Duplex 2205 Stainless Steel Sheet and Plate Supplier

Do you have any questions about our products or are you looking for a professional 2205 stainless steel sheets supplier?

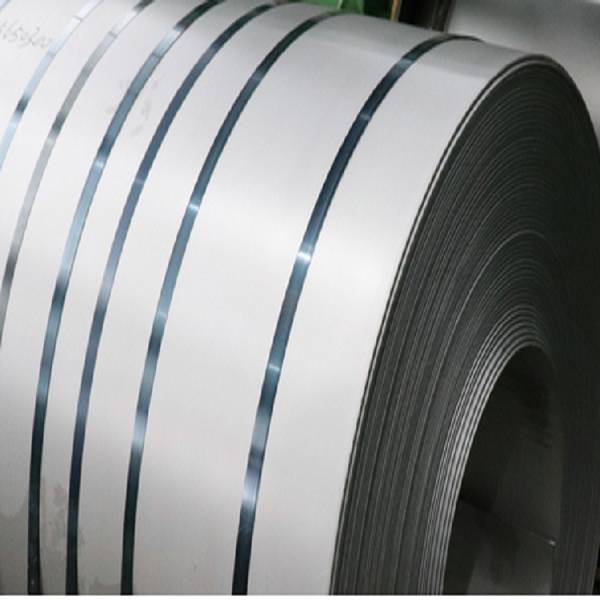

Specification: duplex 2205 stainless steel, Duplex 1.4462 (2205) Sheet and Plate, ASTM A240 Type 2205 Sheet, Alloy 2205 – Duplex Stainless Plate

Features: High strength, excellent corrosion resistance, and good toughness characterize 2205 stainless steel sheets.

Thickness: 0.05mm – 200mm

Width: 600mm – 2000mm

Length: 500mm-12000mm

Standard: ASTM, JIS, EN, GB

Finish: 2B, 2D, Black, NO.1, Anneal pickling

Certification: ISO9001:2015

MOQ: 2MT

Payment method: T/T, LC

Price: Inquiry Factory Price 2205 stainless steel sheets Now

SS 2205 Stainless Steel Sheets&Plates Data Sheet

Ingredients of 2205 Stainless Steel Sheets&Plates

| 2205 | C% | Mn% | Si% | Cr% | Ni% | Mo% | N% | S% | P% |

| ASTM | ≤ 0.03 | ≤ 2.0 | ≤ 1.0 | 22-23 | 4.5-6.5 | 3.0-3.5 | 0.14-0.20 | ≤ 0.02 | ≤ 0.03 |

| EN | ≤ 0.03 | ≤ 2.0 | ≤ 1.0 | 22-23 | 4.5-6.5 | 3.0-3.5 | 0.14-0.20 | ≤ 0.02 | ≤ 0.03 |

| JIS | ≤ 0.03 | ≤ 2.0 | ≤ 1.0 | 21-23 | 4.5-6.5 | 2.5-3.5 | 0.08-0.20 | ≤ 0.03 | ≤ 0.04 |

| GB | ≤ 0.03 | ≤ 2.0 | ≤ 1.0 | 22-23 | 4.5-6.5 | 3.0-3.5 | 0.14-0.20 | ≤ 0.02 | ≤ 0.03 |

Physical Properties of 2205 Stainless Steel Sheets&Plates

| Standards | Density (g/cm³) | Melting point (℃) | Thermal conductivity (W/m-K) | Coefficient of thermal expansion (10^-6/K) |

| ASTM | 7.805 | 1420-1465 | 19.7 at 100 ℃ | 13.7 at 20-100°C |

| JIS | 7.805 | 1400-1460 | 19.0 at 100°C | 13.0 at 20-100°C |

| EN | 7.805 | 1400-1450 | 19.0 at 100°C | 13.0 at 20-100°C |

| GB | 7.805 | 1398-1440 | 19.0 at 100°C | 13.0 at 20-100°C |

Mechanical Properties of 2205 Stainless Steel Sheets&Plates

| Standards | T.S.(MPa) | Y.S.(MPa) | EL.(%) | HB |

| ASTM | ≥ 655 | ≥ 450 | ≥ 25 | ≤ 290 |

| JIS | ≥ 620 | ≥ 450 | ≥ 25 | ≤ 290 |

| EN | 650-880 | ≥ 450 | ≥ 25 | ≤ 310 |

| GB | ≥ 620 | ≥ 450 | ≥ 25 | ≤ 290 |

Product Description of 2205 stainless steel sheets and plates

2205 stainless steel plate is a type of duplex stainless steel, typically composed of 23% chromium, 4% nickel, 0.15% molybdenum, 3% copper, 0.2% nitrogen, and small amounts of iron. It boasts high strength and excellent corrosion resistance, making it widely used in the chemical, marine, petroleum, and food industries.

2205 stainless steel sheet exhibits outstanding resistance to stress corrosion cracking and intergranular corrosion, performing well even in highly corrosive environments. It also possesses excellent mechanical properties, including high strength, good ductility, and toughness, meeting the needs of various complex conditions.

2205 stainless steel plate offers excellent machinability, allowing for cutting, drilling, welding, and other processes using conventional methods, and it is easy to maintain and repair. In applications requiring high corrosion resistance, 2205 stainless steel plate is an ideal choice.

2205 stainless steel plate finds extensive applications in the chemical, marine, petroleum, and food industries, including oil and gas extraction platforms, chemical storage tanks, chemical pipelines, marine engineering, desalination equipment, and food processing machinery.

Features of 2205 Stainless Steel Sheets&Plates

Excellent corrosion resistance: 2205 stainless steel plate performs admirably in both acidic and alkaline environments, boasting outstanding resistance to pitting corrosion and stress corrosion cracking. This makes it widely used in the chemical, marine, and petroleum industries.

High strength and hardness: 2205 stainless steel plate exhibits high strength and hardness, capable of withstanding high pressure and heavy loads, suitable for manufacturing heavy equipment and structures such as pressure vessels and bridges.

Good weldability: Through conventional welding processes, 2205 stainless steel plate can be easily welded, and the welded joints have good strength and corrosion resistance, minimizing the risk of cracking and corrosion.

Cold and hot processing characteristics: 2205 stainless steel plate can be formed and processed through cold rolling, cold drawing, cold bending, and can also be subjected to heat treatment to alter its structure and properties.

High toughness: 2205 stainless steel plate possesses excellent toughness, able to absorb energy when subjected to significant impact and deformation, avoiding brittle fracture.

Easy to clean: 2205 stainless steel plate can effectively remove surface dirt and oil stains, maintaining good hygiene conditions.

Applications of 2205 Stainless Steel Sheets&Plates

Chemical Industry

Because of its excellent corrosion resistance, stress corrosion cracking resistance, and high strength, the 2205 stainless steel sheet is widely used in the manufacture of chemical equipment and pipelines. For example, it is used in the manufacture of equipment such as storage tanks, heat exchangers, reactors, pumps, and valves. This equipment usually requires high-temperature resistance, corrosion resistance, and strength, and 2205 stainless steel meets these requirements. In addition, because the 2205 stainless steel sheet has good welding properties, it is also very convenient for its application in the chemical industry.

Oil and Gas Industry

Due to its good corrosion resistance, high strength and high wear resistance, it can be used to manufacture equipment such as oil well casing, oil tubing and drill pipe to meet the requirements of use in high temperature and pressure and strong corrosive environments. In addition, 2205 stainless steel can also be used in the manufacture of oil and gas storage tanks, pipelines and processing equipment, etc. to ensure the stability and reliability of the equipment under harsh working conditions.

Marine Engineering Industry

2205 stainless steel sheet is widely used in marine engineering because of its high strength, good corrosion resistance and strong resistance to seawater corrosion. It is used in the manufacture of marine platforms, ships, marine equipment, subsea pipelines, etc. Its seawater corrosion resistance makes it an ideal material choice for marine environments.

Food Manufacturing Industry

Because of its excellent corrosion resistance, high strength and good sanitation, 2205 stainless steel sheet is usually an ideal choice when corrosion-resistant materials are required in food manufacturing and processing. It can be used in the manufacture of food processing equipment, restaurant and hotel kitchen equipment, and some food packaging materials that require corrosion resistance and sanitation. In addition, because of its high strength and toughness, the 2205 stainless steel sheet can also be used to process some larger or more complex food processing equipment and kitchen equipment.

Pharmaceutical Industry

2205 stainless steel sheet is also widely used in the pharmaceutical industry due to its chemical stability and anti-corrosion properties, such as the production of reactors, storage tanks, conveying equipment and so on. In addition, it also has good high temperature resistance and mechanical strength, which can be used to manufacture a variety of high-temperature equipment and mechanical components, making it widely used in the pharmaceutical industry as well.

FAQ

Thermoforming of 2205 duplex stainless steel should be performed at temperatures below 600°F to avoid any potential damage to the material. During the thermoforming process, the workpiece should be heated within the range of 1750°F to 2250°F. At these temperatures, the 2205 duplex stainless steel is relatively soft and easy to form. However, if the temperature is too high, the material can become overly malleable and even begin to glow, resulting in the austenite breaking down.

It’s recommended to use solution annealing to relieve any stresses in the material after thermoforming is complete. This process improves the material’s phase rust resistance, endurance, and stability. Stress relief is not recommended for 2205 duplex stainless steel.

To solution anneal 2205 duplex stainless steel, the material should be heated to a temperature of around 1900°F and then cooled in water. It’s important to note that the exact temperature and cooling rate can vary depending on the specific type and thickness of the material. Therefore, it’s important to consult with a professional or reference industry-specific guidelines when performing thermoforming and solution annealing of 2205 duplex stainless steel.

2205 duplex stainless steel is a popular choice for cold forming and cutting applications. However, due to its high strength and hardness, it requires more force for cold forming compared to regular steel. Additionally, one must take into consideration the aspect of spring back, which refers to the material’s tendency to return to its original shape after being bent or stretched. This property can make the cold forming process more difficult and requires careful planning and execution.

To minimize spring back and ensure a successful cold forming process, it is recommended to use high-quality tools and machinery, as well as to carefully design the bending and forming processes. It is also important to note that the 2205 duplex stainless steel may exhibit different properties depending on the temperature and duration of the cold forming process. Therefore, proper temperature control and monitoring are essential to achieve the desired outcome. Overall, with proper planning and execution, 2205 duplex stainless steel can be successfully cold formed to meet a wide range of application requirements.

Heat treatment is an important step in the processing of 2205 duplex stainless steel plates. The recommended minimum annealing temperature is 1900 ° F, which is typically carried out in a furnace. This process helps to relieve stresses and improve the overall ductility of the material. Additionally, solution annealing is commonly used to dissolve any precipitated phases and restore the material’s homogeneity. However, it’s important to avoid stress relief treatments at temperatures below 1900 ° F, as this can cause unwanted precipitation of non-metallic or metallic phases, leading to reduced performance and durability. Therefore, proper heat treatment is crucial to ensuring the best possible properties and performance from 2205 duplex stainless steel plates.

When it comes to mechanical cutting of 2205 duplex stainless steel, it is important to consider the feed rate, cutting speed, and tool material. The feed rate and cutting speed should be reduced by around 20% compared to 316L stainless steel to achieve the same performance. In addition, the use of carbonized blades can increase the cutting speed. The selection of tool material is also crucial for efficient cutting of 2205 stainless steel. Carbide or ceramic cutting tools are recommended due to their high hardness and wear resistance. The composition of the 2205 stainless steel, particularly its high strength and hardness, can pose challenges to mechanical cutting. Therefore, it is important to use appropriate cutting parameters and tools to achieve precise and efficient cuts.

The welding performance of 2205 stainless steel is exceptional, as it maintains excellent corrosion resistance, strength, and durability even after welding. However, it is important to carefully plan the welding process to maintain a good balance of time and temperature, to prevent metal or phase precipitation. 2205 duplex stainless steel can be welded using various methods, including GTAW (TIG), GMAW (MIG), SMAW (“stick” electrode), SAW, FCW, and PAW. The choice of welding method will depend on factors such as the thickness of the material, the required welding speed, and the available equipment. Additionally, it is important to choose the appropriate welding filler material to ensure the desired mechanical and corrosion-resistant properties of the final welded joint.

Metallography is the study of the physical and structural properties of metals and alloys. When it comes to 2205/S31803 plates, it is important to be aware of the intermetallic phase precipitation that can occur between 1300 ° F and 1800 ° F, with the fastest precipitation occurring at 1600 ° F. Therefore, it is necessary to conduct tests on 2205 to ensure that no intermetallic phase is present, with the test standard being ASTM A923.

The desired microstructure of 2205 duplex stainless steel is 50 α / 50 γ, which can be achieved through solid solution annealing at temperatures of 1900 ° F to 1922 ° F (1040 ° C to 1080 ° C). However, if the heat treatment temperature exceeds 2000 ° F, there may be an increase in composition that could affect the microstructure. It is also important to note that like other duplex stainless steels, 2205 alloys are susceptible to phase precipitation.