.

- Optimized heat transfer: The seamless construction and thermal conductivity of the material allow the pipes to perform well in heat exchange and heating applications, increasing system efficiency.

- Long life and reliability: The durability of these pipes means they maintain excellent performance over a long period of time, reducing maintenance requirements and downtime.

- Flexibility: Adaptable to a wide range of temperature and pressure conditions for a variety of applications in different industries.

- Environmentally friendly: Stainless steel is a recyclable material, helping to reduce environmental impact and promote sustainability.

- No Welded Seams: Seamless construction eliminates the weaknesses of welded seams and improves the overall strength and reliability of the pipe.

- Versatility: Stainless steel is used in a variety of industries, including chemical, petroleum, pharmaceutical, and energy, to meet high pressure and high temperature requirements.

These advantages make Stainless Steel High Pressure Heater Tubes ideal for high pressure and high temperature applications, providing durability and reliability for critical operations in industry.

Here are some suggestions for the maintenance of Stainless Steel High Pressure Heater Tubes:

- Regular Cleaning: Regularly clean the surface of the tubes to remove adhesions, dirt and dust to prevent corrosion and clogging.

- Prevent Corrosion: Ensure that the tubes are exposed to an environment that does not cause corrosion and avoid contact with corrosive chemicals.

- Regular Inspection: Check the appearance and condition of the piping regularly and take early action if any abnormalities or damage are found.

- Prevent Shock and Vibration: Avoid strong shock and vibration to prevent structural damage.

- Keep dry: Avoid exposing piping to moisture to prevent corrosion and rust.

- Regularly check connections: Regularly check the connecting parts of the piping to ensure that there are no leaks or looseness.

- Watch the temperature: Ensure that the piping is not exposed to temperatures that exceed its heat-resistant temperature for a prolonged period of time.

- Record Maintenance: Keep a record of the maintenance of your piping, including cleaning, inspection, and repairs.

- Periodic Inspection: Perform periodic inspections and testing of piping as needed to ensure that it meets performance standards.

- Seek professional support: If you have any concerns or questions, seek professional technical support and advice.

By following these maintenance recommendations, you can extend the life of your Stainless Steel High Pressure Heater Tubes and ensure that they will continue to perform reliably in high pressure and high temperature environments. Work with stainless steel pipe suppliers for advice on maintenance and care to ensure optimum performance and reliability.

Stainless Steel High Pressure Heater Tubes are suitable for a wide range of temperatures and pressure conditions, depending on the specification of the tubing, the material and the manufacturing standard. In general, the pressure and temperature resistance of this tubing makes it suitable for the following ranges:

- Temperature Range: Typically suitable for low to high temperature ranges, depending on the material and manufacturing method of the pipe. They can withstand a wide range of temperature conditions from cryogenic environments to high temperature applications.

- Pressure Range: Stainless Steel High Pressure Heater Tubes are designed for use in high pressure work environments and can withstand conditions ranging from moderate to high pressure. The exact pressure resistance depends on the size, material and design criteria of the tubes.

As a result, this type of tubing is suitable for a variety of industries and applications, including chemical, petroleum, medical, energy, etc., and can meet the requirements of different temperature and pressure conditions. When choosing to use Stainless Steel High Pressure Heater Tubes, you should refer to the pipe manufacturer’s technical data according to the specific working conditions and requirements to ensure that the pipes can operate safely and reliably under the expected temperature and pressure conditions.

Seamless pipe has many advantages over welded pipe, including:

- No Welded Seams: Seamless pipes are made from a single piece of material with no welded seams. This eliminates weaknesses that can be caused by welded seams and improves the overall strength and reliability of the pipe.

- Corrosion resistance: Seamless pipes have no welded seams, so there are no potential corrosion spots around welded seams, reducing the risk of corrosion and giving them a longer service life in corrosive environments.

- Optimized Mechanical Properties: Due to the seamless pipe manufacturing process, the shape and size of the pipe can be precisely controlled, resulting in more consistent mechanical properties such as strength, hardness and toughness.

- Smoother inner surface: The relatively smooth inner surface of seamless pipes reduces friction between fluids and particles inside the pipe, improving fluid flow.

- Suitable for high temperatures and pressures: With no welded seams, seamless pipes can withstand higher pressures and temperatures, making them suitable for high temperature and high pressure applications, such as in the petroleum and chemical industries.

- Better appearance: Seamless tubes have a more uniform, smooth appearance and are often used in decorative applications such as architecture and interior design.

- Reduced risk of leakage: The design without welded seams reduces the risk of leakage, especially in high-pressure and high-temperature environments.

- Ease of processing and repair: Seamless tubes are relatively simple to manufacture and easier to process and repair, which helps reduce manufacturing and maintenance costs.

Overall, seamless tubes have advantages in terms of corrosion resistance, mechanical properties, reliability and adaptability due to their lack of welded seams, making them suitable for a wide range of industries and applications, especially under high pressure and high temperature conditions.

Stainless Steel High Pressure Heater Tubes are typically manufactured using stainless steel. Stainless steel has excellent corrosion resistance, high strength, and high temperature resistance, making it an ideal choice for high pressure heater tubing. This piping material is used in a wide variety of industries, including chemical, petroleum, medical, energy, and more. You can work with HUuaxiao stainless steel pipe suppliers to learn more about stainless steel materials to ensure that you choose the right piping material for your application needs.

Selecting the right pipe size is a critical step in ensuring system performance and safety. When working with stainless steel pipe suppliers, the following points can help you choose the right pipe size:

- Working Pressure and Temperature: Determine the maximum working pressure and temperature of your system. This will help determine the pipe size needed to meet system requirements.

- Flow Requirements: Understand the fluid flow requirements of your system. Depending on the flow rate and expected flow rate, the proper pipe size can be selected to ensure adequate flow transfer.

- Pipe Length: Determine the actual length of the pipe, as longer pipes may require a larger diameter to minimize pressure loss.

- System Layout: Consider the system layout, including bends, branches, and connections. These factors affect the flow performance and pressure loss of the pipe.

- Piping material: Determine the stainless steel piping material you will use. Different materials may have different pipe sizing options.

- Standards and codes: Refer to industry standards and codes to ensure that the pipe size you select meets the relevant technical requirements.

- Budget and cost: Consider your budget and cost factors to select a pipe size that meets your performance needs and fits your budget.

When working with stainless steel pipe suppliers, you can consult their expertise for advice on different sizing options. They will be able to provide you with the most appropriate pipe sizing options for your application.

Other products

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China