Industrial Stainless Steel Pipes Suppliers

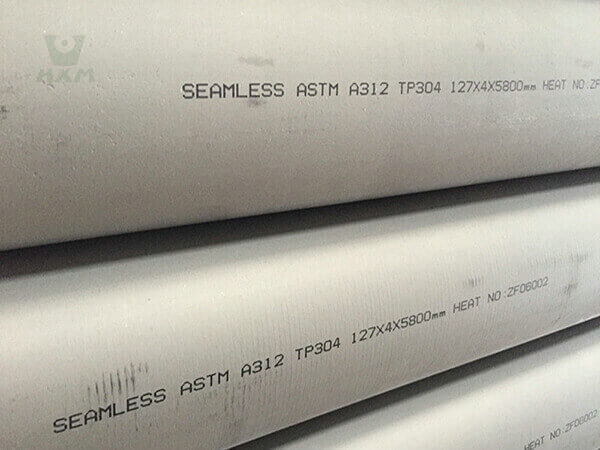

Huaxiao’s stainless steel industrial pipes are manufactured in accordance with modern European production lines, operating in accordance with the quality management system ISO 9001:2015, in compliance with the American organization’s ASTM A312/A778 standard and the international standard ASTM International

Product Description of Industrial Stainless Steel Pipes

Industrial Stainless Steel Pipes are high-quality and durable pipes designed for industrial applications. These pipes are made from corrosion-resistant stainless steel, ensuring excellent performance and longevity. With their strong construction and reliable properties, they are ideal for use in various industries such as oil and gas, chemical, food processing, and more. The industrial stainless steel pipes offer superior resistance to corrosion, high temperatures, and pressure, making them suitable for demanding environments. They are available in various sizes and specifications to meet the specific requirements of different industrial applications. Whether it’s for fluid transportation, structural support, or equipment fabrication, these industrial stainless steel pipes provide the reliability and performance needed for industrial operations. Trust in their quality and durability for your industrial piping needs.

Specification of Industrial Stainless Steel Pipes

Production Standard

GB/T14975-2002 Stainless Steel Seamless Pipe for Structures

GB/T14976-2002 Stainless Steel Seamless Pipe for Fluid Transport

GB/T12771-2000 Stainless Steel Seamless Pipe for Fluid Transport

GB5310-1995 For High-pressure Boiler, Coal Economizer, and Superheater

ASTM A312 Seamless and Welded Austenitic Stainless Steel Tube

ASTM A790 Ferrite/Austenitic Stainless Steel Seamless and Welded Steel Tube for General Use

Main grade mechanical property in different standard

201 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | 260 | 515 | 40 | – | 95 | 217 | – |

JIS | 275 | 520 | 40 | 241 | 100 | – | 253 |

GB | 205 | 515 | 30 | - | 99 | – | - |

202 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | 260 | 620 | 40 | – | – | 241 | – |

JIS | 275 | 520 | 40 | – | 95 | 207 | 218 |

GB | – | – | – | – | – | – | – |

304 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | 205 | 515 | 40 | – | 92 | 201 | – |

JIS | 205 | 520 | 40 | 187 | 90 | – | 200 |

GB | 205 | 515 | 40 | – | 92 | 201 | 210 |

316L | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | 170 | 485 | 40 | – | 95 | 217 | – |

JIS | 175 | 480 | 40 | 187 | 90 | 200 | |

GB | 170 | 485 | 40 | – | 95 | 217 | 220 |

409 | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | – | – | – | – | – | – | – |

JIS | 175 | 360 | 22 | 162 | 80 | – | 175 |

GB | – | – | – | – | – | – | – |

409L | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | 170 | 380 | 20 | – | 88 | 179 | – |

JIS | 175 | 360 | 25 | 162 | 80 | – | 175 |

GB | 170 | 380 | 20 | – | 88 | 179 | 200 |

410S | Y.S./Mpa ≥ | T.S./Mpa ≥ | E.L./% ≥ | HB ≤ | HRB ≤ | HBW ≤ | HV ≤ |

ASTM | 205 | 415 | 22 | – | 89 | 183 | – |

JIS | 205 | 410 | 20 | – | 88 | 183 | 200 |

GB | 205 | 415 | 20 | – | 89 | 183 | 200 |

Features of Industrial Stainless Steel Pipes

Industrial seamless stainless steel pipes exhibit excellent corrosion resistance, making them highly suitable for use in harsh and corrosive environments. The stainless steel material used in these pipes contains a high percentage of chromium, which forms a protective oxide layer on the surface, effectively shielding the pipe from corrosion caused by chemicals, moisture, and other corrosive agents. This corrosion resistance ensures the longevity and durability of the pipes, reducing the need for frequent replacements and maintenance. Whether used in chemical plants, offshore platforms, or other industrial settings, these pipes provide reliable performance even in challenging conditions.

Industrial seamless stainless steel pipes are known for their exceptional strength and durability. These pipes are manufactured using high-quality stainless steel alloys that offer superior mechanical properties. The combination of high tensile strength and excellent ductility ensures that these pipes can withstand heavy loads, high pressures, and extreme temperature variations without compromising their structural integrity. This high strength makes them ideal for applications where reliability and safety are crucial, such as in construction, oil and gas, and manufacturing industries. Additionally, the strong and robust nature of these pipes allows for efficient transportation and handling during installation, further enhancing their overall performance and longevity.

Industrial seamless stainless steel pipes are characterized by their seamless construction, which means they are manufactured without any weld seams or joints along their length. This seamless design offers several advantages. Firstly, it ensures a uniform and smooth interior surface, minimizing the risk of corrosion, scaling, and material buildup. Secondly, the absence of weld seams eliminates weak points in the pipe, enhancing its structural integrity and resistance to leaks and failures. Additionally, the seamless construction allows for precise dimensional accuracy and tight tolerances, ensuring a secure and reliable fit when connecting pipes and components. This seamless nature also facilitates efficient fluid flow, reducing pressure drops and optimizing system performance. Whether used for conveying liquids, gases, or solids, the seamless construction of these stainless steel pipes ensures enhanced efficiency, longevity, and overall performance in various industrial applications.

Industrial seamless stainless steel pipes are available in a wide range of sizes to meet the diverse needs of different applications. Whether you require small-diameter pipes for precise instrumentation or large-diameter pipes for high-capacity fluid transfer, huaxiao stainless steel pipe suppliers have options available to suit your specific requirements. The availability of various sizes enables flexibility in system design and installation, allowing for seamless integration into existing infrastructure or the construction of new systems. Additionally, the wide range of sizes ensures compatibility with different connection methods and fittings, facilitating easy assembly and maintenance. Whether you are working on a small-scale project or a large industrial installation, the availability of different sizes in seamless stainless steel pipes ensures that you can find the right fit for your application, ensuring optimal performance and reliability.

Industrial seamless stainless steel pipes are known for their exceptional durability and longevity. Stainless steel is a highly corrosion-resistant material, which means that these pipes can withstand harsh operating conditions and environments without deteriorating or requiring frequent replacements. The inherent strength and corrosion resistance of stainless steel contributes to the extended lifespan of these pipes, making them a reliable choice for long-term use in industrial applications. With proper installation and maintenance, industrial stainless steel pipes can provide reliable and efficient performance for many years, reducing the need for costly repairs or replacements. Their longevity not only ensures uninterrupted operation but also leads to cost savings and enhanced productivity in industrial settings. Whether it’s transporting fluids, gases, or other substances, the longevity of industrial seamless stainless steel pipes ensures reliable and efficient performance over an extended period, making them a preferred choice in various industries.

Application of Industrial Stainless Steel Pipes

Oil and Gas industry

Industrial Stainless Steel Pipes find extensive usage in the Oil and Gas industry for various applications. They are widely supplied by reputable stainless steel pipe suppliers. These pipes are utilized for transporting oil, gas, and other hydrocarbon fluids from extraction sites to refineries and distribution networks. With their corrosion resistance, high strength, and durability, stainless steel pipes ensure the safe and efficient transfer of fluids, even in harsh and corrosive environments. They play a crucial role in maintaining the integrity and reliability of oil and gas infrastructure, contributing to the smooth operation of the industry.

Chemical Industry

Industrial Stainless Steel Pipes are essential in the Chemical Industry and are readily supplied by huaxiao stainless steel pipe suppliers. These pipes are used for various applications in chemical processing, such as transporting corrosive chemicals, acids, and solvents. The superior corrosion resistance of stainless steel ensures the integrity of the pipes, preventing leaks and contamination. Additionally, stainless steel pipes offer high temperature and pressure resistance, making them suitable for demanding chemical processes. With their reliability and durability, these pipes contribute to the safety and efficiency of chemical plants, providing critical infrastructure for the industry's operations.

Power Generation sector

Industrial Stainless Steel Pipes are widely used in the Power Generation sector and can be sourced from reputable stainless steel pipe suppliers. These pipes play a crucial role in power plants, particularly in applications such as steam generation, condensers, and turbine systems. Stainless steel's excellent heat resistance and corrosion resistance make it an ideal material for handling high-temperature steam and corrosive environments. The pipes ensure the reliable and efficient transportation of steam and other fluids throughout the power generation process. They are also resistant to scaling and oxidation, ensuring long-term performance and minimizing maintenance requirements. With the support of stainless steel pipe suppliers, power generation facilities can obtain high-quality pipes that meet their specific requirements, contributing to the safe and reliable operation of power plants.

Food and Beverage Industry

Industrial Stainless Steel Pipes are essential in the Food and Beverage Industry, and reliable stainless steel pipe suppliers play a vital role in meeting the industry's demands. These pipes are widely used in food processing, beverage production, and storage facilities. Stainless steel's hygienic properties, corrosion resistance, and ease of cleaning make it the preferred choice for handling food and beverages. The smooth interior surface of the pipes prevents bacterial growth and ensures the integrity of the products. They are used for various applications, including conveying liquids, transferring ingredients, and maintaining sanitary conditions.

Pharmaceutical Industry

Stainless steel pipe suppliers play a crucial role in meeting the demands of the Pharmaceutical Industry. Industrial Stainless Steel Pipes are widely used in pharmaceutical manufacturing facilities, laboratories, and cleanroom environments. These pipes are preferred for their excellent corrosion resistance, hygienic properties, and ease of cleaning. They ensure the integrity and purity of pharmaceutical products by preventing contamination and facilitating the smooth transfer of fluids and gases. Stainless steel pipes sourced from reliable suppliers meet stringent quality standards and comply with regulatory requirements, making them suitable for critical applications in the pharmaceutical industry. These pipes are used for processes such as liquid transportation, chemical reactions, and sterile air and gas distribution.

automotive and transportation industry

Stainless steel pipe suppliers play a vital role in meeting the needs of the automotive and transportation industry. Industrial stainless steel pipes are extensively used in various automotive applications, including exhaust systems, fuel delivery systems, and structural components. These pipes offer excellent corrosion resistance, high strength, and durability, making them suitable for withstanding harsh operating conditions and ensuring long-lasting performance. Stainless steel pipes sourced from reliable suppliers meet the industry's quality standards and specifications, ensuring their compatibility with automotive manufacturing processes. By partnering with stainless steel pipe suppliers, the automotive and transportation industry can access a wide range of stainless steel pipes that meet their specific requirements, contributing to the production of reliable, efficient, and high-performance vehicles.

FAQ

Yes, industrial stainless steel pipes are suitable for high-pressure applications. They are designed to withstand the pressure exerted by fluids or gases in various industrial processes. The inherent strength and structural integrity of stainless steel make it an ideal choice for such demanding conditions. Industrial stainless steel pipes are manufactured to meet rigorous quality standards, ensuring their ability to handle high-pressure environments safely and efficiently.

Industrial stainless steel pipes can withstand a wide temperature range, depending on the specific grade and alloy used. Generally, stainless steel has excellent heat resistance properties, allowing it to perform well in high-temperature environments. Common stainless steel grades can typically withstand temperatures ranging from -270°C to 1200°C (-454°F to 2192°F). However, it is essential to consider the specific grade, composition, and application requirements when determining the exact temperature limits for industrial stainless steel pipes. Consulting with stainless steel pipe suppliers or referring to relevant industry standards can provide more specific temperature guidelines for a particular stainless steel grade.

Industrial stainless steel pipes are available in a wide range of sizes and dimensions to meet various application requirements. The sizes of stainless steel pipes typically include the outer diameter (OD), wall thickness (WT), and length. Common OD sizes for industrial stainless steel pipes range from small diameters, such as 1/8″ (3.175 mm), to larger diameters, such as 36″ (914.4 mm) or even larger for specialized applications. The wall thicknesses can vary depending on the specific requirements and pressure ratings of the application. Standard lengths for industrial stainless steel pipes are typically 20 feet (6.1 meters) or 40 feet (12.2 meters), but custom lengths can also be provided.

It’s important to note that the availability of sizes and dimensions may vary depending on the specific grade and type of stainless steel pipe. Stainless steel pipe suppliers and manufacturers can provide detailed information on the available sizes and dimensions for industrial stainless steel pipes based on their product offerings.

Yes, industrial stainless steel pipes are compatible with various types of fittings and connectors. Stainless steel pipes use standard pipe threading or other types of connectors, such as compression fittings, flanges, or welding connections, depending on the specific application and installation requirements. Stainless steel pipes have wide compatibility and can be easily connected to valves, elbows, tees, reducers, and other fittings commonly used in industrial piping systems.

It’s essential to ensure that the fittings and connectors used with industrial stainless steel pipes are also made of compatible materials, such as stainless steel or other suitable alloys, to maintain the integrity and performance of the overall system. Stainless steel pipe suppliers and manufacturers can provide guidance on the appropriate fittings and connectors for specific applications and offer a range of compatible options to ensure proper installation and functionality.

Yes, industrial stainless steel pipes are often available in custom lengths or configurations to meet specific project requirements. Stainless steel pipe suppliers and manufacturers understand that different applications may require pipes of varying lengths, diameters, and configurations. They offer flexibility in terms of customization, allowing customers to order pipes cut to specific lengths or with unique configurations to fit their specific needs.

Customization options may include the choice of diameter, wall thickness, and end connections. Stainless steel pipe suppliers can provide guidance and assistance in determining the most suitable specifications for the desired application and offer tailored solutions to ensure optimal performance and compatibility with the existing system.

It’s advisable to discuss custom requirements with the stainless steel pipe supplier or manufacturer to ensure accurate and precise specifications and to obtain pipes that are perfectly tailored to the project’s needs.

BLOGS

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China