Stainless Steel Tube For Papermaking Supplier

GB/T14976-2002 Stainless Steel Seamless Pipe for Fluid Transport

ASTM A312 Seamless and Welded Austenitic Stainless Steel Tube

ASTM A789 Ferrite/Austenitic Stainless Steel Seamless and Welded Steel Tube for General Use

JIS G3448 Stainless Steel Tube

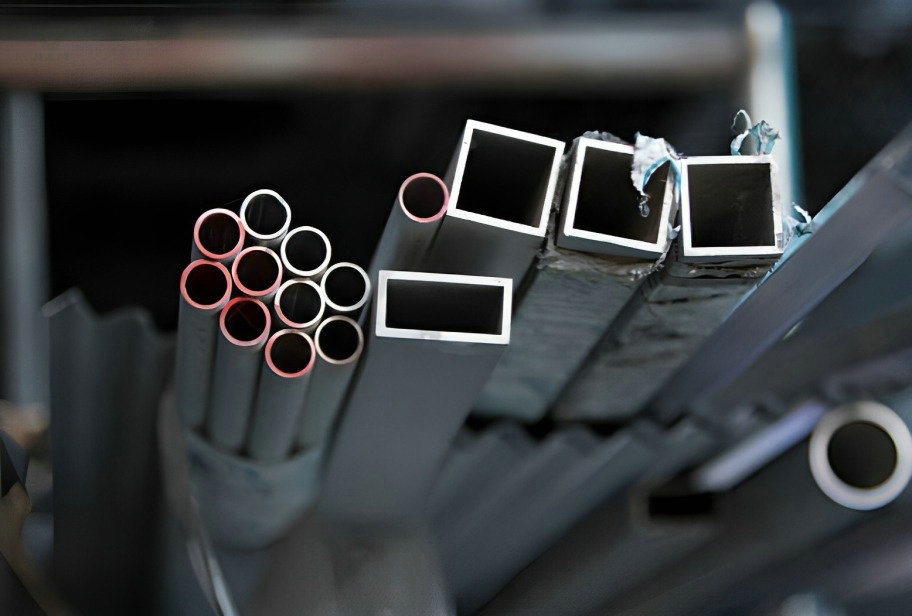

Product Description of Stainless Steel Tube For Papermaking

The Stainless Steel Tube for Papermaking is designed to meet the specific demands of paper production processes. Crafted from corrosion-resistant stainless steel, these tubes offer exceptional durability and longevity, ensuring reliable performance even in harsh papermaking environments. They provide efficient fluid transportation, contributing to the seamless pipe operation of paper machinery and enhancing the overall productivity of paper mills. These seamless pipe are meticulously engineered to withstand the challenges of the papermaking industry, making them an essential component for maintaining efficient and smooth paper production processes.

specification of Stainless Steel Tube For Papermaking

Production Standard of Stainless Steel Tube For Papermaking

GB/T14976-2002 Stainless Steel Seamless Pipe for Fluid Transport

ASTM A312 Seamless Pipe and Welded Austenitic Stainless Steel Tube

ASTM A789 Ferrite/Austenitic Stainless Steel Seamless Pipe and Welded Steel Tube for General Use

JIS G3448 Stainless Steel Tube

Main grade description in different standard

ASTM | DIN / EN | JIS | GB | ISO Name | Other |

S20100 201 | 1.4372 | SUS201 | S35350 | X12CrMnNiN17–7-5 | J1 L1 LH 201J1 |

S20200 202 | 1.4373 | SUS202 | S35450 | X12CrMnNiN18–9-5 | 202 L4, 202 J4, 202 J3 |

S30400 304 | 1.4301 | SUS304 | S30408 | X5CrNi18-10 | 06Cr19Ni10 0Cr18Ni9 |

S31603 316L | 1.4404 | SUS316L | S31603 | X2CrNiMo17-12-2 | 022Cr17Ni12Mo2 00Cr17Ni14Mo2 |

S40900 409 | – | SUH409 | S11168 | X5CrTi12 | 0Cr11Ti |

S40910 409L | 1.4512 | SUH409L | S11163 | X2CrTi12 | 00Cr11Ti 022Cr11Ti |

S41008 410S | 1.4000 | SUS410S | S11306 | X6Cr13 | – |

S43000 430 | 1.4016 | SUS430 | 10Cr17 | X6Cr17 | 1Cr17 |

characteristics of Stainless Steel Tube For Papermaking

Stainless Steel Tubes for Papermaking exhibit exceptional corrosion resistance, making them ideal for use in the harsh and corrosive environments of paper production processes. The stainless steel material used in these tubes contains alloying elements like chromium and nickel, which form a protective oxide layer on the surface, preventing corrosion and deterioration. This resistance to corrosion ensures that the tubes maintain their structural integrity and performance over an extended service life, reducing the need for frequent replacements and minimizing production downtime. Whether exposed to moisture, chemicals, or other corrosive agents commonly found in papermaking, these tubes reliably maintain their functionality, contributing to the efficiency and reliability of paper production operations.

Stainless Steel Tubes for Papermaking offer remarkable high-temperature resistance, a crucial attribute for their application in paper production processes. These tubes are often exposed to elevated temperatures during various stages of paper manufacturing, such as drying and pressing. The inherent heat-resistant properties of stainless steel, coupled with its alloy composition, enable these tubes to withstand the thermal stresses and fluctuations encountered in papermaking operations. The tubes retain their structural integrity and mechanical properties even at high temperatures, ensuring reliable and consistent performance throughout the demanding paper production cycle. This high-temperature resistance contributes to the efficiency and longevity of the tubes, ultimately supporting the smooth operation of papermaking facilities.

Durability is a key characteristic of Stainless Steel Tubes for Papermaking. These tubes are designed to withstand the harsh and demanding conditions present in paper manufacturing processes. The corrosive and abrasive nature of chemicals, pulp, and other materials used in papermaking can take a toll on equipment. Stainless steel’s exceptional durability ensures that these tubes can resist corrosion, erosion, and wear over prolonged usage. This durability extends the service life of the tubes, reducing the need for frequent replacements and minimizing downtime. With their robust construction and resistance to environmental factors, Stainless Steel Tubes for Papermaking provide a reliable and long-lasting solution for the paper industry’s needs.

Stainless Steel Tubes for Papermaking boast a smooth interior surface, which is a crucial characteristic for optimal performance. The smoothness of the interior surface helps prevent the buildup of debris, residues, and contaminants that can affect the efficiency and quality of paper production. This feature ensures unimpeded fluid flow and minimizes the risk of blockages, reducing maintenance and operational disruptions. The smooth interior surface of these tubes also contributes to consistent and reliable paper production, making them a preferred choice for the demanding requirements of the papermaking industry.

Stainless Steel Tubes for Papermaking are constructed with a seamless design, offering numerous advantages for the paper production process. Seamless construction eliminates the presence of welds or joints, ensuring a continuous and smooth inner surface. This characteristic prevents the accumulation of particles, residues, and other impurities that could hinder the papermaking process. The absence of seams also enhances the structural integrity of the tubes, reducing the risk of leaks or failure, and promoting consistent and efficient fluid flow. The seamless design of these tubes contributes to the reliability, durability, and overall performance required for the demanding papermaking industry.

Stainless Steel Tubes for Papermaking exhibit excellent compatibility with various chemicals and fluids commonly used in the paper manufacturing process. The corrosion-resistant nature of stainless steel ensures that the tubes can withstand exposure to acidic or alkaline substances, bleaching agents, and other chemicals encountered during pulping, bleaching, and refining stages. This compatibility minimizes the risk of tube degradation, maintains the integrity of fluids being transported, and contributes to the overall efficiency and reliability of the papermaking operation.

Stainless Steel Tubes for Papermaking offer exceptional versatility in a range of applications within the paper manufacturing industry. These tubes are designed to withstand the demanding conditions of paper production, from high temperatures and corrosive chemicals to the mechanical stresses of fluid transportation. Their corrosion resistance, durability, and smooth interior surface make them suitable for various roles, including transporting fluids, chemicals, and pulp throughout the papermaking process. This versatility ensures efficient and reliable operations, contributing to the overall quality and productivity of the paper industry.

application of Stainless Steel Tube For Papermaking

Stainless Steel Tubes for Papermaking find extensive application throughout the paper manufacturing process. Their unique characteristics make them well-suited for various critical functions within the industry:

- Pulp Processing: These tubes are employed in conveying pulp, chemicals, and additives from one processing stage to another. Their smooth interior surface prevents clogging and ensures efficient pulp transportation.

- Chemical Recovery: Stainless steel tubes are vital for transporting aggressive chemicals used in papermaking, such as bleaching agents and alkaline solutions. Their corrosion resistance safeguards against chemical degradation.

- Steam Condensation: Steam is used for drying paper in the manufacturing process. Stainless steel tubes serve as effective conduits for condensing and distributing steam, contributing to energy-efficient drying operations.

- Waste Water Treatment: Stainless steel tubes play a role in conveying waste water and slurry away from the paper mill. Their resistance to corrosion and chemicals ensures reliable transportation of these substances.

- Coating and Printing: In processes like coating and printing, where precision and uniformity are crucial, these tubes are used for transferring various coatings and colors to paper surfaces.

- Rolls Cooling: Stainless steel tubes facilitate the circulation of cooling water in rolls, preventing overheating and maintaining the proper operating conditions of machinery.

- Product Conveyance: From reel to the final product, these tubes help transport paper rolls, ensuring smooth movement throughout the production line.

- Waste Disposal: Stainless steel tubes assist in transporting waste materials, such as trimmings and rejected paper, for appropriate disposal or recycling.

In each of these applications, the tubes’ corrosion resistance, high-temperature tolerance, durability, and compatibility with various fluids and chemicals are paramount. They contribute to efficient and reliable papermaking processes, ultimately enhancing productivity and product quality. Stainless Steel Tubes for Papermaking are essential components that support the overall success of the paper industry.

FAQ

Stainless steel paper tubes are suitable for a wide range of pulp types, including but not limited to the following:

- Wood pulp (hardwood and softwood pulp): Wood pulp is a common raw material for papermaking, and stainless steel paper tubes can be used for conveying, treating and handling different types of wood pulp, such as poplar, pine, birch and so on.

- Waste pulp: Waste pulp is recovered from waste paper, used for environmental protection and resource recovery. Stainless steel paper tubes can be used for the transportation and treatment of waste pulp.

- Bamboo Pulp: Bamboo pulp is a non-woody fiber raw material, usually used to make specific types of paper. Stainless steel paper tubes can be used to convey and handle bamboo pulp.

- Linen fiber pulp: Linen fiber is a natural fiber raw material, can be used for specific types of pulp preparation. Stainless steel paper tubes can be used to handle flax fiber pulp.

- Grass pulp: grass pulp is prepared from plant grass fibers, commonly used in special-purpose paper manufacturing. Stainless steel paper tube can be used to transport and handle grass pulp.

In short, stainless steel paper tube has corrosion resistance, high temperature resistance and other characteristics, so that it is suitable for a variety of different types of pulp types, so as to meet the different needs of the paper industry.

Stainless steel pipes play a crucial role in the papermaking process by facilitating the transportation of various types of pulp, chemicals, and water within the paper mill. They are used in conveying raw materials such as wood pulp, recycled pulp, and other fiber types to different stages of the paper production line. Additionally, these pipes are essential for transporting chemicals and additives used in pulping, bleaching, and paper treatment processes. Their corrosion resistance and durability ensure the integrity of the papermaking process, while the expertise of stainless steel pipe suppliers ensures reliable and efficient materials for this demanding industry.

The maintenance frequency for stainless steel tubes used in papermaking depends on various factors, including the operating conditions, the type of pulp being processed, and the chemicals involved. Generally, stainless steel tubes are known for their corrosion resistance and durability, which can reduce the need for frequent maintenance. Regular inspections and cleaning are recommended to ensure optimal performance and prevent potential blockages or issues. Collaborating with reliable stainless steel pipe suppliers can provide guidance on maintenance schedules and best practices, helping to prolong the lifespan of the tubes and maintain smooth papermaking operations.

The pricing of stainless steel tubes for papermaking can vary based on factors such as tube dimensions, material grade, quantity, and supplier policies. Collaborating with reputable suppliers like Huaxiao stainless steel pipe suppliers can provide competitive pricing based on market trends and quality standards. It’s advisable to request a quote from the supplier, considering your specific requirements and budget, to determine the exact pricing for the stainless steel tubes needed for your papermaking processes.

Yes, stainless steel tubes designed for papermaking are suitable for various types of paper processes. They are commonly used in processes such as pulp production, paper forming, pressing, drying, and finishing. These tubes are particularly valued for their corrosion resistance, high temperature tolerance, and smooth interior surface, making them suitable for transporting and handling pulp and paper materials. Collaborating with reputable stainless steel pipe suppliers ensures that you can obtain tubes tailored to your specific paper process needs, ensuring efficient and reliable performance.

Yes, these stainless steel pipes for papermaking are manufactured to meet industry standards and specifications. Reputable stainless steel pipe suppliers like Huaxiao ensure that their products adhere to relevant quality standards, including those set by organizations such as ASTM (American Society for Testing and Materials) and other industry-specific standards. This ensures that the pipes meet the required performance, durability, and safety criteria for papermaking applications, providing you with reliable and high-quality products for your operations.

other products

Get In touch

Ready to Elevate Your Projects? Dive into our Stainless Steel Collection and Submit Your Specifications Today!

Phone/WhatsApp/WeChat:

+86 13052085117

Email: [email protected]

Address: RM557, NO.1388 Jiangyue Road, Shanghai China