201 Stainless Steel Sheet and Plate Supplier

Do you have any questions about our products or are you looking for a professional 201 stainless steel sheet and plate supplier?

- Specification: UNS S20100, SAE 30201, ASTM 201, DIN 1.4371, SUS 201, 12X17T9AH4

- Features: Corrosion resistance, high durability, and cost-effectiveness for general-purpose use.

- Thickness: 0.05mm – 200mm; Width: 600mm – 2000mm; Length: 500mm-12000mm

- Finish: 2B, 2D, Black, NO.1, Anneal pickling

Certification: ISO9001:2015

MOQ: 2MT

Payment method: T/T, LC

Price: Inquiry Factory Price 201 stainless steel sheets Now

201 Stainless Steel Sheets & Plates Specifications

-Cold Rolled 201 Stainless Steel Sheets and Plates, Cold rolled 201 sheets, Cold rolled 201 Plates

- Thickness: 0.05mm – 3.0mm

- Width: 600mm – 3500mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etcthe narrowed products pls check in strip products

- Length: 1000mm-6000mm

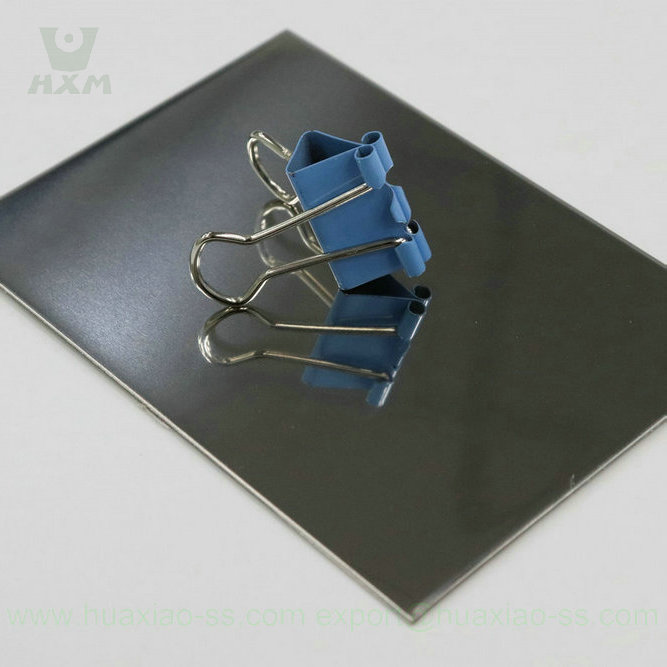

- Finish: 2B, 2D, BA, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching, etc

-Hot Rolled 201 Stainless Steel Sheets and Plates, Hot Rolled 201 Sheets, Hot Rolled 201 Plates,201 PMP, 201 CMP

- Thickness: 1.2mm – 200mm

- Width: 600mm – 3500mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc

- Length: 500mm – 12000mm

- Finish: Black, NO.1, Anneal pickling

201 Stainless Steel Data Sheets

Chemical Component of 201 stainless steel sheet

| 201 | C % | Si % | Mn % | P% | S% | Cr% | Ni% | N% |

| ASTM | ≤ 0.15 | ≤ 1.0 | 5.5-7.5 | ≤ 0.06 | ≤ 0.03 | 16-18 | 3.5-5.5 | ≤ 0.25 |

| JIS | ≤ 0.15 | ≤ 1.0 | 5.5-7.5 | ≤ 0.06 | ≤ 0.03 | 16-18 | 3.5-5.5 | ≤ 0.25 |

| EN | ≤ 0.15 | ≤ 1.0 | 5.5-7.5 | ≤ 0.045 | ≤ 0.015 | 16-18 | 3.5-5.5 | ≤ 0.11 |

| GB | ≤ 0.15 | ≤ 1.0 | 5.5-7.5 | ≤ 0.06 | ≤ 0.03 | 16-18 | 3.5-5.5 | ≤ 0.25 |

Mechanical Property of 201 stainless steel plate

| Standard | Yield Strength (Y.S.) (MPa) | Tensile Strength (T.S.) (MPa) | Elongation (E.L.) (%) | Brinell Hardness (HB) | Rockwell Hardness (HRB) | Brinell Hardness (HBW) | Vickers Hardness (HV) |

|---|---|---|---|---|---|---|---|

| ASTM | 260 | 515 | 40 | – | 95 | 217 | – |

| JIS | 275 | 520 | 40 | 241 | 100 | – | 253 |

| GB | 205 | 515 | 30 | – | 99 | – | – |

Physical Property of 201 stainless steel sheet

| 201 | Density (g/cm³) | Melting point (℃) | Thermal conductivity (W/m-K) | Coefficient of thermal expansion (10^-6/K) |

| ASTM | 7.93 | 1399-1427 | 16.3 | 16.5 |

| JIS | 7.93 | 1398-1427 | 16.3 | 16.5 |

| EN | 7.9 | 1399-1427 | 15 | 16.5 |

| GB | 7.93 | 1398-1427 | 16.3 | 16.5 |

Product Description of 201 stainless steel sheets and plates

201 stainless steel sheet and plate is a common type of stainless steel material, which is divided into cold rolled sheet and hot rolled plate. Here are their specific descriptions:

201 Stainless Steel Cold Rolled Sheet

Cold rolled sheet of 201 stainless steel is produced through a cold rolling process, with a thickness typically below 6.0mm. This type of stainless steel sheet has a smooth and beautiful surface, with various superior mechanical properties.

201 Stainless Steel Hot Rolled Plate

Hot rolled plate of 201 stainless steel, on the other hand, is produced through a hot rolling process, with a thickness typically above 3.0mm. Compared to cold rolled sheet, hot rolled plate has a greater thickness.

The chemical formula of 201 stainless steel sheet and plate is usually 1Cr17Mn6Ni5. Compared to 304 stainless steel, 201 stainless steel has lower nickel and chromium content but higher manganese content. This results in 201 stainless steel having inferior corrosion resistance compared to 304, especially in certain corrosive environments such as acidic conditions or corrosion-prone areas such as deposits and crevices.

Furthermore, due to the higher carbon content of 201 stainless steel, it has relatively higher hardness and strength but poorer toughness. This may lead to some difficulties in processing and welding 201 stainless steel plates. In humid and high-salt environments, 201 stainless steel may be more prone to rusting due to the presence of manganese elements.

Features of 201 Stainless Steel Sheets&Plates

- Good corrosion resistance: 201 stainless steel sheet contains a suitable amount of chromium, giving it good corrosion resistance. Under normal atmospheric conditions, its surface can remain smooth and aesthetically pleasing, suitable for various environments, especially in some humid and high-salt environments where it exhibits excellent corrosion resistance.

- Excellent processing performance: 201 stainless steel plate has excellent processing performance and can be bent, formed, and deep drawn through cold processing methods. The oxide film formed during processing can improve wear resistance and prolong the life of molds. This makes 201 stainless steel sheet highly flexible and malleable during manufacturing processes.

- Moderate strength: Compared to other high-nickel stainless steels like 304 stainless steel, 201 stainless steel sheet has lower nickel content, resulting in moderate strength. This allows it to meet certain usage requirements under general load conditions and provides higher cost-effectiveness in certain applications.

- Low cost: The chemical composition of 201 stainless steel plate is relatively simple, and its cost is lower compared to some high-nickel stainless steels. This makes it an ideal choice for projects with limited budgets and promotes its widespread use in the market.

Application of 201 Stainless Steel Sheets&Plates

Construction Industry

201 stainless steel sheets can be used for building exterior decoration, interior decoration, ceiling, staircase handrails, railings, doors and windows, elevator doors, etc.

Kitchen Appliances

201 stainless steel sheets can be used for the production of kitchen appliances, such as refrigerators, microwave ovens, rice cookers, disinfection cabinets, etc.

Medical Instruments

201 stainless steel sheets can be used for the production of medical equipment, such as surgical instruments, medical syringes, medical utensils, etc.

Home Accessories

201 stainless steel sheets can be used for the production of home accessories, such as aquariums, tableware, decorative artwork, flower pots, etc.

Automotive Industry

201 stainless steel sheets can be used for the production of automotive parts, such as exhaust pipes, body panels, decorative strips, etc.

Our competitive Stainless Steel Sheet and plate

We will answer your email in 24 hours!

FAQ

201 stainless steel and 304 stainless steel are two common stainless steel materials, which have some differences in chemical composition, physical properties, mechanical properties, corrosion resistance, etc.

Chemical Composition: 201 stainless steel contains higher levels of manganese and nitrogen, while 304 stainless steel contains more chromium and nickel.

Physical Properties: 201 stainless steel is slightly less dense than 304 stainless steel and has a smaller modulus of elasticity.

Mechanical Properties: 201 stainless steel is slightly less hard than 304 stainless steel but has better ductility and plasticity.

Corrosion Resistance: 304 stainless steel has better corrosion resistance than 201 stainless steel, especially for chloride ions.

Applications: 201 stainless steel is widely used in decoration, construction, furniture, kitchen utensils, and other fields, while 304 stainless steel is more suitable for high-end kitchenware, chemical equipment, medical equipment, and other fields.

201 stainless steel and 202 stainless steel are two common 2-series stainless steels with the following differences between them:

Chemical Composition: 201 stainless steel has a higher chemical composition of nickel and manganese, while 202 stainless steel has a higher content of chromium and copper.

Different Performance: 201 stainless steel is more resistant to corrosion and heat than 202 stainless steel, but 202 stainless steel is more resistant to wear and fatigue.

Different Applications: As 201 stainless steel is more corrosion and heat-resistant, it is usually used in the manufacture of kitchen appliances, stoves, ovens, refrigeration equipment, and other products that need to be used in high-temperature environments; while 202 stainless steel is more suitable for the manufacture of abrasives, bearings, pump parts and other products that need resistance to wear and corrosion.

Series 2 stainless steels are a family of stainless steels that contain high levels of manganese and nitrogen. Some of the common 2 series stainless steels are 201, 202, 205, 241, 2304 and 2205. Of these, 201 and 202 are the most common 2-series stainless steels and are suitable for many general uses such as the manufacture of kitchen appliances and household items. 205 and 241 are 2-series stainless steels that are specifically used for the manufacture of high temperature equipment and high strength applications. 2304 and 2205 are duplex stainless steels that are high strength and corrosion resistant and are suitable for harsh environments such as the marine and chemical industries.

Yes, 201 stainless steel can meet food standards. There are many different grades of stainless steel, including 201 and 304, among others. All of these grades of stainless steel can be used to manufacture equipment and appliances that come into contact with food. With proper manufacturing and handling processes, 201 stainless steel can meet the relevant standards and requirements of the food industry. However, to ensure that 201 stainless steel is suitable for a specific food application, appropriate testing and verification is required.

Compared to other stainless steel materials, 201 stainless steel sheet is relatively easy to process. 201 stainless steel sheet has high plasticity and malleability, and can be processed in a variety of ways, such as cutting, bending, forming, stamping and welding. However, it should be noted that due to the low strength of 201 stainless steel plate, it needs to be handled with care when carrying out some more complex processing to avoid deformation of the plate or other quality problems. In addition, the physical and chemical properties of the 201 stainless steel sheet should be understood before processing to select the appropriate processing process and tools to ensure processing quality and efficiency.

The service life of 201 stainless steel sheet varies depending on the environment it is in and the conditions of use, and is usually affected by the following factors:

Corrosive Environment: The corrosion resistance of 201 stainless steel sheets is relatively low, and if used in an environment of strong acid, strong alkali, or high salinity, corrosion is likely to occur, resulting in a shortened service life.

Processing Process: 201 stainless steel sheets are prone to deformation and cracking during processing, which may have an impact on the service life if not processed properly.

Temperature Change: 201 stainless steel plate has a weak antioxidant capacity, and is prone to oxidation when used in a high-temperature environment for a long time, resulting in a shortened service life.

Maintenance: If maintenance is not carried out correctly, such as not cleaning and applying anti-rust oil in a timely manner, it will make the surface of 201 stainless steel plate easy to stain and rust stains, which will affect the service life.

Overall, if the 201 stainless steel plate is properly used and maintained, its service life can reach more than 10 years.

The following are some suggestions that can help extend the service life of 201 stainless steel sheets:

Keep it Clean: Regular cleaning of stainless steel surfaces can prevent the accumulation of impurities and dirt that can prevent corrosion from occurring. Using professional stainless steel cleaners and polishes can help clean the surface and maintain the luster.

Avoid Physical Damage: Avoid using sharp tools or heavy objects in direct contact with the stainless steel surface to avoid scratching or denting.

Control the Use Environment: 201 stainless steel sheet is suitable for indoor and outdoor use, but caution is needed when using in high temperature, strong acid or strong alkali environments. Avoid electrochemical reactions when stainless steel is in contact with other metals, such as the battery effect.

Regular Maintenance: regularly inspect and maintain the state of use of 201 stainless steel sheets, including surface condition and connection points. Repair or replace the problematic parts in a timely manner.