Do you have any questions about our products or are you looking for a professional seamless stainless steel pipe supplier?

seamless stainless steel pipe for automobile industry

-

Specifications: ASTM A731, A268 / ASME SA731, SA268

-

Sizes: From 1/2″ NB to 24″ NB

-

Types: Seamless, Welded, EFW, ERW, Manufacturing

-

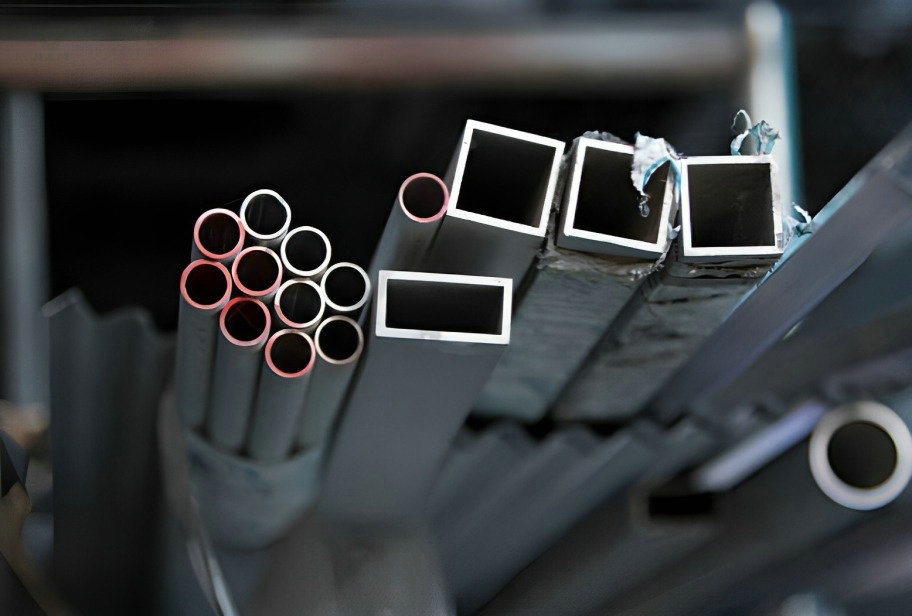

Forms: Round pipes, square pipes, rectangular pipes, elliptical pipes, hydraulic pipes, etc.

-

Certification: ISO9001:2015

-

MOQ: 2MT

-

Payment method: T/T, LC

-

Price: Inquiry Factory Price Now

Seamless Stainless Steel for automobile industry Data Sheet

chemical composition of automobile industry stainless steel pipe

| Grade | Chromium (Cr) | Nickel (Ni) | Carbon (C) | Manganese (Mn) | Silicon (Si) | Phosphorus (P) | Sulfur (S) |

|---|---|---|---|---|---|---|---|

| 1.4301 (AISI 304) | 18.0 – 20.0% | 8.0 – 10.5% | ≤ 0.07% | ≤ 2.0% | ≤ 1.0% | ≤ 0.045% | ≤ 0.015% |

| 1.4401 (AISI 316) | 16.5 – 18.5% | 10.0 – 13.0% | ≤ 0.07% | ≤ 2.0% | ≤ 1.0% | ≤ 0.045% | ≤ 0.015% |

| 1.4512 (AISI 409) | 10.5 – 12.5% | – | ≤ 0.08% | ≤ 1.0% | ≤ 1.0% | ≤ 0.045% | ≤ 0.015% |

| 1.4307 (AISI 304L) | 18.0 – 20.0% | 8.0 – 12.0% | ≤ 0.030% | ≤ 2.0% | ≤ 1.0% | ≤ 0.045% | ≤ 0.015% |

| 1.4016 (AISI 430) | 16.0 – 18.0% | – | ≤ 0.08% | ≤ 1.0% | ≤ 1.0% | ≤ 0.040% | ≤ 0.015% |

| 1.4541 (AISI 321) | 17.0 – 19.0% | 9.0 – 12.0% | ≤ 0.08% | ≤ 2.0% | ≤ 1.0% | ≤ 0.045% | ≤ 0.015% |

| 1.4404 (AISI 316L) | 16.5 – 18.5% | 10.0 – 13.0% | ≤ 0.03% | ≤ 2.0% | ≤ 1.0% | ≤ 0.045% | ≤ 0.015% |

| 1.4818 (ASTM S30415) | 20.0 – 23.0% | 8.0 – 12.0% | ≤ 0.11% | ≤ 2.0% | ≤ 1.0% | ≤ 0.040% | ≤ 0.015% |

| 1.4835 (ASTM S30815) | 20.0 – 22.0% | 10.0 – 12.0% | ≤ 0.10% | ≤ 1.50% | ≤ 1.50% | ≤ 0.040% | ≤ 0.015% |

| 1.4833 (AISI 309) | 22.0 – 24.0% | 12.0 – 15.0% | ≤ 0.20% | ≤ 2.0% | ≤ 1.0% | ≤ 0.045% | ≤ 0.015% |

| 1.4845 (AISI 310) | 24.0 – 26.0% | 19.0 – 22.0% | ≤ 0.25% | ≤ 2.0% | ≤ 1.0% | ≤ 0.045% | ≤ 0.015% |

| – (AISI 442) | 19.5 – 22.5% | 0.6 – 1.0% | ≤ 0.15% | ≤ 1.0% | ≤ 1.0% | ≤ 0.04% | ≤ 0.03% |

| 1.4762 (AISI 446) | 23.0 – 27.0% | 0.3 – 0.6% | – | ≤ 2.0% | ≤ 1.0% | ≤ 0.040% | ≤ 0.03% |

physical property of automobile industry stainless steel pipe

| Grade | Density (g/cm³) | Thermal Expansion (20-100°C) (µm/m°C) | Thermal Conductivity (W/m·K) | Specific Heat Capacity (J/g·K) | Electrical Resistivity (μΩ·cm) |

|---|---|---|---|---|---|

| 1.4301 (AISI 304) | 7.93 | 16.0 | 16.2 | 0.50 | 0.72 |

| 1.4401 (AISI 316) | 8.00 | 16.5 | 14.6 | 0.50 | 0.74 |

| 1.4512 (AISI 409) | 7.74 | 10.2 | 25.2 | 0.49 | 1.17 |

| 1.4307 (AISI 304L) | 7.93 | 16.0 | 16.2 | 0.50 | 0.72 |

| 1.4016 (AISI 430) | 7.75 | 11.0 | 25.0 | 0.47 | 0.60 |

| 1.4541 (AISI 321) | 7.98 | 16.2 | 16.3 | 0.50 | 0.75 |

| 1.4404 (AISI 316L) | 8.00 | 16.5 | 14.6 | 0.50 | 0.75 |

| 1.4818 (ASTM S30415) | 7.90 | 15.0 | 14.9 | 0.50 | 0.70 |

| 1.4835 (ASTM S30815) | 7.85 | 16.2 | 17.1 | 0.49 | 0.90 |

| 1.4833 (AISI 309) | 7.90 | 15.0 | 14.7 | 0.50 | 0.75 |

| 1.4845 (AISI 310) | 7.90 | 15.5 | 14.9 | 0.50 | 0.75 |

| – (AISI 442) | 7.60 | 11.2 | 26.1 | 0.47 | 1.11 |

| 1.4762 (AISI 446) | 7.80 | 10.5 | 24.1 | 0.47 | 1.06 |

mechanical property of automobile industry stainless steel pipe

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HRC) |

|---|---|---|---|---|

| 1.4301 (AISI 304) | 520 | 210 | 45 | 92 |

| 1.4401 (AISI 316) | 530 | 215 | 45 | 95 |

| 1.4512 (AISI 409) | 380 | 310 | 22 | 88 |

| 1.4307 (AISI 304L) | 520 | 210 | 45 | 92 |

| 1.4016 (AISI 430) | 450 | 205 | 22 | 85 |

| 1.4541 (AISI 321) | 515 | 205 | 40 | 92 |

| 1.4404 (AISI 316L) | 520 | 210 | 45 | 92 |

| 1.4818 (ASTM S30415) | 480 | 220 | 45 | 88 |

| 1.4835 (ASTM S30815) | 590 | 350 | 30 | 90 |

| 1.4833 (AISI 309) | 590 | 320 | 40 | 95 |

| 1.4845 (AISI 310) | 590 | 320 | 40 | 95 |

| – (AISI 442) | 480 | 280 | 18 | 92 |

| 1.4762 (AISI 446) | 450 | 220 | 20 | 94 |

Product Description Of

Seamless Stainless Steel for automobile industry

Seamless stainless steel pipes play a pivotal role in the automobile industry, offering an ideal combination of precision, durability, and corrosion resistance. Engineered with meticulous attention to detail, automobile industry stainless steel pipe seamlessly fits into the demanding automotive environment. Seamless stainless steel pipe for automobile industry exhibit exceptional resistance to corrosion, even in the face of moisture, road salts, and other corrosive elements, ensuring a prolonged lifespan. SS pipe for automobile industry facilitate a smooth and uninterrupted flow of fluids, minimizing turbulence and energy consumption. Their high strength enhances the structural integrity of various automotive components, effectively withstanding mechanical stress and vibrations. This reduced maintenance requirement, coupled with their robust performance, contributes to cost savings and increased vehicle reliability. Manufacturers in the automotive sector rely on seamless stainless steel pipes for the quality and precision they bring, guaranteeing safe and dependable vehicles for consumers.

features Of Seamless Stainless Steel for automobile industry

The feature of heat resistance in seamless stainless steel pipes for the automobile industry is a crucial aspect driven by the material’s exceptional properties. Stainless steel, renowned for its heat-resistant characteristics, provides several advantages in this context.

Stainless steel alloys, such as those used in seamless pipes for automobiles, exhibit remarkable thermal stability, allowing them to withstand the extreme temperatures generated in exhaust systems. The scientific explanation behind this heat resistance lies in the alloy’s composition and microstructure.

The key factors contributing to the heat resistance of seamless stainless steel pipes include:

High Chromium Content: Stainless steel alloys contain a significant amount of chromium. This element forms a protective oxide layer on the surface of the steel when exposed to heat, preventing further oxidation and corrosion. This oxide layer remains stable even at elevated temperatures.

Austenitic Structure: Many stainless steel grades used in the automotive industry, like AISI 304 and AISI 316, possess an austenitic microstructure. This structure offers excellent high-temperature mechanical properties, including strength and ductility, making it suitable for withstanding thermal stresses.

Thermal Expansion: Stainless steel’s low thermal expansion coefficient helps maintain dimensional stability when exposed to heat, reducing the risk of warping or deformation in exhaust systems.

Oxidation Resistance: The protective chromium oxide layer not only prevents corrosion but also resists oxidation, ensuring the material’s integrity even in the presence of aggressive exhaust gases at high temperatures.

The ability of seamless stainless steel pipes to resist heat is essential in the automobile industry, particularly in exhaust systems. These pipes can efficiently manage the extreme temperatures and harsh conditions, contributing to the durability and longevity of automotive components. Furthermore, the retention of material properties at high temperatures ensures the safety and performance of vehicles while reducing the need for frequent replacements or repairs, thus aligning with automotive industry standards and regulations.

The corrosion resistance of seamless stainless steel pipes in the automobile industry is a fundamental and scientifically intriguing characteristic. These seamless automobile industry stainless steel pipes play a vital role in enhancing the performance and longevity of exhaust systems due to their exceptional resistance to corrosive elements, especially in the form of exhaust gases. Let’s delve into the scientific underpinnings of this critical feature.

The corrosion resistance of seamless automobile industry stainless steel pipes is primarily attributed to the unique composition and microstructure of stainless steel alloys. Here’s a detailed explanation:

Passive Layer Formation: Stainless steel alloys, such as AISI 304 and AISI 316, contain a significant amount of chromium. When exposed to corrosive elements, like exhaust gases, the chromium within the alloy reacts with oxygen in the environment to form a protective oxide layer on the surface of the steel. This passive layer acts as a barrier, preventing further contact between the corrosive substances and the underlying metal.

Chromium Content: The presence of a minimum chromium content, typically above 10.5%, is crucial. Higher chromium content results in a more robust and protective passive layer, enhancing the steel’s resistance to corrosion.

Acid and Pitting Resistance: Stainless steel’s corrosion resistance extends to acidic conditions and even pitting corrosion, a form of localized corrosion. The passive layer remains stable and self-repairing, maintaining its protective properties even in challenging environments.

Chemical Inertness: In addition to chromium, stainless steel also contains other alloying elements like nickel and molybdenum. These elements further enhance the steel’s resistance to a wide range of corrosive chemicals, making it suitable for withstanding the harsh and varied conditions within automotive exhaust systems.

Temperature Tolerance: Stainless steel’s corrosion resistance is not only limited to room temperature but also extends to the high temperatures encountered in exhaust systems. The passive layer remains intact and protective even when exposed to elevated temperatures.

The ability of seamless stainless steel pipe for automobile industry to resist corrosion in the presence of aggressive exhaust gases is critical for the automobile industry. It ensures that exhaust systems remain free from degradation, leaks, and structural damage, contributing to improved performance and the extended operational life of vehicles. Furthermore, the science behind this corrosion resistance aligns with industry standards, making stainless steel an ideal material for automotive exhaust applications.

The impact resistance of seamless stainless steel pipes in the automobile industry is a key attribute that stems from the material’s unique composition and microstructure. Understanding the scientific basis for this characteristic sheds light on its significance for various automotive applications.

Material Toughness: The impact resistance of seamless stainless steel pipe for automobile industry is closely related to the inherent toughness of stainless steel alloys. These alloys, including AISI 304 and AISI 316, are specifically designed to withstand mechanical stresses, making them ideal for applications where impact resistance is crucial.

Crystal Structure: Stainless steel alloys are primarily composed of an austenitic crystal structure. This crystal structure provides several advantages, including ductility and toughness. When subjected to impact forces, these crystals can deform and absorb energy, preventing fractures and structural failure.

Stress Absorption: The atomic arrangement in stainless steel allows it to effectively absorb and distribute the stress resulting from an impact. The presence of alloying elements, such as nickel and molybdenum, further enhances the steel’s ability to absorb impact energy, reducing the risk of cracks or structural failure.

Microstructural Characteristics: Stainless steel’s microstructure, with its fine-grained and homogeneous nature, contributes to its impact resistance. This microstructure allows for deformation without catastrophic failure, ensuring that the material retains its structural integrity.

Low-Temperature Toughness: Seamless stainless steel pipes maintain their impact resistance even at low temperatures. This is particularly important in the automotive industry, where vehicles are exposed to various weather conditions and temperature extremes.

Manufacturing Consistency: The seamless manufacturing process ensures the structural integrity and consistency of stainless steel pipes, further enhancing their impact resistance. Seamless pipes are devoid of welds, which can act as stress concentration points.

The impact resistance of seamless stainless steel pipe for automobile industry is a crucial factor in various automotive applications, such as exhaust systems and structural components. The scientifically designed material properties allow these pipes to withstand mechanical stresses, impacts, and vibrations that vehicles encounter during operation. The result is a longer service life and reduced maintenance, contributing to the overall safety and durability of automobiles. The science behind this impact resistance reinforces the suitability of stainless steel for the demanding conditions of the automobile industry.

The exceptional strength-to-weight ratio of seamless stainless steel pipe for automobile industry is a fundamental attribute that underlines their suitability for a wide range of applications in the automotive industry. Understanding the scientific basis for this characteristic provides insights into why seamless stainless steel pipes are favored in this context.

Material Composition: The strength-to-weight ratio of seamless automobile industry stainless steel pipe is primarily attributed to its alloy composition. Stainless steel is an iron-based alloy with the addition of elements such as chromium, nickel, and molybdenum. These alloying elements alter the material’s microstructure, enhancing its strength properties without significantly increasing its weight.

Crystal Structure: Stainless steel alloys predominantly feature an austenitic crystal structure. This crystal structure is inherently strong and contributes to the material’s ability to withstand mechanical stresses. The fine and uniform arrangement of atoms in this structure provides high tensile strength while maintaining a relatively low density.

Alloying Elements: The alloying elements in stainless steel play a crucial role in enhancing the strength-to-weight ratio. Chromium, for example, increases the material’s tensile strength, while nickel and molybdenum enhance its overall mechanical properties. These elements work together to provide excellent strength without excessive weight.

Density and Mass: Stainless steel is characterized by its relatively low density compared to many other materials used in the automotive industry. This lower density means that, for a given volume, stainless steel components are lighter than their counterparts made of alternative materials, such as cast iron or carbon steel.

High Tensile Strength: Seamless stainless steel pipes offer high tensile strength, which is the material’s ability to withstand axial loads. This property is essential in automotive applications, especially for components subjected to tensile stresses, such as exhaust systems and structural elements.

Optimized Wall Thickness: Seamless manufacturing processes allow for precise control of the pipe’s wall thickness. This optimization ensures that the pipe provides the necessary strength while avoiding unnecessary weight. Thinner walls are possible without compromising strength, resulting in a more efficient design.

Durability and Longevity: The strength-to-weight ratio contributes to the durability and longevity of seamless stainless steel pipes. These components can withstand the mechanical stresses and vibrations experienced in automotive applications while maintaining their structural integrity over time.

In summary, the remarkable strength-to-weight ratio of seamless stainless steel pipe for automobile industry is the outcome of a well-designed alloy composition, crystal structure, and manufacturing processes. This characteristic allows these pipes to offer the required mechanical strength for automotive applications without adding unnecessary weight. The scientific principles underlying this property confirm the suitability of seamless stainless steel pipes in the automotive industry, where a balance of strength and weight is critical for performance, fuel efficiency, and safety.

The hygienic properties of seamless automobile industry stainless steel pipes are of paramount importance in the automotive industry, especially in applications where cleanliness and sterility are essential. A scientific perspective on this characteristic illuminates why seamless stainless steel pipes are the preferred choice for maintaining hygiene in various automotive components.

Non-Porous Surface: Stainless steel pipes, especially those with seamless construction, feature a non-porous surface. This non-porosity arises from the intrinsic properties of stainless steel, where the crystalline structure leaves no room for gaps or interstices. This means that there are no tiny openings or voids on the pipe’s surface, eliminating the potential for contaminants to lodge in microscopic spaces.

Resistance to Corrosion: Stainless steel, as a material, exhibits an exceptional resistance to corrosion. This property is attributed to the presence of chromium, which forms a protective oxide layer on the surface of the stainless steel. This oxide layer acts as a barrier, preventing corrosive agents, including chemicals and environmental factors, from interacting with the material. In an automotive context, this corrosion resistance ensures that the pipe’s surface remains unharmed and unaffected by exposure to harsh conditions.

Ease of Cleaning: The smooth, non-porous surface of seamless stainless steel pipes simplifies the cleaning process. Contaminants and residues, such as oils, fuels, or particulate matter, can be easily removed from the surface. Furthermore, the absence of cracks or fissures means there are no hidden areas where contaminants might accumulate. The surface can be cleaned with various sanitizing agents, making it suitable for applications where cleanliness is critical, such as food transport or medical devices within vehicles.

Sterilization Capability: Stainless steel can withstand high-temperature sterilization processes, such as autoclaving, without degradation. This ability is crucial in applications where sterility is paramount, such as medical instruments or components that come into contact with food or pharmaceuticals during transport. The stainless steel pipe’s surface can be reliably sterilized without compromising its integrity, ensuring the elimination of harmful microorganisms and contaminants.

Longevity: The hygienic properties of seamless stainless steel pipes contribute to their longevity. The absence of corrosion and the ease of maintaining a clean and sterilized surface ensures that the pipes can withstand the test of time in demanding automotive applications, where durability and consistent performance are imperative.

Safety: The non-reactive nature of stainless steel, along with its hygienic properties, enhances safety in automotive applications. Contaminants or residues on surfaces can lead to corrosion, mechanical failure, or contamination, posing risks to both the vehicle’s operation and the safety of its occupants. The hygienic properties of seamless stainless steel pipes mitigate these risks by providing a clean, sterile, and corrosion-resistant environment.

In conclusion, the hygienic properties of seamless stainless steel pipes in the automotive industry are a result of their non-porous surface, corrosion resistance, ease of cleaning, sterilization capability, longevity, and safety-enhancing characteristics. These properties, rooted in scientific principles, make seamless automobile industry stainless steel pipes the material of choice for maintaining cleanliness and hygiene in various automotive applications, ultimately ensuring both performance and safety.

The fire resistance of seamless stainless steel pipes in the automobile industry is a crucial characteristic that can be explained scientifically. Understanding how seamless stainless steel pipe for automobile industry withstand high temperatures and contribute to the safety and reliability of automotive applications provides valuable insights.

Thermal Conductivity: Stainless steel is known for its relatively low thermal conductivity compared to other materials. This property is beneficial for fire resistance. When exposed to high temperatures, the stainless steel pipe acts as a thermal barrier, limiting the transfer of heat. This helps protect sensitive components, wiring, and other materials in the vicinity of the pipe from direct exposure to extreme heat.

High Melting Point: Stainless steel has a high melting point, making it exceptionally heat-resistant. The exact melting point varies depending on the specific grade of stainless steel, but it is significantly higher than typical operating temperatures in automotive applications. This means that even under extreme conditions, such as engine fires, stainless steel pipes remain structurally stable and do not melt or lose their integrity.

Oxidation Resistance: Stainless steel’s resistance to oxidation at high temperatures is another essential factor in its fire resistance. When exposed to elevated temperatures, stainless steel forms a protective oxide layer on its surface. This oxide layer acts as a shield, preventing the underlying metal from reacting with oxygen and undergoing combustion. As a result, the stainless steel pipe remains fire-resistant and maintains its structural strength.

Non-Combustible Material: Stainless steel is inherently non-combustible. It does not fuel or contribute to fires. This non-combustibility is especially important in automotive applications where safety is paramount. In the event of a fire, a seamless stainless steel pipe will not release flammable gases or add to the intensity of the fire. This characteristic is critical for passenger safety and the overall protection of the vehicle.

Structural Integrity: Even when exposed to high temperatures, seamless stainless steel pipes retain their structural integrity. This property ensures that the pipes continue to perform their intended functions during and after a fire event. For example, exhaust systems and other critical components relying on the stainless steel pipe can maintain their shape and functionality even in the presence of extreme heat.

Reduction of Fire Spread: The fire-resistant nature of seamless automobile industry stainless steel pipes can help contain and limit the spread of fires in automotive applications. By withstanding high temperatures without igniting or weakening, these pipes act as barriers, preventing the fire from rapidly spreading to other areas of the vehicle.

In summary, the fire resistance of seamless stainless steel pipes in the automobile industry is grounded in their low thermal conductivity, high melting point, oxidation resistance, non-combustibility, structural integrity, and their role in reducing the spread of fires. These scientific attributes ensure the safety and reliability of automotive components, making seamless stainless steel pipes a preferred choice in applications where fire resistance is a critical factor.

The characteristic of “Long-Term Value” in seamless stainless steel pipes for automobile industry is rooted in several scientific aspects that explain their enduring worth in automotive applications:

Corrosion Resistance: Stainless steel, including the seamless pipes used in the automotive industry, has exceptional corrosion resistance. This property arises from the formation of a passive oxide layer on the steel’s surface. This layer acts as a shield against environmental factors, such as moisture, chemicals, and road salts. As a result, stainless steel pipes remain corrosion-free even in harsh conditions. This resistance to corrosion ensures that the pipes have a prolonged service life and continue to function optimally over time.

Aging Resistance: Seamless stainless steel pipe for automobile industry are highly resistant to aging processes. They do not experience the same degradation mechanisms that affect other materials. For example, they are immune to rust and do not weaken over time due to environmental exposure. This aging resistance is a fundamental aspect of their long-term value because it means that the pipes maintain their structural integrity and performance characteristics for an extended period.

Fatigue Strength: Stainless steel is known for its high fatigue strength. In the context of the automobile industry, this property is crucial. Seamless stainless steel pipe for automobile industry is subjected to constant vibrations, thermal cycling, and mechanical stresses during vehicle operation. Their high fatigue strength ensures that they do not develop cracks, fractures, or other structural issues over time, contributing to their long-term reliability.

Low Maintenance Requirements: The durability of seamless automobile industry stainless steel pipes significantly reduces maintenance demands. Unlike some other materials that may require frequent inspections, repairs, or replacements, stainless steel pipes remain virtually maintenance-free. This low maintenance requirement translates to cost savings and increased operational efficiency over the life of the vehicle.

Environmental Resistance: Automobiles encounter various environmental conditions, from extreme temperatures to exposure to road debris and chemicals. Seamless stainless steel pipes are built to withstand these challenges. Their resistance to environmental factors ensures that they do not degrade or deteriorate over time, contributing to their long-term value.

Recyclability: Stainless steel is highly recyclable, and this is an environmentally responsible aspect of its long-term value. At the end of their service life, stainless steel pipes can be recycled, reducing the demand for new raw materials and minimizing environmental impact.

Economic Considerations: While the initial cost of seamless stainless steel pipes may be higher than some alternatives, their long-term value becomes evident over time. The extended service life, reduced maintenance expenses, and minimized need for replacements make them a cost-effective choice in the long run.

In conclusion, the long-term value of seamless stainless steel pipes in the automobile industry is scientifically underpinned by their corrosion resistance, aging resistance, fatigue strength, low maintenance requirements, environmental resistance, recyclability, and economic considerations. These attributes ensure that seamless stainless steel pipe for automobile industry provides enduring performance and reliability, making them a valuable choice for automotive applications.

application Of Seamless Stainless Steel for automobile industry

| Grade | Stainless Steel Type | Typical Applications |

|---|---|---|

| 1.4301 (AISI 304) | Austenitic | High corrosion resistance for internal components, fuel tanks. |

| 1.4401 (AISI 316) | Austenitic | Suitable for environments with chlorides. |

| 1.4512 (AISI 409) | Ferritic | Used for applications requiring moderate oxidation resistance, such as exhaust systems. |

| 1.4307 (AISI 304L) | Low Carbon Austenitic | Commonly used in automotive exhaust systems and fuel tanks. |

| 1.4016 (AISI 430) | Ferritic | Used for manufacturing hose clamps. |

| 1.4541 (AISI 321) | Austenitic | Commonly used for manufacturing catalytic converters and turbocharger housings. |

| 1.4404 (AISI 316L) | Austenitic | Often used for making catalytic converter and turbocharger housings. |

| 1.4818 (ASTM S30415)[153 MA] | Austenitic | Frequently used for manufacturing catalytic converter and turbocharger housings. |

FAQ

Seamless stainless steel pipe for automobile industry play a pivotal role across various applications in the automobile industry. Here’s a closer look at how they are employed:

1. Exhaust Systems: Seamless stainless steel pipe for automobile industry is widely favored for automotive exhaust systems due to their exceptional heat resistance and robust durability. They can withstand the high-temperature, corrosive environment of exhaust gases, contributing to enhanced performance and longevity of the exhaust systems.

2. Intake Manifolds: In the realm of intake systems, stainless steel pipes are utilized for creating intake manifolds, ensuring efficient air and fuel delivery to the engine.

3. Front Pipes: As integral components of exhaust systems, front pipes are a key application area for seamless stainless steel pipes. Their ability to resist heat and corrosion ensures the longevity of these critical components.

4. Flexible Hoses: Flexible hoses are essential in connecting various automotive components. Stainless steel pipes are preferred due to their superior strength and resistance to corrosion, ensuring long-lasting performance in critical connections.

5. Catalytic Converters: Automotive catalytic converters need to endure high temperatures and corrosive exhaust gases. Thus, they are often manufactured using stainless steel, which provides the necessary resilience and longevity.

6. Center Pipes: Center pipes, another crucial part of exhaust systems, benefit from the versatility and durability of stainless steel pipes, ensuring the efficient evacuation of exhaust gases.

7. Mufflers: Mufflers demand materials that can withstand high temperatures and resist corrosion effectively. Stainless steel, with its excellent thermal properties and corrosion resistance, is an ideal choice for manufacturing mufflers.

These various applications make use of the outstanding properties of stainless steel, including its exceptional weldability, formability, corrosion resistance, and high tensile strength. This not only fulfills the stringent performance requirements of the automotive industry but also contributes to reduced weight and improved fuel efficiency. In fulfilling these vital roles, stainless steel pipe suppliers serve as key partners in the automotive sector, providing high-quality components that drive performance, longevity, and efficiency.

Utilizing seamless stainless steel pipes in automotive applications offers a multitude of key advantages, making them a preferred choice:

1. Exceptional Durability: Seamless stainless steel pipe for automobile industry is known for their robust durability, with the ability to withstand challenging conditions, including high temperatures and corrosive exhaust gases, ensuring long service life for automotive components.

2. Superior Corrosion Resistance: Seamless stainless steel pipe for automobile industry exhibits exceptional resistance to corrosion, a crucial factor in exhaust and intake systems where exposure to corrosive elements is constant. This resistance contributes to prolonged component life and consistent performance.

3. High-Temperature Resistance: Stainless steel’s innate heat resistance allows these pipes to handle the elevated temperatures associated with exhaust systems, catalytic converters, and turbochargers without deforming or losing structural integrity.

4. Excellent Strength-to-Weight Ratio: Stainless steel offers an exceptional strength-to-weight ratio, allowing for sturdy components without adding unnecessary weight to the vehicle. This feature is essential for maintaining fuel efficiency and overall performance.

5. Hygienic Properties: Seamless stainless steel pipe for automobile industry is easy to clean and sterilize, making them suitable for applications requiring cleanliness. This is especially vital in the automotive sector where exhaust and intake systems should meet strict hygiene standards.

6. High-Quality Welding: Stainless steel’s superior weldability allows for precise and reliable welding processes. This results in leak-free and robust connections, ensuring the integrity of the entire automotive system.

Stainless steel pipe suppliers are key partners in the automotive industry, providing components that combine these advantages to meet the sector’s demanding performance and longevity requirements.

Seamless stainless steel pipe for automobile industry plays a pivotal role in enhancing fuel efficiency in vehicles through several scientific mechanisms:

Reduced Weight: Stainless steel pipe for automobile industry offer excellent strength-to-weight ratios. By utilizing these pipes in exhaust and intake systems, automakers can achieve the desired structural integrity with minimal weight addition. This weight reduction contributes to improved fuel efficiency, as the vehicle requires less energy to move.

Enhanced Heat Management: The heat-resistant nature of stainless steel pipe for automobile industry allows for more efficient exhaust gas management. By optimizing temperature levels within the exhaust system, the engine can operate within its ideal temperature range, improving combustion efficiency and fuel economy.

Corrosion Resistance: Seamless stainless steel pipes’ resistance to corrosion is critical in exhaust systems exposed to acidic and corrosive exhaust gases. Maintaining the structural integrity of exhaust components over time ensures consistent performance and prevents leaks, which could adversely affect fuel efficiency.

Durable Design: Stainless steel pipes’ durability and longevity minimize the need for replacements or repairs. This, in turn, reduces downtime and maintenance costs, contributing to greater vehicle uptime and improved fuel efficiency.

In collaboration with stainless steel pipe suppliers, automotive manufacturers harness the scientific properties of seamless stainless steel pipes to create more fuel-efficient vehicles by reducing weight, optimizing temperature management, and ensuring the durability of critical components.

Seamless stainless steel pipe for automotive industry offer notable cost-effectiveness when compared to other materials for automotive applications, and this is supported by the expertise of stainless steel pipe suppliers. Here’s why:

Longevity and Low Maintenance: Stainless steel pipe for automobile industry have a longer lifespan than many alternative materials due to their corrosion resistance. This results in reduced maintenance and replacement costs, making them a cost-effective choice over the long term.

Reduced Fuel Consumption: Seamless stainless steel pipe for automobile industry contribute to improved fuel efficiency, as previously explained. Lower fuel consumption leads to long-term cost savings for vehicle owners and operators.

Downtime Reduction: The durability and reliability of stainless steel pipe for automobile industry result in reduced vehicle downtime for repairs or replacements. This, in turn, increases productivity and minimizes revenue losses, making stainless steel a cost-effective option.

Environmental Considerations: With stricter emissions regulations, stainless steel pipe for automobile industry help vehicles meet environmental standards. By avoiding penalties and modifications to meet regulations, manufacturers save on potential non-compliance costs.

Optimized Manufacturing: Collaborating with stainless steel pipe suppliers allows automakers to optimize manufacturing processes. The inherent properties of stainless steel can lead to reduced manufacturing and assembly costs.

In summary, while the initial material cost of seamless automotive industry stainless steel pipes might be higher than some alternatives, their cost-effectiveness shines through in terms of longevity, reduced maintenance, improved fuel efficiency, and overall vehicle reliability, making them a favored choice for the automotive industry, supported by the expertise of stainless steel pipe suppliers.

Certainly, seamless stainless steel pipes can be welded or modified to suit various automotive applications, and the expertise of stainless steel pipe suppliers plays a crucial role in this process. Here’s how:

Welding Flexibility: Seamless stainless steel pipe for automobile industry can be welded to create custom shapes or lengths. This adaptability allows manufacturers to design exhaust systems, intake pipes, or other components tailored to specific vehicle models and performance requirements.

Joining Capabilities: Welding seamlessly fuses sections of stainless steel pipe for automobile industry together. This ability is advantageous in the assembly of intricate exhaust systems, ensuring a tight fit, minimal leakage, and optimized exhaust flow.

Modification for Specialized Applications: The high ductility of stainless steel allows it to be bent, flared, or shaped to meet specific automotive needs. This is particularly useful when designing components for unique or high-performance vehicles.

End-to-End Solutions: Stainless steel pipe suppliers often offer comprehensive solutions, including welding, bending, and custom fabrication services. This ensures that manufacturers can obtain fully customized stainless steel pipe components for their automotive applications.

Strength and Durability: Welded and modified stainless steel pipes maintain their exceptional strength, durability, and resistance to corrosion, even after modifications. This ensures the longevity of automotive components.

In essence, seamless stainless steel pipe for automobile industry, supported by the expertise of stainless steel pipe suppliers, provide the versatility and reliability required to meet the diverse demands of the automotive industry. Whether for standard vehicles or specialized applications, stainless steel pipes can be adapted through welding and modifications to fulfill specific requirements.

other seamless stainless steel pipe products

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WeChat: +86 13381673250

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China